Professional Documents

Culture Documents

AS05

AS05

Uploaded by

Vic NairaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

AS05

AS05

Uploaded by

Vic NairaCopyright:

Available Formats

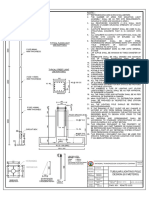

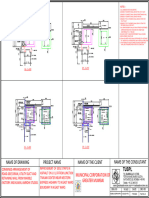

TABLE NOTES ON COLUMNS AND PEDESTALS

- 1 SCHEDULE OF MINIMUM SLAB REINFORCEMENT A. FOR ALL TIED COLUMNS AND PEDESTALS PROVIDE EXTRA 4 SETS OF

GENERAL: THICKNESS MINIMUM TEMPERATURE BARS

TIES AT 100mm O.C. FOR COLUMN REINFORCEMENTS JUST ABOVE THE REINFORCING CONCRETE LINTEL BEAM IN CONCRETE BLOCK STRUCTURAL STEEL

THE GENERAL NOTES AND SPECIAL REQUIREMENTS ARE FLOOR, JUST BELOW THE GIRDER AND AT CONSTRUCTION JOINTS. WALLS A. MATERIALS

100.00 mm 10 mmØ @ 275 mm EACH WAY LINTEL IN BLOCK WALLS ( PER 100mm THICKNESS )

SUPPLEMENTAL AND FORM PART OF THE PLANS, DRAWINGS AND 112.50 mm 10 mmØ @ 238 mm EACH WAY B. COLUMN AND PEDESTAL TIES SHALL BE PROTECTED EVERYWHERE BY 1.STRUCTURAL STEEL - STEEL TO BE USED FOR

SPECIFICATIONS, WHERE DETAILS OR REQUIREMENTS ARE NOT 125.00 mm 10 mmØ @ 212 mm EACH WAY COVERING OF A CONCRETE CAST MONOLITHICALLY WITH THE CORE OF CLEAR SPAN L TOTAL LENGTH MIN fc' HEIGHT OF REINFORCEMENT WEIGTH OF FABRICATION AND ERECTION OF THIS STRUCTURE SHALL

137.50 mm 10 mmØ @ 188 mm EACH WAY

COVERED BY THE PLANS OR SPECIFICATIONS. THESE GENERAL

150.00 mm 10 mmØ @ 175 mm EACH WAY

MINIMUM THICKNESS OF 38mm AND NOT LESS THAN 1 13 TIMES m L + 0.40 MPa LINTEL (cm) BOTTOM TOP LINTEL (lb) COMPLY WITH ALL THE PERTINENT PROVISIONS OF AISC

CONSTRUCTION NOTES SHALL BE USED IN SO FAR AS THEY ARE MAXIMUM SIZE OF COARSE AGGREGATE. SPECIFICATION FOR THE DESIGN, FABRICATION AND

1.20 1.60 13.8 19.08 1 - 10 mm 1 - 10 mm 170

APPLICABLE TO SATISFY REQUIREMENTS OF GOOD CONSTRUCTION E. UNLESS OTHERWISE NOTED IN PLANS, ALL BEDDED SLABS SHALL BE NOTES ON BEAMS AND GIRDERS 1.50 1.90 13.8 19.08 1 - 10 mm 1 - 10 mm 203 ERECTION OF STRUCTURAL STEEL FOR BUILDINGS AISC -

PRACTICE. IN CASE OF QUESTIONS ARISING FROM THE INTERPRETATION REINFORCED WITH 10 mmØ REBAR AT 0.25 m O.C. EACH WAY AT A. UNLESS OTHERWISE NOTED ON PLANS, CAMBER ALL BEAMS AND 1.80 2.20 13.8 19.08 1 - 10 mm 1 - 10 mm 235 14TH EDITION.

OF OR CONFLICT WITH OTHER DOCUMENTS, THE ATTENTION OF THE CENTER OF SLAB AND CONSTRUCTION JOINTS FOR SAME SHALL NOT GIRDERS AT LEAST 6.35mm FOR EVERY 457 CENTIMETERS OF SPAN a. STEEL SHAPES

2.10 2.40 17.2 19.08 1 - 16 mm 1 - 10 mm 266

OWNER / ENGINEERS MUST CALLED IN WRITING. F. BE MORE THAN 6m APART. EXCEPT CANTILEVERS FOR WHICH THE CAMBER SHALL BE AS NOTED IN 2.40 2.80 17.2 19.08 1 - 16 mm 1 - 10 mm 299 WIDE FLANGE, ANGLES, CHANNELS, PLATES SHALL

PROVIDE EXTRA REINFORCEMENTS FOR CORNER SLABS ( TWO PLANS OR AS ORDERED BY THE ENGINEER BUT IN NO CASE LESS THAN 2.70 3.10 17.2 19.08 1 - 20 mm 1 - 10 mm 331 BE ASTM A36. BUILT UP MEMBERS SHALL BE ASTM

GENERAL NOTES: ADJACENT DISCONTINUOUS EDGES AS SHOWN BELOW. 19.05mm FOR EVERY 3m OF FREE SPAN. A36. SUBSTITUTION SHALL ONLY BE ALLOWED IF

3.00 3.40 17.2 29.08 2 - 16 mm 1 - 10 mm 544

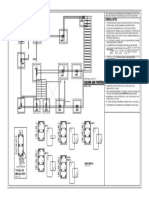

A. ALL REINFORCING BARS SHALL BE OF INTERMEDIATE GRADE WITH A B. TYPICAL BAR BENDING AND CUTTING DETAILS FOR BEAMS AND SUBSTITUTED MATERIALS IS ALSO A36 AND

5 - 10mm BARS @ 0.20 m 3.30 3.70 17.2 29.08 2 - 16 mm 1 - 10 mm 592

MINIMUM YIELD STRENGTH OF fy = 276 MPa ( 40,000 psi ) AND A GIRDERS SHALL BE AS SHOWN IN FIG. 6, FOR FLAT SLABS AND SLAB 3.60 4.00 17.2 29.08 2 - 16 mm 1 - 10 mm 640 PROVIDED FURTHER THAT SECTION MODULI AREA

O.C. BOTTOM BARS

MINIMUM TENSILE STRENGTH OF 483 MPa ( 70,000 psi ) EXCEPT AS FIG. 2 BENDS REFER TO PLAN. AND WEIGHT ARE = OR > THAN THE SPECIFIED

INDICATED. SEE TABLE"A" MATERIAL. REQUEST FOR SUBSTITUTION SHALL BE

20 BAR DIA. LAPPED

B. ALL REINFORCING BAR SIZE 12mm OR BIGGER SHALL BE DEFORMED 5 - 10mm BARS @ 0.20 m

FOR LENGTH OF SPLICE ON COMPRESSION BARS ACCOMPLISHED WITH DETAILED COMPUTATIONS FOR

EMBEDMENT

IN ACCORDANCE WITH ASTM - A615. BARS SMALLER THAN 12mm MAY NOTES ON FOOTINGS O.C. TOP BARS L1 / 5 L1 / 4 L2 / 4 L2 / 4 L3 / 4 THE ABOVE MATERIAL.

BE PLAIN BARS. A. CONTRACTOR SHALL REPORT TO ENGINEER ACTUAL UNUSUAL SOIL 3/4 THE EMBEDMENT b. BOLTS

LENGTH IN TABLE "A"

C. BARS OF REINFORCED CONCRETE EXPOSED TO THE WEATHER CONDITIONS UNCOVERED AND CONFIRM ACTUAL BEARING CAPACITY TOP REINFORCEMENT ALL BOLTS, NUTS AND WASHERS SHALL CONFORM

SHALL BE PREFERABLY BE PROTECTED AT LEAST 38mm AND IN NO OF SOIL IN WRITING BEFORE DEPOSITING CONCRETE. 19.05 mm CLEAR TO A307 OR A325 UNLESS OTHERWISE INDICATED.

WHEN COUNTED

CASE LESS THAN 25mm CONCRETE COVER. THIS PROVISIONS MAYBE B. FOOTING SHALL BE AT LEAST 1.50m BELOW FINISHED GRADE LINE FOR COMPRESSION ANCHOR BOLTS SHALL LIKEWISE BE OF EQUAL

WAIVED WHEN ADEQUATE WATERPROOFING IS PROVIDEDBUT SHALL UNLESS OTHERWISE INDICATED. EXTEND 20 BAR STRENGTH AS A325 BOLTS OF SAME SIZE.

BOTTOM REINF.

60

IN NO CASE LESS THAN 20mm. DIA. BEYOND OPPOSITE

C. UNLESS OTHERWISE SPECIFIED, ALL FOOTINGS SHALL REST ON DENSE c. WELDS

°

FACE OF SUPPORT 19.05 mm CLEAR

D. IN THE INTERPRETATION OF DRAWINGS, INDICATED DIMENSIONS SAND OR VERY HARD CLAY. THIS MAY SOMETIMES REQUIRE ALL WELDS SHALL BE IN ACCORDANCE WITH AWS

HEIGHT OF LINTEL

SHALL GOVERN AND DISTANCES OR SIZES SHALL NOT BE SCALED OVEREXCAVATION ABOUT 1.00m FROM PRESCRIBED BOUNDARY LEVEL. STRUCTURAL WELD CODE D1-1 LATEST REVISION

EXTERIOR GIRDER 0.10 10mm

FOR CONSTRUCTION PURPOSES. SUCH OVEREXCAVATION SHALL BE REPLACED WITH WELL COMPACTED EXTERIOR COLUMN INTERIOR COLUMN SUPPORT FRO SHIELDED METAL ARC WELDING PROCESS,

E. IN REFERENCE TO OTHER DRAWINGS, SEE ARCHITECTURAL CRUSHED ROCK BACKFILL. COMPACTION SHALL BE 95% OF MDD BASED SUPPORT SUPPORT 0.20 ELECTRODES E - 70 SHALL CONFORM TO AWS AS-1

L1 L2 L3

DRAWINGS FOR DEPRESSIONS IN FLOOR SLABS, OPENINGS IN FIG. 7

ON ASTM D698. SPAN L OR LATEST EDITION. SUBMERGED ARC WELDING

SEE TABLE "B" FOR LENGTH FIG. 5

WALLS AND SLABS, INTERIOR PARTITIONS, LOCATION OF DRAINS, D. MINIMUM CONCRETE PROTECTION FOR REINFORCEMENT SHALL BE SEE TABLE"B" PROCESS MAYBE USED AT THE OPTION OF

OF LAPPED SPLICE L + 0.40

ETC. 0.075m CLEAR FOR CONCRETE DEPOSITED AGAINST THE GROUND AND FOR LENGTH OF FABRICATION UPON THE APPROVAL OF ENGINEER.

EMBEDMENT

F. IN CASE OF DISCREPANCIES AS TO THE LAYOUT DIMENSIONS AND 0.05m FOR CONCRETE DEPOSITED AGAINST FORMWORK. TABLE "A"

ELEVATIONS BETWEEN THE STRUCTURAL PLANS AND OTHER B. QUALITY CONTROL

DRAWINGS, THE CONTRACTOR SHALL NOTIFY BOTH THE MASONRY TENSION BARS EMBEDMENT LENGTH & LAP SPLICES

IN CENTIMETERS 1.REFER TO SPECIFICATIONS FOR QUALITY CONTROL

STRUCTURAL ENGINEERS AND OWNER'S REPRESENTATIVE OF SITE UNITS

SCHEDULE OF CHB & CERAMIC BLOCK REINFORCEMENT

fc' = 20.7 MPa fc' = 17.2 MPa

TESTING REQUIREMENTS.

ENGINEER IN WRITING BEFORE PROCEEDING WITH THE AFFECTED REINFORCEMENT NOTES: BAR SIZE 2. STEEL SHAPES

BLOCK

WORK. THICKNESS A. MINIMUM LAPS AT SPLICE = 0.25m DEFORMED EMBEDMENT LAP EMBEDMENT LAP EVERY BATCH OF STRUCTURAL STEEL SHAPE FOR

HORIZONTAL VERTICAL

B. PROVIDE RIGHT ANGLED NOTES ON EMBEDDED PIPES IN CONCRETE

75 mm 10 mmØ AT 10 mmØ @ 600 mm O.C. REINFORCEMENT AT CORNERS 10 mm 30 30 30 30 A. ALL EMBEDDED PIPES FOR UTILITIES, ETC. SHALL BE MAXIMUM 100mmØ FABRICATION SHALL HAVE THE MANUFACTURER'S

NOTE ON CONCRETE MIXES AND PLACING EVERY 0.92m LONG. 12 mm 30 36 30 30 MILL CERTIFICATE SHOWING THEIR CHEMICAL AND

A. THE CONTRACTOR SHALL SUBMIT THE SCHEDULE OF POURING AND

100 mm

3 LAYER

10 mmØ @ 600 mm O.C. SINGLE RIGID GALVANIZED IRON PIPES UNLESS OTHERWISE SPECIFIED

C. WHERE CHB OR CERAMIC BLOCK 16 mm 36 45 30 43 PHYSICAL PROPERTIES.

LOCATIONS AT CONSTRUCTION JOINTS TO THE FIELD ENGINEER AT

150 mm 12 mmØ @ 600 mm O.C.

WALLS ADJOIN COL., RC BEAMS & 20 mm 36 55 39 61

OR APPROVED IN WRITING BY THE STRUCTURAL ENGINEER.

200 mm 12 mmØ AT 12 mmØ @ 600 mm O.C. B. SUCH PIPES WHEN SO EMBEDDED SHALL NOT TAKE UP MORE THAN 3. WELD FINISH

LEAST FOUR ( 4 ) DAYS PRIOR TO THE POURING FOR APPROVAL. WALL DOWELS WITH THE SAME AS 22 mm 52.5 62.5 57.5 65

EVERY VERT. OR HOR. REINFORCEMENT 25 mm 56 95 62 105 FOUR ( 4 ) PERCENT OF THE GROSS AREA OF THE CONCRETE MEMBER. ALL WELDS SHALL FREE FROM UNDERCUTS,

B. WET CURING OF CONCRETE SHALL BE CONTINUOUS FOR MINIMUM 3 LAYER SHALL BE PROVIDED. PINHOLES AND CRACKS. NON-DESTRUCTIVE TESTING

28 mm 71 121 77 131

PERIOD OF TEN ( 10 ) DAYS IMMEDIATELY AFTER POURING. 32 mm 93 158 101 172 (DYE PENETRANT) MAYBE CONDUCTED AT WELDS

C. THE CONTRACTOR SHALL FURNISH AND MAINTAIN ADEQUATE 36 mm 151 179 128 218 DEEMED NOT IN CONFORMITY WITH THE

PROVIDE STIFFENER COLUMN COLUMNS AND BEAMS AT EVERY 3000mm ON

FORMS FOR SHORINGS UNTIL THE CONCRETE MEMBERS HAVE SPECIFICATION AND SHALL BE TO CONTRACTOR'S

CENTER FOR CHB WALL, USE 4 - 12mmØ VERTICAL BARS WITH 10mmØ TIES

ATTAINED THEIR SUFFICIENT STRENGTH FOR WORKING CONDITION ACCOUNT.

ANTICIPATED.

@ 300mm ON CENTER. TABLE "B" NOTES ON COMPACTED FILL

COMPRESSION BARS EMBEDMENT LENGTH & LAP SPLICES A. FILL, BACKFILL AND SUB-GRADES UNDER SLABS AND FOOTINGS SHALL

D. ALL CONCRETE WORKS SHALL BE DONE IN ACCORDANCE WITH THE NOTES ON CONCRETE WALLS IN CENTIMETERS BE COMPACTED TO A MINIMUM 95% OF MAXIMUM DRY DENSITY BASED C. FABRICATION

ACI 318 - 14 BUILDING CODE REQUIREMENTS FOR REINFORCED A. ALL WALLS SHALL BE REINFORCED ACCORDING TO THE FOLLOWING

fc' = 20.7 MPa fc' = 17.2 MPa ON ASTM D-698 FOR EVERY LIFT IN ACCORDANCE WITH THE 1. WELDS

CONCRETE AND ALL STRUCTURAL STEEL WORK IN ACCORDANCE SCHEDULE OF WALL REINFORCEMENT UNLESS OTHERWISE INDICATED BAR SIZE

SPECIFICATIONS. ALL WELDED CONNECTIONS SHALL DEVELOP THE

WITH THE LATEST EDITION OF THE A.I.S.C. SPECIFICATIONS IN SO IN THE PLANS. DEFORMED EMBEDMENT LAP EMBEDMENT LAP

B. MAXIMUM LIFT THICKNESS FOR COMPACTION SHALL BE 250mm. FULL STRENGTH OF THE MEMBERS CONNECTED.

FAR AS THEY DO NOT CONFLICT WITH THE REQUIREMENTS OF THE

SCHEDULE OF CHB & CERAMIC BLOCK REINFORCEMENT 10 mm 20 30 20 30 C. MONITOR QUALITY OF COMPACTION USING AN INDEPENDENT TESTING a. LENGTH OF WELDS:

NATIONAL STRUCTURAL CODE OF THE PHILIPPINES AND LOCAL 12 mm 20 30 21 34

WALL REINFORCEMENT VERTICAL LABORATORY USING ASTM D-1556 CRITERIA. THE MINIMUM LENGTH OF FILLET SHALL NOT BE LESS

CODES. REMARKS 16 mm 23 32.5 26 42.5

THICKNESS HORIZONTAL VERTICAL SECTIONS D. OVERSIZED BOULDERS UNDERNEATH FOOTINGS SHALL BE REMOVED THAN 4 TIMES THE NOMINAL SIZE WHERE

E. A.C.I. REFERS TO AMERICAN CONCRETE INSTITUTE, A.I.S.C. TO 20 mm 28 37.5 31 50

100 mm 10 mmØ @ 250 mm O.C. 10 mmØ @ 300 mm O.C. HOR. BARS @

VERT. STAG.

22 mm 25 45 27.5 57.5 TO PROVIDE FULL BEARING. CAVITY OF VOID EXPOSED SHALL BE INTERMITTENT WELDS MAY BE USED, THE LENGTH

AMERICAN INSTITUTE OF STEEL CONSTRUCTION AND A.S.T.M. TO BARS

125 mm 10 mmØ @ 200 mm O.C. 10 mmØ @ 250 mm O.C. CENTER, VERT. 25 mm 37 51 41 67.5 BACKFILLED WITH LEAN CONCRETE. OF SEGMENT SHALL NOT BE LESS THAN 4 TIMES THE

AMERICAN SOCIETY FOR TESTING MATERIALS. 150 mm 12 mmØ @ 250 mm O.C. 12 mmØ @ 300 mm O.C. BARS STAG. HOR. BARS 28 mm 42 57.5 47 75 WELD SIZE WITH A MINIMUM OF 40mm.

F. UNLESS OTHERWISE INDICATED IN PLANS OR NOTED IN THE 175 mm 12 mmØ @ 220 mm O.C. 12 mmØ @ 250 mm O.C. OUTSIDE VERT. 32 mm 46 64 52 85

200 mm 10 mmØ @ 250 O.C.E.F 10 mmØ @ 300 O.C.E.F. BOTH FACES b. END RETURN OF FILLET WELDS

SPECIFICATIONS, THE MINIMUM 28th DAY CYLINDER COMPRESSIVE BARS

36 mm 51 72

STRENGTH OF CONCRETE SHALL BE AS FOLLOWS:

225 mm

250 mm

10 mmØ @ 200 O.C.E.F.

12 mmØ @ 300 O.C.E.F.

10 mmØ @ 250 O.C.E.F.

12 mmØ @ 350 O.C.E.F.

HOR. BARS SHALL

BE OUTSIDE

NOTES ON SLAB ON GRADE SIDE OR END FILLET WELDS TERMINATING AT END OR

HOR. BARS

A. SLAB SHALL BE PLACED WITH A MAXIMUM WATER CEMENT RATIO OF SIDES SHALL BE RETURNED CONTINUOUSLY FOR A

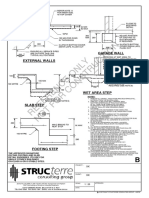

1. FOOTINGS, FOOTING TIE BEAMS: fc' = 20.7 MPa ( 3000 psi )

C. IF BEAM REINFORCING BARS END IN A WALL, THE CLEAR DISTANCE 0.42. ANY DISCREPANCY IN SUMP OR WORKABILITY SHALL BE DISTANCE NOT LESS THAN TWICE THE NOMINAL SIZE

2. COLUMN, PEDESTALS: fc' = 20.7 MPa ( 3000 psi ) REINFORCING BARS SHALL HAVE 25mm MINIMUM CLEAR CONCRETE

FROM THE BAR TO THE FARTHER FACE OF THE WALL SHALL NOT BE REMEDIED BY THE USE OF PLASTICIZER. OF WELD.

3. BEAMS AND GIRDERS: fc' = 20.7 MPa ( 3000 psi ) COVER FROM FACE OF WALL EXCEPT FOR WALLS IN CONTACT WITH

LESS THAN 25mm. EMBEDMENT LENGTH SHALL BE AS SHOWN IN TABLE B. ADDITION OF FLY ASH TYPE "F" IS REQUIRED TO MAXIMUM OF 15% OF c.USE E70 ELECTRODES FOR ALL WELDS IN

4. NON-LOAD BEARING WALL PARTITION, CATCH BASIN, THE GROUND WHERE A MINIMUM OF 62.5mm SHALL BE PROVIDED, AND

"A" FOR TENSION BARS AND TABLE "B" FOR COMPRESSION BARS. CEMENT WEIGHT. STRUCTURAL STEEL.

SIDEWALK (IF ANY): fc' = 17.2 MPa ( 2500 psi ) FOR EXPOSED FACES OF FORMED WALLS WHERE THE MINIMUM SHALL

D. IF THERE ARE TWO OR MORE LAYERS OF REINFORCING BARS, USE C. SLABS SHALL CAST STRAIGHT TO FINISH. OVERTROWELLING SHALL BE 2. BOLTS

BE 50mm CLEAR.

25mm DIAMETER BAR SEPARATORS SPACED ABOUT 90 CENTIMETERS DONE USING HELICOPTER TROWEL. a. MINIMUM EDGE DISTANCE:

G. CONCRETE SHALL BE DEPOSITED IN ITS FINAL POSITION WITHOUT B. CARRY VERTICAL BARS AT LEAST 600mm ABOVE FLOOR LEVEL TO

ON CENTER. IN NO CASE SHALL THERE BE LESS THAN TWO ( 2 ) D. BROADCAST OF CEMENT POWDER SHALL NOT BE ALLOWED DURING THE MINIMUM EDGE DISTANCE OF BOLTS SHALL

SEGREGATION, RE-HANDLING OR FLOWING. PLACING SHALL BE PROVIDE FOR SPLICES, WHEN NECESSARY STOP AT 50mm BELOW TOP

SEPARATORS BETWEEN LAYERS OF BARS. FINISHING OPERATIONS. CONFORM TO THE REQUIREMENTS OF AISC STEEL

DONE PREFERABLY WITH BUGGIES, BUCKETS OR WHEELBARROWS. SLAB OR SOLID BAND WHERE THE WALL ENDS. VERTICAL AND

E. MINIMUM CONCRETE PROTECTION FOR REINFORCING BARS OR STEEL MANUAL 8TH EDITION. THE MAXIMUM EDGE DISTANCE

NO CHUTE WILL BE ALLOWED EXCEPT TO TRANSFER CONCRETE HORIZONTAL BARS SHALL BE SPLICED BY LAPPING A DISTANCE EQUAL

SHAPES SHALL BE AS SHOWN IN FIG. 6. FROM BOLT CENTER SHALL BE 12 TIMES THICKNESS

FROM HOPPERS TO BUGGIES, WHEELBARROWS OR BUCKETS IN 40 BAR DIAMETERS AND WIRED SECURELY WITH NO. 16 G.I. WIRE

OF PLATE BUT NOT TO EXCEED 150mm.

WHICH CASE THEY SHALL NOT EXCEED SIX ( 6 ) METERS IN PROVIDED THAT SPLICES IN ADJACENT BARS ARE STAGGERED AT NOTES ON EQUIPMENT & MACHINERY LAYOUT

b. MINIMUM PITCH

AGGREGATE LENGTH. LEAST 1.60m O.C. (SEE FIG. 3) SEE NOTE A. CONTRACTOR SHALL REFER TO OWNER FURNISHED EQUIPMENT

ON CENTER SPACING OF BOLTS SHALL NOT BE LESS

H. NO DEPOSITING OF CONCRETE SHALL BE ALLOWED WITHOUT THE DIAGRAMS AND LAYOUT TO VERIFY WETHER DISCREPANCIES, THE

40 DIA. b

THAN 3 TIMES THE NOMINAL DIAMETER.

OWNER AND THE ENGINEER SHOULD BE NOTIFIED IN WRITING BEFORE

1.60m O.C.

USE OF VIBRATORS UNLESS AUTHORIZED IN WRITING BY THE 1.60 MIN WEB BARS NOTE:

SEE NOTE 18.75 mm CLEAR FOR JOIST 3. TOLERANCES

DESIGNER AND ONLY FOR UNUSUAL CONDITIONS WHERE VIBRATION 40 DIA. b PROCEEDING WITH ANY AFFECTED WORK.

37.50 mm CLEAR FOR BEAMS SOME VARIATIONS EXPECTED IN THE FINISH OVERALL

h

IS EXTREMELY DIFFICULT TO ACCOMPLISH. ANY POURING REQUIRES FIG. 6 & GIRDERS

DIMENSIONS OF FRAMES SHALL NOT EXCEED THE

ONE SPARE VIBRATOR ALWAYS. 25 mm

SEPARATOR ROLLING TOLERANCES FOR CROSS SECTIONAL

I. SAMPLING FOR COMPRESSIVE STRENGTH TESTS SHALL BE MADE IN FIG. 3

DIMENSIONS, CAMBER AND SWEEP PERMITTED UNDER

0.60

ACCORDANCE WITH SPECIFICATIONS BUT NOT LESS THAN I SET FOR SEE NOTEb

F. WHEN A BEAM CROSSES A GIRDER, REST BEAM BARS ON TOP OF ASTM SPECIFICATION A36.

EACH DAY OF POUR.

J. PULVERIZED FLY ASH ( PFA ) MAY BE SUBSTITUTED TO MAX 15% BY GIRDER BARS, BEAM REINFORCING BARS SHALL BE SYMMETRICALLY

FLOOR LEVEL, FFL. CONTRACTOR MUST VERIFY ALL DIMENSIONS ON SITE D. ERECTION

WEIGHT OF ORDINARY PORTLAND CEMENT TYPE 1. THIS ABOVE THE CENTER LINE WHENEVER POSSIBLE.

G. GENERALLY NO SPLICE SHALL BE PERMITTED AT POINTS WHERE CONTRACTOR MUST SUBMIT MATERIAL SAMPLES TO ARCHITECT 1. BRACING

REQUIREMENT IS ONLY MANDATORY FOR MAT FOUNDATION FOR C. UNLESS OTHERWISE NOTED IN THE PLAN, ALL OPENINGS IN WALLS

CRITICAL BENDING STRESS OCCUR, SPLICES WHERE SO PERMITTED CONTRACTOR MUST SUBMIT SHOP DRAWINGS TO ARCHITECT THE FRAME OF STEEL STRUCTURE SKELETON SHALL BE

CCT AND BBT TANKS AND IS OPTIONAL ELSEWHERE. STRENGTH AND 250mm OR LARGER SHALL BE REINFORCED AROUND WITH 2 - 20mm

SHALL BE AS INDICATED IN TABLE "A" AND "B". WELDED SPLICES SHALL CARRIED UP TRUE AND PLUMB, WITHIN THE LIMITS

WORKABILITY REQUIREMENTS NEED TO SATISFIED IRRESPECTIVE BARS FOR 225mm, 175mm, 150mm WALLS; USE 2 - 12mm BARS ( SEE Fig.

DEVELOP IN TENSION AR LEAST 125% OF THE SPECIFIED YIELD DEFINED IN SECTION 7(h) OF AISC CODE OF STANDARD

OF WHETHER OF PFA HAS BEEN USED OR NOT. 5 ). ALL WALLS SPANNING OPENINGS SHALL HAVE VERTICAL

STRENGTH OF THE BAR. NO MORE THAN 50% OF THE BARS ANY ONE PRACTICE. TEMPORARY BRACING SHALL BE PROVIDED TO

REINFORCEMENTS BENT TO U - FORM LIKE STIRRUPS AND SPACED

NOTES ON CONCRETE SLABS SECTION SHALL BE ALLOWED TO BE SPLICED THEREIN. RESIST ALL LOADS INCLUDING ERECTION EQUIPMENT.

ACCORDING TO THE SCHEDULE UNLESS OTHERWISE NOTED ( SEE

A. ALL SLAB REINFORCEMENT SHALL BE 20.0mm CLEAR MINIMUM FROM 2. ALIGNMENT

SECTION A OF FIG. 4).

BOTTOM AND FROM TOP OF SLAB. NO RIVETING, PERMANENT BOLTING OR WELDING SHALL

B. UNLESS OTHERWISE DETAILED, IN CONTINUOUS SLAB HAVING SAME 2 - BARS BE DONE UNTIL STRUCTURE HAS BEEN PROPERLY

REINFORCEMENT RUNNING IN ONE DIRECTION, REINFORCING BARS U - FORM ALIGNED.

0.40

SHALL BE BENT UP, EXTENDED, OR CUT AS FOLLOWS: 3.SAGRODS AND CROSS BRACING SHALL BE INSTALLED

L1 / 3 L2 / 4 L2 / 4 L3 / 4 L4

OPEN

AND TIGHTENED BEFORE INSTALLATION OF ROOFING OR

FIG. 4 WALL CLADDING.

2 EDGE BARS 0.40 2 - BARS

U - FORM

E. PAINTING AND SURFACE PREPARATION

A

0.40 0.40 1.STEEL TO BE USED FOR ERECTION OF THIS STRUCTURE

SHALL BE PAINTED WITH ONE ( 1 ) SHOP COAT OF RED

FIG. 1

OXIDE PAINT AND ITS SURFACE PREPARED IN

L1 / 3 L1 / 5 L2 / 5

COMPLIANCE WITH THE SPECIFICATIONS.

L1 L2 L3 L4

2.CONTRACTOR TO VERIFY WITH REPRESENTATIVES -

C. IF SLAB ARE REINFORCED BOTHWAYS, BARS ALONG THE SHORTER

SPAN SHALL BE PLACED BELOW THOSE ALONG THE LONG SPAN AT THE 1 STRUCTURAL NOTES PAINTING AND SURFACE PREPARATION SPECIFICATION

BEFORE PROCEEDING WITH WORK.

CENTER AND OVER AT THE SUPPORTS. FOR THE REINFORCING BARS S-02 SCALE: NTS

NEAR THE SUPPORTS, THE SPACING OF THE BARS AT COLUMN STRIPS

SHALL BE APPROXIMATELY ONE AND ONE HALF ( 1 12 ) THAT IN THE

MIDDLE STRIPSBUT NO CASE GREATER THAN TWO AND ONE HALF (2 12 )

TIMES THE SLAB THICKNESS NOR 45 CENTIMETERS..

D. TEMPERATURE BARS FOR SLAB SHALL BE GENERALLY PLACED NEAR

THE FACE IN TENSION AND SHALL NOT BE LESS THAN 0.0025 x BT. ( See

TABLE - 1 )

CIVIL ENGINEER: PRC NO.: PROJECT TITLE: APPROVAL: SHEET CONTENTS: REVISIONS: CAD BY: SHEET NO:

VALIDITY: AS-BUILT TWO STOREY RESIDENCE STRUCTURAL NOTES

PTR NO.:

ISSUED AT: S-02

ISSUED ON: DR. POTENCIANO MALVAR

TIN NO.: LOCATION: MY HOMES SUBDIVISION, BRGY STA ANASTACIA, STO TOMAS OWNER

5 8

ISSUED AT: BATANGAS NO. DESCRIPTION DATE

You might also like

- General: Structural SteelDocument1 pageGeneral: Structural SteelDerf Jayson AdanteNo ratings yet

- Cariño Structural (A3)Document7 pagesCariño Structural (A3)Alvin DeliroNo ratings yet

- Section A-A: NotesDocument1 pageSection A-A: NotesYazan MohammadNo ratings yet

- S-1 RevisedDocument1 pageS-1 Revisedbernard1agoncillioNo ratings yet

- General Construction NotesDocument1 pageGeneral Construction NotesjanelleNo ratings yet

- Guardhouse PDFDocument2 pagesGuardhouse PDFOpendi CharlesNo ratings yet

- STR 1Document1 pageSTR 1Christian BenitezNo ratings yet

- 6.0 Reinforcement 7.0 Concrete 8.0 Post Tensioning: Concrete Mix Performance Criteria TableDocument1 page6.0 Reinforcement 7.0 Concrete 8.0 Post Tensioning: Concrete Mix Performance Criteria Tablenishan_ravinNo ratings yet

- E. Formworks: (Structural)Document1 pageE. Formworks: (Structural)Nonoy Justiniane-Giray JrNo ratings yet

- Standard Drawings PDFDocument42 pagesStandard Drawings PDFOpendi CharlesNo ratings yet

- Cross Drain DrawingDocument1 pageCross Drain DrawingManoj BatraNo ratings yet

- Gen NotesDocument1 pageGen NotesGian OrillosaNo ratings yet

- PDW-TZ-1133 Tubular Lighting Pole DesignDocument1 pagePDW-TZ-1133 Tubular Lighting Pole Designihsan ul haqNo ratings yet

- 1 Detail1Document1 page1 Detail1Opendi CharlesNo ratings yet

- Summary of Submittals by Macro Wall IndustrialDocument4 pagesSummary of Submittals by Macro Wall IndustrialKrysna JorizaNo ratings yet

- Acm TSC VS MF DWG ST 2001Document1 pageAcm TSC VS MF DWG ST 2001Aecom IndiaNo ratings yet

- DRG - SECTION OF CABLE TRENCHDocument1 pageDRG - SECTION OF CABLE TRENCHAmarjit KulkarniNo ratings yet

- CIRCULAR WATER TANK DESIGN-Layout1 AkhilDocument1 pageCIRCULAR WATER TANK DESIGN-Layout1 AkhilVENKAT KALYANNo ratings yet

- 1 Footing Plan PDFDocument1 page1 Footing Plan PDF114 Gopal jagtapNo ratings yet

- Structural Detailing of (G+2) Residential Apartment: Notes and SpecificationDocument1 pageStructural Detailing of (G+2) Residential Apartment: Notes and SpecificationSUBHADIP KARANNo ratings yet

- R A S L I M S-01 Proposed 3-Storey Mix-Used Commercial BuildingDocument1 pageR A S L I M S-01 Proposed 3-Storey Mix-Used Commercial BuildingShariah MelonNo ratings yet

- Typical Truss Detail Construction Notes S-5: Not To Scale Not To Scale Sheet Content: M G Tambalque Design & ConstructionDocument1 pageTypical Truss Detail Construction Notes S-5: Not To Scale Not To Scale Sheet Content: M G Tambalque Design & ConstructionCedrixe MadridNo ratings yet

- Structural Drawings Extension LondonDocument1 pageStructural Drawings Extension LondonVlad CiupituNo ratings yet

- MR - Rasul - Set - 2 - Structural - Drawing-12.RCC NOTES PDFDocument1 pageMR - Rasul - Set - 2 - Structural - Drawing-12.RCC NOTES PDFMr. SinghNo ratings yet

- GennotesDocument1 pageGennotesNeil ArmstrongNo ratings yet

- General Notes-1: Table 1: Lap Splices For RebarsDocument1 pageGeneral Notes-1: Table 1: Lap Splices For RebarsTanvir IslamNo ratings yet

- STR Final 02112319473547375Document20 pagesSTR Final 02112319473547375Muhammad AfrasiyabNo ratings yet

- Ac 036261 001 - 05312022Document1 pageAc 036261 001 - 05312022JAWAHAR TNo ratings yet

- Ac-036261-001 5312022 2Document1 pageAc-036261-001 5312022 2JAWAHAR TNo ratings yet

- Wall & Footing Details: Schedule of Reinforced Concrete BeamDocument1 pageWall & Footing Details: Schedule of Reinforced Concrete BeamJaymark SorianoNo ratings yet

- Khuthi Munarini - A4Document1 pageKhuthi Munarini - A4anzaniNo ratings yet

- Basement Stair-Case Typical Floor Stair-Case: Section B-B' Section B-B'Document1 pageBasement Stair-Case Typical Floor Stair-Case: Section B-B' Section B-B'Bhavya PatelNo ratings yet

- CW - 03 General Notes (Sheet 01 of 02)Document1 pageCW - 03 General Notes (Sheet 01 of 02)Hurriyat AliNo ratings yet

- General Notes Foundations: Two - Storey Residential Building With Roof DeckDocument1 pageGeneral Notes Foundations: Two - Storey Residential Building With Roof DeckKarlo CabanginNo ratings yet

- General Structural Notes Page 1Document1 pageGeneral Structural Notes Page 1piyadang16No ratings yet

- General Construction Notes: Schedule of Minimum Slab ReinforcementDocument2 pagesGeneral Construction Notes: Schedule of Minimum Slab ReinforcementDominic Robiso DatuinNo ratings yet

- General Construction Notes: Schedule of Minimum Slab ReinforcementDocument1 pageGeneral Construction Notes: Schedule of Minimum Slab ReinforcementDominic Robiso DatuinNo ratings yet

- Grade Beam2Document1 pageGrade Beam2tmc.roshen.2024No ratings yet

- PDW-TV-495 6.0 Meters Wide Bituminous Carpet Road-Iso A3Document1 pagePDW-TV-495 6.0 Meters Wide Bituminous Carpet Road-Iso A3ihsan ul haqNo ratings yet

- 1.JVLR Retaining Wall R-1-08Document1 page1.JVLR Retaining Wall R-1-08samir bendreNo ratings yet

- Box Culvert 1Document1 pageBox Culvert 1aloopakoda5No ratings yet

- B FootingsDocument12 pagesB FootingsRiham Massoud SobhyNo ratings yet

- General Notes & Specifications PDFDocument2 pagesGeneral Notes & Specifications PDFPriodeep ChowdhuryNo ratings yet

- Curtain Wall & Crash Barrier DrawingDocument1 pageCurtain Wall & Crash Barrier DrawingSharun ShajiNo ratings yet

- General Construction Notes: Codes and Standards General Notes Reinforcing Steel Beams and GirdersDocument1 pageGeneral Construction Notes: Codes and Standards General Notes Reinforcing Steel Beams and GirdersByen VillanuevaNo ratings yet

- 1.JVLR Retaining Wall R-1-13Document1 page1.JVLR Retaining Wall R-1-13samir bendreNo ratings yet

- Jonai SDLL 2Document1 pageJonai SDLL 2Bhargov PeguNo ratings yet

- Structural ResidenceDocument4 pagesStructural Residence2226558No ratings yet

- Ilovepdf MergedDocument3 pagesIlovepdf MergedCivil MantraNo ratings yet

- Drawing ReferenceDocument1 pageDrawing Referenceadnan.yaseenNo ratings yet

- ST-01 To ST-12Document12 pagesST-01 To ST-12Regina LagaticNo ratings yet

- Clinic Project 01 - 014610Document1 pageClinic Project 01 - 014610Joyce JereNo ratings yet

- 1.JVLR Retaining Wall R-1-10Document1 page1.JVLR Retaining Wall R-1-10samir bendreNo ratings yet

- Awetu - Jimma - Shopes and Public Restroom - STDocument13 pagesAwetu - Jimma - Shopes and Public Restroom - STAhmed KedirNo ratings yet

- S001 76-10526-Detail Design: Adac Midfield Terminal Fire Station Structural General Notes & Details Sheet 1Document1 pageS001 76-10526-Detail Design: Adac Midfield Terminal Fire Station Structural General Notes & Details Sheet 1Mazen Ismail0% (1)

- 4a405 Bathroom Detail-2Document1 page4a405 Bathroom Detail-2Bismo AnggoroNo ratings yet

- Legend: Footpath 2.8.1 Continuous Footpath TreatmentsDocument1 pageLegend: Footpath 2.8.1 Continuous Footpath TreatmentsGhassan Abood HabeebNo ratings yet

- Typical Details of Brick Work Compound Wall in Sewage Pumping Stations - Plan & Section - CompressedDocument1 pageTypical Details of Brick Work Compound Wall in Sewage Pumping Stations - Plan & Section - CompresseddineshNo ratings yet

- ShopDrawings - Part 1Document51 pagesShopDrawings - Part 1YapNo ratings yet

- Lighting System Layout Lighting System Layout: Bedroom 1Document1 pageLighting System Layout Lighting System Layout: Bedroom 1Vic NairaNo ratings yet

- WH AC: Power System Layout Power System LayoutDocument1 pageWH AC: Power System Layout Power System LayoutVic NairaNo ratings yet

- Lighting System Layout Lighting System Layout: Bedroom 2Document1 pageLighting System Layout Lighting System Layout: Bedroom 2Vic NairaNo ratings yet

- Activity Topic - Work Breakdown StructureDocument16 pagesActivity Topic - Work Breakdown StructureVic NairaNo ratings yet

- Makati Project WorkDocument1 pageMakati Project WorkVic NairaNo ratings yet

- AS04Document1 pageAS04Vic NairaNo ratings yet

- BOQ (Foreman)Document3 pagesBOQ (Foreman)Vic NairaNo ratings yet

- Casamingo Drawng-Set FinalDocument21 pagesCasamingo Drawng-Set FinalVic NairaNo ratings yet

- Final Preboard Design 2021Document2 pagesFinal Preboard Design 2021Vic NairaNo ratings yet

- Wind Load Occupancy Category:: Interpolation Interpolation Interpolation InterpolationDocument4 pagesWind Load Occupancy Category:: Interpolation Interpolation Interpolation InterpolationVic NairaNo ratings yet

- Structural Analysis Portal MethodDocument14 pagesStructural Analysis Portal MethodVic NairaNo ratings yet

- Memorandum: Republic of The Philippines National Police Commission Albay Police Provincial Office Manito, AlbayDocument1 pageMemorandum: Republic of The Philippines National Police Commission Albay Police Provincial Office Manito, AlbayVic NairaNo ratings yet

- Losses in PipeDocument9 pagesLosses in PipeNiroexNo ratings yet

- ProjectDocument16 pagesProjectAkshay HalyalNo ratings yet

- Financial Proposal TALIPAPADocument5 pagesFinancial Proposal TALIPAPAMelody Frac ZapateroNo ratings yet

- WSM V/S LSM IS:800-2007: Vishal A. NalwarDocument74 pagesWSM V/S LSM IS:800-2007: Vishal A. NalwarvishalnalwarNo ratings yet

- Transport PhenomenaDocument1 pageTransport PhenomenaVignesh JeeruNo ratings yet

- Review Questions: BLDG Technology Utilities Part1: de Leon, Frialyn ErmengardeDocument40 pagesReview Questions: BLDG Technology Utilities Part1: de Leon, Frialyn ErmengardeFrialynNo ratings yet

- HA3 - Diego Larra EspinoDocument4 pagesHA3 - Diego Larra EspinoDiegoNo ratings yet

- 135 - Guidelines For Classification of Well Control Incidents and Well Integrity Incidents - Rev. 2Document21 pages135 - Guidelines For Classification of Well Control Incidents and Well Integrity Incidents - Rev. 2Sean CurnowNo ratings yet

- Laboratory Manual Ce152p-2Document19 pagesLaboratory Manual Ce152p-2anonymousoreviewerNo ratings yet

- Any Wall 70% None Included: Chemistry Concrete: Excel KeyDocument105 pagesAny Wall 70% None Included: Chemistry Concrete: Excel KeyPruebaNo ratings yet

- BracingsDocument7 pagesBracingsMalavika BabuNo ratings yet

- The Behavior of Horizontally Glued Laminated Beams Using Rubber WoodDocument10 pagesThe Behavior of Horizontally Glued Laminated Beams Using Rubber WoodTiranaNo ratings yet

- M 30 Concrete Mix Design FinalDocument10 pagesM 30 Concrete Mix Design FinalRakesh ReddyNo ratings yet

- 100 Top Fluid Mechanics Multiple Choice Questions With Answers PDFDocument19 pages100 Top Fluid Mechanics Multiple Choice Questions With Answers PDFAdeolu-Idowu AbiolaNo ratings yet

- Tie BarsDocument18 pagesTie BarsKutty Mansoor100% (1)

- Beam Elements: MCEN 4173/5173Document28 pagesBeam Elements: MCEN 4173/5173Santhosh LingappaNo ratings yet

- Assignments-Design of Dam Appurtenant Structures-2022Document2 pagesAssignments-Design of Dam Appurtenant Structures-2022Marew Getie100% (2)

- Document PDFDocument4 pagesDocument PDFck19654840No ratings yet

- Lesson Planning Geotechnical Engineering-I (06Cv54) : Part - ADocument5 pagesLesson Planning Geotechnical Engineering-I (06Cv54) : Part - ArajaanwarNo ratings yet

- Assignment 6 - Somesh Siddharth - A1988520002Document9 pagesAssignment 6 - Somesh Siddharth - A1988520002Somesh SiddharthNo ratings yet

- FMD GTU Study Material E-Notes Unit-4 06042020015456PMDocument5 pagesFMD GTU Study Material E-Notes Unit-4 06042020015456PMRaj PrajapatiNo ratings yet

- Chapter II - Damp Proof Course PDFDocument18 pagesChapter II - Damp Proof Course PDFammar ahmad80% (5)

- Estimate Municipal Building Doti 076 - 077Document436 pagesEstimate Municipal Building Doti 076 - 077Umesh joshiNo ratings yet

- Karimnagar 2Document20 pagesKarimnagar 2Puranam SagarNo ratings yet

- Specs CodeDocument4 pagesSpecs Codemelinda bulosNo ratings yet

- Lugeon Test InterpretationDocument11 pagesLugeon Test InterpretationAñuri OficinaNo ratings yet

- CHP 7.1 (Introduction) PDFDocument6 pagesCHP 7.1 (Introduction) PDFZazliana IzattiNo ratings yet

- Load CalculationDocument5 pagesLoad Calculationمعاذ محمدNo ratings yet

- Astm17 0409Document5 pagesAstm17 0409sidiq7No ratings yet

- Compressible Aerodynamics - Chapter10 - v2 PDFDocument35 pagesCompressible Aerodynamics - Chapter10 - v2 PDFPythonraptorNo ratings yet