Professional Documents

Culture Documents

Engineering Drawings For Spur and Helical Gears Course Thors Academy Flyer

Engineering Drawings For Spur and Helical Gears Course Thors Academy Flyer

Uploaded by

gtsi.draftsmanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Engineering Drawings For Spur and Helical Gears Course Thors Academy Flyer

Engineering Drawings For Spur and Helical Gears Course Thors Academy Flyer

Uploaded by

gtsi.draftsmanCopyright:

Available Formats

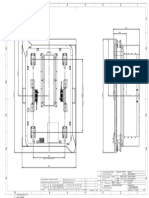

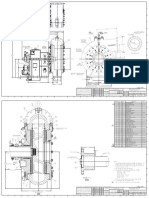

ENGINEERING DRAWINGS FOR

SPUR AND HELICAL GEARS [2ND ED.]

eLearning courses designed to increase productivity and profits

Learning made Simple, Visual,

HELICAL GEAR DATA

D D

203.20

35°

TYP

Z R63.50

TYP

101.60

5.08X45

TYP

Y

2.54X45

50.80

TYP

and Interactive

TYP

C C

This course teaches the fundamental concepts needed to read

165.125

165.100

941.474

941.220

304.80

762.00

R355.60

R177.80

X

R5.08

TYP

A

and interpret a gear drawing. Commonly used terms, such as

60

°

Z 60

°

25.40

A

those found in a gear data block, associated with gear features,

and in notes, are explained to enhance the understanding of

76.20

SECTION Z-Z

184.455

184.607

R1.575

30°

drawing requirements to manufacture mating gear parts.

10.92

44.501

44.450

DETAIL X DETAIL Y

1. Material as per AGMA 2001 Grade 2 Bearing Quality Cleanliness

2. Heat Treat per AGMA 923 Grade 2. THIRD ANGLE PROJECTION

DATE

3. All unspecified radi max 1.5.

2.5

4. Remove all burrs and sharp edges before grinding

Credit Hours

A 5. Part number and logo text deboss 1.5 and height

. 28 HEAT TREAT

NA

A

HELICAL GEAR

DATE

PROPRIETARY AND CONFIDENTIAL

A2

APPLICATION

Learning Objectives

Identify the distinct characteristics that are included on a spur or helical gear drawing.

Recognize a gear data block and the different elements contained within it.

Recognize and understand the importance of various feature attributes that may appear on spur and helical gear drawings,

as well as the associated dimensioning and symbols used.

Understand the different types of notes that may be found on drawings for spur and helical gears.

Table of Contents

I. Distinct Characteristics II. Gear Dimensioning and Symbols III. Notes

• Gear Data Block • Conventional Representations • Material Notes

• Gear Data Information • Datum Features o Type of Metal

o Basic Gear Data o Use of a Bore as a o Quality of Material

o Calculated Gear Data Datum Feature • Special Process Notes

o Proprietary Gear Data o Use of a Journal as a o Surface Finish Notes

• Gear Data Geometry Datum Feature o Shot Peen Notes

o Number of Teeth • Surface Finish Symbols o Coating Notes

o Normal Diametral Pitch

o Normal Pressure Angle • Size Attributes • Heat Treatment Notes

o Helix Angle • Feature Attributes o Through Hardening

o Hand of Helix o Bell Centers o Case Hardening

o Pitch Diameter o Tooth Tip Chamfer Dimension • Quality Notes

o Profile Shift Coefficient o End Face Edge Chamfer o Finishing Processes

o Root Diameter Dimension o Inspection Requirements

o Outside Diameter o Helix and Profile Modifications

o Number of Teeth Spanned -Crowning

o Span Measurement -Circular End Relief

o Center Distance -Circular Tip Relief

o Normal Backlash with Mate o Thread Specifications for

o Mate Number of Teeth Tapped Holes

o Quality Standard and

o Keyways and Keyseats

Accuracy Level

sales@thors.com

1 (330) 576 4448

THORS is bringing together the best minds across many industries to create an ever-

expanding library of courses that will rapidly increase the Manufacturing IQ ® of your team. 5054 Paramount Blvd

Medina, OH 44256

You might also like

- BATTERY RACK, 12V, 384V, 4 Tier, Top BRKR.: Electronic System Support 888-475-9292 WWW - Ess.toDocument2 pagesBATTERY RACK, 12V, 384V, 4 Tier, Top BRKR.: Electronic System Support 888-475-9292 WWW - Ess.tomike00No ratings yet

- KSB Serie MPDocument12 pagesKSB Serie MPJose ValenzuelaNo ratings yet

- Swing Jaw Plate - TCMDocument1 pageSwing Jaw Plate - TCMmoderate machines pvt. ltd.No ratings yet

- Efr52 SpecDocument2 pagesEfr52 Specmike00No ratings yet

- 480V, HD Battery Rack, 12V,: Electronic System Support 888-475-9292 WWW - Ess.toDocument2 pages480V, HD Battery Rack, 12V,: Electronic System Support 888-475-9292 WWW - Ess.tomike00No ratings yet

- TIMPANI TimbalesDocument2 pagesTIMPANI TimbalesIsadora VilugrónNo ratings yet

- Dwg-We0067-013-001 Rev.0Document1 pageDwg-We0067-013-001 Rev.0karthikNo ratings yet

- A B C D E F G H: Manoeuvring AreaDocument1 pageA B C D E F G H: Manoeuvring AreaShotaBarkalaiaNo ratings yet

- Ar 01Document1 pageAr 01Respeto Distrito Santiago CuscoNo ratings yet

- " Te Vas ": I Trumpet in BBDocument1 page" Te Vas ": I Trumpet in BBAnimales En AccionNo ratings yet

- MotorholderfrontDocument1 pageMotorholderfrontnavahnavahnavahNo ratings yet

- Dwg-We0067-013-002 Rev.0Document1 pageDwg-We0067-013-002 Rev.0karthikNo ratings yet

- Deksel P2 Klein 2DDocument1 pageDeksel P2 Klein 2DGuidoNo ratings yet

- Segundo Nivel TipcoDocument1 pageSegundo Nivel TipcoNiiniio Coqiitos Soliito RaperitoNo ratings yet

- Shour-Afarin02@ - Violin I.musxDocument3 pagesShour-Afarin02@ - Violin I.musxMuha NityNo ratings yet

- BALUSTRADE BAL-105a & BAL-103aDocument1 pageBALUSTRADE BAL-105a & BAL-103asangram patilNo ratings yet

- Plano Banda Transportadora 2Document1 pagePlano Banda Transportadora 2Yenier MendozaNo ratings yet

- Clamp Foot PinDocument1 pageClamp Foot PinCốGắngNàoNo ratings yet

- PLANOS ULTIMOS-8-2-21-Layout1Document1 pagePLANOS ULTIMOS-8-2-21-Layout1Darling AntónNo ratings yet

- 1 Unidade SS 201: 1:2 Company ConfidentialDocument1 page1 Unidade SS 201: 1:2 Company ConfidentialPaulo AraújoNo ratings yet

- ArtrodDocument17 pagesArtrodbolivarsefNo ratings yet

- Hibike Euphonium - March Sky Blue Dream (1) - TubaDocument2 pagesHibike Euphonium - March Sky Blue Dream (1) - TubaBruno CarvalhoNo ratings yet

- 57 14 30 2 X 4,50 Durch Alles 9,18 X 90° 2 X 9 Durch Alles 18,25 X 90°Document1 page57 14 30 2 X 4,50 Durch Alles 9,18 X 90° 2 X 9 Durch Alles 18,25 X 90°Maria DragoiNo ratings yet

- Section Y-Y Section X-X: Key PlanDocument1 pageSection Y-Y Section X-X: Key PlansonofalexanderNo ratings yet

- Hy000 B4010 - 0 Pivot Thrust WasherDocument1 pageHy000 B4010 - 0 Pivot Thrust WasherAnyNo ratings yet

- Evaluación de Asentamientos Y Diseño Estructural de La CimentaciónDocument7 pagesEvaluación de Asentamientos Y Diseño Estructural de La CimentaciónJULIO QUENTANo ratings yet

- A Isometric View: z3 x40 (120) z3 x40 (120) Class C Typ. 3 Typ. 12.5Document1 pageA Isometric View: z3 x40 (120) z3 x40 (120) Class C Typ. 3 Typ. 12.5rajitkumar.3005No ratings yet

- He Will Make You Strong String Quartet-Violin 1Document1 pageHe Will Make You Strong String Quartet-Violin 1Dee Olivar CamaongayNo ratings yet

- Billie Jean-PiccoloDocument1 pageBillie Jean-PiccolobrunetNo ratings yet

- 384V, 4 Tier, Top Brkr. Battery Rack, 12V, FT,: Electronic System Support 888-475-9292 WWW - Ess.toDocument2 pages384V, 4 Tier, Top Brkr. Battery Rack, 12V, FT,: Electronic System Support 888-475-9292 WWW - Ess.tomike00No ratings yet

- If in Doubt... Ask!: Pre-Machined Tube For Sub-Assy, Skeleton Frame 2500 HP Frac Pump FrameDocument1 pageIf in Doubt... Ask!: Pre-Machined Tube For Sub-Assy, Skeleton Frame 2500 HP Frac Pump FrameSarah ShenNo ratings yet

- Madeira - River BellsDocument2 pagesMadeira - River BellsWelber SimoesNo ratings yet

- Planos de Una Vivienda MultifamiliarDocument1 pagePlanos de Una Vivienda MultifamiliarAderly Ernesto Achaca TaculiNo ratings yet

- Imensys: DRG Drawn in .......... Angle If in Doubt Please AskDocument1 pageImensys: DRG Drawn in .......... Angle If in Doubt Please AskDholakiya HardikNo ratings yet

- A02 - Plan Parter - A2 - 2Document1 pageA02 - Plan Parter - A2 - 2Bogdan ParaschivNo ratings yet

- I041 - WD - Kitchen Details - 20220722Document3 pagesI041 - WD - Kitchen Details - 20220722Nidhi VermaNo ratings yet

- Ar 02Document1 pageAr 02Respeto Distrito Santiago CuscoNo ratings yet

- Quick Master 35 DD Engineering 2021 155 Temel Detay 3Document1 pageQuick Master 35 DD Engineering 2021 155 Temel Detay 3Zoran PerićNo ratings yet

- A RespostaDocument1 pageA RespostaLeandro de Lima BezerraNo ratings yet

- 2019 Suspension CompDocument10 pages2019 Suspension Compapi-305897190No ratings yet

- 2019 Suspension CompDocument8 pages2019 Suspension Compapi-305897190No ratings yet

- 740 01 04 02 036Document1 page740 01 04 02 036Maria DragoiNo ratings yet

- Ø89 Kbex0086 Exhaust PipeDocument1 pageØ89 Kbex0086 Exhaust PipeUğur BölükbaşıNo ratings yet

- 3.7 - 1270 Pump Assy - 15114504 - 1 PDFDocument2 pages3.7 - 1270 Pump Assy - 15114504 - 1 PDFHery Mardiono HeryNo ratings yet

- 3.7 - 1270 Pump Assy - 15114504Document2 pages3.7 - 1270 Pump Assy - 15114504Hery Mardiono HeryNo ratings yet

- 29 - Sewerage Layout - StampedDocument1 page29 - Sewerage Layout - StampedON ROADING CONTRACTING LLCNo ratings yet

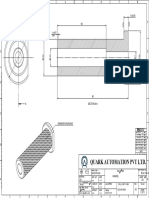

- Q22140010804 New.Document1 pageQ22140010804 New.QUARK AUTOMATIONNo ratings yet

- Aires Del Mayab Tono C-Trompeta - 2Document2 pagesAires Del Mayab Tono C-Trompeta - 2Luis Alonzo JacoboNo ratings yet

- Class A To D Concrete Outline-Class C&DDocument1 pageClass A To D Concrete Outline-Class C&Dshivendra kumarNo ratings yet

- Remote LCP HolderDocument1 pageRemote LCP Holderl1f3b00kNo ratings yet

- Oceans Where Feet May Fail-ViolaDocument3 pagesOceans Where Feet May Fail-ViolaGuilherme SanchezNo ratings yet

- EL CHUPINAZO XARANGA-FlautaDocument1 pageEL CHUPINAZO XARANGA-FlautaJoan BNo ratings yet

- 1 Trab. Practico ADocument1 page1 Trab. Practico AmiauNo ratings yet

- "Yo Quisiera": I TromboneDocument2 pages"Yo Quisiera": I TromboneSantiago Guerra0% (1)

- Hotel 4 Estrellas - dxf-8Document1 pageHotel 4 Estrellas - dxf-8brayanNo ratings yet

- A B C D E F: Edificio ComercialDocument1 pageA B C D E F: Edificio ComercialGustavoLazaroNo ratings yet

- Be - Mechanical Engineering - Semester 6 - 2022 - December - Press Tool Designrev 2019 C SchemeDocument2 pagesBe - Mechanical Engineering - Semester 6 - 2022 - December - Press Tool Designrev 2019 C Scheme218102No ratings yet

- C - MU üSICA - ARRANJAMENTS - Let Me Out Particellas - 01 RequintDocument1 pageC - MU üSICA - ARRANJAMENTS - Let Me Out Particellas - 01 RequintWiteyElCaballeroOscuroNo ratings yet

- A Town With An Ocean View Kikis Delivery Service String QuartetDocument1 pageA Town With An Ocean View Kikis Delivery Service String QuartetEduardo CarranzaNo ratings yet

- Grade S Screw Pin Bow ShackleDocument1 pageGrade S Screw Pin Bow Shacklegtsi.draftsmanNo ratings yet

- WLD On Lifting PointDocument1 pageWLD On Lifting Pointgtsi.draftsmanNo ratings yet

- Verspec WPS WPQDocument6 pagesVerspec WPS WPQgtsi.draftsmanNo ratings yet

- Training Courses For Manufacturing Industry Thors Elearning SolutionsDocument1 pageTraining Courses For Manufacturing Industry Thors Elearning Solutionsgtsi.draftsmanNo ratings yet