Professional Documents

Culture Documents

Super Diamond Clear

Super Diamond Clear

Uploaded by

Elisa Pavez A.Copyright:

Available Formats

You might also like

- Bostik Powermix Tds Rev1 PDFDocument2 pagesBostik Powermix Tds Rev1 PDFRafael Obusan IINo ratings yet

- Carboline Carboguard 890 PDSDocument2 pagesCarboline Carboguard 890 PDSSamNo ratings yet

- Aqua-Cure VOXDocument2 pagesAqua-Cure VOXChris ChanonaNo ratings yet

- Clear Seal NaturalDocument2 pagesClear Seal NaturalElisa Pavez A.No ratings yet

- Devran 201: Cat. # 201B0245/201C0300Document2 pagesDevran 201: Cat. # 201B0245/201C0300Mohamed NouzerNo ratings yet

- Florgard SL: Self Levelling Epoxy Based FlooringDocument3 pagesFlorgard SL: Self Levelling Epoxy Based FlooringRavi KantNo ratings yet

- Carboguard 504 PDSDocument4 pagesCarboguard 504 PDSNicholas ColesNo ratings yet

- Hyperseal-Expert 150-.v2.2 0Document4 pagesHyperseal-Expert 150-.v2.2 0Sergio LeonelNo ratings yet

- 914 EuroCryl ARDocument3 pages914 EuroCryl ARRAVI SHANKER GopalakrishnanNo ratings yet

- Dural Epoxy PrimerDocument3 pagesDural Epoxy PrimershinellajohnsonNo ratings yet

- Kut Thioseal 227: Two Component Gun and Pouring Grade Polysulfide SealantDocument4 pagesKut Thioseal 227: Two Component Gun and Pouring Grade Polysulfide Sealanthafee83No ratings yet

- Epoxy Floor Coating: Description FeaturesDocument2 pagesEpoxy Floor Coating: Description FeaturesRayon 9No ratings yet

- Cmci Cmci: Floor CoatDocument2 pagesCmci Cmci: Floor Coatpravi3434No ratings yet

- Consol Cosmetic: Polymer Modified Portland Cement CoatingDocument2 pagesConsol Cosmetic: Polymer Modified Portland Cement CoatingCiput MardiantoNo ratings yet

- Konsol PDFDocument2 pagesKonsol PDFCiput MardiantoNo ratings yet

- ShaliCure AcrylateDocument2 pagesShaliCure AcrylateSunil Kumar GiriNo ratings yet

- Ornamental Sealer: Product InformationDocument4 pagesOrnamental Sealer: Product InformationGuruNo ratings yet

- Macht Tiefgrund WasserDocument2 pagesMacht Tiefgrund Wassering ndertimNo ratings yet

- Epoxy Coating Solvent Free TDSDocument3 pagesEpoxy Coating Solvent Free TDSMohamed MagdiNo ratings yet

- Linseed Oil TreatmentDocument2 pagesLinseed Oil TreatmentsathiyanNo ratings yet

- DK11 SlurryDocument2 pagesDK11 SlurryRon Jovi GarciaNo ratings yet

- Nitoflor FC145: Constructive SolutionsDocument3 pagesNitoflor FC145: Constructive SolutionstalatzahoorNo ratings yet

- Surflex: N - M F HDocument2 pagesSurflex: N - M F HJohn Shane100% (1)

- Lightweight Aggregates - How Do You Make The Right Decision - NPCADocument2 pagesLightweight Aggregates - How Do You Make The Right Decision - NPCARafael Obusan IINo ratings yet

- 302 Epoxy Ester Floor Paint TDSDocument2 pages302 Epoxy Ester Floor Paint TDSraja qammar100% (1)

- Basf Masterseal 550 Waterproof Wall CoatingDocument3 pagesBasf Masterseal 550 Waterproof Wall Coatingmeja.gamerNo ratings yet

- Aqua Cure VoxDocument2 pagesAqua Cure Voxpravi3434No ratings yet

- Low Odor / Low VOC Acrylic Vinyl Copolymer Emulsion Putty Filler, Nr. 15035Document3 pagesLow Odor / Low VOC Acrylic Vinyl Copolymer Emulsion Putty Filler, Nr. 15035Mostafa Hussein AbdouNo ratings yet

- Hyperdesmo 815Document5 pagesHyperdesmo 815Roger DaoudNo ratings yet

- Carboguard 89dfsfs0 PDSDocument2 pagesCarboguard 89dfsfs0 PDSMayur PatelNo ratings yet

- Paint SpecDocument9 pagesPaint SpectalabizNo ratings yet

- Dolphin Bitumimous TDS - CompressedDocument2 pagesDolphin Bitumimous TDS - CompressedMohanned KhalidNo ratings yet

- PuttyDocument2 pagesPuttyOsama GabrNo ratings yet

- Super Sealer TDSDocument2 pagesSuper Sealer TDSOmer TageldinNo ratings yet

- Cure Tec EngDocument2 pagesCure Tec EngPedroNo ratings yet

- Nano Ceramic Thermal Insulation CoatingDocument2 pagesNano Ceramic Thermal Insulation CoatingAli AlghanimNo ratings yet

- 1 DT 2.6 Prep Corro3 MetaletchprimerDocument4 pages1 DT 2.6 Prep Corro3 Metaletchprimeryoxan25808No ratings yet

- Ficha Técnica Thompsons WaterSealDocument3 pagesFicha Técnica Thompsons WaterSealerick alvaradoNo ratings yet

- Steelshield Ve: Product DescriptionDocument2 pagesSteelshield Ve: Product DescriptionMoin AltafNo ratings yet

- Consol CosmeticDocument2 pagesConsol Cosmeticotong geyongNo ratings yet

- Luxafloor ECO: Water Borne Epoxy Floor CoatingDocument2 pagesLuxafloor ECO: Water Borne Epoxy Floor CoatinglivefreakNo ratings yet

- Super Plio CureDocument2 pagesSuper Plio Curepravi3434No ratings yet

- Tinogalvanize Zinc Rich PrimerDocument2 pagesTinogalvanize Zinc Rich PrimerAbed samadsureyft7vewyrNo ratings yet

- Carboguard 893 SG PDSDocument4 pagesCarboguard 893 SG PDSTrịnh Minh KhoaNo ratings yet

- Jazeera Epo-Mortar SLDocument3 pagesJazeera Epo-Mortar SLAhmad BougeisNo ratings yet

- Jotamastic Protective Brochure 2011 Tcm279 1592Document24 pagesJotamastic Protective Brochure 2011 Tcm279 1592EngTamerNo ratings yet

- Berger: Product SpecificationsDocument2 pagesBerger: Product SpecificationsAabhas UpadhyayaNo ratings yet

- COLD GALVANISING Spray - GBDocument2 pagesCOLD GALVANISING Spray - GBANIL PLAMOOTTILNo ratings yet

- El Hyperdesmo-ClassicDocument4 pagesEl Hyperdesmo-ClassicΙοαννης ΡενκοNo ratings yet

- Sanitile 755 PDSDocument4 pagesSanitile 755 PDSnarmathaNo ratings yet

- Jazeera Epo-Mortar SL5000Document3 pagesJazeera Epo-Mortar SL5000Ahmad BougeisNo ratings yet

- Sikafloor-ColourSeal W 0307Document4 pagesSikafloor-ColourSeal W 0307Chris AdaminovicNo ratings yet

- Dry 135 WR: Silane/Siloxane Water Based Surface Water RepellentDocument2 pagesDry 135 WR: Silane/Siloxane Water Based Surface Water RepellentInsafians PowerNo ratings yet

- Epilux 9 Phenolic CoatingDocument2 pagesEpilux 9 Phenolic CoatingdineshNo ratings yet

- Jazeera Floor GuardDocument3 pagesJazeera Floor GuardAhmad BougeisNo ratings yet

- MasterProtect HB 400 Formerly Thorocoat Product Data 2010646Document5 pagesMasterProtect HB 400 Formerly Thorocoat Product Data 2010646isaiasvinicius80No ratings yet

- X-Shield BugFillDocument2 pagesX-Shield BugFillsamerNo ratings yet

- Flexcrete 500: Epoxy Polysulfide Waterproofing CoatingDocument2 pagesFlexcrete 500: Epoxy Polysulfide Waterproofing CoatingSuresh YadavNo ratings yet

- ROYALPOXY UW 410-tdsDocument3 pagesROYALPOXY UW 410-tdsSyed FaridNo ratings yet

- Sample Hot Work PermitDocument1 pageSample Hot Work PermitFelix EbikineiNo ratings yet

- T P ElastomerDocument63 pagesT P ElastomerSuyash TrivediNo ratings yet

- Maskote WB Zinc Stop Off Zyp02Document1 pageMaskote WB Zinc Stop Off Zyp02bondsivamaniNo ratings yet

- Binder Jetting Process: This ChapterDocument7 pagesBinder Jetting Process: This ChapterHarsh BansalNo ratings yet

- Railim Engineering Company ProfileDocument8 pagesRailim Engineering Company ProfileAlejandro Dela CruzNo ratings yet

- 7 Milling DynamometerDocument5 pages7 Milling DynamometerVirat KohliNo ratings yet

- (YE22) Holemaking 220330 FDocument242 pages(YE22) Holemaking 220330 FJoão PedroNo ratings yet

- Composite Materialslab Text BookDocument49 pagesComposite Materialslab Text BookSHAHBAZ PNo ratings yet

- Fin Irjmets1652476781Document11 pagesFin Irjmets1652476781yash matondkarNo ratings yet

- Theory of Metal Cutting For 2022 GATE ESE PSUs by S K MondalDocument82 pagesTheory of Metal Cutting For 2022 GATE ESE PSUs by S K MondalNabin MukherjeeNo ratings yet

- ENSC3002: Manufacturing and Materials: Lecture 2: Casting IntroductionDocument30 pagesENSC3002: Manufacturing and Materials: Lecture 2: Casting IntroductionRoger HanNo ratings yet

- FoundryDocument9 pagesFoundryMuhammad Tauseef ZafarNo ratings yet

- No.99.TC (FM) .26.1 Dt. 25.10.2007Document2 pagesNo.99.TC (FM) .26.1 Dt. 25.10.2007Preeti goswamiNo ratings yet

- Precision Honing Supplies: Above and Beyond HoningDocument203 pagesPrecision Honing Supplies: Above and Beyond Honingnik stavroginNo ratings yet

- A New Strategy On Designing Fluxes For Aluminum AlDocument19 pagesA New Strategy On Designing Fluxes For Aluminum AlJohn TorrezNo ratings yet

- Vertech Refrigeration Jacket: Reduced Stress Maximum QualityDocument1 pageVertech Refrigeration Jacket: Reduced Stress Maximum QualityRITONo ratings yet

- WP 11 Corrosion Protection Tape Coating123Document3 pagesWP 11 Corrosion Protection Tape Coating123KarthikNo ratings yet

- Press Brake Toolings Catalog - Saras - 1Document40 pagesPress Brake Toolings Catalog - Saras - 1saras precisionNo ratings yet

- Ducting QAP R02 080822Document2 pagesDucting QAP R02 080822Pavul RajNo ratings yet

- Compression CylindersDocument4 pagesCompression CylindersAlber MoelNo ratings yet

- Technical Report 1 - Sdb24103 (Sept 2022) Mohd Iqmal HafizDocument15 pagesTechnical Report 1 - Sdb24103 (Sept 2022) Mohd Iqmal HafiziqmalNo ratings yet

- LE 3101, Finishing OperationsDocument17 pagesLE 3101, Finishing OperationsRupokNo ratings yet

- Astm E1516Document2 pagesAstm E1516alferedNo ratings yet

- Otto Group 2Document23 pagesOtto Group 2otto groupNo ratings yet

- Kansas SawmillsDocument6 pagesKansas SawmillsGregg HockettNo ratings yet

- 3.6 VGO - HDT Unit:: Process DescriptionDocument4 pages3.6 VGO - HDT Unit:: Process DescriptionAkankshya MishraNo ratings yet

- Grades: Crystallization Rate Mooney Viscosity (MS2+2.5) Solution Viscosity Features General GradesDocument3 pagesGrades: Crystallization Rate Mooney Viscosity (MS2+2.5) Solution Viscosity Features General GradesHİLMİKISANo ratings yet

- 5110.003.12 PIG-SIG V PI-May2021Document8 pages5110.003.12 PIG-SIG V PI-May2021MORELLI silvioNo ratings yet

- Unit 8Document2 pagesUnit 8Berina DelicNo ratings yet

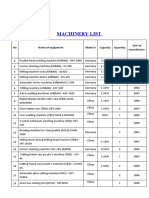

- Machinery List-1Document2 pagesMachinery List-1Hồng HạnhNo ratings yet

Super Diamond Clear

Super Diamond Clear

Uploaded by

Elisa Pavez A.Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Super Diamond Clear

Super Diamond Clear

Uploaded by

Elisa Pavez A.Copyright:

Available Formats

CURING AND SEALING

Master Format #: 03 39 23

SUPER DIAMOND CLEAR

SOLVENT-BASED, HIGH-SOLIDS, NON-YELLOWING

CURE & SEAL FOR CONCRETE

PACKAGING DESCRIPTION

55 gal (208 L) drums

Code: 359A 55 SUPER DIAMOND CLEAR is a solvent-based curing and sealing compound

specially designed to cure new concrete, assuring proper cement hydration and

5 gal (18.9 L) pails

Code: 359A 05 strength gain, while providing a non-yellowing seal to protect and enhance

1 gal (3.8 L) jugs (4 jugs per case) the appearance of concrete. SUPER DIAMOND CLEAR is particularly suited for

Code: 359A 93 curing and sealing exterior architectural concrete, where membrane yellowing

is undesirable. Super Diamond Clear can be tinted with Euclid Universal Color

CLEAN UP

Packs, which are available in 33 standard colors.

Xylene/xylol or acetone

(see “Clean-Up and Removal”)

PRODUCT CHARACTERISTICS

SHELF LIFE

3 years when stored properly FEATURES/BENEFITS PRIMARY APPLICATIONS

• Helps promote development of • Driveways and exterior pavements

SPECIFICATIONS/COMPLIANCES

concrete strength when used as a • Walls and columns

• VOC Content: 648 g/L curing compound

• Dry shake floors

• ASTM C1315 Type 1, Class A • Enhances color and provides gloss

• Curing and sealing decorative

• ASTM C309 Type 1, Classes A and B to the surface

concrete, including colored,

• AASHTO Specification M 148, Type • Will not yellow under ultraviolet stamped, and exposed aggregate

1, Classes A and B exposure surfaces

• Can be tinted with Euclid Universal

Color Packs to even out variegated APPEARANCE

concrete surfaces SUPER DIAMOND CLEAR is a clear liquid

in the container. After application and

COMMON METHODS drying, SUPER DIAMOND CLEAR will

• Industrial solvent-resistant pump- greatly darken concrete and enhance

up sprayer with high solids-nozzle color, and will have a high-gloss

• Short-nap solvent-resistant roller finish. A small test area is strongly

recommended to confirm appearance

prior to beginning full application.

APPLICATION PROPERTIES COVERAGE

These properties are based on laboratory conditions at New Concrete

70 °F. Expect variation based on jobsite conditions. 1st Coat: 300 to 400 ft2/gal (7.4 to 9.8 m2/L)

Solids content: > 25% 2nd Coat: 400 to 450 ft2/gal (9.8 to 11.0 m2/L)

Dry to touch: < 1 hour Existing Concrete & Re-Sealing

Recoat: minimum 2 hours 1st Coat: 400 to 450 ft2/gal (9.8 to 11.0 m2/L)

Foot Traffic: 2 to 4 hours 2nd Coat: 450 to 550 ft2/gal (11.0 to 13.5 m2/L)

Wheel Traffic: 6 to 10 hours *Coverage rates are approximations. Actual coverage will vary

based on temperature, texture, and substrate porosity. Avoid

Moisture Loss (ASTM C156): < 0.40 kg/m2 excessive build-up of sealer, as this may cause discoloration

and/or poor product performance.

19215 Redwood Road • Cleveland, OH 44110 • 800-321-7628 www.euclidchemical.com

DIRECTIONS FOR USE

Surface Preparation: For existing concrete, the surface must be clean of any and all surface contaminants, and free of

standing water. If applying SUPER DIAMOND CLEAR to previously sealed concrete, call Euclid Chemical to check compatibility.

If the chemical makeup of the previous sealer is unknown, a small test section is strongly recommended to check compatibility

between SUPER DIAMOND CLEAR and the old sealer. When applying SUPER DIAMOND CLEAR to freshly poured concrete

as a cure & seal, the surface bleed water must be allowed to evaporate prior to applying SUPER DIAMOND CLEAR, and the

surface must be hard enough as to not be marred during product application.

Mixing: SUPER DIAMOND CLEAR requires no pre-blending prior to use. If using Euclid Universal Color Packs or Euco Grip

with this sealer, please refer to those products’ technical data sheets for mixing instructions.

Application: Apply at the recommended coverage rate using an industrial, solvent-resistant pump-up sprayer with a high-

solids nozzle and a short-nap, solvent-resistant roller. Apply sealer uniformly to the concrete using sprayer, then lightly

backroll the sealer to ensure even coverage. Maintain a “wet edge” while spraying, and backroll over sprayer lap marks

for best appearance. SUPER DIAMOND CLEAR may be applied by roller alone, but extra care must be taken to ensure that

the sealer is applied uniformly, and at the proper coverage rate. Re-distribute any puddles or runs before SUPER DIAMOND

CLEAR dries. Protect freshly coated surfaces from rain or heavy fog for a minimum of 12 hours after application.

Application of SUPER DIAMOND CLEAR too heavily, in too many successive coats, or in multiple coats from re-sealing too

frequently can cause bubbling, whitening, peeling, flaking, and ultimately, poor performance of the product. To prevent

over-application, it is good practice to measure the area to be sealed and then measure the corresponding volume of

product required based on the coverage rate. In addition, applying SUPER DIAMOND CLEAR in hot weather/direct sunlight

or onto a hot surface can cause bubbling.

For additional guidance in applying Euclid Chemical curing and sealing compounds, visit our website to see an instructional

video on the procedure.

CLEAN-UP AND REMOVAL

Tools and equipment may be cleaned with EUCO SOLVENT, xylene/xylol, or acetone (always follow package directions and

warning labels) immediately following use. Clean drips and overspray with one of the above solvents while still wet. Run

cleaning solvent through spray equipment to remove residual materials and prevent clogging of nozzle in future use. If not

cleaned immediately, the sealer may leave an unwanted residue on painted surfaces, glass, or wood.

Dried, cured SUPER DIAMOND CLEAR may be removed with a strong solvent such as EUCO SOLVENT, xylene/xylol, or MEK

(always follow package directions and warning labels). EUCO CLEAN & STRIP is a citrus-based stripper that can also be used

to remove this product. Alternatively, the product can be removed by sandblasting or by other similar mechanical means.

PRECAUTIONS/LIMITATIONS

• Keep SUPER DIAMOND CLEAR away from open flames, sparks, or other sources of ignition

• If using SUPER DIAMOND CLEAR indoors, ensure adequate fresh air ventilation and block all HVAC ducts which may distribute solvent

odor. Extinguish any pilot lights or other sources of ignition prior to starting SUPER DIAMOND CLEAR application.

• SUPER DIAMOND CLEAR will not freeze in storage, but should be allowed to reach at least 50 °F (10 °C) before use

• Surface and ambient temperature during coating applications should be between 40 °F and 90 °F (4 °C and 32 °C)

• Do not apply SUPER DIAMOND CLEAR to frost-filled or frozen substrates

• Do not apply SUPER DIAMOND CLEAR in hot direct sunlight

• Do not apply SUPER DIAMOND CLEAR over bleed water or free-standing water

• Do not apply SUPER DIAMOND CLEAR if rain or heavy fog is expected within 12 hours of application

• Do not thin SUPER DIAMOND CLEAR

• SUPER DIAMOND CLEAR is not resistant to gasoline or other automotive fluids

• SUPER DIAMOND CLEAR will enhance color and darken substrates

• Excessive build up of SUPER DIAMOND CLEAR or puddling of the product during application can lead to failure to dry completely,

bubbling, whitening, peeling and/or flaking of the sealer, and discoloration of the concrete

• Applying thicker than recommended, applying in cool/cold weather, prolonged exposure to moisture (high humidity, rain), or lack of

air flow may result in the sealer remaining soft/wet/tacky for longer than the times found on this data sheet

• When floor covering adhesives will be used following SUPER DIAMOND CLEAR application, a test area is recommended to ensure

compatibility of the adhesive with SUPER DIAMOND CLEAR

• Application of a test area is strongly recommended to confirm final appearance and texture of the product with the end user

• In all cases, consult the product Safety Data Sheet before use

Rev. 04.22

WARRANTY: The Euclid Chemical Company (“Euclid”) solely and expressly warrants that its products shall be free from defects in materials and workmanship for one (1) year from the date of

purchase. Unless authorized in writing by an officer of Euclid, no other representations or statements made by Euclid or its representatives, in writing or orally, shall alter this warranty. EUCLID MAKES

NO WARRANTIES, IMPLIED OR OTHERWISE, AS TO THE MERCHANTABILITY OR FITNESS FOR ORDINARY OR PARTICULAR PURPOSES OF ITS PRODUCTS AND EXCLUDES THE SAME. If any

Euclid product fails to conform with this warranty, Euclid will replace the product at no cost to Buyer. Replacement of any product shall be the sole and exclusive remedy available and buyer shall have

no claim for incidental or consequential damages. Any warranty claim must be made within one (1) year from the date of the claimed breach. Euclid does not authorize anyone on its behalf to make

any written or oral statements which in any way alter Euclid’s installation information or instructions in its product literature or on its packaging labels. Any installation of Euclid products which fails to

conform with such installation information or instructions shall void this warranty. Product demonstrations, if any, are done for illustrative purposes only and do not constitute a warranty or warranty

alteration of any kind. Buyer shall be solely responsible for determining the suitability of Euclid’s products for the Buyer’s intended purposes.

You might also like

- Bostik Powermix Tds Rev1 PDFDocument2 pagesBostik Powermix Tds Rev1 PDFRafael Obusan IINo ratings yet

- Carboline Carboguard 890 PDSDocument2 pagesCarboline Carboguard 890 PDSSamNo ratings yet

- Aqua-Cure VOXDocument2 pagesAqua-Cure VOXChris ChanonaNo ratings yet

- Clear Seal NaturalDocument2 pagesClear Seal NaturalElisa Pavez A.No ratings yet

- Devran 201: Cat. # 201B0245/201C0300Document2 pagesDevran 201: Cat. # 201B0245/201C0300Mohamed NouzerNo ratings yet

- Florgard SL: Self Levelling Epoxy Based FlooringDocument3 pagesFlorgard SL: Self Levelling Epoxy Based FlooringRavi KantNo ratings yet

- Carboguard 504 PDSDocument4 pagesCarboguard 504 PDSNicholas ColesNo ratings yet

- Hyperseal-Expert 150-.v2.2 0Document4 pagesHyperseal-Expert 150-.v2.2 0Sergio LeonelNo ratings yet

- 914 EuroCryl ARDocument3 pages914 EuroCryl ARRAVI SHANKER GopalakrishnanNo ratings yet

- Dural Epoxy PrimerDocument3 pagesDural Epoxy PrimershinellajohnsonNo ratings yet

- Kut Thioseal 227: Two Component Gun and Pouring Grade Polysulfide SealantDocument4 pagesKut Thioseal 227: Two Component Gun and Pouring Grade Polysulfide Sealanthafee83No ratings yet

- Epoxy Floor Coating: Description FeaturesDocument2 pagesEpoxy Floor Coating: Description FeaturesRayon 9No ratings yet

- Cmci Cmci: Floor CoatDocument2 pagesCmci Cmci: Floor Coatpravi3434No ratings yet

- Consol Cosmetic: Polymer Modified Portland Cement CoatingDocument2 pagesConsol Cosmetic: Polymer Modified Portland Cement CoatingCiput MardiantoNo ratings yet

- Konsol PDFDocument2 pagesKonsol PDFCiput MardiantoNo ratings yet

- ShaliCure AcrylateDocument2 pagesShaliCure AcrylateSunil Kumar GiriNo ratings yet

- Ornamental Sealer: Product InformationDocument4 pagesOrnamental Sealer: Product InformationGuruNo ratings yet

- Macht Tiefgrund WasserDocument2 pagesMacht Tiefgrund Wassering ndertimNo ratings yet

- Epoxy Coating Solvent Free TDSDocument3 pagesEpoxy Coating Solvent Free TDSMohamed MagdiNo ratings yet

- Linseed Oil TreatmentDocument2 pagesLinseed Oil TreatmentsathiyanNo ratings yet

- DK11 SlurryDocument2 pagesDK11 SlurryRon Jovi GarciaNo ratings yet

- Nitoflor FC145: Constructive SolutionsDocument3 pagesNitoflor FC145: Constructive SolutionstalatzahoorNo ratings yet

- Surflex: N - M F HDocument2 pagesSurflex: N - M F HJohn Shane100% (1)

- Lightweight Aggregates - How Do You Make The Right Decision - NPCADocument2 pagesLightweight Aggregates - How Do You Make The Right Decision - NPCARafael Obusan IINo ratings yet

- 302 Epoxy Ester Floor Paint TDSDocument2 pages302 Epoxy Ester Floor Paint TDSraja qammar100% (1)

- Basf Masterseal 550 Waterproof Wall CoatingDocument3 pagesBasf Masterseal 550 Waterproof Wall Coatingmeja.gamerNo ratings yet

- Aqua Cure VoxDocument2 pagesAqua Cure Voxpravi3434No ratings yet

- Low Odor / Low VOC Acrylic Vinyl Copolymer Emulsion Putty Filler, Nr. 15035Document3 pagesLow Odor / Low VOC Acrylic Vinyl Copolymer Emulsion Putty Filler, Nr. 15035Mostafa Hussein AbdouNo ratings yet

- Hyperdesmo 815Document5 pagesHyperdesmo 815Roger DaoudNo ratings yet

- Carboguard 89dfsfs0 PDSDocument2 pagesCarboguard 89dfsfs0 PDSMayur PatelNo ratings yet

- Paint SpecDocument9 pagesPaint SpectalabizNo ratings yet

- Dolphin Bitumimous TDS - CompressedDocument2 pagesDolphin Bitumimous TDS - CompressedMohanned KhalidNo ratings yet

- PuttyDocument2 pagesPuttyOsama GabrNo ratings yet

- Super Sealer TDSDocument2 pagesSuper Sealer TDSOmer TageldinNo ratings yet

- Cure Tec EngDocument2 pagesCure Tec EngPedroNo ratings yet

- Nano Ceramic Thermal Insulation CoatingDocument2 pagesNano Ceramic Thermal Insulation CoatingAli AlghanimNo ratings yet

- 1 DT 2.6 Prep Corro3 MetaletchprimerDocument4 pages1 DT 2.6 Prep Corro3 Metaletchprimeryoxan25808No ratings yet

- Ficha Técnica Thompsons WaterSealDocument3 pagesFicha Técnica Thompsons WaterSealerick alvaradoNo ratings yet

- Steelshield Ve: Product DescriptionDocument2 pagesSteelshield Ve: Product DescriptionMoin AltafNo ratings yet

- Consol CosmeticDocument2 pagesConsol Cosmeticotong geyongNo ratings yet

- Luxafloor ECO: Water Borne Epoxy Floor CoatingDocument2 pagesLuxafloor ECO: Water Borne Epoxy Floor CoatinglivefreakNo ratings yet

- Super Plio CureDocument2 pagesSuper Plio Curepravi3434No ratings yet

- Tinogalvanize Zinc Rich PrimerDocument2 pagesTinogalvanize Zinc Rich PrimerAbed samadsureyft7vewyrNo ratings yet

- Carboguard 893 SG PDSDocument4 pagesCarboguard 893 SG PDSTrịnh Minh KhoaNo ratings yet

- Jazeera Epo-Mortar SLDocument3 pagesJazeera Epo-Mortar SLAhmad BougeisNo ratings yet

- Jotamastic Protective Brochure 2011 Tcm279 1592Document24 pagesJotamastic Protective Brochure 2011 Tcm279 1592EngTamerNo ratings yet

- Berger: Product SpecificationsDocument2 pagesBerger: Product SpecificationsAabhas UpadhyayaNo ratings yet

- COLD GALVANISING Spray - GBDocument2 pagesCOLD GALVANISING Spray - GBANIL PLAMOOTTILNo ratings yet

- El Hyperdesmo-ClassicDocument4 pagesEl Hyperdesmo-ClassicΙοαννης ΡενκοNo ratings yet

- Sanitile 755 PDSDocument4 pagesSanitile 755 PDSnarmathaNo ratings yet

- Jazeera Epo-Mortar SL5000Document3 pagesJazeera Epo-Mortar SL5000Ahmad BougeisNo ratings yet

- Sikafloor-ColourSeal W 0307Document4 pagesSikafloor-ColourSeal W 0307Chris AdaminovicNo ratings yet

- Dry 135 WR: Silane/Siloxane Water Based Surface Water RepellentDocument2 pagesDry 135 WR: Silane/Siloxane Water Based Surface Water RepellentInsafians PowerNo ratings yet

- Epilux 9 Phenolic CoatingDocument2 pagesEpilux 9 Phenolic CoatingdineshNo ratings yet

- Jazeera Floor GuardDocument3 pagesJazeera Floor GuardAhmad BougeisNo ratings yet

- MasterProtect HB 400 Formerly Thorocoat Product Data 2010646Document5 pagesMasterProtect HB 400 Formerly Thorocoat Product Data 2010646isaiasvinicius80No ratings yet

- X-Shield BugFillDocument2 pagesX-Shield BugFillsamerNo ratings yet

- Flexcrete 500: Epoxy Polysulfide Waterproofing CoatingDocument2 pagesFlexcrete 500: Epoxy Polysulfide Waterproofing CoatingSuresh YadavNo ratings yet

- ROYALPOXY UW 410-tdsDocument3 pagesROYALPOXY UW 410-tdsSyed FaridNo ratings yet

- Sample Hot Work PermitDocument1 pageSample Hot Work PermitFelix EbikineiNo ratings yet

- T P ElastomerDocument63 pagesT P ElastomerSuyash TrivediNo ratings yet

- Maskote WB Zinc Stop Off Zyp02Document1 pageMaskote WB Zinc Stop Off Zyp02bondsivamaniNo ratings yet

- Binder Jetting Process: This ChapterDocument7 pagesBinder Jetting Process: This ChapterHarsh BansalNo ratings yet

- Railim Engineering Company ProfileDocument8 pagesRailim Engineering Company ProfileAlejandro Dela CruzNo ratings yet

- 7 Milling DynamometerDocument5 pages7 Milling DynamometerVirat KohliNo ratings yet

- (YE22) Holemaking 220330 FDocument242 pages(YE22) Holemaking 220330 FJoão PedroNo ratings yet

- Composite Materialslab Text BookDocument49 pagesComposite Materialslab Text BookSHAHBAZ PNo ratings yet

- Fin Irjmets1652476781Document11 pagesFin Irjmets1652476781yash matondkarNo ratings yet

- Theory of Metal Cutting For 2022 GATE ESE PSUs by S K MondalDocument82 pagesTheory of Metal Cutting For 2022 GATE ESE PSUs by S K MondalNabin MukherjeeNo ratings yet

- ENSC3002: Manufacturing and Materials: Lecture 2: Casting IntroductionDocument30 pagesENSC3002: Manufacturing and Materials: Lecture 2: Casting IntroductionRoger HanNo ratings yet

- FoundryDocument9 pagesFoundryMuhammad Tauseef ZafarNo ratings yet

- No.99.TC (FM) .26.1 Dt. 25.10.2007Document2 pagesNo.99.TC (FM) .26.1 Dt. 25.10.2007Preeti goswamiNo ratings yet

- Precision Honing Supplies: Above and Beyond HoningDocument203 pagesPrecision Honing Supplies: Above and Beyond Honingnik stavroginNo ratings yet

- A New Strategy On Designing Fluxes For Aluminum AlDocument19 pagesA New Strategy On Designing Fluxes For Aluminum AlJohn TorrezNo ratings yet

- Vertech Refrigeration Jacket: Reduced Stress Maximum QualityDocument1 pageVertech Refrigeration Jacket: Reduced Stress Maximum QualityRITONo ratings yet

- WP 11 Corrosion Protection Tape Coating123Document3 pagesWP 11 Corrosion Protection Tape Coating123KarthikNo ratings yet

- Press Brake Toolings Catalog - Saras - 1Document40 pagesPress Brake Toolings Catalog - Saras - 1saras precisionNo ratings yet

- Ducting QAP R02 080822Document2 pagesDucting QAP R02 080822Pavul RajNo ratings yet

- Compression CylindersDocument4 pagesCompression CylindersAlber MoelNo ratings yet

- Technical Report 1 - Sdb24103 (Sept 2022) Mohd Iqmal HafizDocument15 pagesTechnical Report 1 - Sdb24103 (Sept 2022) Mohd Iqmal HafiziqmalNo ratings yet

- LE 3101, Finishing OperationsDocument17 pagesLE 3101, Finishing OperationsRupokNo ratings yet

- Astm E1516Document2 pagesAstm E1516alferedNo ratings yet

- Otto Group 2Document23 pagesOtto Group 2otto groupNo ratings yet

- Kansas SawmillsDocument6 pagesKansas SawmillsGregg HockettNo ratings yet

- 3.6 VGO - HDT Unit:: Process DescriptionDocument4 pages3.6 VGO - HDT Unit:: Process DescriptionAkankshya MishraNo ratings yet

- Grades: Crystallization Rate Mooney Viscosity (MS2+2.5) Solution Viscosity Features General GradesDocument3 pagesGrades: Crystallization Rate Mooney Viscosity (MS2+2.5) Solution Viscosity Features General GradesHİLMİKISANo ratings yet

- 5110.003.12 PIG-SIG V PI-May2021Document8 pages5110.003.12 PIG-SIG V PI-May2021MORELLI silvioNo ratings yet

- Unit 8Document2 pagesUnit 8Berina DelicNo ratings yet

- Machinery List-1Document2 pagesMachinery List-1Hồng HạnhNo ratings yet