Professional Documents

Culture Documents

Indr 371 Homework-4

Indr 371 Homework-4

Uploaded by

meliharslan817Copyright:

Available Formats

You might also like

- Sheet 2 FPDocument4 pagesSheet 2 FPyehyaNo ratings yet

- Accounting Textbook Solutions - 34Document19 pagesAccounting Textbook Solutions - 34acc-expertNo ratings yet

- Math 2930 F 18 Ass 3 SolDocument8 pagesMath 2930 F 18 Ass 3 SolQuentin ThymeNo ratings yet

- Exercises SetupsDocument3 pagesExercises SetupsbridaNo ratings yet

- Chapter 3 SolutionDocument6 pagesChapter 3 Solutionrobertrnicol0% (1)

- Meagal StelplastDocument7 pagesMeagal StelplastShaunJaiprakash100% (3)

- Group 8 - Donner SolutionDocument4 pagesGroup 8 - Donner SolutionMayank MishraNo ratings yet

- Toledo Custom Manufacturing TCM Makes Machined Steel Parts To CustomerDocument2 pagesToledo Custom Manufacturing TCM Makes Machined Steel Parts To CustomerCharlotte0% (1)

- Y. B. Almquist, S. Ashir, L. Brännström - A Guide To Quantitative Methods-Stockholm University (2019)Document343 pagesY. B. Almquist, S. Ashir, L. Brännström - A Guide To Quantitative Methods-Stockholm University (2019)Jenny Pastor100% (1)

- Test Series: 1 Manufacturing System Design (MEL 361) Time: 50 Min Max. Marks: 20Document2 pagesTest Series: 1 Manufacturing System Design (MEL 361) Time: 50 Min Max. Marks: 20Soubhav ChamanNo ratings yet

- Assignment 2 - S17Document2 pagesAssignment 2 - S17Mahmoud Essam AhmedNo ratings yet

- 2015 Homework2 SolutionDocument4 pages2015 Homework2 Solutionnagu323100% (1)

- Gizmoz Study CaseDocument4 pagesGizmoz Study CaseInge Monica100% (1)

- Assignments (Refer To Chapter 2 of Mikell P. Groover's Book)Document3 pagesAssignments (Refer To Chapter 2 of Mikell P. Groover's Book)Linh NguyễnNo ratings yet

- Test #2, Part One, 50 Points: IEGR 410: Simulation Spring 2003 M. SalimianDocument3 pagesTest #2, Part One, 50 Points: IEGR 410: Simulation Spring 2003 M. SalimianbasriNo ratings yet

- Department of Mechanical and Industrial Engineering TechnologyDocument3 pagesDepartment of Mechanical and Industrial Engineering Technologyrealeboga moneiNo ratings yet

- Sample Test Spring 2014 FinalDocument17 pagesSample Test Spring 2014 FinalChristian PetersonNo ratings yet

- ANCM Assignment 1Document6 pagesANCM Assignment 1Aditi RayNo ratings yet

- Opt 25491 2063846081Document9 pagesOpt 25491 2063846081danielesmarNo ratings yet

- Mechanics VII - Test 1Document1 pageMechanics VII - Test 1luchogilmourNo ratings yet

- QH-Case Study Assignment1Document4 pagesQH-Case Study Assignment1Palak ShahNo ratings yet

- Hull Machining of M113 Armoured Personel CarrierDocument6 pagesHull Machining of M113 Armoured Personel CarrierNisar Ahmed RanaNo ratings yet

- GT Mod 2Document33 pagesGT Mod 2Sudheesh SNo ratings yet

- Assignments - Chapter 1 (Post For Students)Document3 pagesAssignments - Chapter 1 (Post For Students)Hoàng Ánh LýNo ratings yet

- Manufacturing SystemDocument43 pagesManufacturing SystemateqahNo ratings yet

- OLA-2 PPS ApplicationsDocument2 pagesOLA-2 PPS ApplicationsCj SesnorioNo ratings yet

- Exercises 2Document2 pagesExercises 2Nguyen Anh ThaoNo ratings yet

- Assignment FMSDocument2 pagesAssignment FMSAnuragShrivastavNo ratings yet

- Arena - Problems For ClassDocument10 pagesArena - Problems For ClassVisakh RadhakrishnanNo ratings yet

- Solution of Assignment 1Document3 pagesSolution of Assignment 1Anonymous 8O9X3QtR475% (4)

- Computer Science Textbook Solutions - 7Document30 pagesComputer Science Textbook Solutions - 7acc-expertNo ratings yet

- Home WorkDocument2 pagesHome WorkVladimir Lenis50% (2)

- ManufacturigCase StudyDocument19 pagesManufacturigCase Studyshruthicivil100% (1)

- Lecture 6-Manual Assembly LinesDocument5 pagesLecture 6-Manual Assembly LinesFatimaNo ratings yet

- Short Sums Related To Time StudyDocument2 pagesShort Sums Related To Time StudyBKC EnterpriseNo ratings yet

- Mime 4100 Final Exam 5/1/2011Document2 pagesMime 4100 Final Exam 5/1/2011derejeNo ratings yet

- Toyota Kanban System PDFDocument10 pagesToyota Kanban System PDFAman SharmaNo ratings yet

- Capacity PlanningDocument29 pagesCapacity PlanningVicky Pandey67% (6)

- PracticeProblems QualityManagement PDFDocument2 pagesPracticeProblems QualityManagement PDFStephanie LamNo ratings yet

- MF40603 Lecture 5Document7 pagesMF40603 Lecture 5kicked.partnershipNo ratings yet

- Assignment 01Document3 pagesAssignment 01Hasan ShahrierNo ratings yet

- Assignment 01Document3 pagesAssignment 01Hasan ShahrierNo ratings yet

- HW 1Document5 pagesHW 1Tuncay AYTEKİNNo ratings yet

- 15P701Document4 pages15P701rajakrishnanNo ratings yet

- Auditoria Final Fresa Torno CNCDocument25 pagesAuditoria Final Fresa Torno CNCJuan David Sandoval HerreraNo ratings yet

- 10iml68 Lab Manual - ModifiedDocument89 pages10iml68 Lab Manual - ModifiedRupa DnNo ratings yet

- Tutorial #2Document4 pagesTutorial #2Omar Abu-obiallaNo ratings yet

- Lean OEEDocument13 pagesLean OEEbasma osamaNo ratings yet

- Automation Solution ManualDocument3 pagesAutomation Solution ManualVinodhkumar PalakodeNo ratings yet

- OM - Assignment 2 - Problem - CPKDocument1 pageOM - Assignment 2 - Problem - CPKanun22No ratings yet

- 15P701Document3 pages15P701rajakrishnanNo ratings yet

- Functions of The Handling SystemDocument51 pagesFunctions of The Handling SystemJim MathilakathuNo ratings yet

- ktra hệ thống sản xuất tích hợpDocument47 pagesktra hệ thống sản xuất tích hợpVũ Quốc KhánhNo ratings yet

- Simulation Exercise Problems For Modelling in ARENA Software PackageDocument7 pagesSimulation Exercise Problems For Modelling in ARENA Software PackagesabarinathNo ratings yet

- Capacityplanning-Unsolved 7 NumericalsDocument2 pagesCapacityplanning-Unsolved 7 NumericalsShanky JainNo ratings yet

- 12 Quality CostDocument29 pages12 Quality CostAntariksh Shahwal100% (1)

- Taller 2 OEEDocument4 pagesTaller 2 OEEAnonymous xlp6qlVJ67% (3)

- Example MS MidtermDocument2 pagesExample MS MidtermDuyên LêNo ratings yet

- Creating a One-Piece Flow and Production Cell: Just-in-time Production with Toyota’s Single Piece FlowFrom EverandCreating a One-Piece Flow and Production Cell: Just-in-time Production with Toyota’s Single Piece FlowRating: 4 out of 5 stars4/5 (1)

- Takt Time: A Guide to the Very Basic Lean CalculationFrom EverandTakt Time: A Guide to the Very Basic Lean CalculationRating: 5 out of 5 stars5/5 (2)

- Understanding OEE in Lean Production: Toyota Production System ConceptsFrom EverandUnderstanding OEE in Lean Production: Toyota Production System ConceptsRating: 5 out of 5 stars5/5 (1)

- Factors Related To The Unemployment Rate: A Statistical AnalysisDocument43 pagesFactors Related To The Unemployment Rate: A Statistical AnalysisRogel RomeroNo ratings yet

- Biosttistics: Screening Test StatisticsDocument9 pagesBiosttistics: Screening Test Statisticszainab100% (1)

- Informs Management Science: This Content Downloaded From 138.25.78.25 On Fri, 29 Jul 2016 19:39:35 UTCDocument13 pagesInforms Management Science: This Content Downloaded From 138.25.78.25 On Fri, 29 Jul 2016 19:39:35 UTCFerchichi NizarNo ratings yet

- Chapter 2 Rice AddDocument4 pagesChapter 2 Rice Addmaele2100% (1)

- System Simulation: Dr. DessoukyDocument183 pagesSystem Simulation: Dr. DessoukyParimal BhambareNo ratings yet

- Ebook PDF Business Statistics 4th Edition by Norean D Sharpe PDFDocument41 pagesEbook PDF Business Statistics 4th Edition by Norean D Sharpe PDFmichael.alexander940100% (48)

- All The Statistical Concept You Required For Data ScienceDocument26 pagesAll The Statistical Concept You Required For Data ScienceAshwin ChaudhariNo ratings yet

- COR006 - MajorPT1Document6 pagesCOR006 - MajorPT1sife.magoyag.cocNo ratings yet

- Biostatistics For The Biological and Health Sciences 2nd Edition Triola Solutions ManualDocument17 pagesBiostatistics For The Biological and Health Sciences 2nd Edition Triola Solutions Manualsartaneurismjmq8j6100% (21)

- Exam 3 ReviewDocument16 pagesExam 3 ReviewSarrahNo ratings yet

- UserManual ReliabilityDocument74 pagesUserManual Reliabilitymatua trevorNo ratings yet

- Wavelet-Based Estimator For The Hurst Parameters of Fractional Brownian SheetDocument20 pagesWavelet-Based Estimator For The Hurst Parameters of Fractional Brownian SheetCristian Rodrigo Ubal NúñezNo ratings yet

- Probability PDFDocument7 pagesProbability PDFJevan CalaqueNo ratings yet

- LP 3 - Data Management, HeheDocument36 pagesLP 3 - Data Management, HeheRiane SabañecoNo ratings yet

- R Studio How ToDocument12 pagesR Studio How ToGerad TeoNo ratings yet

- Quarter K-12 Learning Competencies MelcsDocument4 pagesQuarter K-12 Learning Competencies MelcstitserscradleNo ratings yet

- Quality - Management - Dr. Attia Gomaa-09!09!2019Document410 pagesQuality - Management - Dr. Attia Gomaa-09!09!2019Abdulrahman100% (1)

- Week 4 Continuous Probability Distribution PDFDocument40 pagesWeek 4 Continuous Probability Distribution PDFloompapasNo ratings yet

- Data Science Linear RegressionDocument105 pagesData Science Linear RegressionJaime Prades KošćinaNo ratings yet

- Asset-V1 MITx+CTL - SC3x+2T2016+type@asset+block@SC1x KeyConcepts v6 PDFDocument82 pagesAsset-V1 MITx+CTL - SC3x+2T2016+type@asset+block@SC1x KeyConcepts v6 PDFSparsh Verma0% (1)

- CH5 Data Mining Classification Prepared by Dr. Maher AbuhamdehDocument61 pagesCH5 Data Mining Classification Prepared by Dr. Maher AbuhamdehJagriti SinghNo ratings yet

- Develop A Quality by Design Approach For Analytical Method DevelopmentDocument104 pagesDevelop A Quality by Design Approach For Analytical Method DevelopmentJoe Luis Villa MedinaNo ratings yet

- One Sample T Test - SPSS Tutorials - LibGuides at Kent State UniversityDocument10 pagesOne Sample T Test - SPSS Tutorials - LibGuides at Kent State UniversityBruno SaturnNo ratings yet

- Integrated UncertaintyAnalysis Using RELAP/SDAPSIM/MOD4.0Document11 pagesIntegrated UncertaintyAnalysis Using RELAP/SDAPSIM/MOD4.0Topan SetiadipuraNo ratings yet

- DR Ganesh Patil Medical StatisticsDocument77 pagesDR Ganesh Patil Medical StatisticsKaushal PatelNo ratings yet

- Third Quarter Examination: IN Statistics and ProbabilityDocument3 pagesThird Quarter Examination: IN Statistics and ProbabilityPing Homigop JamioNo ratings yet

- Stat 110, Lecture 7 Continuous Probability Distributions: Bheavlin@stat - Stanford.eduDocument35 pagesStat 110, Lecture 7 Continuous Probability Distributions: Bheavlin@stat - Stanford.edujamesyuNo ratings yet

- Module 2 in IStat 1 Probability DistributionDocument6 pagesModule 2 in IStat 1 Probability DistributionJefferson Cadavos CheeNo ratings yet

Indr 371 Homework-4

Indr 371 Homework-4

Uploaded by

meliharslan817Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Indr 371 Homework-4

Indr 371 Homework-4

Uploaded by

meliharslan817Copyright:

Available Formats

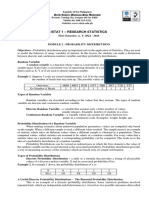

INDR 371 HOMEWORK-4

1. Consider a single-machine production system that produces aluminum sheets for car manufacturing. The

monthly production target is 100 sheets. The minimum and maximum thickness of the aluminum sheets

should be between 2,97 and 3.03 millimeters to meet the car manufacturing standards. The historical data

shows that the thickness of the sheets produced by the current pressing machine has a normal distribution

with a mean of 3.00 mm and a standard deviation of 0.02mm.

(a) (25 pts) Use the normal approximation to the binomial yield model to estimate the probability that

the production requirements are met if the number of items that are manufactured is 100, 110, and

120.

(b) (25 pts) Repeat the same exercise if the required quantity is 1000 and 1000, 1100, and 1200 items

are produced.

2. (50 pts) Consider a production cell with a single worker and several semiautonomous machines. Due to the

issues with the raw material used, with a two percent probability, a product may get stuck in a machine

after the processing, and a repair team is called to remove the product and recalibrate the machine if

that happens. The maintenance takes 45 minutes to complete (including the traveling time of the team)

and during the repair, the is a 40% chance that the product gets damaged. The maintenance teams do

not end their shift before fixing a broken machine (they work overtime if needed). We know the following

parameters for the production system.

• There is a single shift in the factory that lasts 8 hours. The workers take a 20-minute break at the

middle of the shift.

• Machining time for a product is a random variable that is uniformly distributed between 5 and 7

minutes.

• The loading time is normally distributed with a mean of 45 seconds and a standard deviation of 10

seconds. Similarly, the unloading time is also normally distributed with a mean of 30 seconds and a

standard deviation of 5 seconds.

• The quality check takes 1 minute for the worker (if the part is not stuck) and if a part is not stuck

the probability that it passes the quality check is 98.5%.

• It takes 40 seconds for a worker to move from one machine to the other one.

Use a simulation approach to answer the following questions.

(a) What would be the expected production quantities if 2,3,4 or 5 machines are placed in the production

cell?

(b) Assume 3 machines are placed in the cell. How much the daily production quantity would increase

if the stuck probability is reduced by 1 percent?

(c) Assume 3 machines are placed in the cell. How much the daily production quantity would increase

if the successful production probability for the unstuck parts is increased by 1 percent? Comment

on the effectiveness of the system improvements in parts (b) and (c) by comparing the production

increases.

You might also like

- Sheet 2 FPDocument4 pagesSheet 2 FPyehyaNo ratings yet

- Accounting Textbook Solutions - 34Document19 pagesAccounting Textbook Solutions - 34acc-expertNo ratings yet

- Math 2930 F 18 Ass 3 SolDocument8 pagesMath 2930 F 18 Ass 3 SolQuentin ThymeNo ratings yet

- Exercises SetupsDocument3 pagesExercises SetupsbridaNo ratings yet

- Chapter 3 SolutionDocument6 pagesChapter 3 Solutionrobertrnicol0% (1)

- Meagal StelplastDocument7 pagesMeagal StelplastShaunJaiprakash100% (3)

- Group 8 - Donner SolutionDocument4 pagesGroup 8 - Donner SolutionMayank MishraNo ratings yet

- Toledo Custom Manufacturing TCM Makes Machined Steel Parts To CustomerDocument2 pagesToledo Custom Manufacturing TCM Makes Machined Steel Parts To CustomerCharlotte0% (1)

- Y. B. Almquist, S. Ashir, L. Brännström - A Guide To Quantitative Methods-Stockholm University (2019)Document343 pagesY. B. Almquist, S. Ashir, L. Brännström - A Guide To Quantitative Methods-Stockholm University (2019)Jenny Pastor100% (1)

- Test Series: 1 Manufacturing System Design (MEL 361) Time: 50 Min Max. Marks: 20Document2 pagesTest Series: 1 Manufacturing System Design (MEL 361) Time: 50 Min Max. Marks: 20Soubhav ChamanNo ratings yet

- Assignment 2 - S17Document2 pagesAssignment 2 - S17Mahmoud Essam AhmedNo ratings yet

- 2015 Homework2 SolutionDocument4 pages2015 Homework2 Solutionnagu323100% (1)

- Gizmoz Study CaseDocument4 pagesGizmoz Study CaseInge Monica100% (1)

- Assignments (Refer To Chapter 2 of Mikell P. Groover's Book)Document3 pagesAssignments (Refer To Chapter 2 of Mikell P. Groover's Book)Linh NguyễnNo ratings yet

- Test #2, Part One, 50 Points: IEGR 410: Simulation Spring 2003 M. SalimianDocument3 pagesTest #2, Part One, 50 Points: IEGR 410: Simulation Spring 2003 M. SalimianbasriNo ratings yet

- Department of Mechanical and Industrial Engineering TechnologyDocument3 pagesDepartment of Mechanical and Industrial Engineering Technologyrealeboga moneiNo ratings yet

- Sample Test Spring 2014 FinalDocument17 pagesSample Test Spring 2014 FinalChristian PetersonNo ratings yet

- ANCM Assignment 1Document6 pagesANCM Assignment 1Aditi RayNo ratings yet

- Opt 25491 2063846081Document9 pagesOpt 25491 2063846081danielesmarNo ratings yet

- Mechanics VII - Test 1Document1 pageMechanics VII - Test 1luchogilmourNo ratings yet

- QH-Case Study Assignment1Document4 pagesQH-Case Study Assignment1Palak ShahNo ratings yet

- Hull Machining of M113 Armoured Personel CarrierDocument6 pagesHull Machining of M113 Armoured Personel CarrierNisar Ahmed RanaNo ratings yet

- GT Mod 2Document33 pagesGT Mod 2Sudheesh SNo ratings yet

- Assignments - Chapter 1 (Post For Students)Document3 pagesAssignments - Chapter 1 (Post For Students)Hoàng Ánh LýNo ratings yet

- Manufacturing SystemDocument43 pagesManufacturing SystemateqahNo ratings yet

- OLA-2 PPS ApplicationsDocument2 pagesOLA-2 PPS ApplicationsCj SesnorioNo ratings yet

- Exercises 2Document2 pagesExercises 2Nguyen Anh ThaoNo ratings yet

- Assignment FMSDocument2 pagesAssignment FMSAnuragShrivastavNo ratings yet

- Arena - Problems For ClassDocument10 pagesArena - Problems For ClassVisakh RadhakrishnanNo ratings yet

- Solution of Assignment 1Document3 pagesSolution of Assignment 1Anonymous 8O9X3QtR475% (4)

- Computer Science Textbook Solutions - 7Document30 pagesComputer Science Textbook Solutions - 7acc-expertNo ratings yet

- Home WorkDocument2 pagesHome WorkVladimir Lenis50% (2)

- ManufacturigCase StudyDocument19 pagesManufacturigCase Studyshruthicivil100% (1)

- Lecture 6-Manual Assembly LinesDocument5 pagesLecture 6-Manual Assembly LinesFatimaNo ratings yet

- Short Sums Related To Time StudyDocument2 pagesShort Sums Related To Time StudyBKC EnterpriseNo ratings yet

- Mime 4100 Final Exam 5/1/2011Document2 pagesMime 4100 Final Exam 5/1/2011derejeNo ratings yet

- Toyota Kanban System PDFDocument10 pagesToyota Kanban System PDFAman SharmaNo ratings yet

- Capacity PlanningDocument29 pagesCapacity PlanningVicky Pandey67% (6)

- PracticeProblems QualityManagement PDFDocument2 pagesPracticeProblems QualityManagement PDFStephanie LamNo ratings yet

- MF40603 Lecture 5Document7 pagesMF40603 Lecture 5kicked.partnershipNo ratings yet

- Assignment 01Document3 pagesAssignment 01Hasan ShahrierNo ratings yet

- Assignment 01Document3 pagesAssignment 01Hasan ShahrierNo ratings yet

- HW 1Document5 pagesHW 1Tuncay AYTEKİNNo ratings yet

- 15P701Document4 pages15P701rajakrishnanNo ratings yet

- Auditoria Final Fresa Torno CNCDocument25 pagesAuditoria Final Fresa Torno CNCJuan David Sandoval HerreraNo ratings yet

- 10iml68 Lab Manual - ModifiedDocument89 pages10iml68 Lab Manual - ModifiedRupa DnNo ratings yet

- Tutorial #2Document4 pagesTutorial #2Omar Abu-obiallaNo ratings yet

- Lean OEEDocument13 pagesLean OEEbasma osamaNo ratings yet

- Automation Solution ManualDocument3 pagesAutomation Solution ManualVinodhkumar PalakodeNo ratings yet

- OM - Assignment 2 - Problem - CPKDocument1 pageOM - Assignment 2 - Problem - CPKanun22No ratings yet

- 15P701Document3 pages15P701rajakrishnanNo ratings yet

- Functions of The Handling SystemDocument51 pagesFunctions of The Handling SystemJim MathilakathuNo ratings yet

- ktra hệ thống sản xuất tích hợpDocument47 pagesktra hệ thống sản xuất tích hợpVũ Quốc KhánhNo ratings yet

- Simulation Exercise Problems For Modelling in ARENA Software PackageDocument7 pagesSimulation Exercise Problems For Modelling in ARENA Software PackagesabarinathNo ratings yet

- Capacityplanning-Unsolved 7 NumericalsDocument2 pagesCapacityplanning-Unsolved 7 NumericalsShanky JainNo ratings yet

- 12 Quality CostDocument29 pages12 Quality CostAntariksh Shahwal100% (1)

- Taller 2 OEEDocument4 pagesTaller 2 OEEAnonymous xlp6qlVJ67% (3)

- Example MS MidtermDocument2 pagesExample MS MidtermDuyên LêNo ratings yet

- Creating a One-Piece Flow and Production Cell: Just-in-time Production with Toyota’s Single Piece FlowFrom EverandCreating a One-Piece Flow and Production Cell: Just-in-time Production with Toyota’s Single Piece FlowRating: 4 out of 5 stars4/5 (1)

- Takt Time: A Guide to the Very Basic Lean CalculationFrom EverandTakt Time: A Guide to the Very Basic Lean CalculationRating: 5 out of 5 stars5/5 (2)

- Understanding OEE in Lean Production: Toyota Production System ConceptsFrom EverandUnderstanding OEE in Lean Production: Toyota Production System ConceptsRating: 5 out of 5 stars5/5 (1)

- Factors Related To The Unemployment Rate: A Statistical AnalysisDocument43 pagesFactors Related To The Unemployment Rate: A Statistical AnalysisRogel RomeroNo ratings yet

- Biosttistics: Screening Test StatisticsDocument9 pagesBiosttistics: Screening Test Statisticszainab100% (1)

- Informs Management Science: This Content Downloaded From 138.25.78.25 On Fri, 29 Jul 2016 19:39:35 UTCDocument13 pagesInforms Management Science: This Content Downloaded From 138.25.78.25 On Fri, 29 Jul 2016 19:39:35 UTCFerchichi NizarNo ratings yet

- Chapter 2 Rice AddDocument4 pagesChapter 2 Rice Addmaele2100% (1)

- System Simulation: Dr. DessoukyDocument183 pagesSystem Simulation: Dr. DessoukyParimal BhambareNo ratings yet

- Ebook PDF Business Statistics 4th Edition by Norean D Sharpe PDFDocument41 pagesEbook PDF Business Statistics 4th Edition by Norean D Sharpe PDFmichael.alexander940100% (48)

- All The Statistical Concept You Required For Data ScienceDocument26 pagesAll The Statistical Concept You Required For Data ScienceAshwin ChaudhariNo ratings yet

- COR006 - MajorPT1Document6 pagesCOR006 - MajorPT1sife.magoyag.cocNo ratings yet

- Biostatistics For The Biological and Health Sciences 2nd Edition Triola Solutions ManualDocument17 pagesBiostatistics For The Biological and Health Sciences 2nd Edition Triola Solutions Manualsartaneurismjmq8j6100% (21)

- Exam 3 ReviewDocument16 pagesExam 3 ReviewSarrahNo ratings yet

- UserManual ReliabilityDocument74 pagesUserManual Reliabilitymatua trevorNo ratings yet

- Wavelet-Based Estimator For The Hurst Parameters of Fractional Brownian SheetDocument20 pagesWavelet-Based Estimator For The Hurst Parameters of Fractional Brownian SheetCristian Rodrigo Ubal NúñezNo ratings yet

- Probability PDFDocument7 pagesProbability PDFJevan CalaqueNo ratings yet

- LP 3 - Data Management, HeheDocument36 pagesLP 3 - Data Management, HeheRiane SabañecoNo ratings yet

- R Studio How ToDocument12 pagesR Studio How ToGerad TeoNo ratings yet

- Quarter K-12 Learning Competencies MelcsDocument4 pagesQuarter K-12 Learning Competencies MelcstitserscradleNo ratings yet

- Quality - Management - Dr. Attia Gomaa-09!09!2019Document410 pagesQuality - Management - Dr. Attia Gomaa-09!09!2019Abdulrahman100% (1)

- Week 4 Continuous Probability Distribution PDFDocument40 pagesWeek 4 Continuous Probability Distribution PDFloompapasNo ratings yet

- Data Science Linear RegressionDocument105 pagesData Science Linear RegressionJaime Prades KošćinaNo ratings yet

- Asset-V1 MITx+CTL - SC3x+2T2016+type@asset+block@SC1x KeyConcepts v6 PDFDocument82 pagesAsset-V1 MITx+CTL - SC3x+2T2016+type@asset+block@SC1x KeyConcepts v6 PDFSparsh Verma0% (1)

- CH5 Data Mining Classification Prepared by Dr. Maher AbuhamdehDocument61 pagesCH5 Data Mining Classification Prepared by Dr. Maher AbuhamdehJagriti SinghNo ratings yet

- Develop A Quality by Design Approach For Analytical Method DevelopmentDocument104 pagesDevelop A Quality by Design Approach For Analytical Method DevelopmentJoe Luis Villa MedinaNo ratings yet

- One Sample T Test - SPSS Tutorials - LibGuides at Kent State UniversityDocument10 pagesOne Sample T Test - SPSS Tutorials - LibGuides at Kent State UniversityBruno SaturnNo ratings yet

- Integrated UncertaintyAnalysis Using RELAP/SDAPSIM/MOD4.0Document11 pagesIntegrated UncertaintyAnalysis Using RELAP/SDAPSIM/MOD4.0Topan SetiadipuraNo ratings yet

- DR Ganesh Patil Medical StatisticsDocument77 pagesDR Ganesh Patil Medical StatisticsKaushal PatelNo ratings yet

- Third Quarter Examination: IN Statistics and ProbabilityDocument3 pagesThird Quarter Examination: IN Statistics and ProbabilityPing Homigop JamioNo ratings yet

- Stat 110, Lecture 7 Continuous Probability Distributions: Bheavlin@stat - Stanford.eduDocument35 pagesStat 110, Lecture 7 Continuous Probability Distributions: Bheavlin@stat - Stanford.edujamesyuNo ratings yet

- Module 2 in IStat 1 Probability DistributionDocument6 pagesModule 2 in IStat 1 Probability DistributionJefferson Cadavos CheeNo ratings yet