Professional Documents

Culture Documents

S Series

S Series

Uploaded by

shhOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

S Series

S Series

Uploaded by

shhCopyright:

Available Formats

S Series

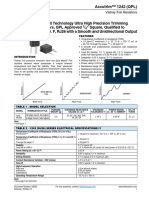

Vishay Foil Resistors

High Precision Foil Resistor with TCR of ± 2.0 ppm/°C,

Tolerance of ± 0.005 % and Load Life Stability of ± 0.005 %

FEATURES

• Temperature coefficient of resistance (TCR):

- 55 °C to + 125 °C, 25 °C ref.

- S10XC / D series: ± 2 ppm/°C typical (see table

1)

- S10XK series: ± 1 ppm/°C typical (see table 1)

• Power rating: to 1 W at + 125 °C

• Resistance tolerance: to ± 0.005 % (50 ppm)

• Load life stability: ± 0.005 % at 70 °C, 2000 h at rated power

• Resistance range: 0.5 Ω to 1 MΩ (for higher or lower

INTRODUCTION values, please contact Application Engineering)

• Vishay Foil resistors are not restricted to standard values;

Bulk Metal® Foil (BMF) technology outperforms all other specific “as required” values can be supplied at no extra

resistor technologies available today for applications that cost or delivery (e.g. 1K2345 vs. 1K)

require high precision and high stability. • Electrostatic discharge (ESD) at least to 25 kV

• Non inductive, non capacitive design

This technology has been pioneered and developed by • Rise time: 1 ns effectively no ringing

Vishay Foil Resistors (VFR), and products based on this • Current noise: 0.010 µVRMS/V of applied voltage (< - 40 dB)

technology are the most suitable for a wide range of • Thermal EMF: 0.05 µV/°C

applications. BMF technology allows the production of • Voltage coefficient: < 0.1 ppm/V

customer-oriented products, designed to satisfy specific • Low inductance: < 0.08 µH

challenging technical requirements. • Non hot-spot design

• Terminal finishes available: lead (Pb)-free, tin/lead alloy

The S series of BMF resistors offers low TCR, excellent load • Matched sets are available on request

life stability, tight tolerance, fast response time, low current (TCR tracking: to 0.5 ppm/°C)

noise, low thermal EMF and low voltage coefficient, all in one • Prototype quantities available in just 5 working days

resistor. or sooner. For more information, please contact

foil@vishaypg.com

The S series is virtually insensitive to destabillizing factors. • For better TCR performances please review the

The resistor element is a solid alloy that displays the datasheets for the Z Series and Z203

desirable bulk properties of its parent material, thus it is

inherently stable and noise free. The standard design of

these resistors provides a unique combination of

characteristics found in no other single resistor.

VFR's application engineering department is available to FIGURE 1 - TYPICAL RESISTANCE CHANGE

advise and to make recommendations. For non-standard VERSUS TEMPERATURE CURVES AND

technical requirements and special applications, please CHORD SLOPES (TCR) OF TWO ALLOY

contact foil@vishaypg.com. TYPES IN MILITARY RANGE

+ 150

TABLE 1 - RESISTANCE VERSUS TCR

+ 100

(- 55 °C to + 125 °C, + 25 °C ref.) –1 ppm/°C +1 ppm/°C

+ 50

TYPICAL TCR AND ΔR

RESISTANCE R 0

RESISTOR(1) (2) MAX SPREAD

VALUE (Ω) (ppm)

(ppm/°C) - 50

S10X(C) / (D) 80 to < 1M ± 2 ± 2.5 - 100

+2 ppm/°C –2 ppm/°C

S10X(K) 80 to < 600K ± 1 ± 2.5 - 150

S10X(C) / (D) ± 2 ± 3.5 - 200

50 to < 80 - 50 - 25 0 + 25 + 50 + 75 + 100 + 125

S10X(K) ± 1 ± 3.5

- 55

S10X(C) / (D) ± 2 ± 4.5 C Alloy K Alloy Temperature (°C)

0.5 to < 50

S10X(K) ± 1 ± 4.5 2 ppm/°C 1 ppm/°C

(1) X refers to S Series model number - see Table 2

(2) (C) and (D) refer to C Foil Alloy Types; (K) refers to the K Foil Alloy type - see Figure 1

* Pb containing terminations are not RoHS compliant, exemptions may apply

Document Number: 63001 For any questions, contact: foil@vishaypg.com www.vishayfoilresistors.com

Revision: 29-Jun-11 1

S Series

Vishay Foil Resistors

FIGURE 2 - STANDARD IMPRINTING AND DIMENSIONS

Front View Rear View

Optional Customer Part Number

L W Print specification, etc. if required

Date Code Resistance

VFR 01 10 XXXXXX Value Code

H XXXX Year Week 100R01

S102C 0.01 % Tolerance

ST1)

SW LL

Model Number

LS Lead Material #22 AWG

Round Solder Coated Copper

(Pb - free coating available)

Note

1. Standoffs provided to allow proper flushing of flux, debris, and contaminates from under resistor after all solder operations.

2. The standoffs shall be so located as to give a lead clearance of 0.010" minimum between the resistor body and the printed circuit board

when the standoffs are seated on the printed circuit board.

TABLE 2 - MODEL SELECTION

AMBIENT TIGHTEST

DIMENSIONS

RESISTANCE MAXIMUM POWER RATING AVERAGE TOLERANCE

MODEL

NUMBER RANGE WORKING WEIGHT VS. LOWEST

(Ω) VOLTAGE at at IN GRAMS F (1) RESISTANCE

INCHES mm VALUE

+ 70 °C + 125 °C (INCHES)

S102C 0.6 W 0.3 W W: 0.105 ± 0.010 2.67 ± 0.25

1 to 150K L: 0.300 ± 0.010 7.62 ± 0.25

(S102J) (2) up to 100K

H: 0.326 ± 0.010 8.28 ± 0.25

0.4 W 0.2 W

300 0.6 ST: 0.010 min. 0.254 min.

S102K SW: 0.040 ± 0.005 1.02 ± 0.13

1 to 100K

(S102L) (2) over 100K LL: 1.000 ± 0.125 25.4 ± 3.18

LS: 0.150 ± 0.005 3.81 ± 0.13

S104D 1.0 W 0.5 W W: 0.160 max. 4.06 max. (0.138)

1 to 500K L: 0.575 max. 14.61 max. (0.565)

(S104F) (1) up to 200K

H: 0.413 max. 10.49 max. (0.413)

350 0.6 W 0.3 W 1.4 ST: 0.035 ± 0.005 0.889 ± 0.13

SW: 0.050 ± 0.005 1.27 ± 0.13 0.005 %/50 Ω

S104K 1 to 300K 0.01 %/25 Ω

over 200K LL: 1.000 ± 0.125 25.4 ± 3.18

LS: 0.400 ± 0.020 10.16 ± 0.51 0.02 %/12 Ω

0.05 %/5 Ω

S105D 1.5 W 0.75 W W: 0.160 max. 4.06 max. (0.138) 0.1 %/2 Ω

1 to 750K L: 0.820 max. 20.83 max. (0.890)

(S105F) (1) up to 300K 0.50 %/1 Ω

H: 0.413 max. 10.49 max. (0.413) 1 %/0.5 Ω

350 0.8 W 0.4 W 1.9 ST: 0.035 ± 0.005 0.889 ± 0.13

S105K 1 to 500K SW: 0.050 ± 0.005 1.27 ± 0.13

over 300K LL: 1.000 ± 0.125 25.4 ± 3.18

LS: 0.650 ± 0.020 16.51 ± 0.51 (0.7 ± 0.05)

2.0 W 1.0 W W: 0.260 max. 6.60 max.

S106D 0.5 to 1M L: 1.200 max. 30.48 max.

up to 400K

H: 0.413 max. 10.49 max.

1.0 W 0.5 W

500 4.0 ST: 0.035 ± 0.005 0.889 ± 0.13

S106K 0.5 to 600K SW: 0.050 ± 0.005 1.27 ± 0.13

over 400K LL: 1.000 ± 0.125 25.4 ± 3.18

LS: 0.900 ± 0.020 22.86 ± 0.51

Notes

(1) S104F and S105F have different package dimensions (see the third column of dimensions). All other specifications are the same.

(2) 0.200" (5.08 mm) lead spacing available - specify S102J for S102C, and S102L for S102K.

www.vishayfoilresistors.com For any questions, contact: foil@vishaypg.com Document Number: 63001

2 Revision: 29-Jun-11

S Series

Vishay Foil Resistors

FIGURE 3 - POWER DERATING CURVE FIGURE 4 - TRIMMING TO VALUES

- 55 °C + 70 °C

(conceptual illustration)

Percent of Rated Power at + 125 °C

200 %

Double Rated Power

175 %

150 %

Interloop Capacitance Current Path

Reduction in Series Before Trimming

125 %

Rated Power

100 % Current Path

After Trimming

Mutual Inductance

75 % Reduction due Trimming Process

to Change in Removes this Material

50 % Current Direction from Shorting Strip Area

Changing Current Path

and Increasing

25 % Resistance

0%

- 75 - 50 - 25 0 25 50 75 100 125 150 175 200

Ambient Temperature (°C) Note: Foil shown in black, etched spaces in white

TABLE 3 - ENVIRONMENTAL PERFORMANCE COMPARISON

MIL-PRF-55182 S-SERIES S-SERIES

CHAR J MAXIMUM ΔR TYPICAL ΔR

Test Group I

Thermal shock, 5 x (- 65 °C to + 150 °C) ± 0.2 % ± 0.01 % (100 ppm) ± 0.002 % (20 ppm)

Short time overload, 6.25 x rated power ± 0.2 % ± 0.01 % (100 ppm) ± 0.003 % (30 ppm)

Test Group II

Resistance temperature characteristics(1) ± 25 ppm/°C ± 6.5 ppm/°C ± 2.0 ppm/°C

Low temperature storage (24 h at - 65 °C) ± 0.15 % ± 0.01 % (100 ppm) ± 0.002 % (20 ppm)

Low temperature operation

± 0.15 % ± 0.01 % (100 ppm) ± 0.002 % (20 ppm)

(45 min, rated power at - 65 °C)

Terminal strength ± 0.2 % ± 0.01 % (100 ppm) ± 0.002 % (20 ppm)

Test Group III

Dielectric Withstanding Voltage (DWV) ± 0.15 % ± 0.01 % (100 ppm) ± 0.002 % (20 ppm)

Resistance to solder heat ± 0.1 % ± 0.01 % (100 ppm) ± 0.005 % (50 ppm)

Moisture resistance ± 0.4 % ± 0.05 % (500 ppm) ± 0.01 % (100 ppm)

Test Group IV

Shock ± 0.2 % ± 0.01 % (100 ppm) ± 0.002 % (20 ppm)

Vibration ± 0.2 % ± 0.01 % (100 ppm) ± 0.002 % (20 ppm)

Test Group V

Life test at 0.3 W/+ 125 °C

2000 h ± 0.5 % ± 0.015 % (150 ppm) ± 0.01 % (100 ppm)

10 000 h ± 2.0 % ± 0.05 % (500 ppm) ± 0.03 % (300 ppm)

Test Group Va

Life test at 0.6 W (2 x rated power)/+ 70 °C, 2000 h ± 0.5 % ± 0.015 % (150 ppm) ± 0.01 % (100 ppm)

Test Group VI

High temperature exposure (2000 h at + 175 °C) ± 2.0 % ± 0.1 % (1000 ppm) ± 0.05 % (500 ppm)

Test Group VII

Voltage coefficient 5 ppm/V < 0.1 ppm/V < 0.1 ppm/V

(1) See Table 1.

Document Number: 63001 For any questions, contact: foil@vishaypg.com www.vishayfoilresistors.com

Revision: 29-Jun-11 3

S Series

Vishay Foil Resistors

FIGURE 5 - LONG-TERM STABILITY OVER 29 YEARS (0.1W AT 70°C, 50 SAMPLES S102C,

10KΩ)

40

20

0

ΔR/R (ppm)

-20

-40

-60

-80

-100

-120

0 5 10 15 20 25 30

Time (Years)

STANDARD OPERATIONS AND TEST IMPROVED PERFORMANCE TESTING (IPT)

CONDITIONS

A. Standard Test Operations: The preceding information is based on product directly off

the production line. Improved performance (meaning

By 100 % Inspection

increased time stability with load and other stresses) is

• Short-time overload (6.25 x rated power for 5 s)

available through factory conducted “Improved Performance

• Resistance - tolerance check

Testing”. The test routine is usually tailored to the user’s

• Visual and mechanical stability objectives and IPT-processed resistors can exhibit

By Sample Inspection improved load-life stability levels of less than 50 ppm.

• TCR

• Environmental tests per table 3 on a quarterly basis to Various screen test routines are available and all anticipated

establish performance by similarity stresses must be taken into account before settling on one

B. Standard Test Conditions: specific test routine. VFR's application engineering

• Lead test point: 0.5" (12.7 mm) from resistor body department is prepared to discuss and recommend

• Temperature: + 23 °C ± 2 °C appropriate routines given the full spectrum of anticipated

• Relative humidity: per MIL-STD-202 stresses and stability requirements.

TABLE 4 - “S” SERIES SPECIFICATIONS

Stability (1)

Load life at 2000 h ± 0.015 % (150 ppm) Maximum ΔR at 0.3 W/+ 125 °C

± 0.005 % (50 ppm) Maximum ΔR at 0.1 W/+ 70 °C

Load life at 10 000 h ± 0.05 % (500 ppm) Maximum ΔR at 0.3 W/+ 125 °C

± 0.01 % (100 ppm) Maximum ΔR at 0.05 W/+ 125 °C

Current Noise 0.010 µV (RMS)/V of applied voltage (- 40 dB)

High Frequency Operation

Rise time 1.0 ns at 1 kΩ

Inductance (L) (2) 0.1 µH maximum; 0.08 µH typical

Capacitance (C) 1.0 pF maximum; 0.5 pF typical

Voltage Coefficient < 0.1 ppm/V (3)

Thermal Electromotive Force (EMF) (4) 0.1 µV/°C Maximum; 0.05 µV/°C typical

1 µV/W (Model S102C)

Notes

Load life ΔR maximum can be reduced by 80 %, please contact applications engineering department.

(1)

(2)

Inductance (L) due mainly to the leads.

(3)

The resolution limit of existing test equipment (within the measurement capability of the equipment, or “essentially zero”.)

(4)

µV/°C relates to EMF due to lead temperature difference and µV/watt due to power applied to the resistor.

www.vishayfoilresistors.com For any questions, contact: foil@vishaypg.com Document Number: 63001

4 Revision: 29-Jun-11

S Series

Vishay Foil Resistors

TABLE 5 - GLOBAL PART NUMBER INFORMATION (1)

NEW GLOBAL PART NUMBER: Y000780K5000V9L (preferred part number format)

DENOTES PRECISION VALUE CHARACTERISTICS

Y R=Ω 0 = standard

K = kΩ 9 = lead (Pb)-free

M = MΩ 1 to 999 = custom

Y 0 0 0 7 8 0 K 5 0 0 0 V 9 L

PRODUCT CODE RESISTANCE TOLERANCE PACKAGING

0007 = S102C V = ± 0.005 % L = bulk pack

0785 = S102J T = ± 0.01 %

0062 = S102K Q = ± 0.02 %

0786 = S102L A = ± 0.05 %

0011 = S104D B = ± 0.1 %

5011 = S104F C = ± 0.25 %

0101 = S104K D = ± 0.5 %

4101 = S104L F = ± 1.0 %

0012 = S105D

4012 = S105F

0102 = S105K

4102 = S105L

0013 = S106D

0103 = S106K

FOR EXAMPLE: ABOVE GLOBAL ORDER Y0007 80K5000 V 9 L:

TYPE: S102C

VALUE: 80.5 kΩ

ABSOLUTE TOLERANCE: ± 0.005 %

TERMINATION: lead (Pb)-free

PACKAGING: bulk pack

HISTORICAL PART NUMBER: S102C T 80K500 V B (will continue to be used)

S102C T 80K500 V B

MODEL TERMINATION RESISTANCE VALUE TOLERANCE PACKAGING

S102C T = lead (Pb)-free 250R00 = 250.00 Ω V = ± 0.005 % B = bulk pack

S102J None = tin/lead alloy 5K2310 = 5.231 kΩ T = ± 0.01 %

S102K 1M000 = 1 MΩ Q = ± 0.02 %

S102L A = ± 0.05 %

S104D B = ± 0.1 %

S104F C = ± 0.25 %

S104K D = ± 0.5 %

S104L F = ± 1.0 %

S105D

S105F

S105K

S105L

S106D

S106K

Note

(1) For non-standard requests, please contact application engineering.

Document Number: 63001 For any questions, contact: foil@vishaypg.com www.vishayfoilresistors.com

Revision: 29-Jun-11 5

Legal Disclaimer Notice

Vishay Precision Group

Disclaimer

ALL PRODUCTS, PRODUCT SPECIFICATIONS AND DATA ARE SUBJECT TO CHANGE WITHOUT NOTICE.

Vishay Precision Group, Inc., its affiliates, agents, and employees, and all persons acting on its or their

behalf (collectively, “Vishay Precision Group”), disclaim any and all liability for any errors, inaccuracies or

incompleteness contained herein or in any other disclosure relating to any product.

The product specifications do not expand or otherwise modify Vishay Precision Group’s terms and

conditions of purchase, including but not limited to, the warranty expressed therein.

Vishay Precision Group makes no warranty, representation or guarantee other than as set forth in the terms

and conditions of purchase. To the maximum extent permitted by applicable law, Vishay Precision

Group disclaims (i) any and all liability arising out of the application or use of any product, (ii) any and

all liability, including without limitation special, consequential or incidental damages, and (iii) any and

all implied warranties, including warranties of fitness for particular purpose, non-infringement and

merchantability.

Information provided in datasheets and/or specifications may vary from actual results in different

applications and performance may vary over time. Statements regarding the suitability of products for

certain types of applications are based on Vishay Precision Group’s knowledge of typical requirements that

are often placed on Vishay Precision Group products. It is the customer’s responsibility to validate that a

particular product with the properties described in the product specification is suitable for use in a particular

application.

No license, express, implied, or otherwise, to any intellectual property rights is granted by this document, or

by any conduct of Vishay Precision Group.

The products shown herein are not designed for use in life-saving or life-sustaining applications unless

otherwise expressly indicated. Customers using or selling Vishay Precision Group products not expressly

indicated for use in such applications do so entirely at their own risk and agree to fully indemnify Vishay

Precision Group for any damages arising or resulting from such use or sale. Please contact authorized

Vishay Precision Group personnel to obtain written terms and conditions regarding products designed for

such applications.

Product names and markings noted herein may be trademarks of their respective owners.

Document No.: 63999 www.vishaypg.com

Revision: 27-Apr-2011 1

You might also like

- Build Your Own Doug Coil MachineDocument139 pagesBuild Your Own Doug Coil Machinelefty51100% (3)

- A Guide to Electronic Maintenance and RepairsFrom EverandA Guide to Electronic Maintenance and RepairsRating: 4.5 out of 5 stars4.5/5 (7)

- 250rd Datasheet - 021753Document6 pages250rd Datasheet - 021753amr elnawamNo ratings yet

- Vishay Foil Resistors: FeaturesDocument7 pagesVishay Foil Resistors: FeaturesMahemehr MehrNo ratings yet

- Componete ElectronicoDocument5 pagesComponete ElectronicoStuxnetNo ratings yet

- Accutrim™ 1242 (QPL) : Vishay Foil ResistorsDocument5 pagesAccutrim™ 1242 (QPL) : Vishay Foil ResistorsDaniel HubencuNo ratings yet

- Resistor SMD SizesDocument11 pagesResistor SMD Sizescarlos.antouryNo ratings yet

- Sfr16S/25/25H: Vishay BccomponentsDocument11 pagesSfr16S/25/25H: Vishay BccomponentsMuhammad BilalNo ratings yet

- LVM Series: Current Sensing Metal Chip ResistorDocument2 pagesLVM Series: Current Sensing Metal Chip ResistorOrlando SantofimioNo ratings yet

- A2 Pressure Transmitter: Data SheetDocument4 pagesA2 Pressure Transmitter: Data SheetpatrickNo ratings yet

- Bourns CRM2512 DatasheetDocument5 pagesBourns CRM2512 DatasheetbarisNo ratings yet

- Ω), Surface Mount: Vishay DaleDocument3 pagesΩ), Surface Mount: Vishay DaleRodrigo BronzeriNo ratings yet

- HTR India - Products - Current Sense Resistors - Ceramic Encased Resistor - RL (English)Document3 pagesHTR India - Products - Current Sense Resistors - Ceramic Encased Resistor - RL (English)crplzNo ratings yet

- Fixed Carbon Composition Resistors: CharacteristicsDocument3 pagesFixed Carbon Composition Resistors: CharacteristicsHiru SegwayNo ratings yet

- Ω), Surface Mount: Vishay DaleDocument3 pagesΩ), Surface Mount: Vishay DaleGermánNo ratings yet

- RCA-HP E3: Vishay DraloricDocument10 pagesRCA-HP E3: Vishay DraloricMohendra PatiNo ratings yet

- Surface Mount - 200W SMF SeriesDocument6 pagesSurface Mount - 200W SMF Seriesm3y54mNo ratings yet

- VH Hermetic VH Hermetic: TCR of 1 Ppm/°c, Tolerance To 0.005% and Load-Life Stability of 0.005%Document6 pagesVH Hermetic VH Hermetic: TCR of 1 Ppm/°c, Tolerance To 0.005% and Load-Life Stability of 0.005%Daniel HubencuNo ratings yet

- NIC Components NCSR SeriesDocument5 pagesNIC Components NCSR SeriesNICCompNo ratings yet

- RNCP Series: Stackpole Electronics, IncDocument4 pagesRNCP Series: Stackpole Electronics, IncGabriel VargasNo ratings yet

- T491 Series Industrial Grade Mno: Tantalum Surface Mount Capacitors - Standard TantalumDocument24 pagesT491 Series Industrial Grade Mno: Tantalum Surface Mount Capacitors - Standard TantalumSebastian ChaileNo ratings yet

- Isa-Plan // Precision Resistors: SMV-PW // Size 4723Document3 pagesIsa-Plan // Precision Resistors: SMV-PW // Size 4723AliNo ratings yet

- Surface Mount 600W SZ1SMB SeriesDocument8 pagesSurface Mount 600W SZ1SMB SeriesmkNo ratings yet

- HiaDocument4 pagesHiappanagos5664No ratings yet

- Resistor 1k - Vishay - 0.6wDocument3 pagesResistor 1k - Vishay - 0.6wLEDNo ratings yet

- Vishay Resistors Precision mpr24Document7 pagesVishay Resistors Precision mpr24SamaelNo ratings yet

- HTR India - Products - Current Sense Resistors - Current Sense Open Frame Resistors - OA (English)Document4 pagesHTR India - Products - Current Sense Resistors - Current Sense Open Frame Resistors - OA (English)crplzNo ratings yet

- Active Sensors CERAVAC Transmitters CTR 100 / CTR 91: Advantages To The User Typical ApplicationsDocument4 pagesActive Sensors CERAVAC Transmitters CTR 100 / CTR 91: Advantages To The User Typical Applicationsreza behroozNo ratings yet

- NIC Components NNT SeriesDocument3 pagesNIC Components NNT SeriesNICCompNo ratings yet

- Bourns CRM0805 DatasheetDocument5 pagesBourns CRM0805 DatasheetbarisNo ratings yet

- WSL... 18 High Power: Ω), Surface-MountDocument4 pagesWSL... 18 High Power: Ω), Surface-MountMohendra PatiNo ratings yet

- HTR India - Products - Current Sense Resistors - Current Sense Open Frame Resistor - HEW (English)Document3 pagesHTR India - Products - Current Sense Resistors - Current Sense Open Frame Resistor - HEW (English)crplzNo ratings yet

- Abl 16.000MHZ B2 PDFDocument3 pagesAbl 16.000MHZ B2 PDFkarthik4096No ratings yet

- Inbound 1310313221Document2 pagesInbound 1310313221freedownNo ratings yet

- RCS E3: VishayDocument10 pagesRCS E3: VishayMae MegumiNo ratings yet

- Accutrim™ 1240 (RJ26 Style) : Vishay Foil ResistorsDocument5 pagesAccutrim™ 1240 (RJ26 Style) : Vishay Foil ResistorsSlavaSH2No ratings yet

- DSA00116625Document7 pagesDSA00116625Ricardo Campos LandaetaNo ratings yet

- Page 11Document1 pagePage 11Erik SavoieNo ratings yet

- Tantalum Surface Mount CapacitorsDocument24 pagesTantalum Surface Mount CapacitorsgausscanaveaNo ratings yet

- Electrical Characteristics: Full Rated Voltage at 85 ºC, Derate Linearly To 50% Rated Voltage at 105 ºCDocument3 pagesElectrical Characteristics: Full Rated Voltage at 85 ºC, Derate Linearly To 50% Rated Voltage at 105 ºCLullaby summerNo ratings yet

- 180 Ohm ResistorDocument11 pages180 Ohm ResistorNidhi PanditNo ratings yet

- Vishay Dale: FeaturesDocument6 pagesVishay Dale: FeaturesnemoneoNo ratings yet

- Pressure Transducer: SpecificationsDocument9 pagesPressure Transducer: SpecificationsWILLIAM AGUDELONo ratings yet

- Antalex: Vishay SpragueDocument13 pagesAntalex: Vishay SpragueDaniel RetcelNo ratings yet

- (Safety Regulations) : Ceramic Disc CapacitorsDocument6 pages(Safety Regulations) : Ceramic Disc CapacitorsPedro GomezNo ratings yet

- NIC Components NSWC High Voltage SeriesDocument2 pagesNIC Components NSWC High Voltage SeriesNICCompNo ratings yet

- Codificare Rezistente SMD 60A Are 412 Ohmi CF TabelDocument6 pagesCodificare Rezistente SMD 60A Are 412 Ohmi CF Tabelromeo1966No ratings yet

- NIC Components NSHC SeriesDocument2 pagesNIC Components NSHC SeriesNICCompNo ratings yet

- 1N5225 EicDocument2 pages1N5225 EicTop Techno Lab CompanyNo ratings yet

- D Series: Vishay BccomponentsDocument7 pagesD Series: Vishay BccomponentsjairomarcanoNo ratings yet

- MFR CatalogDocument4 pagesMFR Catalogchitti409No ratings yet

- D/CRCW E3: VishayDocument10 pagesD/CRCW E3: VishayBenyamin Farzaneh AghajarieNo ratings yet

- ERC (Military RNC/RNR) : Vishay DaleDocument3 pagesERC (Military RNC/RNR) : Vishay DaleshhNo ratings yet

- NIC Components NTC-T SeriesDocument10 pagesNIC Components NTC-T SeriesNICCompNo ratings yet

- Wika Ac1Document4 pagesWika Ac1DOUBENo ratings yet

- 1 5ke130aDocument7 pages1 5ke130ad4wq3No ratings yet

- ), Surface Mount: Vishay DaleDocument4 pages), Surface Mount: Vishay DaleLeonardoMartinNo ratings yet

- rnp50s eDocument2 pagesrnp50s eSentral AvrNo ratings yet

- SBSM Data SheetDocument4 pagesSBSM Data SheetAlex JonesNo ratings yet

- LM334Document26 pagesLM3342567daNo ratings yet

- A4988 DatasheetDocument20 pagesA4988 DatasheetJose OnoNo ratings yet

- Electric CurrentDocument119 pagesElectric CurrentSM_Ing.No ratings yet

- MP EM Ass 13: RC CircuitsDocument11 pagesMP EM Ass 13: RC CircuitsBlueAstroNo ratings yet

- Cell Phone Detector Project ReportDocument34 pagesCell Phone Detector Project ReportParamjit Singh75% (8)

- Transistor AF and RF Circuits - Allan Lytel PDFDocument127 pagesTransistor AF and RF Circuits - Allan Lytel PDFYou Look100% (2)

- PLC Based Load Sharing On Slide ShareDocument28 pagesPLC Based Load Sharing On Slide ShareHemu Bhai PatelNo ratings yet

- Procedure For Registration of IT Units in MaharashtraDocument17 pagesProcedure For Registration of IT Units in MaharashtraHarie JamesNo ratings yet

- I&M Lect 4Document57 pagesI&M Lect 4Renatus KatunduNo ratings yet

- Altronic DSG1611DUPS Gauge Install. - Oper. Instructions (FORM DSG1611DUPS II)Document47 pagesAltronic DSG1611DUPS Gauge Install. - Oper. Instructions (FORM DSG1611DUPS II)francis_mouille_iiNo ratings yet

- Electricity - Practice Sheet - 10th Board Booster 2.0 2024Document6 pagesElectricity - Practice Sheet - 10th Board Booster 2.0 2024jyotikushwahasmart0222No ratings yet

- Chapter 4 - Circuit TheoremsDocument26 pagesChapter 4 - Circuit TheoremsSarah Azlina100% (1)

- Norma S-311-P-18LDocument18 pagesNorma S-311-P-18LAugusto RadaelliNo ratings yet

- Atto Farad DetectionDocument133 pagesAtto Farad DetectionrobidjoNo ratings yet

- Bearing Damage-Resulting From Shaft Voltage and CurrentDocument23 pagesBearing Damage-Resulting From Shaft Voltage and CurrentAnil_NambiaruveetilNo ratings yet

- Bridge MethodsDocument20 pagesBridge Methods1234t0411No ratings yet

- QD77MS User Manual PDFDocument1,044 pagesQD77MS User Manual PDFNikanthNo ratings yet

- RME Past BoardDocument100 pagesRME Past Boardglenn100% (2)

- Phys Int CC CH 19 - Electrical Circuits - Answers PDFDocument6 pagesPhys Int CC CH 19 - Electrical Circuits - Answers PDFmayaNo ratings yet

- (Kill: A Novel Approach For The Thermal Characterization of ElectronicDocument9 pages(Kill: A Novel Approach For The Thermal Characterization of ElectronicMahmudi P2 Fisika LIPINo ratings yet

- Omron Tl-YsDocument6 pagesOmron Tl-Ysedi susantoNo ratings yet

- Ohmicontrols Final BrochureDocument9 pagesOhmicontrols Final BrochureAnoop SaneNo ratings yet

- Leakage SensorsDocument4 pagesLeakage SensorsВиктор ПанзыгаNo ratings yet

- Unbalance Protection of Fuseless, Split-Wye, Grounded, Shunt Capacitor Banks PDFDocument4 pagesUnbalance Protection of Fuseless, Split-Wye, Grounded, Shunt Capacitor Banks PDFRajuNo ratings yet

- LC37D90Document208 pagesLC37D90Piter De AzizNo ratings yet

- G3MB 202Document5 pagesG3MB 202Saw LinNo ratings yet

- LS Industrial Systems Brake Chopper ManualDocument2 pagesLS Industrial Systems Brake Chopper ManualHafis ArdikaNo ratings yet

- Electronics QuestionnaireDocument4 pagesElectronics QuestionnaireRenie FedericoNo ratings yet

- 29UM69GDocument24 pages29UM69GClaudio Teruo TanakaNo ratings yet