Professional Documents

Culture Documents

2023 NW - Solar Steam-Driven Membrane Filtration For High Flux Water Purification

2023 NW - Solar Steam-Driven Membrane Filtration For High Flux Water Purification

Uploaded by

Guilherme BuenoOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

2023 NW - Solar Steam-Driven Membrane Filtration For High Flux Water Purification

2023 NW - Solar Steam-Driven Membrane Filtration For High Flux Water Purification

Uploaded by

Guilherme BuenoCopyright:

Available Formats

nature water

Article https://doi.org/10.1038/s44221-023-00059-8

Solar steam-driven membrane filtration for

high flux water purification

Received: 29 April 2022 Xueyang Wang 1,4, Zhenhui Lin1,4, Jintong Gao2, Zhenyuan Xu 2,

Xiuqiang Li 3 , Ning Xu1, Jinlei Li1, Yan Song1, Hanyu Fu1, Wei Zhao1,

Accepted: 1 March 2023

Shuaihao Wang 1, Bin Zhu1, Ruzhu Wang 2 & Jia Zhu 1

Published online: 3 April 2023

Check for updates In recent years, interfacial solar steam generation has shown great potential

for desalination with high solar-to-steam conversion efficiency. However,

the freshwater production rate is still limited by the substantial latent heat

of water evaporation and condensation efficiency. Here we designed an

interfacial solar steam-driven reverse osmosis/nanofiltration device that

generates high pressure that pushes water molecules through a filtration

membrane to achieve separation from ions. The solar steam-driven reverse

osmosis device reaches a water production rate as high as 81 kg m−2 h−1

under 12 sun illumination. Moreover, a theoretical model indicates that

there still exists attractive room to further improve the freshwater output

by optimizing the thermal insulation and expansion ratio of the device.

This work paves a new way to design highly efficient miniaturized or

decentralized drinking water devices.

In recent years, with the growth of the population and the rise of indus- separation membrane, has a low theoretical thermodynamic energy.

trialization, freshwater resources have become very scarce1–3. Solar The ideal energy consumption of the thermodynamically constant-

thermal desalination, especially interfacial solar steam generation with pressure RO filtration process for seawater at 35,000 ppm salt is

dramatically improved evaporation efficiency4–18, offers a promising 1.6 kWh m−3 (refs. 47–49). The actual energy spent in the RO stage with a

pathway to alleviate the water crisis with minimum environmental typical water recovery of 50% is ~1.8 kWh m−3 (6.48 kJ kg−1), approaching

impact. Advanced interfacial solar heating techniques show more than the thermodynamic limit49,50.

90% energy efficiency and flourishing application prospects19–35. How- Here, we first combine interfacial solar steam generation technol-

ever, evaporation needs to overcome the vaporization enthalpy of ogy with membrane filtration-based water purification technology

water (which varies slightly around 2,455.6 kJ kg−1), which significantly to improve the water production rate of solar thermal desalination.

limits the solar to freshwater output. Typically, the theoretical water Specifically, the high-temperature high-pressure steam generated by

evaporation rate of the single-stage solar still is about 1.47 kg m−2 h−1 interfacial solar heating pushes water molecules through the RO/NF

under 1 sun illumination32,36. Although some technologies, such as membrane to achieve separation from ions. Compared with the conven-

multi-stage evaporation and low-pressure evaporation, have been tional solar-steam condensation method, the solar steam-driven (SSD)-

developed to increase the water production rate further, the vapori- RO/NF method dramatically reduces the energy required for separation

zation enthalpy of water is still considerable (achieving, for example, since it avoids the direct evaporation of water molecules (Fig. 1a).

a water production rate of 2.94 kg m−2 h−1 under 1 sun illumination for According to the developed theoretical model, the theoretical water

ten-stage evaporation)37–46. production rate of the SSD-RO method is two orders of magnitude

On the other hand, reverse osmosis (RO)/nanofiltration (NF), higher than that of the single-stage solar-steam condensation method,

which realizes the separation of ions and water molecules through a and is comparable to and even greater than that of photovoltaic-driven

1

National Laboratory of Solid State Microstructures, College of Engineering and Applied Sciences, Jiangsu Key Laboratory of Artificial Functional

Materials, Nanjing University, Nanjing, P. R. China. 2Engineering Research Center of Solar Power and Refrigeration (MOE), Institute of Refrigeration and

Cryogenics, Shanghai Jiao Tong University, Shanghai, P. R. China. 3Key Laboratory for Intelligent Nano Materials and Devices of Ministry of Education, and

Institute for Frontier Science, Nanjing University of Aeronautics and Astronautics, Nanjing, P. R. China. 4These authors contributed equally: Xueyang Wang

and Zhenhui Lin. e-mail: xiuqiang.li@nuaa.edu.cn; jiazhu@nju.edu.cn

Nature Water | Volume 1 | April 2023 | 391–398 391

Article https://doi.org/10.1038/s44221-023-00059-8

Solar steam-driven filtration system

RO/NF

Piston Brine membrane

Steam

Pressure

Solar evaporator

Freshwater

Interfacial solar heating

b c 300

1,200

production rate (kg kWh–1)

Theoretical steam

Theoretical water

temperature (K)

1,000

200

800

100

600

400

0

0 10 20 30 0 10 20 30

Solar power density (kW m–2) Solar power density (kW m–2)

Fig. 1 | A schematic and the theoretical water production rate of the b, The theoretical steady-state temperature of steam achieved by interfacial

SSD-RO/NF system. a, A schematic of the SSD-RO/NF system. High-temperature solar heating with ideal thermal insulation. Water was the medium of interfacial

high-pressure steam generated by interfacial solar heating pushes water solar heating to generate steam in the calculation. c, The theoretical water

molecules through the RO/NF membrane to achieve separation from ions. production rate of the SSD-RO method.

RO (PV-RO) (Fig. 1b,c; more details about the model can be found in the thermal conductivity51,52 less than 0.003 W m−1 K−1. The inner wall

Supplementary Figs. 1–6 and Supplementary Note 1). Experimentally of the booster cavity was attached to a waterproof SiO2 nano-aerogel

we achieved up to 81 kg m−2 h−1 under 12 sun illumination by designing felt with thermal conductivity of 0.012 W m−1 K−1 to further suppress

and optimizing the materials, optics, thermals and structures of the heat loss. The transparent glass at the top was made into a double-layer

SSD-RO device. This work is expected to provide a new strategy toward structure, with a vacuum (<5 Pa) between the two glass layers to inhibit

high throughput solar thermal desalination. heat transfer. Also, nylon with low thermal conductivity was selected as

the pressure-sensing piston under the premise of mechanical support.

Design and setup of the SSD-RO/NF device Numerical calculations also show that the expansion ratio of steam in

The design and construction of the SSD-RO/NF device are shown in the booster cavity is an important factor for the water production rate

Fig. 2. This SSD-RO/NF device mainly consists of a booster cavity, pres- of the SSD-RO/NF device. The expansion ratio relates to the amount

sure-sensing piston, seawater cavity, freshwater cavity and cylinder of internal energy of steam converted to mechanical energy for water

(Supplementary Figs. 7 and 8 and Supplementary Tables 1 and 2 for filtration53–55 (Supplementary Fig. 9 and Supplementary Note 2). Con-

the SSD-RO/NF device construction details). The high-temperature sidering the volume of the device and the minimum starting pressure

high-pressure steam is generated by interfacial solar heating in the of the RO/NF membrane, we achieved a maximum steam expansion

booster cavity. Then, the steam pushes the piston below and seawater ratio of 8. Finally, to prevent the condensation of small droplets dur-

through the RO/NF membrane to complete water filtration. According ing evaporation from affecting the transmittance, the inner wall of the

to our theoretical calculations, the thermal insulation performance of transparent glass was treated with O2 plasma and its surface was made

the device determines the temperature and pressure of steam, which super-hydrophilic56 (Supplementary Fig. 10).

further determine the water production rate of the SSD-RO/NF device

(Supplementary Fig. 2). Thus, the thermal insulation of the SSD-RO/ Design of the solar evaporator

NF device has been carefully designed and optimized. Specifically, the To ensure that interfacial solar heating generates high-temperature

vacuum between the sidewall interlayers of the booster cavity and sea- high-pressure steam in the closed booster cavity, in addition to the

water cavity prominently suppresses heat conduction and convection. excellent thermal insulation SSD-RO/NF of the device, the solar evapo-

The vacuum between interlayers was pumped to less than 5 Pa to make rator should provide stable and efficient steam at high temperature and

Nature Water | Volume 1 | April 2023 | 391–398 392

Article https://doi.org/10.1038/s44221-023-00059-8

Pressure

sensor

High pressure steam

Temperature Sink

sensor

Booster cavity

Vacuum insulation Water

Seawater inlet

Sink cavity

Pressure-

sensing piston

Freshwater

RO/NF

cavity/outlet

membrane

Cylinder 20 cm

Fig. 2 | The design and setup of the SSD-RO/NF device. A schematic (left) and to insulate against heat conduction and convection. The pressure sensor and

photograph (right) of the SSD-RO/NF device. The SSD-RO/NF device is composed thermocouples were attached in the booster cavity to monitor the temperature

of a booster cavity, pressure-sensing piston, seawater cavity, freshwater cavity, and pressure of the steam.

RO/NF membrane and cylinder. The vacuum in the sidewall interlayers was used

high pressure. To obtain this unique evaporator, it is essential to care- experimental setup. Thermocouples located at the above evaporator

fully tailor structures for both high temperature/pressure resistance (T-steam) and evaporative ethanol medium (T-bulk) were attached

and heat localization, in addition to general considerations of optical to monitor the internal temperature of the booster cavity. A pressure

design and water supply. We developed an evaporator consisting of a detector (P-steam) is mounted on the upper right side of the booster

top solar absorber and bottom thermal insulator (Fig. 3a). As the pivotal cavity to detect the real-time pressure of steam. The output of fresh-

part of the evaporator, the top solar absorber needs to have microme- water (M-freshwater) was measured by a quality balance. In the proof-

tre-sized pores for vapour escape, efficient solar absorption, water of-concept test, ethanol was chosen as the medium of interfacial solar

supply and high temperature/pressure resistance. Therefore, carbon heating in the booster cavity because the vaporization enthalpy of

foam was chosen as the initial substrate for solar absorber fabrication ethanol is ~920 kJ kg−1, which is much less than that of water, and high

because of its porous structure and high temperature/pressure resist- pressures are more likely to occur at low temperatures59. The transient

ance. To enhance hydrophilicity and solar absorption57,58, the original pressure behaviour of ethanol steam in the booster cavity under various

surface of carbon foam was coated with multi-walled carbon nano- solar power densities is shown in Fig. 4b. The final steady-state pres-

tubes (CNTs). Scanning electron microscopy (SEM) images are shown in sures reached 0.21, 0.34, 0.60, 0.84, 0.97 and 1.12 MPa under 2, 3, 5, 8,

Fig. 3b,c. Water contact angle measurement shows that the surface of 10 and 12 suns, respectively. The experimental steady-state tempera-

the carbon foam/CNTs becomes hydrophilic, which is ideal for efficient ture of steam is shown in Fig. 4c, which agrees well with our COMSOL

water supply (Fig. 3d). Figure 3e suggests that the carbon foam/CNTs simulation. The minor deviations are probably due to uncertainties in

achieves a high solar absorption of 98.7% (from 280 to 2,500 nm) after the experimental measurements and simplifications in the model (see

coating CNTs, compared with the 92.4% solar absorption of the original model details in Supplementary Note 4). Notably, the temperature of

carbon foam (see Methods for more details about fabrication). Due to the bulk ethanol increased only slightly under various solar densities,

the excellent thermal stability of carbon foam/CNTs, after annealing at which means that most energy is utilized for the generation of high-

200, 400 and 600 °C for 2 h successively, its porous structure retains temperature high-pressure steam (Supplementary Figs. 12 and 13).

integrity (Fig. 3f–h), and its solar absorption has been maintained at Then, we studied the water production performance of the SSD-

~98% (Fig. 3e). Thermogravimetry (TG) also provides direct evidence RO/NF device using simulated seawater with 10,000 mg l−1 NaCl. The

of its excellent thermal stability, revealing almost no weight loss below work process of the SSD-RO/NF device is shown in Supplementary

600 °C. The conventional carbon black/non-woven absorber initially Figs. 14–16. The results show that RO membrane filtration started at

decomposes at ~70 °C and almost completely decomposes at ~500 °C 12 suns, and the water production rate reached 81 kg m−2 h−1 (with a

(Fig. 3i). Additionally, a bottom stand should have a low density for ratio of the water production rate to the incident solar flux of

floating and low thermal conductivity for heat localization. After careful 6.75 kg kWh−1). The NF membrane is started at 5 suns, with water pro-

analysis and screening, high-temperature resistant aluminium silicate duction rates of 40, 78.2, 134.5 and 180.4 kg m−2 h−1 under 5, 8, 10 and

foam with a low thermal conductivity of <0.03 W m−1 K−1 was selected 12 suns, respectively (Fig. 4d). Moreover, the SSD-RO/NF device showed

for bottom floating and thermal insulation. In a closed system with an uncompromised stabilized water production rate after six cycles

high solar concentrations, the heat localization of the solar evapora- (Fig. 4e,f). The ion rejections of the SSD-RO/NF device were evaluated

tor is vital to achieving the high temperature of the solar evaporator. under 12 suns with 10,000 ppm feed solutions. The results show that

COMSOL simulations show that the temperature of the evaporator the rejections of Ca2+, Mg2+, SO2− + −

4 , Na and F are 99.98%, 99.96%, 99.98%,

increases by ~100 °C in a closed system when the thermal conductivity 99.5% and 99.97%, respectively, in the SSD-RO device. The ion concen-

of the solar evaporator decreases by an order of magnitude (from 0.4 trations in purified water are below the World Health Organization

to 0.04 W m−1 K−1) (Fig. 3j, Supplementary Note 3 and Fig. 11). standards for drinking water60 (Fig. 4g). The rejections reached 97.6%,

97%, 97.3%, 73.5% and 97.3% for Ca2+, Mg2+, SO2− + −

4 , Na and F in the SSD-NF

Performance of the SSD-RO/NF device device (Fig. 4g). A comparison of the performance of our SSD-RO device

With the desired design of the SSD-RO/NF device and evaporator, the with several recent works on passive solar steam evaporation

performance of the SSD-RO/NF device was next characterized with and condensation is shown in Fig. 4h and Supplementary Table 3. The

a high-powered solar simulator. Figure 4a shows a schematic of the water production rate of the SSD-RO device is much higher than

Nature Water | Volume 1 | April 2023 | 391–398 393

Article https://doi.org/10.1038/s44221-023-00059-8

a b c

Thermal insulator

floating

d e 100 i

100

After contact

Spectral instensity (a.u.)

98

80

Absorption (%)

102.2° Carbon foam

Weight (%)

96 60

Carbon foam/CNTs

After 200 °C

94 After 400 °C 40

After 600 °C Carbon black

20 /non-woven

92

Carbon foam Carbon foam Carbon foam

/CNTs 0 /CNTs

90

500 1,000 1,500 2,000 2,500 25 200 400 600

Wavelength (nm) Temperature (°C)

f g h j

400

Temperature (°C)

300

200

1 sun

2 suns 4 suns

100 3 suns 5 suns

0.01 0.04 0.10 0.40

K (W m–1 K–1)

Fig. 3 | Designs and characterizations of the solar evaporator of the SSD- that the solar absorption of the carbon foam/CNTs remains at ~98%. f–h, SEM

RO/NF device. a, A schematic of the solar evaporator of the SSD-RO/NF device images of the carbon foam/CNTs after high-temperature annealing at 200 °C

that consists of a top solar absorber (carbon foam/CNTs) and a bottom thermal (f), 400 °C (g) and 600 °C (h). Its porous structure retains integrity after high-

insulator (aluminium silicate foam). b, A SEM image of the carbon foam/CNTs. temperature annealing. Scale bar, 500 μm. Inset: optical photos of carbon

Scale bar, 500 μm. c, A high-resolution SEM image of CNTs on the carbon foam. foam/CNTs. Scale bar, 1 cm. i, TG curves of the carbon foam/CNTs and carbon

Scale bar, 200 nm. d, Water contact angles for the carbon foam and carbon black/non-woven. j, The simulated temperature of the solar evaporator with

foam/CNTs, suggesting that the carbon foam is hydrophobic while the carbon various thermal conductivities in the closed system. The dashed lines refer to

foam/CNTs is super-hydrophilic, as a water drop rapidly infiltrates into it in the temperature of the solar evaporator when the thermal conductivity is 0.04

only 2 ms. e, The solar absorption spectra of the carbon foam, carbon foam/ and 0.4, respectively. Much more energy is localized in the solar evaporator

CNTs and carbon foam/CNTs after high-temperature annealing, suggesting with lower thermal conductivity.

state-of-the-art solar steam evaporation and condensation systems. of 144.55 kg m−2 h−1. When the SSD-NF device generated a pressure of

Although not within the scope of this work, it shows similar perfor- 0.7 MPa under concentrated 12 suns on 21 June 2022, the water produc-

mance compared with PV-RO technologies (Supplementary Table 4 tion rate reached 245.07 kg m−2 h−1. The Na+ rejections of the SSD-RO

and Fig. 17). These results indicate that the SSD-RO/NF device is capable and SSD-NF devices are 99.5% and 72% (Supplementary Fig. 19). The

of high water production rates in which RO/NF filtration is driven by NaCl concentration in the feed solution is 10,000 ppm. The water

interfacial solar steam generation. production cost of the laboratory-level SSD-RO desalination system

To further demonstrate the performance in its practical applica- was estimated using the life cycle cost method to be about US$11.79/

tion, an outdoor experiment was conducted in Nanjing, China. As tonne (Supplementary Note 5 and Table 5).

shown in Supplementary Fig. 18, a Fresnel lens was used to concentrate

sunlight onto the device. The real-time solar irradiation during the Model simulation and calculation

experiment was recorded by a meteorological station. When natural To gain insights into the present experiment and obtain a guideline

sunlight was concentrated to 16 suns on 1 July 2022, the SSD-RO device for further improving the water production rate of the SSD-RO/NF

generated a pressure of 1.1 MPa and reached a water production rate device, we used a theoretical model consisting of COMSOL simulation

Nature Water | Volume 1 | April 2023 | 391–398 394

Article https://doi.org/10.1038/s44221-023-00059-8

a b c

200

1.2 2 suns 3 suns 5 suns

8 suns 10 suns

Steam temperature (°C)

150

12 suns

Pressure (MPa)

0.8

P-steam 100

Experimental

0.4

T-steam 50 Simulated

T-bulk 0 0

0 30 60 90 0 2 4 6 8 10 12

Time (min) Solar power density (kW m–2)

d 200 e 100

80

Water production rate

Water production rate

150

SSD-NF

(kg m–2 h–1)

(kg m–2 h–1)

SSD-RO 60

100

40

50

20

0

0

2 4 6 8 10 12 1 2 3 4 5 6

M-freshwater

Solar power density (kW m–2) SSD-RO cycle

f g h

5 suns 8 suns

NF RO 100 Condensation

200 10 suns 12 suns 100

Purified water production

Evaporation

Water production rate

80 Our work

rate (kg m–2 h–1)

150

(kg m–2 h–1)

Rejection (%)

10

60

100

40

50 1

20

0

0

1 2 3 4 5 6 F–

Ca2+ Mg2+ SO42– Na+ 1,000 10,000

SSD-NF cycle

Solar power density (W m–2)

Fig. 4 | Performance of the SSD-RO/NF device. a, A schematic of the SSD-RO/NF device under various solar power densities. e, The water production

experimental setup. The pressure of the steam (P-steam), the temperature of rate of the SSD-RO device under 12 sun illumination over six cycles. f, The water

the steam (T-steam), the temperature of the bulk (T-bulk) and the mass of the production rate of the SSD-NF device under various solar power densities over

produced freshwater (M-freshwater) during the test were carefully monitored six cycles. g, The rejection of five primary ions for the SSD-RO/NF device for

and recorded. b, The real-time pressure of steam in the booster cavity under concentrations in the feed solutions of 10,000 ppm. h, A comparison of the

various solar power densities. c, The measured and simulated steady-state water production rate of the SSD-RO device with previous passive solar steam

temperature of steam in the booster cavity under various solar power densities. evaporation and condensation works. A complete list of the results reported in

The data are presented as mean ± s.d. (n = 5). d, The water production rate of the this graph is given in Supplementary Table 3.

and numerical calculation. The COMSOL simulation takes the thermal illumination. When the expansion ratio is further increased (from 5

insulation of the SSD-RO device as input and predicts the steady-state to 6), the water production rate increases from 124.5 to 131.1 kg kWh−1

temperature of the steam. The numerical model calculates the water under 30 sun illumination. Clearly, further improvements in water

production rate of the SSD-RO device on the basis of the simulated production rate are achieved by further optimizing the thermal

steady-state temperature of the steam. As shown in Fig. 5a (where the insulation and expansion ratio of the device. More details about the

heat transfer coefficient is h = 5 and the emittance ε = 0.86, describ- model can be found in Supplementary Note 4, Figs. 20 and 21, and

ing the actual thermal insulation of our designed device, red line), Tables 6 and 7.

the simulated steady-state temperature is in good agreement with

the experimental measurements (Fig. 4c). It is found that, when we Conclusions

further reduce h and ε, the simulated steady-state temperature of the We successfully developed an SSD-RO/NF device for water purification.

steam and the water production rate increase observably under the After careful designs and experiments, the SSD-RO device is demon-

same solar power density (Fig. 5a,b). For example, when the thermal strated to have a water production rate of up to 81 kg m−2 h−1 under

insulation reaches h = 1, ε = 0.15, the simulated steady-state tempera- 12 sun illumination, much higher than previous works on passive solar

ture is increased from 553 to 646 K, and the corresponding water steam evaporation and condensation. Future devices with better ther-

production rate is increased from 107.1 to 124.5 kg kWh−1 under 30 sun mal insulation designs and a more rational expansion ratio to achieve

Nature Water | Volume 1 | April 2023 | 391–398 395

Article https://doi.org/10.1038/s44221-023-00059-8

a 700 b

h = 1, ε = 0.15, V2/V1 = 6

h = 1, ε = 0.15

140 h = 1, ε = 0.15, V2/V1 = 5

h = 1, ε = 0.86

Predicted water production

Steam temperature (K)

600 h = 5, ε = 0.86 h = 1, ε = 0.86, V2/V1 = 5

h = 5, ε = 0.86, V2/V1 = 5

rate (kg kWh–1)

120

500

100

400

300 80

0 10 20 30 0 10 20 30

Solar power density (kW m–2) Solar power density (kW m–2)

Fig. 5 | Analysis and simulation of the SSD-RO device performance. a, The is described by h = 5 and ε = 0.86 . b, The predicted water production rate of the

simulated temperature of the steam with various thermal insulations, including SSD-RO device with various thermal insulations and expansion ratios. V2/V1 is the

conduction and convection. The actual thermal insulation of the device (red line) expansion ratio.

higher water production rates are desired. It is also believed that this Data availability

strategy could improve the decentralized economic feasibility and The data generated or analysed during this study are included in this

reliability of solar thermal desalination devices and contribute solidly published article and its supporting information files. Source data are

to the global water–energy nexus. provided in this paper. Supplementary figure source data are also avail-

able on Figshare at https://doi.org/10.6084/m9.figshare.22188103.v1.

Methods

Preparation of the carbon foam/CNT absorber References

Carbon foam of type PPI 110 (110 pores per inch) was purchased from S. 1. Mekonnen, M. M. & Hoekstra, A. Y. Four billion

S. New Materials. A certain amount of CNTs was dispersed in a mixture people facing severe water scarcity. Sci. Adv. 2,

of water (97.6 wt%) and N-methyl-2-pyrrolidone (2.4 wt%) to form a sus- e1500323 (2016).

pension with concentration of 2 mg ml−1 by ultrasonic vibration for 1 h 2. Haddeland, I. et al. Global water resources affected by human

and then coated on carbon foam with vacuum assistance. The obtained interventions and climate change. Proc. Natl Acad. Sci. USA 111,

carbon foam/CNTs was dried at 70 °C in a vacuum for 30 min. Typically, 3251–3256 (2014).

CNT suspension solution volumes of 3 ml were used to prepare carbon 3. Shannon, M. A. et al. Science and technology for water

foam/CNTs with a diameter of 4 cm. purification in the coming decades. Nature 452, 301–310 (2008).

4. Zhou, L. et al. 3D self-assembly of aluminium nanoparticles

Measurement of water production rate for plasmon-enhanced solar desalination. Nat. Photonics 10,

A solar simulator (HPL-F1000; Ploptics) was used for the indoor 393–398 (2016).

water filtration tests. The solar flux/absorber area was 28.26 cm2 in 5. Wang, X. et al. An interfacial solar heating assisted liquid sorbent

the indoor water filtration tests. The incident intensity of sunlight atmospheric water generator. Angew. Chem. Int. Ed. 131, 12182–

was measured by using a thermopile sensor (PowerMax-USB PM 30; 12186 (2019).

COHERENT). The steam and bulk temperatures were monitored by 6. Li, X. et al. Graphene oxide-based efficient and scalable solar

using K-type thermocouples. The mass change of the filtered water desalination under one sun with a confined 2D water path. Proc.

was recorded by a high-accuracy electronic balance (FA 2004, 0.1 mg Natl Acad. Sci. USA 113, 13953–13958 (2016).

accuracy) and later used to determine the water production rate. All 7. Zhou, L. et al. Self-assembly of highly efficient, broadband

indoor tests were performed at a temperature of ~25 °C and relative plasmonic absorbers for solar steam generation. Sci. Adv. 2,

humidity of ~50%. The RO and NF membranes were purchased from e1501227 (2016).

RisingSun Membrane Technology. The concentrations of ions in the 8. Hu, X. et al. Tailoring graphene oxide‐based aerogels for efficient

filtered water were examined by inductively coupled plasma optical solar steam generation under one sun. Adv. Mater. 29, 1604031

emission spectroscopy (PTIMA 5300 DV; PerkinElmer). The area of (2017).

solar flux is the same as the area of the absorber (50.26 cm2) in the 9. Ni, G. et al. Steam generation under one sun enabled by a

outdoor water filtration tests. The ambient temperature for the out- floating structure with thermal concentration. Nat. Energy 1,

door test was ~35 °C. 16126 (2016).

10. Zhao, F. et al. Highly efficient solar vapour generation via

Material characterizations hierarchically nanostructured gels. Nat. Nanotechnol. 13,

Micro images of the carbon foam/CNTs were captured by SEM (MIRA3; 489–495 (2018).

TESCAN). An ultraviolet–visible spectroscope (UV-3600; Shimadzu) 11. He, S. et al. Nature-inspired salt resistant bimodal porous solar

equipped with an integrating sphere (ISR-3100) was used to measure evaporator for efficient and stable water desalination. Energy

the solar absorption spectra of the samples in the 280–2,500 nm range. Environ. Sci. 12, 1558–1567 (2019).

TG analysis was carried out by using a simultaneous thermal analyser 12. Xu, W. et al. Efficient water transport and solar steam generation

(STA449; Netzsch) under flowing air at a heating rate of 10 °C min−1. via radially, hierarchically structured aerogels. ACS Nano 13,

High-temperature annealing of the carbon foam/CNTs was carried 7930–7938 (2019).

out by using a ceramic fibre muffle furnace (TMF-4-13TP; Zhetu). The 13. Zhang, P., Li, J., Lv, L., Zhao, Y. & Qu, L. Vertically aligned graphene

water contact angles of the samples were measured by using a surface sheets membrane for highly efficient solar thermal generation of

tension–contact angle meter (Digidrop; GBX). clean water. ACS Nano 11, 5087–5093 (2017).

Nature Water | Volume 1 | April 2023 | 391–398 396

Article https://doi.org/10.1038/s44221-023-00059-8

14. Li, Y. et al. 3D‐printed, all‐in‐one evaporator for high‐efficiency 38. Zhang, L. et al. Passive, high-efficiency thermally-localized solar

solar steam generation under 1 sun illumination. Adv. Mater. 29, desalination. Energy Environ. Sci. 14, 1771–1793 (2021).

1700981 (2017). 39. Brogioli, D., La Mantia, F. & Yip, N. Y. Thermodynamic analysis and

15. Li, J. et al. Interfacial solar steam generation enables fast‐ energy efficiency of thermal desalination processes. Desalination

responsive, energy‐efficient, and low‐cost off‐grid sterilization. 428, 29–39 (2018).

Adv. Mater. 30, 1805159 (2018). 40. Chiavazzo, E., Morciano, M., Viglino, F., Fasano, M. & Asinari, P.

16. Li, X., Cooper, T., Xie, W. & Hsu, P.-C. Design and utilization of Passive solar high-yield seawater desalination by modular and

infrared light for interfacial solar water purification. ACS Energy low-cost distillation. Nat. Sustain. 1, 763–772 (2018).

Lett. 6, 2645–2657 (2021). 41. Hu, Y. et al. A reconfigurable and magnetically responsive

17. Ghasemi, H. et al. Solar steam generation by heat localization. assembly for dynamic solar steam generation. Nat. Commun. 13,

Nat. Commun. 5, 4449 (2014). 4335 (2022).

18. Bae, K. et al. Flexible thin-film black gold membranes with 42. Mu, X. et al. A robust starch-polyacrylamide hydrogel with

ultrabroadband plasmonic nanofocusing for efficient solar vapour scavenging energy harvesting capacity for efficient solar

generation. Nat. Commun. 6, 10103 (2015). thermoelectricity-freshwater cogeneration. Energy Environ. Sci.

19. Xu, N. et al. Synergistic tandem solar electricity-water generators. 15, 3388–3399 (2022).

Joule 4, 347–358 (2020). 43. Wang, F. et al. A high-performing single-stage invert-structured

20. Xia, Y. et al. Spatially isolating salt crystallisation from water solar water purifier through enhanced absorption and

evaporation for continuous solar steam generation and salt condensation. Joule 5, 1602–1612 (2021).

harvesting. Energy Environ. Sci. 12, 1840–1847 (2019). 44. Xu, N. et al. A water lily-inspired hierarchical design for stable

21. Wu, L. et al. Highly efficient three-dimensional solar evaporator and efficient solar evaporation of high-salinity brine. Sci. Adv. 5,

for high salinity desalination by localized crystallization. Nat. eaaw7013 (2019).

Commun. 11, 521 (2020). 45. Wang, W. et al. Simultaneous production of fresh water

22. Zhao, L. et al. A passive high-temperature high-pressure solar and electricity via multistage solar photovoltaic membrane

steam generator for medical sterilization. Joule 4, 2733–2745 distillation. Nat. Commun. 10, 3012 (2019).

(2020). 46. Geng, H. et al. Plant leaves inspired sunlight-driven purifier for

23. Yang, P. et al. Solar-driven simultaneous steam production and high-efficiency clean water production. Nat. Commun. 10, 1512

electricity generation from salinity. Energy Environ. Sci. 10, (2019).

1923–1927 (2017). 47. Spiegler, K. & El-Sayed, Y. The energetics of desalination

24. Zhang, Y. et al. Manipulating unidirectional fluid transportation processes. Desalination 134, 109–128 (2001).

to drive sustainable solar water extraction and brine-drenching 48. Stoughton, R. & Lietzke, M. Calculation of some thermodynamic

induced energy generation. Energy Environ. Sci. 13, 4891–4902 properties of sea salt solutions at elevated temperatures from

(2020). data on NaCl solutions. J. Chem. Eng. Data 10, 254–260 (1965).

25. Li, J. et al. Over 10 kg m−2 h−1 evaporation rate enabled 49. Wang, Z. et al. Pathways and challenges for efficient solar-thermal

by a 3D interconnected porous carbon foam. Joule 4, desalination. Sci. Adv. 5, eaax0763 (2019).

928–937 (2020). 50. Elimelech, M. & Phillip, W. A. The future of seawater desalination:

26. Xu, N. et al. A scalable fish-school inspired self-assembled energy, technology, and the environment. Science 333, 712–717

particle system for solar-powered water-solute separation. Natl (2011).

Sci. Rev. 8, nwab065 (2021). 51. Kwon, J.-S., Jang, C. H., Jung, H. & Song, T.-H. Effective thermal

27. Xu, N. et al. Mushrooms as efficient solar steam‐generation conductivity of various filling materials for vacuum insulation

devices. Adv. Mater. 29, 1606762 (2017). panels. Int. J. Heat Mass Transf. 52, 5525–5532 (2009).

28. Li, X. et al. Enhancement of interfacial solar vapor generation by 52. Wakili, K. G., Stahl, T. & Brunner, S. Effective thermal conductivity

environmental energy. Joule 2, 1331–1338 (2018). of a staggered double layer of vacuum insulation panels. Energy

29. Singh, S. C. et al. Solar-trackable super-wicking black metal Build. 43, 1241–1246 (2011).

panel for photothermal water sanitation. Nat. Sustain. 3, 938–946 53. Organ, A. J. Thermodynamics and Gas Dynamics of the Stirling

(2020). Cycle Machine (Cambridge Univ. Press, 1992).

30. Shi, Y., Ilic, O., Atwater, H. A. & Greer, J. R. All-day fresh water 54. Formosa, F. & Despesse, G. Analytical model for Stirling cycle

harvesting by microstructured hydrogel membranes. Nat. machine design. Energy Convers. Manag. 51, 1855–1863 (2010).

Commun. 12, 2797 (2021). 55. Bao, J. & Zhao, L. A review of working fluid and expander

31. Zhang, L. et al. Highly efficient and salt rejecting solar evaporation selections for organic Rankine cycle. Renew. Sust. Energ. Rev. 24,

via a wick-free confined water layer. Nat. Commun. 13, 849 (2022). 325–342 (2013).

32. Zhou, L., Li, X., Ni, G. W., Zhu, S. & Zhu, J. The revival of thermal 56. DeRosa, R. L., Schader, P. A. & Shelby, J. E. Hydrophilic nature of

utilization from the Sun: interfacial solar vapor generation. Natl silicate glass surfaces as a function of exposure condition. J. Non-

Sci. Rev. 6, 562–578 (2019). cryst. Solids 331, 32–40 (2003).

33. Li, X. et al. Storage and recycling of interfacial solar steam 57. Xiong, Z. C., Zhu, Y. J., Qin, D. D., Chen, F. F. & Yang, R. L.

enthalpy. Joule 2, 2477–2484 (2018). Flexible fire‐resistant photothermal paper comprising ultralong

34. Menon, A. K., Haechler, I., Kaur, S., Lubner, S. & Prasher, R. S. hydroxyapatite nanowires and carbon nanotubes for solar energy‐

Enhanced solar evaporation using a photo-thermal umbrella for driven water purification. Small 14, 1803387 (2018).

wastewater management. Nat. Sustain. 3, 144–151 (2020). 58. Zhang, Q., Xu, W. & Wang, X. Carbon nanocomposites with high

35. Ni, G. et al. A salt-rejecting floating solar still for low-cost photothermal conversion efficiency. Sci. China Mater. 61, 905–914

desalination. Energy Environ. Sci. 11, 1510–1519 (2018). (2018).

36. Tao, P. et al. Solar-driven interfacial evaporation. Nat. Energy 3, 59. Henke, S., Kadlec, P. & Bubník, Z. Physico-chemical properties of

1031–1041 (2018). ethanol—compilation of existing data. J. Food Eng. 99, 497–504

37. Xu, Z. et al. Ultrahigh-efficiency desalination via a thermally- (2010).

localized multistage solar still. Energy Environ. Sci. 13, 830–839 60. Edition, F. Guidelines for drinking-water quality. WHO Chronicle

(2020). 38, 104–108 (2011).

Nature Water | Volume 1 | April 2023 | 391–398 397

Article https://doi.org/10.1038/s44221-023-00059-8

Acknowledgements Additional information

We acknowledge the micro-fabrication centre of the National Supplementary information The online version contains supplementary

Laboratory of Solid State Microstructures (NLSSM) for technique material available at https://doi.org/10.1038/s44221-023-00059-8.

support. J.Z. acknowledges support from the XPLORER PRIZE.

This work was jointly supported by the National Natural Science Correspondence and requests for materials should be addressed to

Foundation of China (nos. 51925204, 52102262, 52003116 and Xiuqiang Li or Jia Zhu.

92262305), Natural Science Foundation of Jiangsu Province (nos.

BK20220035 and BK20200340), National Key Research and Peer review information Nature Water thanks Jianhua Zhou and the

Development Program of China (no. 2022YFA1404704), Program for other, anonymous, reviewers for their contribution to the peer review

Innovative Talents and Entrepreneur in Jiangsu Province and Jiangsu of this work.

Planned Projects for Postdoctoral Research Funds (no. 2020Z018)

and Nanjing University of Aeronautics and Astronautics Startup Fund Reprints and permissions information is available at

(4017-YQR22012). www.nature.com/reprints.

Author contributions Publisher’s note Springer Nature remains neutral with regard to

J.Z., X.L. and X.W. conceived and planned this research. X.W., Y.S., W.Z. jurisdictional claims in published maps and institutional affiliations.

and S.W. did the experiments. X.W., Z.L., J.G., Z.X., N.X., J.L. and H.F.

contributed to the thermal model and theoretical calculation analysis. Springer Nature or its licensor (e.g. a society or other partner) holds

X.W., Z.L., N.X., J.L., B.Z., X.L., R.W. and J.Z. organized the data and exclusive rights to this article under a publishing agreement with

wrote the paper. All authors discussed the results and approved the the author(s) or other rightsholder(s); author self-archiving of the

final version of the paper. accepted manuscript version of this article is solely governed by the

terms of such publishing agreement and applicable law.

Competing interests

The authors declare no competing financial interests. Readers are © The Author(s), under exclusive licence to Springer Nature Limited

welcome to comment on the online version of the paper. 2023

Nature Water | Volume 1 | April 2023 | 391–398 398

You might also like

- Metric FoldableDocument2 pagesMetric FoldableChaswell Hanna100% (2)

- The Study On Combined Desalination and Power Generation System Using Solar PondDocument5 pagesThe Study On Combined Desalination and Power Generation System Using Solar PondSree HariNo ratings yet

- Solar Evaporation of WaterDocument7 pagesSolar Evaporation of WaterAbrahamNo ratings yet

- 2021 - Achieving High-Quality Freshwater From A Self-Sustainable Integrated Solar Redox-Flow Desalination DeviceDocument9 pages2021 - Achieving High-Quality Freshwater From A Self-Sustainable Integrated Solar Redox-Flow Desalination Deviceary.engenharia1244No ratings yet

- Hydrogen 02 00002 v3Document15 pagesHydrogen 02 00002 v3hammadbedo00No ratings yet

- 1 - Published ArticleDocument7 pages1 - Published Articleالسيد ابراهيم عبدالعزيز عبداللهNo ratings yet

- Parametric Investigation of A Double-Effect SolarDocument10 pagesParametric Investigation of A Double-Effect SolarkgmaheswaranNo ratings yet

- BaboiDocument11 pagesBaboiSiyyadula Chandra SekharNo ratings yet

- 1 s2.0 S0011916423000942 MainDocument13 pages1 s2.0 S0011916423000942 MaintulusnadumaNo ratings yet

- Theoretical and Experimental Investigation On A GAX Based NH3 H2O - 2020 - SolarDocument13 pagesTheoretical and Experimental Investigation On A GAX Based NH3 H2O - 2020 - SolarLENNART CHRIS BRUNA MUÑOZNo ratings yet

- Desalination: Shalabh C. Maroo, D. Yogi GoswamiDocument12 pagesDesalination: Shalabh C. Maroo, D. Yogi Goswamiابانوب جمالNo ratings yet

- Basic Hydrodynamic Aspects of A Solar Energy Based Desalination ProcessDocument10 pagesBasic Hydrodynamic Aspects of A Solar Energy Based Desalination Processagmibrahim5055No ratings yet

- Applied Energy: Shuang-Fei Li, Zhen-Hua Liu, Zhi-Xiong Shao, Hong-Shen Xiao, Ning XiaDocument10 pagesApplied Energy: Shuang-Fei Li, Zhen-Hua Liu, Zhi-Xiong Shao, Hong-Shen Xiao, Ning XiamohamedNo ratings yet

- 2ahsan SS TEDocument10 pages2ahsan SS TEahsan.iut2No ratings yet

- Analysis of An Innovative Water Desalination System UsingDocument10 pagesAnalysis of An Innovative Water Desalination System Usingbandi.shandrasekharNo ratings yet

- OTECDocument14 pagesOTECTALLURI LAKSHMI PRASANNANo ratings yet

- Simulated Production of Electric Power and Desalination Using Solar-OTEC Hybrid SystemDocument13 pagesSimulated Production of Electric Power and Desalination Using Solar-OTEC Hybrid SystemamfNo ratings yet

- Harvesting Water Drop Energy by A Sequential Contact Electrification andDocument7 pagesHarvesting Water Drop Energy by A Sequential Contact Electrification andREIVAX LOL REPLAYSNo ratings yet

- 6 - 2009 - El-Sebaii - Thermal Performance of A Single Basin Solar Still With PCM As Storage MediumDocument9 pages6 - 2009 - El-Sebaii - Thermal Performance of A Single Basin Solar Still With PCM As Storage Mediumnadeem fazalNo ratings yet

- Solar-Assisted Dual-Effect Adsorption Cycle For THDocument8 pagesSolar-Assisted Dual-Effect Adsorption Cycle For THGonzalo BenavidesNo ratings yet

- Abud ArabiDocument10 pagesAbud ArabiClemen AlarconNo ratings yet

- Challenges and Opportunities For Solar Evaporation: ReviewDocument36 pagesChallenges and Opportunities For Solar Evaporation: Reviewkhairani najibahNo ratings yet

- Comparison of Alternative Molten Electrolytes For Water Splitting To Generate Hydrogen FuelDocument8 pagesComparison of Alternative Molten Electrolytes For Water Splitting To Generate Hydrogen FuelOgie CabNo ratings yet

- Solar Water Purification Research PaperDocument4 pagesSolar Water Purification Research Paperpkzoyxrif100% (1)

- Efficient Desalination by Layered Heating of Saline Waterjournal of Physics Conference SeriesDocument14 pagesEfficient Desalination by Layered Heating of Saline Waterjournal of Physics Conference SeriesMaria Fernanda Viteri OrozcoNo ratings yet

- Naim 2003Document10 pagesNaim 2003Jyotin KateshiaNo ratings yet

- Song Et Al-2018-Advanced ScienceDocument9 pagesSong Et Al-2018-Advanced ScienceAli CiritNo ratings yet

- Ctae 004Document12 pagesCtae 004Kannadas PuthuvalNo ratings yet

- EnergíaDocument12 pagesEnergíaSHEILA GINIVA BUSTOS YAIMANo ratings yet

- Enhancement of Distillate Output of Double Basin Solar Still With Vacuum TubesDocument6 pagesEnhancement of Distillate Output of Double Basin Solar Still With Vacuum TubesNanthakumarNo ratings yet

- Passive Solar High-Yield Seawater Desalination by Modular and Low-Cost DistillationDocument10 pagesPassive Solar High-Yield Seawater Desalination by Modular and Low-Cost DistillationAngelina GultomNo ratings yet

- 10 1016@j Solmat 2020 110489Document12 pages10 1016@j Solmat 2020 110489김종구No ratings yet

- Operational Strategy of A Two-Step Thermochemical Process For Solar Hydrogen ProductionDocument9 pagesOperational Strategy of A Two-Step Thermochemical Process For Solar Hydrogen ProductiondavidoncyNo ratings yet

- Sakthivel 2010Document8 pagesSakthivel 2010ritikNo ratings yet

- Bubble Wrap The Key To A New Floating Solar Thermal SystemDocument2 pagesBubble Wrap The Key To A New Floating Solar Thermal SystemEditor IJTSRDNo ratings yet

- Enhanced Solar Evaporation Using A Photo-Thermal Umbrella: Towards Zero Liquid Discharge Wastewater ManagementDocument26 pagesEnhanced Solar Evaporation Using A Photo-Thermal Umbrella: Towards Zero Liquid Discharge Wastewater Managementgovinda reddyNo ratings yet

- 1 s2.0 S2214714421004360 MainDocument11 pages1 s2.0 S2214714421004360 MainAJAYNo ratings yet

- Sustainable Seawater Desalination by Permeate Gap Membrane Distillation TechnologyDocument6 pagesSustainable Seawater Desalination by Permeate Gap Membrane Distillation Technologymona aminNo ratings yet

- 1 s2.0 S2214157X23011747 MainDocument16 pages1 s2.0 S2214157X23011747 MainNura MuazNo ratings yet

- Intro To Osmotic Power Osmotic Power Sistem BasicDocument4 pagesIntro To Osmotic Power Osmotic Power Sistem BasicSubzero BillNo ratings yet

- Wang 2017Document12 pagesWang 2017nicole delgadoNo ratings yet

- Yuan 2021Document13 pagesYuan 2021Sirine SaidiNo ratings yet

- Multi-Effect Solar Water Still With Evaporation Pressure Self-Reduction CapabilityDocument5 pagesMulti-Effect Solar Water Still With Evaporation Pressure Self-Reduction CapabilityMorteza KhashehchiNo ratings yet

- A Desalination BatteryDocument5 pagesA Desalination BatteryMarco Villegas BermúdezNo ratings yet

- Ocean Thermal Energy Conversion: UIS EGADocument33 pagesOcean Thermal Energy Conversion: UIS EGA1341131No ratings yet

- Performance Study of Fog Desalination System Coupled With Evacuated TubeDocument14 pagesPerformance Study of Fog Desalination System Coupled With Evacuated TubeAhmed HamedNo ratings yet

- B-C - 2017 - Theoretical Analysis To Determine The Efficiency of A CuO-water Nanofluid Based-Flat Plate Solar CollectorDocument12 pagesB-C - 2017 - Theoretical Analysis To Determine The Efficiency of A CuO-water Nanofluid Based-Flat Plate Solar Collectorsebastian perez murilloNo ratings yet

- ResearchDocument8 pagesResearchندى حسينNo ratings yet

- Simulation Modeling The Performance of OceanDocument12 pagesSimulation Modeling The Performance of OceanarunNo ratings yet

- FLACS SystemDocument10 pagesFLACS SystemSalvatore MonacoNo ratings yet

- C 0 FFDocument24 pagesC 0 FFSammmNo ratings yet

- Thermal Science and Engineering Progress: SciencedirectDocument10 pagesThermal Science and Engineering Progress: Sciencedirectابانوب جمالNo ratings yet

- Energy Conversion and Management: A.E. Kabeel, Z.M. Omara, F.A. EssaDocument6 pagesEnergy Conversion and Management: A.E. Kabeel, Z.M. Omara, F.A. EssaGauravGuptaNo ratings yet

- 1 s2.0 S0013468620313323 MainDocument11 pages1 s2.0 S0013468620313323 MainThong NguyenNo ratings yet

- Energy: H. Rosyid, R. Koestoer, N. Putra, Nasruddin, A.A. Mohamad, YanuarDocument9 pagesEnergy: H. Rosyid, R. Koestoer, N. Putra, Nasruddin, A.A. Mohamad, YanuarIvanNo ratings yet

- What Is Renewable EnergyDocument7 pagesWhat Is Renewable EnergyShubham SinghNo ratings yet

- Bay Kara 2004Document8 pagesBay Kara 2004Abderrahmane AbderrahmaniNo ratings yet

- Cost Analysis of Different Solar Still ConfigurationsDocument8 pagesCost Analysis of Different Solar Still ConfigurationshashimhasnainhadiNo ratings yet

- Elbar y Hamdy SSDocument4 pagesElbar y Hamdy SSClemen AlarconNo ratings yet

- Solar Desalination System Using Spray Ev PDFDocument8 pagesSolar Desalination System Using Spray Ev PDFMousaNo ratings yet

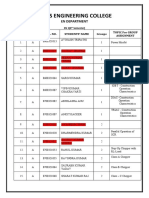

- Bmas Engineering College: en DepartmentDocument3 pagesBmas Engineering College: en DepartmentCharan MangipudyNo ratings yet

- Operation Instructions Danfoss - ENG PDFDocument84 pagesOperation Instructions Danfoss - ENG PDFrubicsNo ratings yet

- Astm d924 08Document7 pagesAstm d924 08Fany OchNo ratings yet

- Manual de Servicio de Split Marca Fujitsu Modelo Arg25alcDocument63 pagesManual de Servicio de Split Marca Fujitsu Modelo Arg25alcdaniel perezNo ratings yet

- Mech 2Document71 pagesMech 2Gino Mandado0% (1)

- MMMDocument34 pagesMMMVaibhav Vithoba NaikNo ratings yet

- Sinusoidal Waveform or Sine Wave in An AC Circuit PDFDocument16 pagesSinusoidal Waveform or Sine Wave in An AC Circuit PDFshahanbashaNo ratings yet

- UntitledDocument10 pagesUntitledLoveroop SinghNo ratings yet

- Dynamics 1e AnswersDocument28 pagesDynamics 1e AnswersArturo José Jumpa SanchezNo ratings yet

- NEET: (11th) Rotational Motion: QuestionsDocument32 pagesNEET: (11th) Rotational Motion: QuestionsSuriyanarayana KNo ratings yet

- Dissertation Topics Fluid MechanicsDocument6 pagesDissertation Topics Fluid MechanicsHowToFindSomeoneToWriteMyPaperSingapore100% (1)

- Overview of The Project 1.1Document44 pagesOverview of The Project 1.1sharmila saravananNo ratings yet

- P 6Document175 pagesP 6Paul Caesar100% (2)

- 202 Physics: Shaimaa Abd El-RaofDocument19 pages202 Physics: Shaimaa Abd El-RaofdrshimoNo ratings yet

- EBook Etextbook 978 0077687342 Vector Mechanics For Engineers Dynamics 11Th Edition PDF Docx Kindle Full ChapterDocument62 pagesEBook Etextbook 978 0077687342 Vector Mechanics For Engineers Dynamics 11Th Edition PDF Docx Kindle Full Chapterjesse.haywood244100% (38)

- Equation of StateDocument6 pagesEquation of StateJanardhan CnNo ratings yet

- Wpe 1 DPPDocument4 pagesWpe 1 DPPAbhaya RanjanNo ratings yet

- LMP 91200Document31 pagesLMP 91200brandt_br7991No ratings yet

- 3.2.1 Electric Dipole Elds in A Homogeneous Space: R J R P R R P R R R J R J R P P J R P R RDocument10 pages3.2.1 Electric Dipole Elds in A Homogeneous Space: R J R P R R P R R R J R J R P P J R P R RSanghyeok ParkNo ratings yet

- 05 Physics 11se Ub EndDocument6 pages05 Physics 11se Ub Endpecan_lisa38No ratings yet

- Electrical Machine & Control SystemsDocument24 pagesElectrical Machine & Control SystemsHatem DheerNo ratings yet

- Curriculum Map: School of Mount St. MaryDocument11 pagesCurriculum Map: School of Mount St. MaryJayson LabsanNo ratings yet

- AQA GCSE Physics Equation Practice Paper 2 Recall and Applyv1.1Document16 pagesAQA GCSE Physics Equation Practice Paper 2 Recall and Applyv1.1wasif.hello123100% (1)

- IC307 Industrial Instrumentation - IDocument2 pagesIC307 Industrial Instrumentation - IAKSHAY KRISHNA K RNo ratings yet

- Sage University Indore: Department of Computer Science and Information TechnologyDocument50 pagesSage University Indore: Department of Computer Science and Information TechnologyAbhishek PatelNo ratings yet

- McQuay MDB-ER Technical Manual Eng PDFDocument136 pagesMcQuay MDB-ER Technical Manual Eng PDFTaufik 'opics' AkbarNo ratings yet

- Lesson 5 332acDocument12 pagesLesson 5 332acSrinivasa Rao DNo ratings yet

- 101 ExercisesDocument94 pages101 ExercisesMichael A. Alonso RodriguezNo ratings yet

- Ansys Fluent Simulation Report SideDocument7 pagesAnsys Fluent Simulation Report SideA-31 Abhinav VermaNo ratings yet