Professional Documents

Culture Documents

MMS COM Completed

MMS COM Completed

Uploaded by

misbahuddin md0 ratings0% found this document useful (0 votes)

5 views4 pagesThe document compares the syllabus of materials engineering across multiple universities.

1. The syllabus covers topics like crystal structure, defects, mechanical properties, phase transformations, diffusion, and phase diagrams. Concepts like dislocations, strengthening mechanisms, interpretation of phase diagrams, and Fick's laws of diffusion are discussed.

2. Other topics included are fatigue, creep, and fracture mechanisms. The effects of metallurgical variables on metal fatigue are examined. Determination of fatigue strength and creep behavior are also summarized.

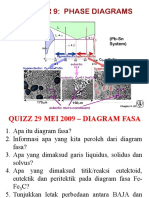

3. Different types of phase diagrams are outlined according to the solubility of components in solid and liquid states. Properties of solid solutions, eutectic systems, and age hardening processes

Original Description:

Metallurgy and Material Testing syllabus

Original Title

MMS COM completed

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document compares the syllabus of materials engineering across multiple universities.

1. The syllabus covers topics like crystal structure, defects, mechanical properties, phase transformations, diffusion, and phase diagrams. Concepts like dislocations, strengthening mechanisms, interpretation of phase diagrams, and Fick's laws of diffusion are discussed.

2. Other topics included are fatigue, creep, and fracture mechanisms. The effects of metallurgical variables on metal fatigue are examined. Determination of fatigue strength and creep behavior are also summarized.

3. Different types of phase diagrams are outlined according to the solubility of components in solid and liquid states. Properties of solid solutions, eutectic systems, and age hardening processes

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

0 ratings0% found this document useful (0 votes)

5 views4 pagesMMS COM Completed

MMS COM Completed

Uploaded by

misbahuddin mdThe document compares the syllabus of materials engineering across multiple universities.

1. The syllabus covers topics like crystal structure, defects, mechanical properties, phase transformations, diffusion, and phase diagrams. Concepts like dislocations, strengthening mechanisms, interpretation of phase diagrams, and Fick's laws of diffusion are discussed.

2. Other topics included are fatigue, creep, and fracture mechanisms. The effects of metallurgical variables on metal fatigue are examined. Determination of fatigue strength and creep behavior are also summarized.

3. Different types of phase diagrams are outlined according to the solubility of components in solid and liquid states. Properties of solid solutions, eutectic systems, and age hardening processes

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

You are on page 1of 4

MMS(U23ME301) Syllabus Comparison Sheet

Unit LIET (A) OU NIT DURGAPUR JNTUH VNRVJIET

Introduction: Basic

concepts about Stability of

Phases and equilibrium;

Introduction: Introduction to Materials Types of Phase Metal structure and crystallization

engineering, scope of metallurgy, Imperfections in crystals, Dislocations in Transformations, Order of Introduction - atom binding, ionic

classification of materials- metals and crystals, Types of dislocations, Critical transformations. bond, covalent bond, metallic bond,

alloys,ceramics, polymers and resolved shear stress, Effect of slip and and Vander Waals forces; Overview

composites, Bonds in solids, Space twinning on the plastic deformation, Jogs Phase Equilibria: Phase diagrams: binary of metal structure and crystallization.

lattice, unit cell, crystal structure, crystal and its effect on yield phenomenon, Hall- Thermodynamics of phase and ternary, principles of Constitution of alloys Introduction;

directions and Petch equation, Ornge Pell effect, cold and changes, phase diagrams alloying, Hume-Rothery Classification of alloys or

planes,crystalimperfections- hot working, strain hardening and and equilibria in relation to rules. Strengthening compounds; Pure metal; Intermediate

1

pointdefects,linedefects,surfacedefects,v Bauchinger effect, recovery, Free energy-composition mechanisms, solid alloy phase or compound -

olumedefects.Typesofdislocations,Hall- Recrystallization, Grain growth and its diagrams. Interpretation of solution, work hardening, intermetallic compounds or valency

Petchequation,Orange peel effect, cold effect on mechanical properties of metals. phase diagrams, precipitation hardening, compounds, interstitial compounds,

and hot working, strain hardening and Fracture: Types of fracture in metals, modes determination and dispersion strengthening. and electron compounds; Solid

Bauchinger effect Recovery, of fracture, Griffith theory of brittle fracture, calculations. Solid-liquid solutions; Substitutional solid

Recrystallisation,. Crack propagation, ductile fracture, Fracture Miscibility gap; invariant solution - factors that control the

under combined stress. reaction. Principles of range of solubility in alloy system;

ternary phase diagram, Interstitial solid solutions.

Examples of a few metallic

and ceramic phase

diagrams.

Remarks No Deviation from OU Syllabus

2 Fracture:DuctileandBrittlefracture,Fatig Fatigue: S-N curve, Structure of fatigue Diffusion: Iron carbon diagram, Phase diagrams Introduction;

ue:S- fracture specimen. Fatigue crack Phenomenological equation isothermal, and Coordinates of phase diagrams;

Ncurve,Structureoffatiguefracturespecim propagation, effect of metallurgical variables of diffusion, Chemical continuous cooling Experimental methods - construction

en,Fatiguecrackpropagation,modes of on fatigue of metal, low cycle fatigue, potential gradient, Fick’s transformation diagrams; of equilibrium diagrams by thermal

fracture, ductile to brittle transition, cumulative fatigue and fatigue damage, first law of diffusion, influence of alloying analysis, metallographic methods,

crack initiation and propagation, Effect Experimental determination of fatigue diffusion coefficient elements on and X-ray diffraction; Type-I-Two

of metallurgical variables on fatigueof strength (RR-Moore Test), Factors to be (diffusivity), representation transformation metals completely soluble in the

metal, Experimental determination of considered for the improvement of the of diffusion flux in terms of characteristics. liquid and solid states; Chemical

fatigue strength (RR-Moore Test).Creep: fatigue life. Creep: Creep strength, creep chemical potential gradient; composition of phases; relative

Creep strength, Creep curve, curve, creep deformation mechanisms, creep Nernst-Einstein Equation, amounts of each phase; Equilibrium

Creepdeformation test, differences between creep curve and Diffusion in ideal solution cooling of a solid solution alloy;

mechanisms,CreepTest. stress rupture curve. Diffusion: Fick’s law of and in solutions with Diffusion; Nonequilibrium cooling;

diffusion, application of diffusion theory in positive and negative Homogenization; Properties of solid-

mechanical engineering. deviation; Uphill diffusion, solution alloys; Variation of Type I;

determination of diffusion Type II-Two metals completely

coefficient (diffusivity) for soluble in the liquid state and

Unit LIET (A) OU NIT DURGAPUR JNTUH VNRVJIET

ideal binary solid solution

in terms of jump frequency

and jump distance, atomic

mechanism of diffusion,

Expression of diffusion

coefficient (diffusivity) for completely insoluble in the solid

self diffusion in pure metal state; Type III-Two metals completely

or diffusion in soluble in the liquid state but only

substitutional solid solution partly soluble in the solid state;

through vacancy Properties of eutectic alloy systems;

mechanism and in Age hardening – solution treatment,

interstitial solid solution; and aging process; Type IV-The

Steady state diffusion and congruent-melting intermediate

transient diffusion; Fick’s phase; Type V-The peritectic reaction;

second law of diffusion; Type VI-Two liquids partly soluble in

determination of self the liquid state: the monotectic

diffusion coefficient by reaction; Type VII-two metals

radioactive method; insoluble in the liquid and solid

solution of Fick’s second states; Interrelation of basic types;

law: analysis of carburizing Transformations in the solid state -

and decarburizing allotropy, order-disorder

processes; solution of transformation, the eutectoid reaction,

Fick’s second law for the peritectoid reaction, and complex

variable diffusivity: diagrams; Study of important binary

Boltzmann-Matano phase diagrams of Cu-Ni, Al-Si,Sb-

analysis, Matano interface, Pb,Pt-Ag,Bi-Cd,Cu-Pb,CuSn,and Fe-

determination of diffusivity Fe3C.

as a function of

concentration; Diffusion in

substitution solid solution:

Kirkendall effect, Darken’s

analysis

Remarks No Deviation from OU Syllabus

3 Structure of Alloys: Types of solid Structure of Alloys: Construction and Liquid-Solid Phase Heat treatment - The heat treatment of steel

solution, Substitution solids, Hume interpretation of thermal equilibrium Transformation: Principles annealing, normalizing, Introduction; Full Annealing;

Rothary’s rules for solid solution, TTT diagram of binary nonferrous alloys, study of Solidification in metals hardening and tempering Spheroidizing; Stress-relief

diagram,Constructionandinterpretationof of eutectic, eutectoid, peritectic, peritectoid and alloys: of steels, hardenability annealing; Process annealing;

Binaryequilibriumdiagram,Isomorphous, reactions. Iron-Iron Carbide Equilibrium thermodynamics involved, Normalizing; Hardening; The

EutecticandPeritecticdiagrams, phase diagram, construction and interpretation. eutectic and peritectic isothermal transformation diagram;

rule, Iron-Iron Carbide equilibrium Types of plain carbon steels, cast iron and Solidification, Transformation to Pearlite 57 and

diagram, Intermediate phases and phase their properties and characteristics. Homogeneous and Bainite; Cooling curves and I-T

rule, Iron-Iron Carbideequilibrium heterogeneous nucleation, Diagram; Transformation on

diagram construction and interpretation, Mechanisms of growth. continuous cooling; Position of the I-

Unit LIET (A) OU NIT DURGAPUR JNTUH VNRVJIET

T curves; Hardening or austenitizing

temperature; Homogeneity of

austenite; Mechanism of heat removal

during quenching - vapor-blanket

cooling state (stage A), vapor

transport cooling stage (stage B),

Liquid cooling stage (stage C);

Quenching medium; Temperature of

quenching medium; Surface

Types of Plain Carbon Steels, Cast Iron condition - methods to minimize the

and their properties andCharacteristics. Rapid Solidification formation of scale - copper plating,

Processing. protective atmosphere, liquid-salt

pots, and cast-iron chips; Size and

Mass; Hardenability; Use of

Hardenability data; Tempering;

Austempering; Surface heat treatment

or case hardening; Carburizing; Heat

treatment after carburizing;

Cyaniding and Carbonitriding;

Nitriding; Flame hardening;

Induction Hardening; Residual

Stresses; Hardenable carbon steels.

Remarks No Deviation from OU Syllabus

4 AlloySteels:Effectsofalloyingelementslik Heat Treatment: Annealing, Normalising, Solid State Phase Introduction to important Alloy steels Introduction; Purpose of

eNickel,Chromium,Manganese,Silicona Hardening, Tempering, Construction and Transformations: ferrous alloys, stainless alloying; Effect of alloying elements

ndTungsten,Titanium.,StudyaboutStainle interpretation of T.T.T Curve. Austempering Nucleation and growth steels, special steels, cast upon Ferrite; Effect of alloying

ss steels, HSS, Maraging steels, Brass, and Martempering. Case Hardening: Kinetics, homogeneous and irons, aluminium alloys elements upon carbide; Influence of

Bronze, Muntz Metal, Invar, Duralumin Carburising, Nitriding, Carbo-nitriding, heterogeneous alloying elements on the iron-iron

and Ti Alloy (Ti-6Al-4V) – Flame Hardening and Induction Hardening. transformation, carbide diagram; Effect of alloying

theircompositionandProperties. Brief introduction of Age hardening. Precipitation: Coherency, elements in tampering; Classification

Microscopy: Construction and age hardening, particle of steels - nickel steel, chromium

Principles of Optical Microscope, Coarsening. Ostwald steel, nickel-chromium steels,

Application and Limitation of Optical ripening, Order-disorder manganese steels, molybdinum steels,

Microscope, Principle of Electron transformation, spinodal tungsten steels, venedium steels,

Microscope, Performance of Optical and decomposition, massive silicon steels, stainless steels,

Electron Microscopes. transformations. martensitic stainless steels, ferritic

stainless steels, austenitic stainless

steels, precipitation-hardening

stainless steels, maraging steels, and

ausforming. Tool steels Classification

of tool steels; Selection of tool steels;

Comparative properties; Non-

deforming properties; Depth of

Unit LIET (A) OU NIT DURGAPUR JNTUH VNRVJIET

hardening; Toughness; Wear

resistance; Red-hardness;

Machinability; Resistance to

decarburization; Brand names; Water-

hardening tool steels (Group W);

Shock resisting tool steels (Group S);

Cold-work tool steels; Hot-work tool

steels (Group H); High speed tool

steels; Mold Steels (Group P);

Special purpose tool steels; Heat

treatment of tool steels; Overview of

tool failures; Special cutting materials

– satellites, cemented carbides, and

ceramic tools.

Remarks No Deviation from OU Syllabus

Selection of materials: Criteria of selecting

Cast iron Introduction; Types of cast

materials for automotive components viz

iron; White cast iron; Malleable cast

Cylinder block, Cylinder head, Piston, Solid State Phase

Heat Treatment: Annealing, iron; Pearlitic malleable iron; Gray

Piston ring, Gudgeon pin, Connecting rod, Transformations in steel:

Normalizing, Hardening, Tempering, cast iron; Silicon in cast iron; Sulfur

Crank shaft, Crank case, Cam, Cam shaft, Reconstructive and

Construction andinterpretation of in cast iron; Manganese in cast iron;

Engine valve, Gear wheel, Clutch plate, displacive transformations;

T.T.TCurve,Austempering and Phosphorus in cast iron; Heat

Axle bearings, Chassis, Spring, body panel Pearlitic transformation:

Martempering. Case Hardening: treatment of grey iron, Size and

radiator, brake lining etc. Application of mechanism and kinetics:

Carburizing, Nitriding, Carbo-nitriding, Titanium alloys, copper distribution of graphite flakes;

non-metallic materials such as composite, Johnson-Mehl equation,

Flame Hardening, InductionHardening. base alloys. Superalloys, Mechanical properties and

ceramic and polymers in automobile. morphology of pearlite;

Composites: shape memory alloys – applications of grey cast iron; Chilled

5 Testing of materials: Universal testing Bainitic transformation:

Ceramics,crystallineceramics,glasses,pro classification, heat cast iron; Nodular cast iron; Alloy

machine-tension, compression, bending and mechanism and kinetics;

pertiesandapplicationsofceramics,polym treatment, properties and cast irons. 58 Non-ferrous metals and

shear tests, Hardness testing- Rockwell, morphology of upper

ers- applications. alloys Introduction; Copper and its

Brinnell’s and Vicker’s diamond methods. bainite and lower bainite;

polymerization,thermoplasticsandthermo alloys - Copper, temper designation

Toughness measurement- Izod and Charpy Martensitic transformation:

settingplastics,propertiesandapplications of copper and copper alloys, and

methods, Torsion test. Non-Destructive Mechanism- diffusionless

ofpolymers,matrixandreinforcement,rule copper alloys; Aluminum and its

Testing methods: Ultrasonic testing, displacive nature;

ofmixtures. alloys - Aluminum, Alloy designation

Magnetic Particle Testing, Liquid penetrant morphology of high carbon

system, and temper designation;

testing, Radiographic testing, Eddy Current and low carbon martensite.

Titanium and Titanium alloys.

Testing, Visual Testing and Thermal/Infra-

Overview of solidification of metals

Red Testing.

Remarks No Deviation from OU Syllabus

You might also like

- CAMPBELL (1933) Greek and Roman Plated CoinsDocument75 pagesCAMPBELL (1933) Greek and Roman Plated Coinspax_romana870No ratings yet

- Chemistry LY5XEpAVilQ4y8IuTJsxDocument5 pagesChemistry LY5XEpAVilQ4y8IuTJsxdasmanashkousik16No ratings yet

- MSC SylabusDocument5 pagesMSC SylabusAyyan FerozNo ratings yet

- Mining Syllabus, B.I.T SindriDocument38 pagesMining Syllabus, B.I.T Sindriazad15_90No ratings yet

- BTech CBCS Course Structure With Syllabi - Minerals and Metallurgical EngineeringDocument38 pagesBTech CBCS Course Structure With Syllabi - Minerals and Metallurgical EngineeringGumnam BandaNo ratings yet

- ME 210 Metallurgy and Materials EngineeringDocument5 pagesME 210 Metallurgy and Materials Engineeringnandan144No ratings yet

- Chemistry: Class: XII-JEEDocument44 pagesChemistry: Class: XII-JEEtortenhumNo ratings yet

- ME 210 Metallurgy and Materials EngineeringDocument5 pagesME 210 Metallurgy and Materials EngineeringkannanNo ratings yet

- JEE Main 2021 Chemistry SyllabusDocument8 pagesJEE Main 2021 Chemistry SyllabusVaniNo ratings yet

- JEE Main 2021 Chemistry SyllabusDocument8 pagesJEE Main 2021 Chemistry SyllabusVaniNo ratings yet

- Syllabus AMIIWDocument1 pageSyllabus AMIIWdebduttamallikNo ratings yet

- Mmse Apj KtuDocument5 pagesMmse Apj KtuSherwinNo ratings yet

- JEE Main Chemistry Syllabus EbookDocument8 pagesJEE Main Chemistry Syllabus EbookDipanjanNo ratings yet

- PHP KC TZ NaDocument7 pagesPHP KC TZ NaAditya TiwariNo ratings yet

- Paper V Unit-I: Classical Mechanics Ii (25 Marks) LECTURES 25 + 5 TutorialDocument5 pagesPaper V Unit-I: Classical Mechanics Ii (25 Marks) LECTURES 25 + 5 Tutorialzoo zooNo ratings yet

- SYLLABUSDocument7 pagesSYLLABUSRohit KumarNo ratings yet

- ME309 Metallurgy and Material Science PDFDocument4 pagesME309 Metallurgy and Material Science PDFPremnath G100% (1)

- Physics Syllabus For Main ExaminationDocument8 pagesPhysics Syllabus For Main ExaminationsarfarajansariNo ratings yet

- Birla Institute of Technology and Science, Pilani: Pilani Campus AUGS/ AGSR DivisionDocument6 pagesBirla Institute of Technology and Science, Pilani: Pilani Campus AUGS/ AGSR DivisionIkshwakNo ratings yet

- JEE MAIN 2021 CHEMISTRY Syllabus Section - A Physical ChemistryDocument7 pagesJEE MAIN 2021 CHEMISTRY Syllabus Section - A Physical ChemistryMayank NautiyalNo ratings yet

- Journal of The Mechanics and Physics of SolidsDocument23 pagesJournal of The Mechanics and Physics of SolidsjotagacsNo ratings yet

- Phase Diagram PDFDocument22 pagesPhase Diagram PDFAbhishek KumarNo ratings yet

- Chemistry PGTDocument7 pagesChemistry PGTAnkit BhardwajNo ratings yet

- Subject Title: Strength of Materials Class: Second Year: Instructor Name: Dr. Ziad Sh. AL SarrafDocument46 pagesSubject Title: Strength of Materials Class: Second Year: Instructor Name: Dr. Ziad Sh. AL SarrafHumam Al-fayyadhNo ratings yet

- Syllabus PH.D Entrance 2021 FinalDocument26 pagesSyllabus PH.D Entrance 2021 FinalSwapna HNo ratings yet

- Department of Ocean Engineering Iit Madras, Chennai 600036 Syllabus For Ms/Ph.D. Admission TestDocument5 pagesDepartment of Ocean Engineering Iit Madras, Chennai 600036 Syllabus For Ms/Ph.D. Admission TestGOKUL PRASADNo ratings yet

- Department Chemistry PG SyllabusDocument40 pagesDepartment Chemistry PG Syllabusrihana yadavNo ratings yet

- Precipitation Hardening in Metals - T GladmanDocument7 pagesPrecipitation Hardening in Metals - T GladmanSouryatanu SahaNo ratings yet

- Zambrano 2020Document24 pagesZambrano 2020jonathan arayaNo ratings yet

- In Uence of The Cooling Rate On The Ageing of Lead-Calcium AlloysDocument5 pagesIn Uence of The Cooling Rate On The Ageing of Lead-Calcium AlloysDilfredo RuizNo ratings yet

- Jee Mains Deleted TopicsDocument4 pagesJee Mains Deleted TopicsseekotivishalNo ratings yet

- MME 291 Slide-2 Phase DiagramDocument45 pagesMME 291 Slide-2 Phase DiagramEntertainment GamingNo ratings yet

- Chemistry Syllabus For CUET - How To Prepare Chemistry For CUET - CUET 2022 PrepDocument7 pagesChemistry Syllabus For CUET - How To Prepare Chemistry For CUET - CUET 2022 Preppm0589639No ratings yet

- Code: MTT218 Mechanical Behavior & Testing of Materials Credit: 04 L-T-P: (3-1-0) Course ContentDocument1 pageCode: MTT218 Mechanical Behavior & Testing of Materials Credit: 04 L-T-P: (3-1-0) Course Contentrishikesh vaishnavNo ratings yet

- 113107048Document4 pages113107048Hiren MistryNo ratings yet

- Mechanical Engg SyllabusDocument33 pagesMechanical Engg SyllabusKRISHNA KANT GUPTANo ratings yet

- Deleted SyllabusDocument7 pagesDeleted Syllabusnikhils.ind18No ratings yet

- Schmauder 2011Document6 pagesSchmauder 2011Supun RanganaNo ratings yet

- Ias Mains - PhysicsDocument4 pagesIas Mains - PhysicsVinay MittalNo ratings yet

- Chemistry Syllabus: Subjects Topic To Be CoveredDocument4 pagesChemistry Syllabus: Subjects Topic To Be CoveredAnanya NNo ratings yet

- Kuet Ipe Full SyllabusDocument22 pagesKuet Ipe Full SyllabusTamanna KamalNo ratings yet

- Verification and Validation Issues in Advanced Numerical Modeling: Pitting CorrosionDocument33 pagesVerification and Validation Issues in Advanced Numerical Modeling: Pitting CorrosionBoulHich BoulHichNo ratings yet

- Sssihl Admissions 2018 Test Syllabus ProfessionalDocument7 pagesSssihl Admissions 2018 Test Syllabus ProfessionalDeeptiNainaniNo ratings yet

- Influence of Loading Orientation On Deformation Localization of Irradiated TungstenDocument11 pagesInfluence of Loading Orientation On Deformation Localization of Irradiated Tungstenlizhijie20082006No ratings yet

- Stem Test PlannerDocument24 pagesStem Test PlannerMrinal DahariaNo ratings yet

- Physics SyllabusDocument3 pagesPhysics SyllabusAmit YadavNo ratings yet

- ChemDocument3 pagesChemshivammishraupsccse2024air1No ratings yet

- Fatigue Behavior of A356/357 Aluminum Cast Alloys. Part II - Effect of Microstructural ConstituentsDocument14 pagesFatigue Behavior of A356/357 Aluminum Cast Alloys. Part II - Effect of Microstructural ConstituentsMajed NesrineNo ratings yet

- Course HandoutDocument4 pagesCourse HandoutjagyanjitNo ratings yet

- UPSC CSE Mains Chemistry Syllabus: Paper - IDocument1 pageUPSC CSE Mains Chemistry Syllabus: Paper - ImkgchemNo ratings yet

- Cohesive Fracture and Scaling: CE-430 & MS-441Document3 pagesCohesive Fracture and Scaling: CE-430 & MS-441MsmMostafaNo ratings yet

- Syllabus For BITSATDocument17 pagesSyllabus For BITSATPRAKHAR GUPTANo ratings yet

- Physics UPSC SyllabusDocument4 pagesPhysics UPSC SyllabusPrashanth MatetiNo ratings yet

- Interaction Mechanism of Non-Metallic Particles WiDocument6 pagesInteraction Mechanism of Non-Metallic Particles WiRichart ChaiyakmaneeNo ratings yet

- 2T3SXwrzTYa zDSypgnH4wDocument6 pages2T3SXwrzTYa zDSypgnH4wSaya FjjdNo ratings yet

- Chemistry SyllabusDocument4 pagesChemistry SyllabusPriyank SharmaNo ratings yet

- 64 113 Syllabus - ChemistryDocument154 pages64 113 Syllabus - ChemistrySm Bikash Kumar MohonNo ratings yet

- Jee Advanced 2024 SyllabusDocument10 pagesJee Advanced 2024 SyllabusVansh JainNo ratings yet

- Chem f111 General Chemistry1Document3 pagesChem f111 General Chemistry1Nishant KhandelwalNo ratings yet

- Metal Complex - DNA InteractionsFrom EverandMetal Complex - DNA InteractionsNick HadjiliadisNo ratings yet

- Photonic Crystals: Molding the Flow of Light - Second EditionFrom EverandPhotonic Crystals: Molding the Flow of Light - Second EditionNo ratings yet

- Syllabus Comparision SHEET METROLOGY AND INSTRUMENTATION LAB BoSDocument1 pageSyllabus Comparision SHEET METROLOGY AND INSTRUMENTATION LAB BoSmisbahuddin mdNo ratings yet

- Rse Unit-1 NotesDocument15 pagesRse Unit-1 Notesmisbahuddin mdNo ratings yet

- TQM The Malcolm Baldrige National Quality AwardDocument6 pagesTQM The Malcolm Baldrige National Quality Awardmisbahuddin mdNo ratings yet

- MP LAB COM CompletedDocument3 pagesMP LAB COM Completedmisbahuddin mdNo ratings yet

- Material Testing Lab ManualDocument39 pagesMaterial Testing Lab Manualmisbahuddin mdNo ratings yet

- FMHM Important Question and AnswerDocument6 pagesFMHM Important Question and Answermisbahuddin mdNo ratings yet

- AskelandPhuleNotes CH10PrintableDocument76 pagesAskelandPhuleNotes CH10PrintablejoshibecNo ratings yet

- Phase RuleDocument30 pagesPhase RuleVansh YadavNo ratings yet

- 2011 Nov-1Document24 pages2011 Nov-1ratheesh1981No ratings yet

- Handbook Al HPDC Alloys For Structural Casts RHEINFELDEN ALLOYS 2017 enDocument55 pagesHandbook Al HPDC Alloys For Structural Casts RHEINFELDEN ALLOYS 2017 engurtekinkubra8No ratings yet

- Chapter - 09 - Phase DiagramDocument43 pagesChapter - 09 - Phase Diagramchisanwn100% (1)

- Materials and Design: Da Li, Ligang Liu, Yunkun Zhang, Chunlei Ye, Xuejun Ren, Yulin Yang, Qingxiang YangDocument6 pagesMaterials and Design: Da Li, Ligang Liu, Yunkun Zhang, Chunlei Ye, Xuejun Ren, Yulin Yang, Qingxiang YangjoeljNo ratings yet

- Lecture 12 (Alluminium and Its Alloy)Document16 pagesLecture 12 (Alluminium and Its Alloy)Nhihonium oxideNo ratings yet

- Ca Ve Ba Sferoya EtkisiDocument9 pagesCa Ve Ba Sferoya Etkisiİğrek Takım TezgahlarıNo ratings yet

- سنوات سابقة خواصDocument64 pagesسنوات سابقة خواصmechanical depNo ratings yet

- Aluminium - Copper - Silicon: Hans Leo Lukas, Nathalie LebrunDocument13 pagesAluminium - Copper - Silicon: Hans Leo Lukas, Nathalie LebrunMuhammad victoryan nadezulNo ratings yet

- Week 11Document12 pagesWeek 11lduran_63No ratings yet

- Phase Diagrams of Binary SystemsDocument4 pagesPhase Diagrams of Binary SystemsLisa Valois PedrigalNo ratings yet

- Applied Energy: Jose Pereira Da Cunha, Philip EamesDocument12 pagesApplied Energy: Jose Pereira Da Cunha, Philip EamesJose Luis Sarango DiazNo ratings yet

- 2021 Makrovets Thermodynamic Assessment Phase Equilibria SrO-Al2O3 SystemDocument6 pages2021 Makrovets Thermodynamic Assessment Phase Equilibria SrO-Al2O3 SystemJorge AbranteNo ratings yet

- LostfoamcastingDocument88 pagesLostfoamcastingNikhil KanojiNo ratings yet

- Treatment of A Liquid AluminumDocument55 pagesTreatment of A Liquid AluminumLilian Jefferson Malavazi100% (1)

- Phase Diagrams: Solubility LimitDocument163 pagesPhase Diagrams: Solubility LimitseaNo ratings yet

- Phase Transformations and Heat TreatmentDocument76 pagesPhase Transformations and Heat TreatmentJimmy HarvianNo ratings yet

- Lab 7 - Phase DiagramsDocument7 pagesLab 7 - Phase Diagramsabd333No ratings yet

- Stefanescu - Science and Engineering of Casting SolidificationDocument354 pagesStefanescu - Science and Engineering of Casting SolidificationThais FernandesNo ratings yet

- Application of MetalsDocument132 pagesApplication of MetalsMohammed Ashiq0% (1)

- Assignment 8 SolutionDocument6 pagesAssignment 8 SolutionBrishen Hawkins100% (1)

- Aluminum Casting FundamentalDocument9 pagesAluminum Casting FundamentalchinwaihoongNo ratings yet

- AlFeCu ReviewDocument25 pagesAlFeCu ReviewJaqueline Altidis100% (1)

- Thermal Equilibrium DiagramDocument65 pagesThermal Equilibrium DiagramShohel RanaNo ratings yet

- Animated Figure 9.20: SketchDocument11 pagesAnimated Figure 9.20: SketchmarkkkkkNo ratings yet

- Assignment PhaseDiaDocument5 pagesAssignment PhaseDiaAnshu Kumar GuptaNo ratings yet

- Phase DiagramsDocument14 pagesPhase DiagramsDave Harrison FloresNo ratings yet

- Iron-Iron Carbide Phase Diagram ExampleDocument3 pagesIron-Iron Carbide Phase Diagram ExampleBenjamin Enmanuel Mango DNo ratings yet