Professional Documents

Culture Documents

WSM 7 Column

WSM 7 Column

Uploaded by

balram121220000 ratings0% found this document useful (0 votes)

5 views23 pagesThis document summarizes the design of an axially loaded reinforced concrete column. It provides the equations to calculate the safe load capacity of short and long columns. For the given problem of a 6m unsupported column, it is classified as a long column. The required cross sectional area and steel reinforcement are calculated. A square column section of 350mm is chosen. 4-16T and 4-18T bars are provided as main reinforcement. Lateral ties of 6mm diameter bars spaced at 250mm c/c are specified to confine the longitudinal bars.

Original Description:

Original Title

WSM_7_Column

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document summarizes the design of an axially loaded reinforced concrete column. It provides the equations to calculate the safe load capacity of short and long columns. For the given problem of a 6m unsupported column, it is classified as a long column. The required cross sectional area and steel reinforcement are calculated. A square column section of 350mm is chosen. 4-16T and 4-18T bars are provided as main reinforcement. Lateral ties of 6mm diameter bars spaced at 250mm c/c are specified to confine the longitudinal bars.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

5 views23 pagesWSM 7 Column

WSM 7 Column

Uploaded by

balram12122000This document summarizes the design of an axially loaded reinforced concrete column. It provides the equations to calculate the safe load capacity of short and long columns. For the given problem of a 6m unsupported column, it is classified as a long column. The required cross sectional area and steel reinforcement are calculated. A square column section of 350mm is chosen. 4-16T and 4-18T bars are provided as main reinforcement. Lateral ties of 6mm diameter bars spaced at 250mm c/c are specified to confine the longitudinal bars.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 23

Working stress method

Lecture 7: Design of axially loaded column

Column

• Compression member-A structural member, which carries axial

compressive force

• Column- a vertical member which is predominantly under axial

compression.

• Column is a compression member

• The safe load on a column (B.3)

P=(area of concrete)x(permissible direct compressive stress in concrete)

+(area of compression steel)x(permissible compressive stress in steel)

=Acxσcc+Ascxσsc [σsc-Table 21, σcc – Table 22]

(The effect of minimum eccentricity is incorporated in the above equation)

Long column: -B3.3 : effective length/least lateral dimension > 12

leff/b> 12

In such case, buckling will occur at much lower safe load

The safe load for a long column will be reduced by a reduction factor

Cr=1.25-leff/(48 b)

Note for leff/b=12 , Cr=1.25-12/48=1.0, Hence, for short column for which

slenderness ration leff/b< 12 buckling will not occur and no reduction of safe load

will take place.

Unsupported

length/unbraced length

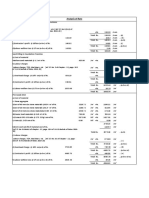

A reinforced concrete column is to support a load of 1000 kN inclusive of

s/w. The column is effectively held in position at both ends and

restrained against rotation at one of the ends. The unsupported length

of the column is 6 m. Using M25 concrete and Fe 415 steel, design and

detail the column. Consider a square section of side not exceeding 350

mm.

leff=0.8x6000=4800 mm, leff/b =4800/350=13.7>12

Hence, it is a long column

• Reduction factor, Cr=1.25-leff/(48 b)=1.25-13.71/48=0.964

Safe load will be reduced by a factor 0.964.

Let us take conservatively Cr=0.95, as the size may be less than 350 mm

• Assuming 1% steel, if A is the gross area of the column

P=Acxσcc+Ascxσsc = (0.99Ax6+0.01Ax190)x0.95=1000x103 N

A=134264.2 mm2

• Adopting square column, side of square= sqrt(134264.2)=366.4 mm

But, side should not exceed 350 mm,

Hence, adopt square column of side 350 mm (b=350 mm)

[ For rectangular section, if there is no side restriction, say b=300 mm,

Other side will be =134264.2/300=447.5 mm

We can adopt then b=300 mm x D=450 mm]

• Now, in our case, adopting a square column section of b=D=350

mm, let us calculate the steel:

P=Acxσcc+Ascxσsc

0.964x((3502-Asc)x6+Ascx190)=1000x103 N

Asc=1643.2 mm2

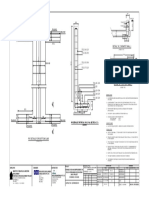

Provide 4-16T and 4-18T, Asc=4xpi/4x162+4xpi/4x182=1822.12 mm2

• Minimum steel-0.8% of cross-sectional area required to transmit the

load (A, required)=0.8/100x3502=980 mm2

(more than this steel we have provided), Hence, OK.

• Maximum steel: 6% of gross area (preferably within 4%)

• Minimum bar diameter: 12 mm

• Minimum number of bars= 4 bars rectangular section and 6 for

circular section

Lateral tie

• Used to tie the longitudinal bars

1. so that they behave like a single unit,

2. lateral buckling (outward movement) of longitudinal bars can be

prevented

3. Under the action of lateral force, moment and shear forces will be

induced in the column. These tie will then resist the shear force.

4. Improves ductile behaviour of the column

• Slenderness limit check: l= 6000 < 60 xb =60x350 =21000 mm

Hence OK

• Diameter of tie should be more than ¼(diameter of largest

longitudinal bar)=1/4( 18 mm) =4.5 mm

and should be more than 6 mm

Let us adopt dimeter of lateral tie as 6 mm

• Spacing of the tie should not be more than

i) least lateral dimension, b =350 mm

ii) 16 times diameter of the main bar=16x16=256 mm

iii) 48 times diameter of the tie = 48x6= 288 mm

iv) 300 mm

Hence spacing of the tie should not be more than 256 mm

Let us adopt 6 (φ) mm MS tie @ 250 c/c

See SP 34

You might also like

- Raft+foundationDocument8 pagesRaft+foundationRavi Kumar100% (3)

- RC Module 10 Short ColumnsDocument16 pagesRC Module 10 Short ColumnsEddie BoongalingNo ratings yet

- Design of Column - 02Document5 pagesDesign of Column - 02Engr Swapan100% (2)

- Balok Komposit Baja Berselubung BetonDocument11 pagesBalok Komposit Baja Berselubung BetonFuadNo ratings yet

- RCD2 - Design of ColumnsDocument19 pagesRCD2 - Design of Columnscharles guetaNo ratings yet

- NCCI - Design of Fixed Column Base JointsDocument23 pagesNCCI - Design of Fixed Column Base Jointsมานะ จรูญพงษ์ศักดิ์No ratings yet

- Design of The Low Head Slide Gate: A) Structural SteelDocument17 pagesDesign of The Low Head Slide Gate: A) Structural SteelAlok Sarkar100% (2)

- Voided Slabs Vs Solid Slabs ComparisonDocument1 pageVoided Slabs Vs Solid Slabs ComparisonOscar CerecedoNo ratings yet

- Axial ColumnDocument26 pagesAxial ColumnV.m. RajanNo ratings yet

- Unit 6 Design of ColumnsDocument74 pagesUnit 6 Design of ColumnsManoj SharmaNo ratings yet

- Module V Full PDFDocument85 pagesModule V Full PDFsuhan abdullahNo ratings yet

- Short Columns by CharifDocument21 pagesShort Columns by CharifMiski45No ratings yet

- Chapter 7 - Short ColumnsDocument46 pagesChapter 7 - Short ColumnsEarl Rajim RiogelonNo ratings yet

- Singly Reinforced Beam Design ProcedureDocument33 pagesSingly Reinforced Beam Design ProcedureAnonymous ALBuK8vOm100% (1)

- MODULE VIII ColumnDocument19 pagesMODULE VIII ColumnNiel John BaquilarNo ratings yet

- RCD Columns1 PDFDocument14 pagesRCD Columns1 PDFchristianNo ratings yet

- Axial Loaded Column - ProblemDocument6 pagesAxial Loaded Column - ProblemFerdiano YogiNo ratings yet

- Reinforced Concrete Design Module 10 Subject: CE 74A-Reinforced Concrete DesignDocument25 pagesReinforced Concrete Design Module 10 Subject: CE 74A-Reinforced Concrete DesignJemson VictorioNo ratings yet

- 2.column DesignDocument6 pages2.column DesignJamali AdamNo ratings yet

- Column Design Name of WorkDocument43 pagesColumn Design Name of WorkrupakhasanNo ratings yet

- Design of ColumnDocument27 pagesDesign of Columnamit_saxena_10No ratings yet

- Column Design Name of Work:-: PK - Nandwana@yahoo - Co.inDocument27 pagesColumn Design Name of Work:-: PK - Nandwana@yahoo - Co.innsureshbabu0% (1)

- 107 ConcreteDocument44 pages107 Concretenoadspls2029No ratings yet

- Column Design Name of WorkDocument43 pagesColumn Design Name of WorkPalani KumarNo ratings yet

- Analysis and Design of RC Columns (Based On 2010NSCP)Document34 pagesAnalysis and Design of RC Columns (Based On 2010NSCP)Angel Lisette LaoNo ratings yet

- Pile Foundation 18-10-10Document101 pagesPile Foundation 18-10-10patel jatin100% (2)

- Design of Reinforced Concrete Columns PDFDocument26 pagesDesign of Reinforced Concrete Columns PDFMa Gh100% (1)

- Rc2module 5 ReqDocument7 pagesRc2module 5 ReqRanie boy CabanillaNo ratings yet

- LOCAL BUCKLING2 VisualBeeDocument24 pagesLOCAL BUCKLING2 VisualBeeMart Brevin BitonNo ratings yet

- 6 - Axially Loaded ColumnsDocument11 pages6 - Axially Loaded ColumnsThe bestNo ratings yet

- 2a Balok Komposit Baja Berselubung BetonDocument11 pages2a Balok Komposit Baja Berselubung BetonPramugo AndiNo ratings yet

- RCD Chapter 7Document40 pagesRCD Chapter 7jereck loquisoNo ratings yet

- Column Two MarksDocument25 pagesColumn Two MarksDharanidharan JNo ratings yet

- Design of ColumnsDocument18 pagesDesign of Columnsjanvictorsantos17No ratings yet

- Axial Load Capacity of Columns: (Short) : N ST G ST G ST STDocument9 pagesAxial Load Capacity of Columns: (Short) : N ST G ST G ST STAurora VillalunaNo ratings yet

- Tied and Spiral ColumnsDocument8 pagesTied and Spiral ColumnsChristian Kerr Dela CernaNo ratings yet

- Httpss1.Ebalqa - Coursesncentermoodlepluginfile.php226522mod Resourcecontent1RC220notes - PDF 3Document62 pagesHttpss1.Ebalqa - Coursesncentermoodlepluginfile.php226522mod Resourcecontent1RC220notes - PDF 3Leen aboznamehNo ratings yet

- армирование колонаDocument25 pagesармирование колонаtangerineNo ratings yet

- Torsion and ColumnDocument31 pagesTorsion and ColumnAlexandra Diane Cusipag RamiroNo ratings yet

- Sub: Elementary Structural Design: Name Enroll NoDocument39 pagesSub: Elementary Structural Design: Name Enroll Noreddi.demullu007No ratings yet

- Steel Design Project: Laterally Supported and Unsupported Beams, Columns, Column Base Plate, ConnectionsDocument24 pagesSteel Design Project: Laterally Supported and Unsupported Beams, Columns, Column Base Plate, Connectionsozzieastro96% (24)

- 04 ColumnDocument18 pages04 ColumnSamantha Isabel S AguimbagNo ratings yet

- Chapter 3. Axially Loaded Members: Plain Concrete Columns Prohibited: Possibility of Bending Is Always PresentDocument25 pagesChapter 3. Axially Loaded Members: Plain Concrete Columns Prohibited: Possibility of Bending Is Always PresentGhaith Al-HouraniNo ratings yet

- Document 3Document32 pagesDocument 3NUR FATINAH BINTI ZOLKIFLI 5ENo ratings yet

- Design of ColumnDocument10 pagesDesign of Columntamoor aliNo ratings yet

- Lecture (2) - Design of Axially Loaded Short Tied and Spiral ColumnsDocument40 pagesLecture (2) - Design of Axially Loaded Short Tied and Spiral ColumnsSayed Ahmed EL-SayedNo ratings yet

- One-Way and Two-Way SlabsDocument5 pagesOne-Way and Two-Way SlabsMark Kim BadiangNo ratings yet

- Short Column DesignDocument7 pagesShort Column DesignNelsonDay100% (2)

- Chapter 5 - BeamDocument12 pagesChapter 5 - Beamlau lauNo ratings yet

- Mod 4Document35 pagesMod 4Eesha NairNo ratings yet

- Joist SlabDocument13 pagesJoist SlabAhmed Nabil80% (5)

- Flexural TheoryDocument62 pagesFlexural TheoryReceb AgaNo ratings yet

- PCI 6th Edition - Connection DesignDocument102 pagesPCI 6th Edition - Connection Designjeovan100% (1)

- Chapter 9: Analysis and Design of Short Columns Subjected To Axial Loads With Small EccentricitiesDocument5 pagesChapter 9: Analysis and Design of Short Columns Subjected To Axial Loads With Small EccentricitiesRogie Neth AbatayoNo ratings yet

- 3 - Compression Member PDFDocument43 pages3 - Compression Member PDFYetty Oktavianita100% (2)

- Design of FootingDocument41 pagesDesign of FootingmanishNo ratings yet

- T-Beam Design Ex 5.3Document6 pagesT-Beam Design Ex 5.3mikeengineeringNo ratings yet

- RC Lecture 11 - ColumnsDocument19 pagesRC Lecture 11 - ColumnsShean Berwin GonzalesNo ratings yet

- Composite Structures of Steel and Concrete: Beams, Slabs, Columns and Frames for BuildingsFrom EverandComposite Structures of Steel and Concrete: Beams, Slabs, Columns and Frames for BuildingsNo ratings yet

- Cylindrical Compression Helix Springs For Suspension SystemsFrom EverandCylindrical Compression Helix Springs For Suspension SystemsNo ratings yet

- APznzaaYJJmNJzCiNqMBIsyv9jImcgKp-gr-E6k6X6NJyDNyQNvRWe_-k278Gp6uNSVo320JWabESbrg9naqItbUBVq25fDwrwcm81LRjAAM79Eu4qCFOkcgjE_8p1Qr3IG54bE5FcknhM2_2YUTA5DWkZNEV7Xb8-nx20Yrx9CSl4WeKPOCuxHNG9EaC4L4omwHBpXYn3n9sbyRq1OOnDocument12 pagesAPznzaaYJJmNJzCiNqMBIsyv9jImcgKp-gr-E6k6X6NJyDNyQNvRWe_-k278Gp6uNSVo320JWabESbrg9naqItbUBVq25fDwrwcm81LRjAAM79Eu4qCFOkcgjE_8p1Qr3IG54bE5FcknhM2_2YUTA5DWkZNEV7Xb8-nx20Yrx9CSl4WeKPOCuxHNG9EaC4L4omwHBpXYn3n9sbyRq1OOnbalram12122000No ratings yet

- L3 - Design of Connections - WeldedDocument33 pagesL3 - Design of Connections - Weldedbalram12122000No ratings yet

- BreakwaterDocument14 pagesBreakwaterbalram12122000No ratings yet

- Steel Note 01Document12 pagesSteel Note 01balram12122000No ratings yet

- LSM 9 - Pile Foundation PDocument36 pagesLSM 9 - Pile Foundation Pbalram12122000No ratings yet

- LSM10 - Design of Pile CapDocument19 pagesLSM10 - Design of Pile Capbalram12122000No ratings yet

- Port (Part-II)Document31 pagesPort (Part-II)balram12122000No ratings yet

- Reinforced Concrete Design-AKC-Lecture-2Document17 pagesReinforced Concrete Design-AKC-Lecture-2balram12122000No ratings yet

- Port (Part-1)Document31 pagesPort (Part-1)balram12122000No ratings yet

- Reading Material 15BDocument7 pagesReading Material 15Bbalram12122000No ratings yet

- Reading Material 15ADocument9 pagesReading Material 15Abalram12122000No ratings yet

- Short Col DesignDocument17 pagesShort Col DesignBhavin ShahNo ratings yet

- Properties of Reinforced Concrete and Composite Action by Assoc. Prof. Dr. Bashar S. MohammedDocument2 pagesProperties of Reinforced Concrete and Composite Action by Assoc. Prof. Dr. Bashar S. MohammedCyrus HongNo ratings yet

- AD 283 - The Use of Discontinuous Columns in Simple ConstructionDocument3 pagesAD 283 - The Use of Discontinuous Columns in Simple Constructionsymon ellimacNo ratings yet

- Determining The Potential Alkali-Silica Reactivity of Combinations of Cementitious Materials and Aggregate (Accelerated Mortar-Bar Method)Document6 pagesDetermining The Potential Alkali-Silica Reactivity of Combinations of Cementitious Materials and Aggregate (Accelerated Mortar-Bar Method)Satya kaliprasad vangaraNo ratings yet

- PSC Unit 3Document18 pagesPSC Unit 3Santosh ReddyNo ratings yet

- Composite Construction MethodsDocument33 pagesComposite Construction Methodscristian santillanNo ratings yet

- Prestressed Concrete Analysis and Design Fundamentals 2nd Ed PDFDocument1,108 pagesPrestressed Concrete Analysis and Design Fundamentals 2nd Ed PDFCarlos Alberto Pacheco Sierra100% (1)

- 31CDocument14 pages31CAfia S HameedNo ratings yet

- Detail "A" (Parapet Wall) : R/F Details For Typical Wing Wall Section (C-C)Document1 pageDetail "A" (Parapet Wall) : R/F Details For Typical Wing Wall Section (C-C)sathiyanNo ratings yet

- Topic About Engineering Research PaperDocument6 pagesTopic About Engineering Research Paperscxofyplg100% (1)

- Thesis TWP Maatkamp FinalDocument201 pagesThesis TWP Maatkamp FinalSérgio BernardesNo ratings yet

- Earthquake Safety MeasuresDocument37 pagesEarthquake Safety MeasuresJohn Robert GabrielNo ratings yet

- Designing Buildings To Resist Explosive ThreatsDocument17 pagesDesigning Buildings To Resist Explosive ThreatsMai KawayapanikNo ratings yet

- TN31Document21 pagesTN31Anthony RuthNo ratings yet

- 02-Annexure A - Civil & Finishing Works-Super Structure, Senegal-090723Document26 pages02-Annexure A - Civil & Finishing Works-Super Structure, Senegal-090723Ablaye GueyeNo ratings yet

- MES Assets Estimate-R1Document25 pagesMES Assets Estimate-R1Jayashri MallickNo ratings yet

- MivanDocument243 pagesMivanvinu4everyone0% (1)

- Material & Labour Cost Projection - 4units of 1bed ApartmentsDocument3 pagesMaterial & Labour Cost Projection - 4units of 1bed ApartmentsChikadibia OkoroNo ratings yet

- Internship SeminarDocument28 pagesInternship Seminarkavya kruthiNo ratings yet

- Steel ExampleDocument177 pagesSteel Examplelomo2002No ratings yet

- CE6710 Bridges Intro 1Document53 pagesCE6710 Bridges Intro 1Pranay ReddyNo ratings yet

- Condition Assessment and Cathodic Protection of Reinforced Concrete Cooling TowerDocument20 pagesCondition Assessment and Cathodic Protection of Reinforced Concrete Cooling TowerPhilip Albert HutapeaNo ratings yet

- Assignment 06 With SolutionDocument10 pagesAssignment 06 With SolutionAshok Kumar RajanavarNo ratings yet

- 2023 BongtilesDocument38 pages2023 BongtilesmailinNo ratings yet

- WS May 2, 2022 Delivery ListDocument2 pagesWS May 2, 2022 Delivery ListJohn Jefferson V. OrnidoNo ratings yet

- Design For Steel Circular Columns (R1)Document8 pagesDesign For Steel Circular Columns (R1)rahul1433No ratings yet

- DGF PIPERACK - CALC-commentsDocument81 pagesDGF PIPERACK - CALC-commentsAhmed MohamedNo ratings yet