Professional Documents

Culture Documents

1.14.1 MTC-11372 - Tube - 1 TUBING

1.14.1 MTC-11372 - Tube - 1 TUBING

Uploaded by

groupj.sr.servicesCopyright:

Available Formats

You might also like

- NUR 205-Week 5 Pre Class Assignment WI 21Document6 pagesNUR 205-Week 5 Pre Class Assignment WI 21Oliver Namyalo100% (3)

- Page 1 of 6: Test Certificate No. 0000052877Document6 pagesPage 1 of 6: Test Certificate No. 0000052877panduranganraghurama78% (9)

- Test Certificate 16mmDocument1 pageTest Certificate 16mmSabyasachi Bangal50% (4)

- Jindal Steel & Power Limited: Test Certificate No. 0000247591, Revision No. 000 Date: 03.09.2018Document1 pageJindal Steel & Power Limited: Test Certificate No. 0000247591, Revision No. 000 Date: 03.09.2018Mohammad Adil50% (2)

- BukowskiDocument5 pagesBukowskisalome davitulianiNo ratings yet

- MTC Inv 053 PDFDocument1 pageMTC Inv 053 PDFBeshnu Garanaik100% (2)

- 304 1.5MM PCDocument1 page304 1.5MM PCsabir hussain100% (1)

- Customer Specification Shipment/Delivery No.: GL 5.65 SODocument1 pageCustomer Specification Shipment/Delivery No.: GL 5.65 SOMANIMARAN QC100% (1)

- Test Method: Tensile: IS 1608 Bend: IS 1599 Impact: IS 1757 Chemical:ASTM E 415/ IS8811Document1 pageTest Method: Tensile: IS 1608 Bend: IS 1599 Impact: IS 1757 Chemical:ASTM E 415/ IS8811akash_smhs0% (1)

- ZTE H298A Admin ManualDocument19 pagesZTE H298A Admin Manualjosefm665699No ratings yet

- Dilip Tube 20 January 2023Document1 pageDilip Tube 20 January 2023पवन द्विवेदीNo ratings yet

- Tube 20 January 2023Document1 pageTube 20 January 2023पवन द्विवेदीNo ratings yet

- Customer Specification Shipment/Delivery No.: GL 5.65 SODocument1 pageCustomer Specification Shipment/Delivery No.: GL 5.65 SOParesh Mehta100% (1)

- Img 0001Document1 pageImg 0001Harish RanaNo ratings yet

- 1.5MM 304Document1 page1.5MM 304pankaj kumarNo ratings yet

- 2211J5444 90mm WeldablesDocument1 page2211J5444 90mm WeldablesChethan Nagaraju KumbarNo ratings yet

- Customer Specification Shipment/Delivery No.: GL 5.65 SODocument1 pageCustomer Specification Shipment/Delivery No.: GL 5.65 SOshekarNo ratings yet

- Customer Specification Shipment/Delivery No.: GL 5.65 SODocument1 pageCustomer Specification Shipment/Delivery No.: GL 5.65 SOBilal Luhar100% (2)

- Certificado Tubo 1.1-2 AC SC SCH 80 X 5.8-1Document1 pageCertificado Tubo 1.1-2 AC SC SCH 80 X 5.8-1Raul Esteban Jaimes GalvisNo ratings yet

- Ribo TC 324 (00000003)Document1 pageRibo TC 324 (00000003)Vinay YadavNo ratings yet

- UGINEDocument1 pageUGINEjesusNo ratings yet

- MetroDocument1 pageMetrotariqananNo ratings yet

- Customer Specification Shipment/Delivery No.: GL 5.65 SODocument1 pageCustomer Specification Shipment/Delivery No.: GL 5.65 SOarhamenterprises5401No ratings yet

- Western India Forgings PVT LTD: ISO 9001, IATF 16949, ISO 14001, OHSAS 18001, PED AD 2000 Merkblatt WO CERTIFIED COMPANYDocument1 pageWestern India Forgings PVT LTD: ISO 9001, IATF 16949, ISO 14001, OHSAS 18001, PED AD 2000 Merkblatt WO CERTIFIED COMPANYDeipak HoleNo ratings yet

- 4.0X1500. 23920 E250a DoDocument1 page4.0X1500. 23920 E250a Dosatyaprakashgond100% (1)

- MS Sheets MTCDocument6 pagesMS Sheets MTCAmit Kumar OjhaNo ratings yet

- 20MM - 63.150 TonDocument1 page20MM - 63.150 TonRAJKUMAR CHATTERJEE. (RAJA.)No ratings yet

- 20MM - 63.150 TonDocument1 page20MM - 63.150 TonRAJKUMAR CHATTERJEE. (RAJA.)No ratings yet

- Dossier Merla - ODB 4604279Document33 pagesDossier Merla - ODB 4604279Indira briceñoNo ratings yet

- Page 2 of 6: Test Certificate No. 0000052877Document1 pagePage 2 of 6: Test Certificate No. 0000052877pranesh kadam100% (2)

- Universal 1-2 Clase 6000 Tipo 316Document2 pagesUniversal 1-2 Clase 6000 Tipo 316comercial 3100% (1)

- Punjab Bevel Gears Ltd. Sahibabad.: KNL Driveline Parts Pvt. Ltd. Material Test CertificateDocument1 pagePunjab Bevel Gears Ltd. Sahibabad.: KNL Driveline Parts Pvt. Ltd. Material Test CertificateargmsfNo ratings yet

- Test CertificateDocument2 pagesTest CertificatePRITESH100% (2)

- Inspection Certificate: Customer: CommodityDocument1 pageInspection Certificate: Customer: CommodityGisella Mariel Rubilar100% (1)

- 2324MTC037 11362Document1 page2324MTC037 11362Shrikrushna DalviNo ratings yet

- Anup SS304L TC 1Document2 pagesAnup SS304L TC 1B.M Industrial Works100% (1)

- Aluminium Rod Material Detail PDFDocument1 pageAluminium Rod Material Detail PDFPradeep SNo ratings yet

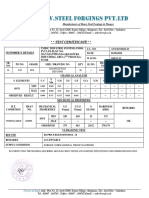

- A.V.Steel Forgings PVT - LTD: Test CertificateDocument1 pageA.V.Steel Forgings PVT - LTD: Test CertificateNirmit GandhiNo ratings yet

- Rydon Industries PVT LTD: Details of Inspection Description SpecificationDocument1 pageRydon Industries PVT LTD: Details of Inspection Description SpecificationmuthuselvanNo ratings yet

- C60 68719 - 25 QtyDocument1 pageC60 68719 - 25 QtyMohammad Shanawaz MNo ratings yet

- TRDR 300204825BDocument2 pagesTRDR 300204825BVidya SheeshNo ratings yet

- AcerinoxDocument1 pageAcerinoxOmkar PrindavankarNo ratings yet

- R CrmnonbistcDocument4 pagesR Crmnonbistcgopuvinu4uNo ratings yet

- Apl Apollo Tubes Limited Unit-Iii: Works-Vill-Kudavali Plot No-M-1, Murbad, 421401, Thane (MS)Document1 pageApl Apollo Tubes Limited Unit-Iii: Works-Vill-Kudavali Plot No-M-1, Murbad, 421401, Thane (MS)devanshbhuvansht.823No ratings yet

- 1300 - Ec0313Document5 pages1300 - Ec0313Deepak HoleNo ratings yet

- H.T Strand - 3 Specification RequirementsDocument12 pagesH.T Strand - 3 Specification RequirementsKannan MurugesanNo ratings yet

- 1300 EC2192 SignedDocument4 pages1300 EC2192 SignedDeepak HoleNo ratings yet

- 6 - Pipe MTCDocument1 page6 - Pipe MTCsnehalmdeshmukh100% (2)

- 1485 - Ec0251Document6 pages1485 - Ec0251Deepak HoleNo ratings yet

- 1426 Ec1942Document3 pages1426 Ec1942Deipak HoleNo ratings yet

- Window MTCDocument4 pagesWindow MTCshamshadkadavath1998No ratings yet

- Certificati LSE03-61172 P. 10-11-17-18Document6 pagesCertificati LSE03-61172 P. 10-11-17-18pippoNo ratings yet

- 1299 - Ec0176Document4 pages1299 - Ec0176Deipak HoleNo ratings yet

- Coupler Plate RM Pipe TC 2Document1 pageCoupler Plate RM Pipe TC 2shindemitesh17No ratings yet

- Coupler Plate RM Pipe TCDocument1 pageCoupler Plate RM Pipe TCshindemitesh17No ratings yet

- Transformer AuxilariesDocument9 pagesTransformer Auxilariesindrajit mondalNo ratings yet

- Certificats BackupDocument17 pagesCertificats BackupS. KaciouiNo ratings yet

- 1466 - Ec0044Document5 pages1466 - Ec0044Deipak HoleNo ratings yet

- Quantity and Quality Certificate (EN 10204/3.1) : PAGE:1/7Document1 pageQuantity and Quality Certificate (EN 10204/3.1) : PAGE:1/7Nilton Santillan Ortega100% (1)

- Certif Tu inDocument18 pagesCertif Tu inSri GangaNo ratings yet

- MTC 2257 SPECTRA 304 HR COIL 8mm X 1250Document1 pageMTC 2257 SPECTRA 304 HR COIL 8mm X 1250Amit Kumar OjhaNo ratings yet

- 21stC - DLL-03 (Sept. 05-09)Document3 pages21stC - DLL-03 (Sept. 05-09)Marites VardeleonNo ratings yet

- OTEC Advanced Composite Cold Water Pipe: Final Technical ReportDocument160 pagesOTEC Advanced Composite Cold Water Pipe: Final Technical ReportFauzan Hizbu RahmanNo ratings yet

- Choice of Upscale Ethnic RestaurantsDocument27 pagesChoice of Upscale Ethnic Restaurantsvidhi_153No ratings yet

- Anuga Exhibitors List EuropeanDocument3 pagesAnuga Exhibitors List EuropeanChrist HansenNo ratings yet

- The Scottish Country Dance BookDocument40 pagesThe Scottish Country Dance BookRory Corbett100% (1)

- Cisco Intelligent WAN (IWAN) - 5Document15 pagesCisco Intelligent WAN (IWAN) - 5Priscila FloresNo ratings yet

- NOTICEDocument126 pagesNOTICEowsaf2No ratings yet

- Practice Set in Inorganic ChemistryDocument3 pagesPractice Set in Inorganic ChemistryKalachuchiNo ratings yet

- Prelim Notes AccountingDocument63 pagesPrelim Notes AccountingKristine Camille GodinezNo ratings yet

- Sierra-Cedar 2016-2017 HRSystemsSurvey WhitePaperDocument116 pagesSierra-Cedar 2016-2017 HRSystemsSurvey WhitePaperAbdul WahidNo ratings yet

- 28/08/2016 1 Advanced Research Methodology... RU, Bangalore-64Document38 pages28/08/2016 1 Advanced Research Methodology... RU, Bangalore-64Ananthesh RaoNo ratings yet

- How Google's Ten Things We Know To Be True'could Guide The Development of Mental Health Mobile AppsDocument10 pagesHow Google's Ten Things We Know To Be True'could Guide The Development of Mental Health Mobile AppsAsma HussainNo ratings yet

- Ecat Entrance Test - 2: PhysicsDocument12 pagesEcat Entrance Test - 2: PhysicsXXXNo ratings yet

- Hansatsu Exhibit Text OnlyDocument6 pagesHansatsu Exhibit Text OnlyosvarxNo ratings yet

- Software Project Management Risk ManagementDocument7 pagesSoftware Project Management Risk Managementsibhat mequanintNo ratings yet

- Remunerasi RSDocument39 pagesRemunerasi RSalfanNo ratings yet

- Detailed Lesson Plan in Grade 7 ScienceDocument11 pagesDetailed Lesson Plan in Grade 7 ScienceMariel Biason100% (3)

- Lista MuzicaDocument151 pagesLista MuzicaFlaviu FertuNo ratings yet

- 3.balindong District Hospital-Completion of Ward, Pharmacy and Laboratory 6,970,000Document3 pages3.balindong District Hospital-Completion of Ward, Pharmacy and Laboratory 6,970,000Rexter UnabiaNo ratings yet

- May 2014Document48 pagesMay 2014debtwiggNo ratings yet

- 11 - Agriculture, Animal Husbandry and FisheriesDocument11 pages11 - Agriculture, Animal Husbandry and FisheriesRaj MauryaNo ratings yet

- Traditional Picnic Table: Step by Step InstructionsDocument3 pagesTraditional Picnic Table: Step by Step InstructionsMarco SilvaNo ratings yet

- The King of 64 Squares: Vishwanathan AnandDocument8 pagesThe King of 64 Squares: Vishwanathan Anandboris edison100% (1)

- White Nationalism (S) : Imperio, Globalización y Diversidad en Los Países de Habla Inglesa Mariola Ruiz RodríguezDocument9 pagesWhite Nationalism (S) : Imperio, Globalización y Diversidad en Los Países de Habla Inglesa Mariola Ruiz RodríguezCarlota DcpNo ratings yet

- Reflective Writing: Survival GuideDocument2 pagesReflective Writing: Survival GuideWendy GuNo ratings yet

- 1985 Ferranti Technical Handbook Standard ICs 198503Document766 pages1985 Ferranti Technical Handbook Standard ICs 198503helveciotfNo ratings yet

1.14.1 MTC-11372 - Tube - 1 TUBING

1.14.1 MTC-11372 - Tube - 1 TUBING

Uploaded by

groupj.sr.servicesOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

1.14.1 MTC-11372 - Tube - 1 TUBING

1.14.1 MTC-11372 - Tube - 1 TUBING

Uploaded by

groupj.sr.servicesCopyright:

Available Formats

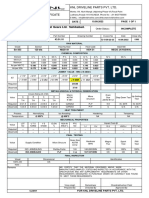

CERTIFIED AS PER EN 10204 3.

1

MILL TEST CERTIFICATE

CUSTOMER LAMAR USA TC NO. FLQA20230515-01 DATE 15.05.2023

PRODUCT SEAMLESS STAINLESS STEEL TUBE BRIGHT ANNEALED

P.O. NO. 11372 DATED --

SPECIFICATION ASTM A269/A213 TP316L

PO SR. LOT NO GRADE DIMENSION LENGTH QTY. TOTAL QTY.

NO. (OD/THK) (MM) (PIECE) (MTR)

1 20230409-03 TP-316L O.D.1/2” X W.T. 0.049”X 20FT -- 1376 --

2 20230417-10 TP-316L O.D.1/2” X W.T. 0.065”X 20FT -- 200 --

3 20230418-01 TP-316L O.D.3/8” X W.T. 0.065”X 20FT -- 100 --

CHEMICAL COMPOSITION (%)

PO ELEMENT C SI MN S P CR NI MO ---

SR. HEAT NO MIN. - - - - - 16.000 10.000 2.000 ---

NO. MAX. 0.035 1.000 2.000 0.030 0.045 18.000 15.000 3.000 ---

1 N211227AT11 --- 0.013 0.389 0.99 0.0013 0.027 16.08 10.03 2.02 ---

2 N211227AT11 --- 0.013 0.389 0.99 0.0013 0.027 16.08 10.03 2.02 ---

3 N211227AT11 --- 0.013 0.389 0.99 0.0013 0.027 16.08 10.03 2.02 ---

PHYSICAL COMPOSITION (MECHANICAL & TECHNOLOGICAL CHARACTERISTICS)

ELONGATI

TENSILE YIELD

PO STRENG STRENG

ON

HARDNESS

(%) BEND/ HYDR

(HRB) FLATTEN REV. MICRO

TH TH

G.L. 50 F LARE REV. MACR O PMI

SR HEAT NO (M .) (MPA.) ING FLAT S TRUCTUR

PA TEST BEND O TEST TEST TEST

MM TEST TEST E TEST

TEST (PSIG)

NO (485 (170 (35%

(90 MAX.)

MIN) MIN) MIN.)

N211227 642 310 61

1 75/76 OK NA NA NA OK OK

AT11 653 314 62

N211227 610 254 66

2 64/65 OK NA NA NA OK OK

AT11 618 256 67

N211227 660 260 71

3 75/76 OK NA NA NA OK OK

AT11 665 266 72

HEAT TREATMENT EDDY CURRENT IGC TEST MARKING PO STATUS

TEST ASTM E426 ASTM A262 E

ANNEALED AT 1080OC TEMPERATURE FOUND COMFIT / SPECIFICATION / GRADE / SIZE OD X

& FOLLOWED BY WATER QUENCHING. COMPLETE

SATISFACTORY THICKNESS X LENGTH / HEAT NO.

REMARKS:-

100% DIMENSION, VISUAL AND SURFACE INSPECTION CONDUCTED & FOUND SATISFACTORY.

MECHANICAL/PHYSICAL TEST CONDUCTED & FOUND SATISFACTORY.

CHEMICAL TEST CONDUCTED - FOUND SATISFACTORY.

100% HYDRO TEST CONDUCTED WITH HOLDING TIME 10 SECOND AND FOUND SATISFACTORY.

WATER USED FOR HYDRO TEST HAS CHLORIDE CONTENT LESS THAN 30 PPM.

100% PMI TEST CONDUCTED & FOUND SATISFACTORY.

100% EDDY CURRENT TEST CONDUCTED – FOUND SATISFACTORY.

WE CERTIFY THAT THE DELIVERED MATERIAL HAS BEEN TESTED IN ACCORDANCE WITH THE SPECIFICATION AND THE RESULTS COMPLY WITH THE

REQUISITE OF THE ORDER

(QA & QC)

COMFIT & VALVES PVT LTD

PAGE :- 01 OF 01

You might also like

- NUR 205-Week 5 Pre Class Assignment WI 21Document6 pagesNUR 205-Week 5 Pre Class Assignment WI 21Oliver Namyalo100% (3)

- Page 1 of 6: Test Certificate No. 0000052877Document6 pagesPage 1 of 6: Test Certificate No. 0000052877panduranganraghurama78% (9)

- Test Certificate 16mmDocument1 pageTest Certificate 16mmSabyasachi Bangal50% (4)

- Jindal Steel & Power Limited: Test Certificate No. 0000247591, Revision No. 000 Date: 03.09.2018Document1 pageJindal Steel & Power Limited: Test Certificate No. 0000247591, Revision No. 000 Date: 03.09.2018Mohammad Adil50% (2)

- BukowskiDocument5 pagesBukowskisalome davitulianiNo ratings yet

- MTC Inv 053 PDFDocument1 pageMTC Inv 053 PDFBeshnu Garanaik100% (2)

- 304 1.5MM PCDocument1 page304 1.5MM PCsabir hussain100% (1)

- Customer Specification Shipment/Delivery No.: GL 5.65 SODocument1 pageCustomer Specification Shipment/Delivery No.: GL 5.65 SOMANIMARAN QC100% (1)

- Test Method: Tensile: IS 1608 Bend: IS 1599 Impact: IS 1757 Chemical:ASTM E 415/ IS8811Document1 pageTest Method: Tensile: IS 1608 Bend: IS 1599 Impact: IS 1757 Chemical:ASTM E 415/ IS8811akash_smhs0% (1)

- ZTE H298A Admin ManualDocument19 pagesZTE H298A Admin Manualjosefm665699No ratings yet

- Dilip Tube 20 January 2023Document1 pageDilip Tube 20 January 2023पवन द्विवेदीNo ratings yet

- Tube 20 January 2023Document1 pageTube 20 January 2023पवन द्विवेदीNo ratings yet

- Customer Specification Shipment/Delivery No.: GL 5.65 SODocument1 pageCustomer Specification Shipment/Delivery No.: GL 5.65 SOParesh Mehta100% (1)

- Img 0001Document1 pageImg 0001Harish RanaNo ratings yet

- 1.5MM 304Document1 page1.5MM 304pankaj kumarNo ratings yet

- 2211J5444 90mm WeldablesDocument1 page2211J5444 90mm WeldablesChethan Nagaraju KumbarNo ratings yet

- Customer Specification Shipment/Delivery No.: GL 5.65 SODocument1 pageCustomer Specification Shipment/Delivery No.: GL 5.65 SOshekarNo ratings yet

- Customer Specification Shipment/Delivery No.: GL 5.65 SODocument1 pageCustomer Specification Shipment/Delivery No.: GL 5.65 SOBilal Luhar100% (2)

- Certificado Tubo 1.1-2 AC SC SCH 80 X 5.8-1Document1 pageCertificado Tubo 1.1-2 AC SC SCH 80 X 5.8-1Raul Esteban Jaimes GalvisNo ratings yet

- Ribo TC 324 (00000003)Document1 pageRibo TC 324 (00000003)Vinay YadavNo ratings yet

- UGINEDocument1 pageUGINEjesusNo ratings yet

- MetroDocument1 pageMetrotariqananNo ratings yet

- Customer Specification Shipment/Delivery No.: GL 5.65 SODocument1 pageCustomer Specification Shipment/Delivery No.: GL 5.65 SOarhamenterprises5401No ratings yet

- Western India Forgings PVT LTD: ISO 9001, IATF 16949, ISO 14001, OHSAS 18001, PED AD 2000 Merkblatt WO CERTIFIED COMPANYDocument1 pageWestern India Forgings PVT LTD: ISO 9001, IATF 16949, ISO 14001, OHSAS 18001, PED AD 2000 Merkblatt WO CERTIFIED COMPANYDeipak HoleNo ratings yet

- 4.0X1500. 23920 E250a DoDocument1 page4.0X1500. 23920 E250a Dosatyaprakashgond100% (1)

- MS Sheets MTCDocument6 pagesMS Sheets MTCAmit Kumar OjhaNo ratings yet

- 20MM - 63.150 TonDocument1 page20MM - 63.150 TonRAJKUMAR CHATTERJEE. (RAJA.)No ratings yet

- 20MM - 63.150 TonDocument1 page20MM - 63.150 TonRAJKUMAR CHATTERJEE. (RAJA.)No ratings yet

- Dossier Merla - ODB 4604279Document33 pagesDossier Merla - ODB 4604279Indira briceñoNo ratings yet

- Page 2 of 6: Test Certificate No. 0000052877Document1 pagePage 2 of 6: Test Certificate No. 0000052877pranesh kadam100% (2)

- Universal 1-2 Clase 6000 Tipo 316Document2 pagesUniversal 1-2 Clase 6000 Tipo 316comercial 3100% (1)

- Punjab Bevel Gears Ltd. Sahibabad.: KNL Driveline Parts Pvt. Ltd. Material Test CertificateDocument1 pagePunjab Bevel Gears Ltd. Sahibabad.: KNL Driveline Parts Pvt. Ltd. Material Test CertificateargmsfNo ratings yet

- Test CertificateDocument2 pagesTest CertificatePRITESH100% (2)

- Inspection Certificate: Customer: CommodityDocument1 pageInspection Certificate: Customer: CommodityGisella Mariel Rubilar100% (1)

- 2324MTC037 11362Document1 page2324MTC037 11362Shrikrushna DalviNo ratings yet

- Anup SS304L TC 1Document2 pagesAnup SS304L TC 1B.M Industrial Works100% (1)

- Aluminium Rod Material Detail PDFDocument1 pageAluminium Rod Material Detail PDFPradeep SNo ratings yet

- A.V.Steel Forgings PVT - LTD: Test CertificateDocument1 pageA.V.Steel Forgings PVT - LTD: Test CertificateNirmit GandhiNo ratings yet

- Rydon Industries PVT LTD: Details of Inspection Description SpecificationDocument1 pageRydon Industries PVT LTD: Details of Inspection Description SpecificationmuthuselvanNo ratings yet

- C60 68719 - 25 QtyDocument1 pageC60 68719 - 25 QtyMohammad Shanawaz MNo ratings yet

- TRDR 300204825BDocument2 pagesTRDR 300204825BVidya SheeshNo ratings yet

- AcerinoxDocument1 pageAcerinoxOmkar PrindavankarNo ratings yet

- R CrmnonbistcDocument4 pagesR Crmnonbistcgopuvinu4uNo ratings yet

- Apl Apollo Tubes Limited Unit-Iii: Works-Vill-Kudavali Plot No-M-1, Murbad, 421401, Thane (MS)Document1 pageApl Apollo Tubes Limited Unit-Iii: Works-Vill-Kudavali Plot No-M-1, Murbad, 421401, Thane (MS)devanshbhuvansht.823No ratings yet

- 1300 - Ec0313Document5 pages1300 - Ec0313Deepak HoleNo ratings yet

- H.T Strand - 3 Specification RequirementsDocument12 pagesH.T Strand - 3 Specification RequirementsKannan MurugesanNo ratings yet

- 1300 EC2192 SignedDocument4 pages1300 EC2192 SignedDeepak HoleNo ratings yet

- 6 - Pipe MTCDocument1 page6 - Pipe MTCsnehalmdeshmukh100% (2)

- 1485 - Ec0251Document6 pages1485 - Ec0251Deepak HoleNo ratings yet

- 1426 Ec1942Document3 pages1426 Ec1942Deipak HoleNo ratings yet

- Window MTCDocument4 pagesWindow MTCshamshadkadavath1998No ratings yet

- Certificati LSE03-61172 P. 10-11-17-18Document6 pagesCertificati LSE03-61172 P. 10-11-17-18pippoNo ratings yet

- 1299 - Ec0176Document4 pages1299 - Ec0176Deipak HoleNo ratings yet

- Coupler Plate RM Pipe TC 2Document1 pageCoupler Plate RM Pipe TC 2shindemitesh17No ratings yet

- Coupler Plate RM Pipe TCDocument1 pageCoupler Plate RM Pipe TCshindemitesh17No ratings yet

- Transformer AuxilariesDocument9 pagesTransformer Auxilariesindrajit mondalNo ratings yet

- Certificats BackupDocument17 pagesCertificats BackupS. KaciouiNo ratings yet

- 1466 - Ec0044Document5 pages1466 - Ec0044Deipak HoleNo ratings yet

- Quantity and Quality Certificate (EN 10204/3.1) : PAGE:1/7Document1 pageQuantity and Quality Certificate (EN 10204/3.1) : PAGE:1/7Nilton Santillan Ortega100% (1)

- Certif Tu inDocument18 pagesCertif Tu inSri GangaNo ratings yet

- MTC 2257 SPECTRA 304 HR COIL 8mm X 1250Document1 pageMTC 2257 SPECTRA 304 HR COIL 8mm X 1250Amit Kumar OjhaNo ratings yet

- 21stC - DLL-03 (Sept. 05-09)Document3 pages21stC - DLL-03 (Sept. 05-09)Marites VardeleonNo ratings yet

- OTEC Advanced Composite Cold Water Pipe: Final Technical ReportDocument160 pagesOTEC Advanced Composite Cold Water Pipe: Final Technical ReportFauzan Hizbu RahmanNo ratings yet

- Choice of Upscale Ethnic RestaurantsDocument27 pagesChoice of Upscale Ethnic Restaurantsvidhi_153No ratings yet

- Anuga Exhibitors List EuropeanDocument3 pagesAnuga Exhibitors List EuropeanChrist HansenNo ratings yet

- The Scottish Country Dance BookDocument40 pagesThe Scottish Country Dance BookRory Corbett100% (1)

- Cisco Intelligent WAN (IWAN) - 5Document15 pagesCisco Intelligent WAN (IWAN) - 5Priscila FloresNo ratings yet

- NOTICEDocument126 pagesNOTICEowsaf2No ratings yet

- Practice Set in Inorganic ChemistryDocument3 pagesPractice Set in Inorganic ChemistryKalachuchiNo ratings yet

- Prelim Notes AccountingDocument63 pagesPrelim Notes AccountingKristine Camille GodinezNo ratings yet

- Sierra-Cedar 2016-2017 HRSystemsSurvey WhitePaperDocument116 pagesSierra-Cedar 2016-2017 HRSystemsSurvey WhitePaperAbdul WahidNo ratings yet

- 28/08/2016 1 Advanced Research Methodology... RU, Bangalore-64Document38 pages28/08/2016 1 Advanced Research Methodology... RU, Bangalore-64Ananthesh RaoNo ratings yet

- How Google's Ten Things We Know To Be True'could Guide The Development of Mental Health Mobile AppsDocument10 pagesHow Google's Ten Things We Know To Be True'could Guide The Development of Mental Health Mobile AppsAsma HussainNo ratings yet

- Ecat Entrance Test - 2: PhysicsDocument12 pagesEcat Entrance Test - 2: PhysicsXXXNo ratings yet

- Hansatsu Exhibit Text OnlyDocument6 pagesHansatsu Exhibit Text OnlyosvarxNo ratings yet

- Software Project Management Risk ManagementDocument7 pagesSoftware Project Management Risk Managementsibhat mequanintNo ratings yet

- Remunerasi RSDocument39 pagesRemunerasi RSalfanNo ratings yet

- Detailed Lesson Plan in Grade 7 ScienceDocument11 pagesDetailed Lesson Plan in Grade 7 ScienceMariel Biason100% (3)

- Lista MuzicaDocument151 pagesLista MuzicaFlaviu FertuNo ratings yet

- 3.balindong District Hospital-Completion of Ward, Pharmacy and Laboratory 6,970,000Document3 pages3.balindong District Hospital-Completion of Ward, Pharmacy and Laboratory 6,970,000Rexter UnabiaNo ratings yet

- May 2014Document48 pagesMay 2014debtwiggNo ratings yet

- 11 - Agriculture, Animal Husbandry and FisheriesDocument11 pages11 - Agriculture, Animal Husbandry and FisheriesRaj MauryaNo ratings yet

- Traditional Picnic Table: Step by Step InstructionsDocument3 pagesTraditional Picnic Table: Step by Step InstructionsMarco SilvaNo ratings yet

- The King of 64 Squares: Vishwanathan AnandDocument8 pagesThe King of 64 Squares: Vishwanathan Anandboris edison100% (1)

- White Nationalism (S) : Imperio, Globalización y Diversidad en Los Países de Habla Inglesa Mariola Ruiz RodríguezDocument9 pagesWhite Nationalism (S) : Imperio, Globalización y Diversidad en Los Países de Habla Inglesa Mariola Ruiz RodríguezCarlota DcpNo ratings yet

- Reflective Writing: Survival GuideDocument2 pagesReflective Writing: Survival GuideWendy GuNo ratings yet

- 1985 Ferranti Technical Handbook Standard ICs 198503Document766 pages1985 Ferranti Technical Handbook Standard ICs 198503helveciotfNo ratings yet