Professional Documents

Culture Documents

QT 625

QT 625

Uploaded by

Waleed ElzanatiOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

QT 625

QT 625

Uploaded by

Waleed ElzanatiCopyright:

Available Formats

Qual-Tech Engineers, Inc.

The 201 Johnson Road – Building #1 ∙ Suite 203

Electrical Houston, PA 15342-1300

Power

Engineers Phone 724-873-9275 – Fax 724-873-8910

www.QualTechEng.com

AN EXAMPLE OF A STANDARD

ARC FLASH PPE LABELING STRATEGY

1.0 BACKGROUND INFORMATION:

1. The basis for the labeling of equipment for potential electric arc flash hazards is:

a. NEC 2020 Article 110.16:

110.16 Arc-Flash Hazard Warning.

(A) General. Electrical equipment, such as switchboards, switchgear, panelboards,

industrial control panels, meter socket enclosures, and motor control centers, that is in

other than dwelling units, and is likely to require examination, adjustment, servicing, or

maintenance while energized, shall be field or factory marked to warn qualified persons

of potential electric arc flash hazards. The marking shall meet the requirements in

110.21(B) and shall be located so as to be clearly visible to qualified persons before

examination, adjustment, servicing, or maintenance of the equipment.

(B) Service Equipment. In other than dwelling units, in addition to the requirements

in 110.16(A), a permanent label shall be field or factory applied to service equipment

rated 1200 amps or more. The label shall meet the requirements of 110.21(B) and

contain the following information:

(1) Nominal system voltage

(2) Available fault current at the service overcurrent protective devices

(3) The clearing time of service overcurrent protective devices based on the

available fault current at the service equipment

(4) The date the label was applied

Exception: Service equipment labeling shall not be required if an arc flash label is

applied in accordance with acceptable industry practice.

Informational Note No. 1: NFPA 70E-2018, Standard for Electrical Safety in

the Workplace, provides guidance, such as determining severity of potential

exposure, planning safe work practices, arc flash labeling, and selecting

personal protective equipment. [Note: NFPA 70E-2021 is now in effect.]

Informational Note No. 2: ANSI Z535.4-2011, Product Safety Signs and

Labels, provides guidelines for the design of safety signs and labels for

application to products.

Informational Note No. 3: Acceptable industry practices for equipment

labeling are described in NFPA 70E-2018, Standard for Electrical Safety in the

Workplace. This standard provides specific criteria for developing arc-flash

labels for equipment that provides nominal system voltage, incident energy

levels, arc-flash boundaries, minimum required levels of personal protective

equipment, and so forth.

An Example of a Standard Page 1 Qual-Tech Engineers, Inc.

Arc Flash PPE Labeling Strategy

b. NFPA 70E-2021 Article 130.5(H):

(H) Equipment Labeling. Electrical equipment such as switchboards, panelboards,

industrial control panels, meter socket enclosures, and motor control centers that are in

other than dwelling units and that are likely to require examination, adjustment, servicing,

or maintenance while energized, shall be marked with a label containing all the following

information:

(1) Nominal system voltage

(2) Arc flash boundary

(3) At least one of the following:

a. Available incident energy and the corresponding working distance, or the arc

flash PPE category …

b. Minimum arc rating of clothing

c. Site-specific level of PPE

Exception No. 1: Unless changes in electrical distribution system(s) render the label

inaccurate, labels applied prior to the effective date of this edition of the standard shall

be acceptable if they complied with the requirements for equipment labeling in the

standard in effect at the time the labels were applied.

Exception No. 2: In supervised industrial installations where conditions of maintenance

and engineering supervision ensure that only qualified persons monitor and service the

system, the information required in 130.5(H)(1) through 130.5(H)(3) shall be permitted

to be documented in a manner that is readily available to persons likely to perform

examination, servicing, maintenance, and operation of the equipment while energized.

The method of calculating and the data to support the information for the label

shall be documented. The data shall be reviewed for accuracy at intervals not to

exceed 5 years. Where the review of data identifies a change that renders the label

inaccurate, the label shall be updated.

The owner of the electrical equipment shall be responsible for the documentation,

installation, and maintenance of the field-marked label.

2. It is planned that virtually all equipment at 480V and above would be labeled, except

for terminal boxes associated with motors, based on NEC 2020 Article 110.16 and

NFPA 70E-2021 Article 130.5 (H).

3. With regard to the low voltage (< 240V) systems, the IEEE Standard 1584-2018 states,

“Sustainable arcs are possible but less likely in three-phase systems operating at 240V

nominal or less with an available short-circuit less than 2000A”.

4. Based on items 1 and 2 above, the goal is to label virtually all equipment at 480V that has

a bolted panel or door that can be accessible to an electrician when it is energized.

Specific guidelines for 480V systems are given as follows:

a. Motors and 277V lighting would not be labeled.

b. Transformers that step down from 480V to lower voltages would be labeled.

c. Panels and disconnect switches would be labeled.

d. Where motors are fed directly from an MCC switch or breaker, there is nothing down-

line to label.

e. Equipment that is down-line of a VFD would be labeled the same as if the VFD were

bypassed. (The protection from the VFD for a fault is generally as fast or faster than

the up-line device.)

f. Where the device is too small for the label, such as a welding receptacle or other

mounted receptacle, but still fits the criteria given above, a label is to be put as close to

the device as possible. This could be on the wall near to the device.

An Example of a Standard Page 2 Qual-Tech Engineers, Inc.

Arc Flash PPE Labeling Strategy

5. For 240V and 208V systems that are fed by sources of Isc > 2000A, the same guidelines

as for 480V systems would apply as given in item 4 above.

6. It is XYZ’s objective to define labels which are generally applicable to XYZ systems, but

that do not give the specific calculations for each particular location. The XYZ labels are in

accordance with NFPA 70E guidelines. In some cases the XYZ labeling is more

conservative than what is recommended in NFPA 70E. The following labeling strategy

details are used by XYZ:

a. Information for both arc flash PPE level and shock protection are given. (The shock

protection information is not required by NFPA-70E, but it is commonly included on

labels throughout the industry.)

b. For medium voltage systems (1 kV through 34.5 kV) PPE = 2 is the minimum PPE to

be used for working on energized equipment.

c. For low voltage systems (< 1000V), when circuit breakers are used for protection,

PPE = 2 is the minimum PPE to be used for working on energized equipment.

(For more detailed information on this topic, see Section 2.0 at this link

http://www.qualtecheng.com/docs/arc-flash-hazard/QT-632.pdf .)

d. The PPE Level that has been determined for a given location is to be used for the

switching of that device unless a risk assessment has determined that it is not required.

(See Section 4.0.)

7. Although there are no standards on working distances, in this document the labels are

based on the following typical working distances:

208V to 750V 18” Working Distance

1 kV to 8 kV 24” Working Distance

8 kV to 15 kV 36” Working Distance

8. The arc flash labels are based on the equipment being properly installed and properly

maintained.

9. The labeling strategy is based on PPE levels of 0, 2, & 4.

a. 0 – The incident energy is < 1.2 cal/cm2.

b. 2 – The incident energy is < 8.0 cal/cm2.

c. 4 – The incident energy is < 40 cal/cm2.

An Example of a Standard Page 3 Qual-Tech Engineers, Inc.

Arc Flash PPE Labeling Strategy

2.0 DEFINITIONS

Approach Boundaries for Shock & Flash Protection

The shock protection boundaries are applicable to the situation in which approaching personnel are

exposed to live parts. The boundary definitions, as given in NFPA-70E 2021 Article 100, are given

below. More detailed information with regard to the application of these boundaries is given in NFPA

70E-2021 Articles 130.4 and 130.5.

Limited Approach Boundary – An approach limit at a distance from an exposed energized

electrical conductor or circuit part within which a shock hazard exists. (It is the closest

distance an unqualified person can approach, unless accompanied by a qualified

person.)

Restricted Approach Boundary – An approach limit at a distance from an exposed

energized electrical conductor or circuit part within which there is an increased

likelihood of electric shock, due to electrical arc-over combined with inadvertent

movement for personnel working in close proximity to the energized electrical

conductor or circuit part. (It is the closest distance to exposed energized electrical

conductor or circuit part a qualified person can approach without proper PPE and

tools.)

Arc Flash Boundary – When an arc flash hazard exists, an approach limit at a distance from

an arc source at which incident energy equals 1.2 cal/cm2 (5 J/cm2).

Informational Note: According to the Stoll skin burn injury model, the onset of

a second degree burn on unprotected skin is likely to occur at an exposure of

1.2 cal/cm2 (5 J/cm2) for one second.

A summary of the boundaries for unqualified and qualified persons is given as follows.

When there are exposed live parts, Unqualified Persons:

- Must stay beyond the limited approach boundary (unless special circumstances exist,

as are defined in NFPA 70E-2021 Article 130.4) and the arc flash boundary.

- Must not cross the restricted approach boundary under any circumstances.

When there are exposed live parts, Qualified Persons:

- Must stay beyond the restricted approach boundary and the arc flash boundary unless

equipped with the proper PPE and tools.

An Example of a Standard Page 4 Qual-Tech Engineers, Inc.

Arc Flash PPE Labeling Strategy

3.0 CLOTHING STRATEGY

The labeling is based on plant personnel having the appropriate clothing available. The key issues

are noted as follows:

1. OPERATORS – In some locations it may be common practice for an equipment operator

to perform a task where there is a potential incident energy of < 1.2 cal/cm2. (This is

referred to as PPE Level 0.). To perform this task with the appropriate PPE level of 0,

there are several options:

a. Option 1 - The operator is normally dressed in safety glasses, heavy-duty leather

shoes, short-sleeve cotton shirt, and pants (such as denim cotton blue jeans). To

reach a PPE level of 0, he/she would put on an appropriate cotton jacket, hearing

protection (ear canal inserts), and leather gloves. (All underwear is to be cotton with

no synthetic materials.)

b. Option 2 - The operator is normally dressed in a PPE level of 0 which includes safety

glasses, heavy-duty leather shoes, long-sleeve cotton shirt, pants (such as denim

cotton blue jeans), and hearing protection (ear canal inserts). To reach a PPE level of

0, he/she would put on leather gloves. (All underwear is to be cotton with no synthetic

materials.)

2. ELECTRICIANS - Electricians need to be prepared to perform tasks with PPE Levels of

0 (< 1.2 cal/cm2), 2 (< 8 cal/cm2), and 4 (< 40 cal/cm2). Clothing strategies could include

the following:

a. Option 1 - The electrician is normally dressed in safety glasses, short-sleeve cotton

shirt, pants (such as denim cotton blue jeans), and leather shoes. (All underwear is

to be cotton with no synthetic materials.)

i. To perform tasks which are a PPE Level 0, he/she would put on

- an appropriate cotton jacket,

- hearing protection (ear canal inserts), and

- heavy-duty leather gloves as needed.

Arc Flash PPE Level 2 is required if any part of the body or clothing is exposed

to energized circuit parts within the defined working distance. He/She would

use insulated gloves and tools as required.

ii. To perform tasks which are a PPE Level 2, he/she would put on

- properly fitted arc-rated coveralls (> 8 cal/cm2),

- hearing protection (ear canal inserts),

- arc-rated balaclava,

- hard hat with arc-rated face shield, and

- insulating gloves with leather protectors.

He/She would use insulated tools as required.

iii. To perform tasks which are a PPE Level 4, he/she would put on

- hearing protection (ear canal inserts),

- hard hat,

- flash suit jacket, pants, and hood (> 40 cal/cm2), and

- arc-rated gloves.

He/She would use insulated tools as required.

b. Option 2 - The electrician is normally dressed in safety glasses, long-sleeve cotton

shirt, pants (such as denim cotton blue jeans), and leather shoes. (All underwear is

to be cotton with no synthetic materials.)

i. To perform tasks which are a PPE Level 0, he/she would put on

- hearing protection (ear canal inserts), and

- heavy-duty leather gloves as needed.

Arc Flash PPE Level 2 is required if any part of the body or clothing is exposed

to energized circuit parts within the defined working distance. He/She would

use insulated gloves and tools as required.

An Example of a Standard Page 5 Qual-Tech Engineers, Inc.

Arc Flash PPE Labeling Strategy

ii. To perform tasks which are a PPE Level 2, he/she would put on

- properly fitted arc-rated coveralls (> 8 cal/cm2),

- hearing protection (ear canal inserts),

- arc-rated balaclava,

- hard hat with arc-rated face shield, and

- insulating gloves with leather protectors.

He/She would use insulated tools as required.

iii. To perform tasks which are a PPE Level 4, he/she would put on

- hearing protection (ear canal inserts),

- hard hat,

- flash suit jacket, pants, and hood (> 40 cal/cm2), and

- arc-rated gloves.

He/She would use insulated tools as required.

c. Option 3 - The electrician is normally dressed in safety glasses, arc-rated shirt and

pants (> 8 cal/cm2), and leather shoes. (All underwear is to be cotton with no synthetic

materials.)

i. To perform tasks which are a PPE level of 0, he/she would put on

- hearing protection (ear canal inserts), and

- heavy-duty leather gloves as needed.

Arc Flash PPE Level 2 is required if any part of the body or clothing is exposed

to energized circuit parts within the defined working distance. He/She would

use insulated gloves and tools as required.

ii. To perform tasks which are a PPE level of 2, he/she would put on

- hearing protection (ear canal inserts),

- arc-rated balaclava,

- hard hat with arc-rated face shield, and

- insulating gloves with leather protectors.

He/She would use insulated tools as required.

iii. To perform tasks which are a PPE level of 4, he/she would put on

- hearing protection (ear canal inserts),

- hard hat,

- flash suit jacket, pants, and hood (> 40 cal/cm2), and

- arc-rated gloves.

He/She would use insulated tools as required.

d. Clarifying Notes:

i. Where reference is made above to use leather gloves for arc flash protection, it

is acceptable to use insulating rubber gloves with leather protectors.

ii. The leather protectors are not to be used alone as leather work gloves.

An Example of a Standard Page 6 Qual-Tech Engineers, Inc.

Arc Flash PPE Labeling Strategy

4.0 CAUTIONS

The following items are noted here:

1. Equipment Maintenance – The PPE labels are based on the proper operation of the

up-line protective equipment. The protective equipment must be maintained and working

properly for the PPE recommendation on the label to be appropriate for that location.

a. Consequently, the proper maintenance of all equipment is a basic requirement for a

good safety program.

b. There is a note at the bottom of each label that emphasizes this point.

2. Switching – As described in NFPA 70E-2018 130.2(A)(4) and Table 130.5(C), a normal

operating condition of a circuit breaker, switch, contactor, or starter exists if all of the

following are true. In that case, there is no likelihood of an arc flash incident.

a. The equipment is properly installed.

b. The equipment is properly maintained.

c. The equipment is used in accordance with instructions included in the listing and

labeling and in accordance with manufacturer’s instructions.

d. The equipment doors are closed and secured.

e. All equipment covers are in place and secured.

f. There is no evidence of impending failure.

It is XYZ’s policy that the PPE Level determined for a given location is to be used for the

switching of that device unless a Risk Assessment has determined that it is not required.

(See Section 1.0, item 6.c.)

3. PPE = 0 – In this document PPE = 0 corresponds to a maximum incident energy of

1.2 cal/cm2 at the defined working distance. If any part of the body or clothing is exposed

to energized circuit parts within the defined working distance, then PPE = 2 is required.

For example, if the qualified person is working on energized equipment with exposed

energized circuit parts, the person must wear the appropriate PPE. If the working

distance is 18”, the PPE level is 0, and the person is wearing cotton clothing (which is

permissible) and leather gloves, it is essential that the parts of the body with exposed

cotton clothing be beyond the 18” working distance. If the person is wearing leather and

rubber gloves (as needed) and is working directly on the energized equipment, there may

be a part of the arms that is covered with cotton sleeves but is within the 18”. If that is the

case, PPE = 2 is required.

This issue is significant, because the cotton clothing is flammable and as the working

distance is reduced the incident energy increases exponentially. Consequently, if cotton

clothing is exposed within the working distance, it could catch on fire during an arcing

event.

An Example of a Standard Page 7 Qual-Tech Engineers, Inc.

Arc Flash PPE Labeling Strategy

5.0 LABELS

A summary of the labels is given in Table 1. An illustration of the labels is given in the following

sections.

Table 1

Summary of Standard XYZ Company PPE Labels

Based on NFPA 70E-2021

Nominal Working Min PPE Arc Flash PPE = 2 Shock Boundaries Label Equipment

Label System Distance PPE Rating Boundary Distance Glove Limited Restricted Size Metal Open

Name Volts (Inches) Category (cal/cm2) (feet) (feet) Class Approach Approach (Inches) Enclosed Air

Equipment Labels

XYZ480-0 480 18 0 1.2 1.5 0 3 ft 6 in 1 ft 4x3 X

XYZ480-2 480 18 2 8.0 6.0 0 3 ft 6 in 1 ft 4x3 X

XYZ480-4 480 18 4 40.0 17.0 5.0 0 3 ft 6 in 1 ft 4x3 X

XYZ480>4 480 18 >4 4x3 X

XYZ4160-2 4,160 24 2 8.0 10.0 1 5 ft 2 ft 2 in 4x3 X

XYZ4160-4 4,160 24 4 40.0 30.0 10.0 1 5 ft 2 ft 2 in 4x3 X

XYZ13800-2 13,800 36 2 8.0 15.0 2 5 ft 2 ft 2 in 4x3 X

XYZ13800-4 13,800 36 4 40.0 45.0 15.0 2 5 ft 2 ft 2 in 4x3 X

XYZ-P PPE 4x6

XYZ-B Boundaries 7x4

Remote Switching

XYZ0-R Any Voltage 0 4x3

XYZ2-R Any Voltage 2 4x3

XYZ4-R Any Voltage 4 4x3

An Example of a Standard Page 8 Qual-Tech Engineers, Inc.

Arc Flash PPE Labeling Strategy

5.1 Main Switchgear & Next Down-Line Devices

Labels 480V - These labels are intended for metal-enclosed equipment rated 480V where the

working distance is > 18 inches.

ARC FLASH AND SHOCK HAZARD ARC FLASH AND SHOCK HAZARD

APPROPRIATE PPE REQUIRED APPROPRIATE PPE REQUIRED

Based on NFPA 70E-2021 & XYZ Company Safety Directives Based on NFPA 70E-2021 & XYZ Company Safety Directives

ARC FLASH PPE LEVEL 0: ARC FLASH PPE LEVEL 2:

Working Distance ≥ 18"

Minimum PPE Rating = 1.2 cal/cm2

Arc Flash Boundary = 1 ft 6 in

0 Working Distance ≥ 18"

Minimum PPE Rating = 8 cal/cm2

Arc Flash Boundary = 6 ft

2

SHOCK PROTECTION - 480 VAC SHOCK PROTECTION - 480 VAC

Insulating Glove Class 0 Insulating Glove Class 0

Limited Approach Boundary 3 ft 6 in Limited Approach Boundary 3 ft 6 in

Restricted Approach Boundary 1 ft Restricted Approach Boundary 1 ft

CAUTION: CAUTION:

Ensure that all of the appropriate safety procedures Ensure that all of the appropriate safety procedures

are followed. The PPE Level designation on this are followed. The PPE Level designation on this

equipment is based on the proper installation and equipment is based on the proper installation and

maintenance of the up-line protective device. maintenance of the up-line protective device.

XYZ480-0

XYZ480-2

ARC FLASH AND SHOCK HAZARD ARC FLASH AND SHOCK HAZARD

APPROPRIATE PPE REQUIRED Based on NFPA 70E-2021 & XYZ Company Safety Directives

Based on NFPA 70E-2021 & XYZ Company Safety Directives

ARC FLASH PPE LEVEL >4:

ARC FLASH PPE LEVEL 4:

Working Distance ≥ 18"

Minimum PPE Rating = 40 cal/cm2

Arc Flash Boundary = 17 ft

4

The potential arc flash incident

energy is greater than 40 cal/cm2

for a working distance of 18”.

Operation or insertion/removal (racking)

>4

Note: PPE = 2 at a working distance of 5 ft. of switching device is not to be done

unless the equipment is deenergized

SHOCK PROTECTION - 480 VAC and confirmed to be deenergized.

Insulating Glove Class 0 No work is to be done on energized

Limited Approach Boundary 3 ft 6 in electrical conductors.

Restricted Approach Boundary 1 ft

CAUTION: SHOCK PROTECTION - 480 VAC

Ensure that all of the appropriate safety procedures

are followed. The PPE Level designation on this Energized parts are not to be exposed.

equipment is based on the proper installation and

maintenance of the up-line protective device.

XYZ480>4

XYZ480-4

An Example of a Standard Page 9 Qual-Tech Engineers, Inc.

Arc Flash PPE Labeling Strategy

Labels for 4160V – This label is intended to be used on 4160 volt metal-enclosed equipment

where the working distance is > 24 inches.

ARC FLASH AND SHOCK HAZARD ARC FLASH AND SHOCK HAZARD

APPROPRIATE PPE REQUIRED APPROPRIATE PPE REQUIRED

Based on NFPA 70E-2021 & XYZ Company Safety Directives Based on NFPA 70E-2021 & XYZ Company Safety Directives

ARC FLASH PPE LEVEL 2: ARC FLASH PPE LEVEL 4:

Working Distance ≥ 24"

Minimum PPE Rating = 8 cal/cm2

Arc Flash Boundary = 10 ft

2 Working Distance ≥ 24"

Minimum PPE Rating = 40 cal/cm2

Arc Flash Boundary = 30 ft

Note: PPE = 2 at a working distance of 10 ft.

4

SHOCK PROTECTION – 4160 VAC SHOCK PROTECTION – 4160 VAC

Insulating Glove Class 1 Insulating Glove Class 1

Limited Approach Boundary 5 ft Limited Approach Boundary 5 ft

Restricted Approach Boundary 2 ft 2 in Restricted Approach Boundary 2 ft 2 in

CAUTION: CAUTION:

Ensure that all of the appropriate safety procedures Ensure that all of the appropriate safety procedures

are followed. The PPE Level designation on this are followed. The PPE Level designation on this

equipment is based on the proper installation and equipment is based on the proper installation and

maintenance of the up-line protective device. maintenance of the up-line protective device.

XYZ4160-2 XYZ4160-4

Labels for 13,800V – This label is intended to be used on 13,800 volt metal-enclosed

equipment where the working distance is > 36 inches.

ARC FLASH AND SHOCK HAZARD ARC FLASH AND SHOCK HAZARD

APPROPRIATE PPE REQUIRED APPROPRIATE PPE REQUIRED

Based on NFPA 70E-2021 & XYZ Company Safety Directives Based on NFPA 70E-2021 & XYZ Company Safety Directives

ARC FLASH PPE LEVEL 2: ARC FLASH PPE LEVEL 4:

Working Distance ≥ 36"

Minimum PPE Rating = 8 cal/cm2

Arc Flash Boundary = 15 ft

2 Working Distance ≥ 36"

Minimum PPE Rating = 40 cal/cm2

Arc Flash Boundary = 45 ft

Note: PPE = 2 at a working distance of 15 ft.

4

SHOCK PROTECTION – 13,800 VAC SHOCK PROTECTION – 13,800 VAC

Insulating Glove Class 2 Insulating Glove Class 2

Limited Approach Boundary 5 ft Limited Approach Boundary 5 ft

Restricted Approach Boundary 2 ft 2 in Restricted Approach Boundary 2 ft 2 in

CAUTION: CAUTION:

Ensure that all of the appropriate safety procedures Ensure that all of the appropriate safety procedures

are followed. The PPE Level designation on this are followed. The PPE Level designation on this

equipment is based on the proper installation and equipment is based on the proper installation and

maintenance of the up-line protective device. maintenance of the up-line protective device.

XYZ13800-2 XYZ13800-4

An Example of a Standard Page 10 Qual-Tech Engineers, Inc.

Arc Flash PPE Labeling Strategy

Label PPE

This label is for PPE as defined in NFPA 70E-2021. It is possible to accomplish the PPE

levels with variations in clothing from those given below. - This label is intended to be

posted in key locations, such as substations, for general information.

PROTECTIVE CLOTHING AND

PERSONAL PROTECTIVE EQUIPMENT PPE

Based on NFPA 70E-2021 & XYZ Company Safety Directives

ARC FLASH PPE LEVEL 0 (For Tasks < 1.2 cal/cm2)

Nonmelting fiber underlayers (e.g. cotton) Safety glasses or safety goggles

Nonmelting fiber long sleeve shirt & pants (e.g. cotton) Hearing protection (ear canal inserts)

Arc Flash PPE Level 2 is required if any part of the body Leather gloves

or clothing is exposed to energized circuit parts within Insulating gloves and tools as needed

the defined working distance.

ARC FLASH PPE LEVEL 2 (For Tasks < 8 cal/cm2)

Nonmelting fiber underlayers (e.g. cotton) Hearing protection (ear canal inserts)

Arc-rated long sleeve shirt & pants or coverall (> 8 cal/cm2) Insulating gloves with leather protectors

Safety glasses or safety goggles Heavy-duty leather shoes

Hard hat, arc-rated face shield, and arc-rated balaclava Insulated tools

ARC FLASH PPE LEVEL 4 (For Tasks < 40 cal/cm2)

Nonmelting fiber underlayers (e.g. cotton) Hearing protection (ear canal inserts)

Arc-rated long sleeve shirt & pants or coverall Arc-rated gloves

Arc-rated arc flash suit and hood (system > 40 cal/cm2) Heavy-duty leather shoes

Safety glasses or safety goggles Insulated tools

Hard hat

XYZ-P

An Example of a Standard Page 11 Qual-Tech Engineers, Inc.

Arc Flash PPE Labeling Strategy

Label BOUNDARIES

This label is to provide a definition of the various boundaries. - This label

is intended to be posted in key locations, such as substations, for general

information.

APPROACH BOUNDARIES

FOR SHOCK & FLASH PROTECTION

As Defined in NFPA 70E-2021

DEFINITIONS OF APPROACH BOUNDARIES:

LIMITED APPROACH BOUNDARY – An approach

limit at a distance from an exposed energized electrical

conductor or circuit part within which a shock hazard exists.

(It is the closest distance an unqualified person can

approach, unless accompanied by a qualified person.)

RESTRICTED APPROACH BOUNDARY – An

approach limit at a distance from an exposed energized

electrical conductor or circuit part within which there is an

increased likelihood of electric shock, due to electrical

arc-over combined with inadvertent movement, for

personnel working in close proximity to the energized

electrical conductor or circuit part. (It is the closest

distance to exposed energized electrical conductor or

circuit part a qualified person can approach without

proper PPE and tools.)

ARC FLASH BOUNDARY - When an arc flash hazard

exists, an approach limit at a distance from an arc source

at which incident energy equals 1.2 cal/cm2 (5 J/cm2).

BOUNDARY REQUIREMENTS WHEN THERE

IS AN EXPOSED ENERGIZED ELECTRICAL

CONDUCTOR OR CIRCUIT PART:

UNQUALIFIED PERSONS must stay beyond the

limited approach boundary and/or the arc flash

boundary, as dictated by the tasks being performed.

QUALIFIED PERSONS must stay beyond the

restricted approach boundary and/or the arc flash

boundary, unless equipped with the proper PPE and

tools, as dictated by the tasks being performed.

XYZ-B

An Example of a Standard Page 12 Qual-Tech Engineers, Inc.

Arc Flash PPE Labeling Strategy

5.2 Remote Switching

These labels are for remote switching locations at any voltage.

ARC FLASH AND SHOCK HAZARD ARC FLASH AND SHOCK HAZARD

APPROPRIATE PPE REQUIRED APPROPRIATE PPE REQUIRED

Based on NFPA 70E-2021 & XYZ Company Safety Directives Based on NFPA 70E-2021 & XYZ Company Safety Directives

ARC FLASH PPE LEVEL 0:

Minimum PPE Rating = 1.2 cal/cm2

Remote Operation of Switching Device 0

ARC FLASH PPE LEVEL 2:

Minimum PPE Rating = 8 cal/cm2

Remote Operation of Switching Device 2

CAUTION: CAUTION:

During Remote Breaker Switching, During Remote Breaker Switching,

EVACUATE THE SUBSTATION. EVACUATE THE SUBSTATION.

The person switching should have an The person switching should have an

observer standing by the adjacent door. observer standing by the adjacent door.

CAUTION: CAUTION:

Ensure that all of the appropriate safety procedures Ensure that all of the appropriate safety procedures

are followed. The PPE Level designation on this are followed. The PPE Level designation on this

equipment is based on the proper installation and equipment is based on the proper installation and

maintenance of the up-line protective device. maintenance of the up-line protective device.

XYZ0-R XYZ2-R

ARC FLASH AND SHOCK HAZARD

APPROPRIATE PPE REQUIRED

Based on NFPA 70E-2021 & XYZ Company Safety Directives

4

ARC FLASH PPE LEVEL 4:

Minimum PPE Rating = 40 cal/cm2

Remote Operation of Switching Device

CAUTION:

During Remote Breaker Switching,

EVACUATE THE SUBSTATION.

The person switching should have an

observer standing by the adjacent door.

CAUTION:

Ensure that all of the appropriate safety procedures

are followed. The PPE Level designation on this

equipment is based on the proper installation and

maintenance of the up-line protective device.

XYZ4-R

Qual-Tech Engineers, Inc.

QT-625-1020 201 Johnson Road ∙ Building #1 - Suite 203

Houston, PA 15342-1300

724-873-9275

FAX 724-873-8910

www.QualTechEng.com

An Example of a Standard Page 13 Qual-Tech Engineers, Inc.

Arc Flash PPE Labeling Strategy

You might also like

- Offshore Electrical Engineering ManualFrom EverandOffshore Electrical Engineering ManualRating: 4 out of 5 stars4/5 (9)

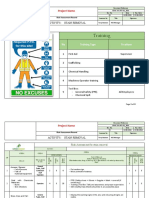

- Safety Behavior Observation Checklist: Observe Quietly. Mark Each Observation ItemDocument1 pageSafety Behavior Observation Checklist: Observe Quietly. Mark Each Observation Itemkhrayzie bhone100% (3)

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsFrom Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsRating: 4 out of 5 stars4/5 (1)

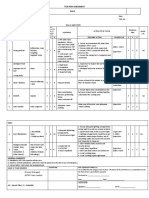

- Job Safety Analysis (JSA) - Rebar Installation/steel Fixing DateDocument1 pageJob Safety Analysis (JSA) - Rebar Installation/steel Fixing DatenabeelNo ratings yet

- Carrier Access Widebank ManualDocument452 pagesCarrier Access Widebank ManualKyle SasserNo ratings yet

- Pre Spud InspectionDocument8 pagesPre Spud InspectionAgus Alexandri100% (3)

- Page 1 of 6: Effective Date 7/2007 PS01005002EDocument4 pagesPage 1 of 6: Effective Date 7/2007 PS01005002EkrcdewanewNo ratings yet

- Specification No: ELRS /SPEC/ SI /0015: Government of IndiaDocument12 pagesSpecification No: ELRS /SPEC/ SI /0015: Government of Indiavikas katiyarNo ratings yet

- Short-Circuit Current Ratings of Equipment: Daniel R Neeser (S.M. IEEE)Document4 pagesShort-Circuit Current Ratings of Equipment: Daniel R Neeser (S.M. IEEE)octavinavarro8236No ratings yet

- SohorcsiDocument16 pagesSohorcsiJorge VegaNo ratings yet

- ANSI MV TechTopics81 ENDocument2 pagesANSI MV TechTopics81 ENSabri GünaydınNo ratings yet

- Tia Eia 613Document19 pagesTia Eia 613NeatMarineNo ratings yet

- Fairgrounds What You Need To KnowDocument4 pagesFairgrounds What You Need To KnowTheJosephNoob ustNo ratings yet

- National Grid Design Handbook dh01Document26 pagesNational Grid Design Handbook dh01akmezim100% (2)

- 650V 123 Installation Manual HA467649U002Document101 pages650V 123 Installation Manual HA467649U002vdalsheroqNo ratings yet

- TT Surge Protection Devices and NEC Code 2020 v2Document5 pagesTT Surge Protection Devices and NEC Code 2020 v2abdulkawi alasharyNo ratings yet

- DisignDocument2 pagesDisignMomen MahmoudNo ratings yet

- Operator Manual - P PDFDocument70 pagesOperator Manual - P PDFAndrew MorrisonNo ratings yet

- 26 00 00 - Basic Electrical Materials and MethodsDocument4 pages26 00 00 - Basic Electrical Materials and MethodsChris Benedict S. GalvezNo ratings yet

- Operator Manual - N PDFDocument71 pagesOperator Manual - N PDFAndrew MorrisonNo ratings yet

- Surge Protective Devices-Rev01Document15 pagesSurge Protective Devices-Rev01Mohamed HamedNo ratings yet

- Saes T 887 PDFDocument15 pagesSaes T 887 PDFAkhlaque ShamsiNo ratings yet

- Arc Flash Study The Six Steps PDFDocument7 pagesArc Flash Study The Six Steps PDFCarlos Lino Rojas AgüeroNo ratings yet

- Basics of Intrinsically Safe and Non - Intrinsically Safe SystemsDocument8 pagesBasics of Intrinsically Safe and Non - Intrinsically Safe Systemsnivprash8811No ratings yet

- Specification For Surge/Transient Protection: Part 1 - General 1.1 Related DocumentsDocument8 pagesSpecification For Surge/Transient Protection: Part 1 - General 1.1 Related Documentsmarissa LovaNo ratings yet

- RCD Protection: Changes To The Requirements Concerning Surge ProtectionDocument2 pagesRCD Protection: Changes To The Requirements Concerning Surge Protectionsdd dfsaNo ratings yet

- Ha 465492Document170 pagesHa 465492Gabriel Leite Dos SantosNo ratings yet

- 3 SWDocument11 pages3 SWDaniel EnteroNo ratings yet

- Tender Specs ROSOV CH 7 BDocument17 pagesTender Specs ROSOV CH 7 BShakeel AhmedNo ratings yet

- ESDE Part4Document32 pagesESDE Part4chandra boseNo ratings yet

- Power Line Carrier Communication: Engineering DepartmentDocument29 pagesPower Line Carrier Communication: Engineering DepartmentFaisalabad West T/L &S/SNo ratings yet

- CPS6000-Systems (-48V DC Power) Installation ManualDocument44 pagesCPS6000-Systems (-48V DC Power) Installation ManualM. MorenoNo ratings yet

- 8902 LS (Parker)Document20 pages8902 LS (Parker)abdohalim248No ratings yet

- Project Specification: Motor-Control Centers For HvacDocument15 pagesProject Specification: Motor-Control Centers For HvacSoumojit SamantaNo ratings yet

- Ip 16 12 1Document12 pagesIp 16 12 1DhanushNo ratings yet

- Kavr100 DDocument130 pagesKavr100 DIndra Aryana0% (1)

- SECTION 16464 Switchgear, Low Voltage (600 Volts and Below)Document12 pagesSECTION 16464 Switchgear, Low Voltage (600 Volts and Below)no nameNo ratings yet

- 48TMSS05R0 Pilot Cable Termination Equipment With CabinetDocument20 pages48TMSS05R0 Pilot Cable Termination Equipment With CabinetMohamed NasrNo ratings yet

- Manual Kidde ConvencionalDocument102 pagesManual Kidde ConvencionalSantiago AguilarNo ratings yet

- Fire Alarm InstallationDocument156 pagesFire Alarm Installationcarlos vasquezNo ratings yet

- MR Mk30 Regulador TensionDocument269 pagesMR Mk30 Regulador TensionAnonymous 10zKm4n93No ratings yet

- Cooper Bussman NSC CRDocument21 pagesCooper Bussman NSC CRrjpatil19No ratings yet

- Connection AgreementDocument8 pagesConnection AgreementTAHIR HUSAINNo ratings yet

- Works Masterspec 260573Document12 pagesWorks Masterspec 260573wester_bisNo ratings yet

- TNCR024 PDFDocument7 pagesTNCR024 PDFkoshkeNo ratings yet

- BCPM - SQD - z205387-0dDocument22 pagesBCPM - SQD - z205387-0dEduardo Gomes CytranguloNo ratings yet

- Iec 61010-1Document2 pagesIec 61010-1chauhan77kantaNo ratings yet

- 24 V DC Over 110 V AcDocument6 pages24 V DC Over 110 V Acesakkiraj1590No ratings yet

- NPS/003/017 - Technical Specification For A Ground Mounted Distribution Switchgear Remote Control SystemDocument17 pagesNPS/003/017 - Technical Specification For A Ground Mounted Distribution Switchgear Remote Control SystemkotiniNo ratings yet

- Nonincendive Equipment For Use in Hazardous (Classified) Locations IAEI MagazineDocument5 pagesNonincendive Equipment For Use in Hazardous (Classified) Locations IAEI Magazinemohamed abd el razekNo ratings yet

- Key Changes To Nfpa 70E: Application NoteDocument4 pagesKey Changes To Nfpa 70E: Application NoteRodrigo AndrésNo ratings yet

- Applications Note 02Document4 pagesApplications Note 02Anonymous NR43tawQfDNo ratings yet

- ICT SpecificationDocument99 pagesICT SpecificationZaid HijjawiNo ratings yet

- Rlxib Iha User ManualDocument123 pagesRlxib Iha User ManualLuis TorresNo ratings yet

- Air Conditioner NamePlate SpecsDocument4 pagesAir Conditioner NamePlate SpecsAlex ColstonNo ratings yet

- LFCB 102Document211 pagesLFCB 102Văn Quang NgôNo ratings yet

- NFPA 70E Arc Flash Considerations For MV EquipmentDocument65 pagesNFPA 70E Arc Flash Considerations For MV EquipmentMOHSIN_IIUI100% (1)

- Chapter 6 Building Services and Systems: Section 601 General 601.1 ScopeDocument23 pagesChapter 6 Building Services and Systems: Section 601 General 601.1 ScopeChrizzy 123No ratings yet

- Iec 947 Ect150 PDFDocument28 pagesIec 947 Ect150 PDFGoogool YNo ratings yet

- Areva MFACDocument30 pagesAreva MFACFerry A ViawanNo ratings yet

- 900 Spe 5001 Met&systDocument30 pages900 Spe 5001 Met&systyoi_123No ratings yet

- Safe Use of Smart Devices in Systems Important to Safety in Nuclear Power PlantsFrom EverandSafe Use of Smart Devices in Systems Important to Safety in Nuclear Power PlantsNo ratings yet

- Substation DC Auxiliary SupplyDocument8 pagesSubstation DC Auxiliary SupplyWaleed ElzanatiNo ratings yet

- Fire-Fighting Precautions in SubstationDocument6 pagesFire-Fighting Precautions in SubstationWaleed ElzanatiNo ratings yet

- ATS Arc Flash BrochureDocument3 pagesATS Arc Flash BrochureWaleed ElzanatiNo ratings yet

- Arc Flash and NFPA 70E: Safe Work PracticesDocument22 pagesArc Flash and NFPA 70E: Safe Work PracticesWaleed ElzanatiNo ratings yet

- GauthamRam MScThesisDocument196 pagesGauthamRam MScThesisWaleed ElzanatiNo ratings yet

- 58 WetzerDocument6 pages58 WetzerWaleed ElzanatiNo ratings yet

- MSDS - TESAAdhesive - Tile Adhesive Part BDocument4 pagesMSDS - TESAAdhesive - Tile Adhesive Part BJudianto TanaNo ratings yet

- Cloralex Max MsdsDocument6 pagesCloralex Max MsdsnaranjerosNo ratings yet

- Mutual Solvent MSDSDocument5 pagesMutual Solvent MSDSizzybjNo ratings yet

- Chem Service Inc.: Material Safety Data SheetDocument30 pagesChem Service Inc.: Material Safety Data SheetAlessandro GucciNo ratings yet

- Operators Manual M15Document88 pagesOperators Manual M15SMM ENTREPRISENo ratings yet

- Safety Data Sheet: Musol SolventDocument15 pagesSafety Data Sheet: Musol SolventHưng Lê TrungNo ratings yet

- Check List - 2B: Environmental Audit Checklist During Construction StageDocument2 pagesCheck List - 2B: Environmental Audit Checklist During Construction StagexohaibaliNo ratings yet

- AOI 22 Winter Operations and Snow PlanDocument41 pagesAOI 22 Winter Operations and Snow PlanGrec MirceaNo ratings yet

- CBLM - Apply OSH Practice in A CBT&A Environment - Version - 2Document46 pagesCBLM - Apply OSH Practice in A CBT&A Environment - Version - 2সত্য চন্দ্র প্রামাণিক100% (1)

- Ca Clean Ii - 643557 - GB - en - V-1.0.2 - SDBDocument9 pagesCa Clean Ii - 643557 - GB - en - V-1.0.2 - SDBInna FaridahNo ratings yet

- Safety Alert 49 - Cable Pulling IncidentDocument1 pageSafety Alert 49 - Cable Pulling IncidentsarojNo ratings yet

- SOP For Breakdown Maintenance - 1Document6 pagesSOP For Breakdown Maintenance - 1Pandu BirumakovelaNo ratings yet

- Motion Um002 en PDocument132 pagesMotion Um002 en PomkarNo ratings yet

- 25-Ra Use of Portable Pipe Threading MachineDocument4 pages25-Ra Use of Portable Pipe Threading MachineAsad Ayaz100% (1)

- Controlled Rapid Plant Shutdown PlanDocument5 pagesControlled Rapid Plant Shutdown PlaneffendiNo ratings yet

- Operating Manual: High Pressure Pump P52/54-270-30KWDocument132 pagesOperating Manual: High Pressure Pump P52/54-270-30KWclaygonNo ratings yet

- Manual SAE 400 G7Document60 pagesManual SAE 400 G7america1591No ratings yet

- RA of Manual ChippingDocument2 pagesRA of Manual ChippingMohamedSaidNo ratings yet

- Health and Safety For ResearchersDocument15 pagesHealth and Safety For Researchersaufar syehanNo ratings yet

- Risk Assessment For Stain RemovalDocument4 pagesRisk Assessment For Stain Removalطارق رضوانNo ratings yet

- Animal Production (Swine) NCII - 17dec2013Document78 pagesAnimal Production (Swine) NCII - 17dec2013Laurie Carr Landicho100% (1)

- 07-f05 Ohs Ms Document RegisterDocument3 pages07-f05 Ohs Ms Document RegisterSn AhsanNo ratings yet

- Open Cast Working MCQDocument7 pagesOpen Cast Working MCQOm KeshariNo ratings yet

- 1804.1804S TDSDocument3 pages1804.1804S TDSGavin ShenNo ratings yet

- SITE SELECTION AND SOIL ANALYSIS PPT GRade 10Document20 pagesSITE SELECTION AND SOIL ANALYSIS PPT GRade 10Antonio Jarligo CompraNo ratings yet

- Ia - Civil Technology LM Grade 7 & 8 P&DDocument84 pagesIa - Civil Technology LM Grade 7 & 8 P&DAngel Jr Arizo Lim100% (2)

- CSHP 23bh0170 MPB Pag Asa, Echague VBM Cons. CorpDocument47 pagesCSHP 23bh0170 MPB Pag Asa, Echague VBM Cons. CorpDionisio VerzolaNo ratings yet