Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

4 viewsEa 102

Ea 102

Uploaded by

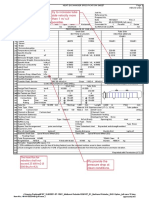

Najmul SaqibThis document provides specifications for an aspen exchanger that exchanges heat between a shell side and tube side. It exchanges 452486 BTU/h of heat with an effective mean temperature difference of 208.31°F. The exchanger has a 10.136 inch shell diameter, 120 inches in length, with 155 square feet of effective surface area across 1 shell. It contains 81 tubes that are 0.75 inches in diameter and made of carbon steel.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You might also like

- TEMA Sheet Heat Exchanger Specification SheetDocument3 pagesTEMA Sheet Heat Exchanger Specification SheetSonNguyen100% (1)

- Timmerhaus - Cryogenic Process EngineeringDocument24 pagesTimmerhaus - Cryogenic Process EngineeringMaria Andreina MontañezNo ratings yet

- Aspen Exchanger Design and Rating Shell & Tube V10: File: E-501-A - 1.edr Printed: 22/03/2019 at 05:07:09 A. M. TEMA SheetDocument2 pagesAspen Exchanger Design and Rating Shell & Tube V10: File: E-501-A - 1.edr Printed: 22/03/2019 at 05:07:09 A. M. TEMA SheetLandaNo ratings yet

- Heat Exchanger Sizing E-5000 #1Document2 pagesHeat Exchanger Sizing E-5000 #1Luis Enrique Leyva OvalleNo ratings yet

- Heat Exchanger Sizing E-3010A #1Document2 pagesHeat Exchanger Sizing E-3010A #1Luis Enrique Leyva Ovalle100% (1)

- Heat Exchanger Sizing E-7010 #1Document2 pagesHeat Exchanger Sizing E-7010 #1Luis Enrique Leyva OvalleNo ratings yet

- Ea 101Document2 pagesEa 101Najmul SaqibNo ratings yet

- Aspen Exchanger Design and Rating Shell & Tube V11Document1 pageAspen Exchanger Design and Rating Shell & Tube V11Luis NewballNo ratings yet

- L-R Intercambiador Coraza y Tubos PDFDocument1 pageL-R Intercambiador Coraza y Tubos PDFAlejandro OsorioNo ratings yet

- CrudoDocument2 pagesCrudoAndrés Felipe TáutivaNo ratings yet

- Output - ITEM NO. 113486 - 24 Inch at 10000 KGHRDocument1 pageOutput - ITEM NO. 113486 - 24 Inch at 10000 KGHRyadav yadavNo ratings yet

- Aspen Exchanger Design and Rating Shell & Tube V11Document1 pageAspen Exchanger Design and Rating Shell & Tube V11Ginna RodriguezNo ratings yet

- ShellTubeHE Hot PT Konigs E-202 ColdDocument1 pageShellTubeHE Hot PT Konigs E-202 Coldeka prasetiaNo ratings yet

- TEMA Sheet CorregidoDocument1 pageTEMA Sheet Corregidosaragineth.saNo ratings yet

- Output - ITEM NO. 106773 - 20 Inch at 10000 KG Per HRDocument1 pageOutput - ITEM NO. 106773 - 20 Inch at 10000 KG Per HRyadav yadavNo ratings yet

- Htri 105 PDFDocument1 pageHtri 105 PDFhirenpatel_62No ratings yet

- 240-05-DTS-009 V-501 Air ReceiverDocument20 pages240-05-DTS-009 V-501 Air ReceiverEmran NazirNo ratings yet

- 240-05-DTS-010 V-400 Regenaration Gas SeperatorDocument20 pages240-05-DTS-010 V-400 Regenaration Gas SeperatorEmran NazirNo ratings yet

- Aspen Exchanger Design and Rating Shell & Tube V10: File: B1 - 26.edr Printed: 7/1/2019 at 11:00:15 PMDocument1 pageAspen Exchanger Design and Rating Shell & Tube V10: File: B1 - 26.edr Printed: 7/1/2019 at 11:00:15 PMAlex AgualemaNo ratings yet

- Output PDFDocument1 pageOutput PDFAlex AgualemaNo ratings yet

- 2400-05-DTS-005cooling TowerDocument19 pages2400-05-DTS-005cooling TowerEmran NazirNo ratings yet

- 240-05-DTS-000 Fire Water PumpDocument19 pages240-05-DTS-000 Fire Water PumpEmran NazirNo ratings yet

- 240-05-DTS-XXX Flare StackDocument18 pages240-05-DTS-XXX Flare StackEmran NazirNo ratings yet

- Data Sheet Gas Scrubber 42 InchDocument32 pagesData Sheet Gas Scrubber 42 InchWijayantoNo ratings yet

- TEMA Sheed L-R ExchangerDocument1 pageTEMA Sheed L-R ExchangerAlejandra BuenoNo ratings yet

- Aspen Exchanger Design and Rating Shell & Tube V12: File: E-105.edr Printed: 24/01/2023 at 4:39:51 P. M. TEMA SheetDocument1 pageAspen Exchanger Design and Rating Shell & Tube V12: File: E-105.edr Printed: 24/01/2023 at 4:39:51 P. M. TEMA SheetNATALIA SALAZAR OROZCONo ratings yet

- Aspen Exchanger Design and Rating Shell & Tube V12: File: E-103 - 1.edr Printed: 24/01/2023 at 7:11:33 P. M. TEMA SheetDocument1 pageAspen Exchanger Design and Rating Shell & Tube V12: File: E-103 - 1.edr Printed: 24/01/2023 at 7:11:33 P. M. TEMA SheetNATALIA SALAZAR OROZCONo ratings yet

- T1 235, T2 116, 219 Tubos, 2 Pases, Aire 448308 LB - HR Rev1.segDocument1 pageT1 235, T2 116, 219 Tubos, 2 Pases, Aire 448308 LB - HR Rev1.segTIPAZONo ratings yet

- E-105 Cooler-IIIDocument1 pageE-105 Cooler-IIIAl FareshNo ratings yet

- Aspen Exchanger Design and Rating Shell & Tube V12: File: E-102 - 1.edr Printed: 24/01/2023 at 8:20:10 P. M. TEMA SheetDocument1 pageAspen Exchanger Design and Rating Shell & Tube V12: File: E-102 - 1.edr Printed: 24/01/2023 at 8:20:10 P. M. TEMA SheetNATALIA SALAZAR OROZCONo ratings yet

- Thermal and Hydraulic AnalysisDocument1 pageThermal and Hydraulic AnalysisSikander MushtaqNo ratings yet

- Aspen Exchanger Design and Rating Shell & Tube V10Document1 pageAspen Exchanger Design and Rating Shell & Tube V10Alex AgualemaNo ratings yet

- Aspen Exchanger Design and Rating Shell & Tube V9Document1 pageAspen Exchanger Design and Rating Shell & Tube V9Maira Alejandra GuzmánNo ratings yet

- Case 2Document1 pageCase 2nirajkulkarni09No ratings yet

- Heat Exchanger Rev - 02Document1 pageHeat Exchanger Rev - 02TKT ConsultantNo ratings yet

- PASES, AIRE 448308 LB - HR REVaa1.SEGDocument1 pagePASES, AIRE 448308 LB - HR REVaa1.SEGTIPAZONo ratings yet

- Caso de Studio Xchanger 1Document5 pagesCaso de Studio Xchanger 1fabianNo ratings yet

- Case 5Document1 pageCase 5nirajkulkarni09No ratings yet

- MSS SP 58Document1 pageMSS SP 58octa aldyNo ratings yet

- Shell&TubeResults 215E009Document5 pagesShell&TubeResults 215E009ganis supriadiNo ratings yet

- Tema SheetDocument1 pageTema SheetMayank AgrawalNo ratings yet

- Shell & Tube Heat ExchangerDocument3 pagesShell & Tube Heat ExchangerBesuidenhout Engineering Solutions and ConsultingNo ratings yet

- Case 4Document1 pageCase 4nirajkulkarni09No ratings yet

- Aspen Exchanger Design and Rating Shell & Tube V10Document1 pageAspen Exchanger Design and Rating Shell & Tube V10MAYANK AGRAWALNo ratings yet

- Heat Exchanger Sizing AC-6050 #1Document2 pagesHeat Exchanger Sizing AC-6050 #1Luis Enrique Leyva OvalleNo ratings yet

- Case 3Document1 pageCase 3nirajkulkarni09No ratings yet

- Consub TemaDocument1 pageConsub TemaMAYANK AGRAWALNo ratings yet

- Heat Exchanger Specification SheetDocument2 pagesHeat Exchanger Specification Sheettatiana alvarezNo ratings yet

- Aspen Exchanger Design and Rating Shell & Tube V8.8Document3 pagesAspen Exchanger Design and Rating Shell & Tube V8.8Camila Florencia ScarlatoNo ratings yet

- Aspen Exchanger Design and Rating Shell & Tube V12Document1 pageAspen Exchanger Design and Rating Shell & Tube V12TIPAZONo ratings yet

- 1Document1 page1kkkprotNo ratings yet

- Tubos y Coraza PDFDocument2 pagesTubos y Coraza PDFsamara navasNo ratings yet

- Tubos y Coraza PDFDocument2 pagesTubos y Coraza PDFsamara navasNo ratings yet

- E-313 DesignDocument1 pageE-313 DesignAamir SultanNo ratings yet

- Aspen Exchanger Design and Rating Shell & Tube V10: File: Printed: 1/31/2023 at 3:41:24 PM TEMA SheetDocument1 pageAspen Exchanger Design and Rating Shell & Tube V10: File: Printed: 1/31/2023 at 3:41:24 PM TEMA Sheetvaratharajan g rNo ratings yet

- Case 6Document1 pageCase 6nirajkulkarni09No ratings yet

- E-200 TEMA SheetDocument1 pageE-200 TEMA Sheetuse for school google drive storageNo ratings yet

- E 101Document21 pagesE 101EberVelazquezChantacaNo ratings yet

- Aspen Exchanger Design and Rating Shell & Tube V11Document1 pageAspen Exchanger Design and Rating Shell & Tube V11anggun 119280087No ratings yet

- SQ8167 - 01 - Methanol Reboiler - BKU Option - (Alt Case 10 Deg Approach) .HTRI 6th Aug 21-CmtdDocument4 pagesSQ8167 - 01 - Methanol Reboiler - BKU Option - (Alt Case 10 Deg Approach) .HTRI 6th Aug 21-CmtdSRINo ratings yet

- Seven-Storey Office Building: 1 1.1 Arrangement and LoadingDocument26 pagesSeven-Storey Office Building: 1 1.1 Arrangement and LoadingRanjit SinghNo ratings yet

- PHY 483 - Lecture1Document18 pagesPHY 483 - Lecture1Michael AdesanyaNo ratings yet

- Exam Weekly Exam6Document4 pagesExam Weekly Exam6Astra BeckettNo ratings yet

- 14 Thermal WorkbookDocument20 pages14 Thermal WorkbooktioluwalopedadaNo ratings yet

- 6.thermodynamics: Material Downloaded From SUPERCOP 1/8Document8 pages6.thermodynamics: Material Downloaded From SUPERCOP 1/8Abhinash MahapatroNo ratings yet

- (Total 1 Mark) : IB Questionbank Chemistry 1Document18 pages(Total 1 Mark) : IB Questionbank Chemistry 1Jen JenNo ratings yet

- MCQ - Unit Ii - Chemical ThermodynamicsDocument46 pagesMCQ - Unit Ii - Chemical ThermodynamicsAC BajanaNo ratings yet

- Physics FormulasDocument5 pagesPhysics FormulasMethyl OrangeNo ratings yet

- ICE Assignment 15032017 035808AMDocument5 pagesICE Assignment 15032017 035808AMGerlan Madrid MingoNo ratings yet

- 1 Secondary - Homework Sheet: H Oh Academy For ChemistryDocument7 pages1 Secondary - Homework Sheet: H Oh Academy For ChemistryMark FahimNo ratings yet

- PPT#2 PDFDocument63 pagesPPT#2 PDFMary Hazel Sarto, V.No ratings yet

- Phase 2 Report On Environmental Building Regulations & Guidelines To Achieve Energy Efficiency in Bangalore CityDocument161 pagesPhase 2 Report On Environmental Building Regulations & Guidelines To Achieve Energy Efficiency in Bangalore CityreshmaNo ratings yet

- A2-2.2-18 - WTHMT - Experimental and Numerical ApproachDocument10 pagesA2-2.2-18 - WTHMT - Experimental and Numerical ApproachCristian CNo ratings yet

- X Steam Tables (English Units)Document8 pagesX Steam Tables (English Units)Troy ThennisNo ratings yet

- Physics 2: Heat TransferDocument22 pagesPhysics 2: Heat TransferAndreana Amor GulayNo ratings yet

- Atomic PhysicsDocument31 pagesAtomic PhysicsOnur YavuzcetinNo ratings yet

- I PU Viva QuestionsDocument4 pagesI PU Viva QuestionsPoornima M SNo ratings yet

- Search Able Fundamentals FM BookDocument816 pagesSearch Able Fundamentals FM BookPrabal AcharyaNo ratings yet

- Kichael Carley Acoustics-11-23Document13 pagesKichael Carley Acoustics-11-23eki7777No ratings yet

- Mapua University: School of Chemical, Biological, Material Engineering and Sciences (CBMES)Document12 pagesMapua University: School of Chemical, Biological, Material Engineering and Sciences (CBMES)Ryan NobleNo ratings yet

- Personalized, Comprehensive Course ReviewDocument16 pagesPersonalized, Comprehensive Course ReviewLeyla thrxNo ratings yet

- ASTM E1269 - 0specific Heat by DSCDocument6 pagesASTM E1269 - 0specific Heat by DSCnolanjcNo ratings yet

- Correlation Lecture Mesl 02 Thermodynamics Fluid MechanicsDocument4 pagesCorrelation Lecture Mesl 02 Thermodynamics Fluid Mechanicsjustinegabuya82No ratings yet

- Jntuk 2 1 Thermodynamics Nov 2017 Q.PDocument8 pagesJntuk 2 1 Thermodynamics Nov 2017 Q.PsaiNo ratings yet

- Assignment 4Document3 pagesAssignment 4Saurabh BhimwalNo ratings yet

- Midterm Exam ThermodynamicsDocument10 pagesMidterm Exam ThermodynamicsRoselyn BenavidezNo ratings yet

- 2nd PERIODICAL EXAMINATION 8Document3 pages2nd PERIODICAL EXAMINATION 8Mariz Subong GandulinNo ratings yet

- Energetics Worksheet 3 AnswersDocument5 pagesEnergetics Worksheet 3 Answersreyhanehfaraji.2007No ratings yet

- All India Integrated Test Series: JEE (Advanced) - 2022Document11 pagesAll India Integrated Test Series: JEE (Advanced) - 2022Beyond ur imaginationNo ratings yet

Ea 102

Ea 102

Uploaded by

Najmul Saqib0 ratings0% found this document useful (0 votes)

4 views2 pagesThis document provides specifications for an aspen exchanger that exchanges heat between a shell side and tube side. It exchanges 452486 BTU/h of heat with an effective mean temperature difference of 208.31°F. The exchanger has a 10.136 inch shell diameter, 120 inches in length, with 155 square feet of effective surface area across 1 shell. It contains 81 tubes that are 0.75 inches in diameter and made of carbon steel.

Original Description:

Original Title

EA-102

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document provides specifications for an aspen exchanger that exchanges heat between a shell side and tube side. It exchanges 452486 BTU/h of heat with an effective mean temperature difference of 208.31°F. The exchanger has a 10.136 inch shell diameter, 120 inches in length, with 155 square feet of effective surface area across 1 shell. It contains 81 tubes that are 0.75 inches in diameter and made of carbon steel.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

4 views2 pagesEa 102

Ea 102

Uploaded by

Najmul SaqibThis document provides specifications for an aspen exchanger that exchanges heat between a shell side and tube side. It exchanges 452486 BTU/h of heat with an effective mean temperature difference of 208.31°F. The exchanger has a 10.136 inch shell diameter, 120 inches in length, with 155 square feet of effective surface area across 1 shell. It contains 81 tubes that are 0.75 inches in diameter and made of carbon steel.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 2

Aspen Exchanger Design and Rating Shell & Tube V11 Page 1

File: Printed: 2/29/2024 at 7:22:55 PM

TEMA Sheet

Heat Exchanger Specification Sheet

1 Company:

2 Location:

3 Service of Unit: Feed/LubeOil Product Exchanger Our Reference:

4 Item No.: Your Reference:

5 Date: Rev No.: Job No.: EA-102

6 Size 1

: 0.1181 - 120 in Type: AEM Horizontal Connected in: 1 parallel 1 series

7 Surf/unit(eff.) 155 ft² Shells/unit 1 Surf/shell(eff.) 155 ft²

8 PERFORMANCE OF ONE UNIT

9 Fluid allocation Shell Side Tube Side

10 Fluid name 16a->17 3a->TO HX-3(4)

11 Fluid quantity, Total lb/h 3350 4800

12 Vapor (In/Out) lb/h 0 0 0 46

13 Liquid lb/h 3350 3350 4800 4754

14 Noncondensable lb/h 0 0 0 0

15

16 Temperature (In/Out) °C 287.28 168.69 63.92 156.7

17 Bubble / Dew point °F / / 287.06 / 1528.52 286.42 / 1527.79

18 Density Vapor/Liquid lb/ft³ / 45.117 / 50.456 / 53.408 0.237 / 49.39

19 Viscosity cp / 0.2659 / 1.5508 / 16.7783 0.0117 / 1.7911

20 Molecular wt, Vap 30.13

21 Molecular wt, NC

22 Specific heat BTU/(lb-F) / 0.6839 / 0.5799 / 0.4845 0.4947 / 0.5717

23 Thermal conductivity BTU/(ft-h-F) / 0.057 / 0.066 / 0.073 0.016 / 0.068

24 Latent heat BTU/lb 539.3 212.2

25 Pressure (abs) psi 51.83 51.73 63.99 63.38

26 Velocity (Mean/Max) ft/s 0.18 / 0.22 0.35 / 0.53

27 Pressure drop, allow./calc. psi 5 0.1 5 0.61

28 Fouling resistance (min) ft²-h-F/BTU 0.001 0.007 0.009 Ao based

29 Heat exchanged 452486 BTU/h MTD (corrected) 208.31 °F

30 Transfer rate, Service 14.01 Dirty 14.01 Clean 16.29 BTU/(h-ft²-F)

31 CONSTRUCTION OF ONE SHELL Sketch

32 Shell Side Tube Side

33 Design/Vacuum/test pressure psi 70 / / 100 / /

34 Design temperature / MDMT °C 315 / 240 /

S2 S1 T2

35 Number passes per shell 1 1

36 Corrosion allowance in 0.125 0.125 T1

37 Connections In in 1 1.38 / - 1 0.742 / -

38 Size/Rating Out 1 1.049 / - 1 1.049 / -

39 ID Intermediate / - / -

40 Tube #: 81 OD: 0.75 Tks. Average 0.083 in Length: 10 ft Pitch: 0.9375 in Tube pattern:30

41 Tube type: Plain Insert:None Fin#: #/ft Material:Carbon Steel

42 Shell Carbon Steel ID 10.136 OD 10.75 in Shell cover -

43 Channel or bonnet Carbon Steel Channel cover Carbon Steel

44 Tubesheet-stationary Carbon Steel - Tubesheet-floating -

45 Floating head cover - Impingement protection None

46 Baffle-cross Carbon Steel Type Single segmental Cut(%d) 33.98 Horizontal

Spacing: c/c 4 in

47 Baffle-long - Seal Type Inlet 6.4833 in

48 Supports-tube U-bend 0 Type

49 Bypass seal Tube-tubesheet joint Expanded only (2 grooves)(App.A 'i')

50 Expansion joint - Type None

51 RhoV2-Inlet nozzle 178 Bundle entrance 3 Bundle exit 2 lb/(ft-s²)

52 Gaskets - Shell side - Tube side Flat Metal Jacket Fibe

53 Floating head -

54 Code requirements ASME Code Sec VIII Div 1 TEMA class R - refinery service

55 Weight/Shell 1299.1 Filled with water 1586.5 Bundle 611.5 lb

56 Remarks

57

58

Aspen Exchanger Design and Rating Shell & Tube V11 Page 2

File: Printed: 2/29/2024 at 7:22:55 PM

Overall Summary

1 Size 10.136 X 120 in Type AEM Hor Connected in 1 parallel 1 series

2 Surf/Unit (gross/eff/finned) 159 / 155 / ft² Shells/unit 1

3 Surf/Shell (gross/eff/finned) 159 / 155 / ft²

4 Simulation PERFORMANCE OF ONE UNIT

5 Shell Side Tube Side Heat Transfer Parameters

6 Process Data In Out In Out Total heat load BTU/h 452486

7 Total flow lb/h 3350 4800 Eff. MTD/ 1 pass MTD °F 208.31 / 208.34

8 Vapor lb/h 0 0 0 46 Actual/Reqd area ratio - fouled/clean 1 / 1.16

9 Liquid lb/h 3350 3350 4800 4754

10 Noncondensable lb/h 0 0 Coef./Resist. BTU/(h-ft²-F) ft²-h-F/BTU %

11 Cond./Evap. lb/h 0 46 Overall fouled 14.01 0.0714

12 Temperature °C 287.28 168.69 63.92 156.7 Overall clean 16.29 0.0614

13 Bubble Point °F 287.06 286.42 Tube side film 24.43 0.0409 57.36

14 Dew Point °F 1528.52 1527.79 Tube side fouling 111.23 0.009 12.6

15 Vapor mass fraction 0 0 0 0.01 Tube wall 3704.47 0.0003 0.38

16 Pressure (abs) psi 51.83 51.73 63.99 63.38 Outside fouling 999.95 0.001 1.4

17 DeltaP allow/cal psi 5 0.1 5 0.61 Outside film 49.57 0.0202 28.26

18 Velocity ft/s 0.17 0.15 0.17 0.53

19 Liquid Properties Shell Side Pressure Drop psi %

20 Density lb/ft³ 45.117 50.456 53.408 49.39 Inlet nozzle 0.02 25.08

21 Viscosity cp 0.2659 1.5508 16.7783 1.7911 InletspaceXflow 0 1.1

22 Specific heat BTU/(lb-F) 0.6839 0.5799 0.4845 0.5717 Baffle Xflow 0.02 21.76

23 Therm. cond. BTU/(ft-h-F) 0.057 0.066 0.073 0.068 Baffle window 0.01 7.34

24 Surface tension dynes/cm 21.3 OutletspaceXflow 0 1.65

25 Molecular weight 455.02 455.02 82.72 382.72 Outlet nozzle 0.04 43.06

26 Vapor Properties Intermediate nozzles

27 Density lb/ft³ 0.237 Tube Side Pressure Drop psi %

28 Viscosity cp 0.0117 Inlet nozzle 0.44 71.63

29 Specific heat BTU/(lb-F) 0.4947 Entering tubes 0 0.01

30 Therm. cond. BTU/(ft-h-F) 0.016 Inside tubes 0.02 2.97

31 Molecular weight 30.13 Exiting tubes 0 0.03

32 Two-Phase Properties Outlet nozzle 0.15 25.35

33 Latent heat BTU/lb 539.3 212.2 Intermediate nozzles

34 Heat Transfer Parameters Velocity / Rho*V2 ft/s lb/(ft-s²)

35 Reynolds No. vapor 525.01 Shell nozzle inlet 1.99 178

36 Reynolds No. liquid 2734.36 469 38.2 354.41 Shell bundle Xflow 0.17 0.15

37 Prandtl No. vapor 0.86 Shell baffle window 0.1 0.09

38 Prandtl No. liquid 7.76 32.99 268.69 36.54 Shell nozzle outlet 3.07 476

39 Heat Load BTU/h BTU/h Shell nozzle interm

40 Vapor only 0 0 ft/s lb/(ft-s²)

41 2-Phase vapor 0 458 Tube nozzle inlet 8.31 3692

42 Latent heat 0 21258 Tubes 0.17 0.53

43 2-Phase liquid 0 77050 Tube nozzle outlet 13.42 2980

44 Liquid only -452486 353720 Tube nozzle interm

45 Tubes Baffles Nozzles: (No./OD)

46 Type Plain Type Single segmental Shell Side Tube Side

47 ID/OD in 0.584 / 0.75 Number 27 Inlet in 1 / 1.66 1 / 1.05

48 Length act/eff ft 10 / 9.7472 Cut(%d) 33.98 Outlet 1 / 1.315 1 / 1.315

49 Tube passes 1 Cut orientation H Intermediate / /

50 Tube No. 81 Spacing: c/c in 4 Impingement protection None

51 Tube pattern 30 Spacing at inlet in 6.4833

52 Tube pitch in 0.9375 Spacing at outlet in 6.4833

53 Insert None

54 Vibration problem (HTFS / TEMA) No / RhoV2 violation No

You might also like

- TEMA Sheet Heat Exchanger Specification SheetDocument3 pagesTEMA Sheet Heat Exchanger Specification SheetSonNguyen100% (1)

- Timmerhaus - Cryogenic Process EngineeringDocument24 pagesTimmerhaus - Cryogenic Process EngineeringMaria Andreina MontañezNo ratings yet

- Aspen Exchanger Design and Rating Shell & Tube V10: File: E-501-A - 1.edr Printed: 22/03/2019 at 05:07:09 A. M. TEMA SheetDocument2 pagesAspen Exchanger Design and Rating Shell & Tube V10: File: E-501-A - 1.edr Printed: 22/03/2019 at 05:07:09 A. M. TEMA SheetLandaNo ratings yet

- Heat Exchanger Sizing E-5000 #1Document2 pagesHeat Exchanger Sizing E-5000 #1Luis Enrique Leyva OvalleNo ratings yet

- Heat Exchanger Sizing E-3010A #1Document2 pagesHeat Exchanger Sizing E-3010A #1Luis Enrique Leyva Ovalle100% (1)

- Heat Exchanger Sizing E-7010 #1Document2 pagesHeat Exchanger Sizing E-7010 #1Luis Enrique Leyva OvalleNo ratings yet

- Ea 101Document2 pagesEa 101Najmul SaqibNo ratings yet

- Aspen Exchanger Design and Rating Shell & Tube V11Document1 pageAspen Exchanger Design and Rating Shell & Tube V11Luis NewballNo ratings yet

- L-R Intercambiador Coraza y Tubos PDFDocument1 pageL-R Intercambiador Coraza y Tubos PDFAlejandro OsorioNo ratings yet

- CrudoDocument2 pagesCrudoAndrés Felipe TáutivaNo ratings yet

- Output - ITEM NO. 113486 - 24 Inch at 10000 KGHRDocument1 pageOutput - ITEM NO. 113486 - 24 Inch at 10000 KGHRyadav yadavNo ratings yet

- Aspen Exchanger Design and Rating Shell & Tube V11Document1 pageAspen Exchanger Design and Rating Shell & Tube V11Ginna RodriguezNo ratings yet

- ShellTubeHE Hot PT Konigs E-202 ColdDocument1 pageShellTubeHE Hot PT Konigs E-202 Coldeka prasetiaNo ratings yet

- TEMA Sheet CorregidoDocument1 pageTEMA Sheet Corregidosaragineth.saNo ratings yet

- Output - ITEM NO. 106773 - 20 Inch at 10000 KG Per HRDocument1 pageOutput - ITEM NO. 106773 - 20 Inch at 10000 KG Per HRyadav yadavNo ratings yet

- Htri 105 PDFDocument1 pageHtri 105 PDFhirenpatel_62No ratings yet

- 240-05-DTS-009 V-501 Air ReceiverDocument20 pages240-05-DTS-009 V-501 Air ReceiverEmran NazirNo ratings yet

- 240-05-DTS-010 V-400 Regenaration Gas SeperatorDocument20 pages240-05-DTS-010 V-400 Regenaration Gas SeperatorEmran NazirNo ratings yet

- Aspen Exchanger Design and Rating Shell & Tube V10: File: B1 - 26.edr Printed: 7/1/2019 at 11:00:15 PMDocument1 pageAspen Exchanger Design and Rating Shell & Tube V10: File: B1 - 26.edr Printed: 7/1/2019 at 11:00:15 PMAlex AgualemaNo ratings yet

- Output PDFDocument1 pageOutput PDFAlex AgualemaNo ratings yet

- 2400-05-DTS-005cooling TowerDocument19 pages2400-05-DTS-005cooling TowerEmran NazirNo ratings yet

- 240-05-DTS-000 Fire Water PumpDocument19 pages240-05-DTS-000 Fire Water PumpEmran NazirNo ratings yet

- 240-05-DTS-XXX Flare StackDocument18 pages240-05-DTS-XXX Flare StackEmran NazirNo ratings yet

- Data Sheet Gas Scrubber 42 InchDocument32 pagesData Sheet Gas Scrubber 42 InchWijayantoNo ratings yet

- TEMA Sheed L-R ExchangerDocument1 pageTEMA Sheed L-R ExchangerAlejandra BuenoNo ratings yet

- Aspen Exchanger Design and Rating Shell & Tube V12: File: E-105.edr Printed: 24/01/2023 at 4:39:51 P. M. TEMA SheetDocument1 pageAspen Exchanger Design and Rating Shell & Tube V12: File: E-105.edr Printed: 24/01/2023 at 4:39:51 P. M. TEMA SheetNATALIA SALAZAR OROZCONo ratings yet

- Aspen Exchanger Design and Rating Shell & Tube V12: File: E-103 - 1.edr Printed: 24/01/2023 at 7:11:33 P. M. TEMA SheetDocument1 pageAspen Exchanger Design and Rating Shell & Tube V12: File: E-103 - 1.edr Printed: 24/01/2023 at 7:11:33 P. M. TEMA SheetNATALIA SALAZAR OROZCONo ratings yet

- T1 235, T2 116, 219 Tubos, 2 Pases, Aire 448308 LB - HR Rev1.segDocument1 pageT1 235, T2 116, 219 Tubos, 2 Pases, Aire 448308 LB - HR Rev1.segTIPAZONo ratings yet

- E-105 Cooler-IIIDocument1 pageE-105 Cooler-IIIAl FareshNo ratings yet

- Aspen Exchanger Design and Rating Shell & Tube V12: File: E-102 - 1.edr Printed: 24/01/2023 at 8:20:10 P. M. TEMA SheetDocument1 pageAspen Exchanger Design and Rating Shell & Tube V12: File: E-102 - 1.edr Printed: 24/01/2023 at 8:20:10 P. M. TEMA SheetNATALIA SALAZAR OROZCONo ratings yet

- Thermal and Hydraulic AnalysisDocument1 pageThermal and Hydraulic AnalysisSikander MushtaqNo ratings yet

- Aspen Exchanger Design and Rating Shell & Tube V10Document1 pageAspen Exchanger Design and Rating Shell & Tube V10Alex AgualemaNo ratings yet

- Aspen Exchanger Design and Rating Shell & Tube V9Document1 pageAspen Exchanger Design and Rating Shell & Tube V9Maira Alejandra GuzmánNo ratings yet

- Case 2Document1 pageCase 2nirajkulkarni09No ratings yet

- Heat Exchanger Rev - 02Document1 pageHeat Exchanger Rev - 02TKT ConsultantNo ratings yet

- PASES, AIRE 448308 LB - HR REVaa1.SEGDocument1 pagePASES, AIRE 448308 LB - HR REVaa1.SEGTIPAZONo ratings yet

- Caso de Studio Xchanger 1Document5 pagesCaso de Studio Xchanger 1fabianNo ratings yet

- Case 5Document1 pageCase 5nirajkulkarni09No ratings yet

- MSS SP 58Document1 pageMSS SP 58octa aldyNo ratings yet

- Shell&TubeResults 215E009Document5 pagesShell&TubeResults 215E009ganis supriadiNo ratings yet

- Tema SheetDocument1 pageTema SheetMayank AgrawalNo ratings yet

- Shell & Tube Heat ExchangerDocument3 pagesShell & Tube Heat ExchangerBesuidenhout Engineering Solutions and ConsultingNo ratings yet

- Case 4Document1 pageCase 4nirajkulkarni09No ratings yet

- Aspen Exchanger Design and Rating Shell & Tube V10Document1 pageAspen Exchanger Design and Rating Shell & Tube V10MAYANK AGRAWALNo ratings yet

- Heat Exchanger Sizing AC-6050 #1Document2 pagesHeat Exchanger Sizing AC-6050 #1Luis Enrique Leyva OvalleNo ratings yet

- Case 3Document1 pageCase 3nirajkulkarni09No ratings yet

- Consub TemaDocument1 pageConsub TemaMAYANK AGRAWALNo ratings yet

- Heat Exchanger Specification SheetDocument2 pagesHeat Exchanger Specification Sheettatiana alvarezNo ratings yet

- Aspen Exchanger Design and Rating Shell & Tube V8.8Document3 pagesAspen Exchanger Design and Rating Shell & Tube V8.8Camila Florencia ScarlatoNo ratings yet

- Aspen Exchanger Design and Rating Shell & Tube V12Document1 pageAspen Exchanger Design and Rating Shell & Tube V12TIPAZONo ratings yet

- 1Document1 page1kkkprotNo ratings yet

- Tubos y Coraza PDFDocument2 pagesTubos y Coraza PDFsamara navasNo ratings yet

- Tubos y Coraza PDFDocument2 pagesTubos y Coraza PDFsamara navasNo ratings yet

- E-313 DesignDocument1 pageE-313 DesignAamir SultanNo ratings yet

- Aspen Exchanger Design and Rating Shell & Tube V10: File: Printed: 1/31/2023 at 3:41:24 PM TEMA SheetDocument1 pageAspen Exchanger Design and Rating Shell & Tube V10: File: Printed: 1/31/2023 at 3:41:24 PM TEMA Sheetvaratharajan g rNo ratings yet

- Case 6Document1 pageCase 6nirajkulkarni09No ratings yet

- E-200 TEMA SheetDocument1 pageE-200 TEMA Sheetuse for school google drive storageNo ratings yet

- E 101Document21 pagesE 101EberVelazquezChantacaNo ratings yet

- Aspen Exchanger Design and Rating Shell & Tube V11Document1 pageAspen Exchanger Design and Rating Shell & Tube V11anggun 119280087No ratings yet

- SQ8167 - 01 - Methanol Reboiler - BKU Option - (Alt Case 10 Deg Approach) .HTRI 6th Aug 21-CmtdDocument4 pagesSQ8167 - 01 - Methanol Reboiler - BKU Option - (Alt Case 10 Deg Approach) .HTRI 6th Aug 21-CmtdSRINo ratings yet

- Seven-Storey Office Building: 1 1.1 Arrangement and LoadingDocument26 pagesSeven-Storey Office Building: 1 1.1 Arrangement and LoadingRanjit SinghNo ratings yet

- PHY 483 - Lecture1Document18 pagesPHY 483 - Lecture1Michael AdesanyaNo ratings yet

- Exam Weekly Exam6Document4 pagesExam Weekly Exam6Astra BeckettNo ratings yet

- 14 Thermal WorkbookDocument20 pages14 Thermal WorkbooktioluwalopedadaNo ratings yet

- 6.thermodynamics: Material Downloaded From SUPERCOP 1/8Document8 pages6.thermodynamics: Material Downloaded From SUPERCOP 1/8Abhinash MahapatroNo ratings yet

- (Total 1 Mark) : IB Questionbank Chemistry 1Document18 pages(Total 1 Mark) : IB Questionbank Chemistry 1Jen JenNo ratings yet

- MCQ - Unit Ii - Chemical ThermodynamicsDocument46 pagesMCQ - Unit Ii - Chemical ThermodynamicsAC BajanaNo ratings yet

- Physics FormulasDocument5 pagesPhysics FormulasMethyl OrangeNo ratings yet

- ICE Assignment 15032017 035808AMDocument5 pagesICE Assignment 15032017 035808AMGerlan Madrid MingoNo ratings yet

- 1 Secondary - Homework Sheet: H Oh Academy For ChemistryDocument7 pages1 Secondary - Homework Sheet: H Oh Academy For ChemistryMark FahimNo ratings yet

- PPT#2 PDFDocument63 pagesPPT#2 PDFMary Hazel Sarto, V.No ratings yet

- Phase 2 Report On Environmental Building Regulations & Guidelines To Achieve Energy Efficiency in Bangalore CityDocument161 pagesPhase 2 Report On Environmental Building Regulations & Guidelines To Achieve Energy Efficiency in Bangalore CityreshmaNo ratings yet

- A2-2.2-18 - WTHMT - Experimental and Numerical ApproachDocument10 pagesA2-2.2-18 - WTHMT - Experimental and Numerical ApproachCristian CNo ratings yet

- X Steam Tables (English Units)Document8 pagesX Steam Tables (English Units)Troy ThennisNo ratings yet

- Physics 2: Heat TransferDocument22 pagesPhysics 2: Heat TransferAndreana Amor GulayNo ratings yet

- Atomic PhysicsDocument31 pagesAtomic PhysicsOnur YavuzcetinNo ratings yet

- I PU Viva QuestionsDocument4 pagesI PU Viva QuestionsPoornima M SNo ratings yet

- Search Able Fundamentals FM BookDocument816 pagesSearch Able Fundamentals FM BookPrabal AcharyaNo ratings yet

- Kichael Carley Acoustics-11-23Document13 pagesKichael Carley Acoustics-11-23eki7777No ratings yet

- Mapua University: School of Chemical, Biological, Material Engineering and Sciences (CBMES)Document12 pagesMapua University: School of Chemical, Biological, Material Engineering and Sciences (CBMES)Ryan NobleNo ratings yet

- Personalized, Comprehensive Course ReviewDocument16 pagesPersonalized, Comprehensive Course ReviewLeyla thrxNo ratings yet

- ASTM E1269 - 0specific Heat by DSCDocument6 pagesASTM E1269 - 0specific Heat by DSCnolanjcNo ratings yet

- Correlation Lecture Mesl 02 Thermodynamics Fluid MechanicsDocument4 pagesCorrelation Lecture Mesl 02 Thermodynamics Fluid Mechanicsjustinegabuya82No ratings yet

- Jntuk 2 1 Thermodynamics Nov 2017 Q.PDocument8 pagesJntuk 2 1 Thermodynamics Nov 2017 Q.PsaiNo ratings yet

- Assignment 4Document3 pagesAssignment 4Saurabh BhimwalNo ratings yet

- Midterm Exam ThermodynamicsDocument10 pagesMidterm Exam ThermodynamicsRoselyn BenavidezNo ratings yet

- 2nd PERIODICAL EXAMINATION 8Document3 pages2nd PERIODICAL EXAMINATION 8Mariz Subong GandulinNo ratings yet

- Energetics Worksheet 3 AnswersDocument5 pagesEnergetics Worksheet 3 Answersreyhanehfaraji.2007No ratings yet

- All India Integrated Test Series: JEE (Advanced) - 2022Document11 pagesAll India Integrated Test Series: JEE (Advanced) - 2022Beyond ur imaginationNo ratings yet