Professional Documents

Culture Documents

Six Ways To Improve Global Supply Chains

Six Ways To Improve Global Supply Chains

Uploaded by

ayesha baber0 ratings0% found this document useful (0 votes)

10 views2 pagesThe document outlines 10 ways to improve global supply chains: 1) Ease transportation delays through digital tracking; 2) Prioritize public health to ensure access to critical supplies and ingredients; 3) Manage labor shortages by investing in digital infrastructure to support remote work; 4) Digitize documentation to provide end-to-end visibility and reduce costs; 5) Optimize company-owned inventory levels; 6) Form a supply chain council to align strategy and improve communication; 7) Mitigate geopolitical tensions through partnerships and diplomacy; 8) Improve visibility across the entire supply chain; 9) Cultivate healthy supplier relationships; and 10) Establish green initiatives to minimize the carbon footprint.

Original Description:

Original Title

six ways to improve global supply chains

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document outlines 10 ways to improve global supply chains: 1) Ease transportation delays through digital tracking; 2) Prioritize public health to ensure access to critical supplies and ingredients; 3) Manage labor shortages by investing in digital infrastructure to support remote work; 4) Digitize documentation to provide end-to-end visibility and reduce costs; 5) Optimize company-owned inventory levels; 6) Form a supply chain council to align strategy and improve communication; 7) Mitigate geopolitical tensions through partnerships and diplomacy; 8) Improve visibility across the entire supply chain; 9) Cultivate healthy supplier relationships; and 10) Establish green initiatives to minimize the carbon footprint.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

0 ratings0% found this document useful (0 votes)

10 views2 pagesSix Ways To Improve Global Supply Chains

Six Ways To Improve Global Supply Chains

Uploaded by

ayesha baberThe document outlines 10 ways to improve global supply chains: 1) Ease transportation delays through digital tracking; 2) Prioritize public health to ensure access to critical supplies and ingredients; 3) Manage labor shortages by investing in digital infrastructure to support remote work; 4) Digitize documentation to provide end-to-end visibility and reduce costs; 5) Optimize company-owned inventory levels; 6) Form a supply chain council to align strategy and improve communication; 7) Mitigate geopolitical tensions through partnerships and diplomacy; 8) Improve visibility across the entire supply chain; 9) Cultivate healthy supplier relationships; and 10) Establish green initiatives to minimize the carbon footprint.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

You are on page 1of 2

Six ways to Improve Global Supply Chains

In a fast-paced global economy, it’s important to keep your supply chain running as

efficiently as possible. Following are the ways to improve your organization’s efficiency and

succeed in the global supply chain.

1. Easing transportation jams

Dramatic increase in container freight rates, off-shoring rose in costs, orders

sometimes took months to fill. For these reasons, experts have called for digital

tracking that eases logistical delays. Identify logjams and allow firms to take action

that eases delivery problems.

2. Prioritizing public health

Shortage or not having access to critical ingredients or active drug ingredients made

manufacturing process impossible and it is difficult to produce needed products. Such

as personal protective equipment, medical supplies, pharmaceuticals, and electric

vehicle batteries, among others. To mitigate these problem, improve the public health

infrastructure. Otherwise it will be difficult to resolve supply chain disruptions as long

as major public health challenges roil the workforce

3. Managing labor shortage

Labor shortage and economic shocks have roiled supply chains and generated delays,

cost increases, and a range of logistical challenges. As a result, inflation has returned

as an economic problem, and there are complications linked to underlying shifts in the

workforce A McKinsey report recommends that public and private sector leaders

invest in digital infrastructure to make it easier for workers to access broadband,

perform their tasks, operate remotely, and deal with pandemics, automation, and

demographic shifts.

4. Digitization

Trade needs to move away from paper documentation into digital record keeping.

This involves bringing accurate data and processes together under one unified

platform to provide end to end visibility. It also reduce costs and accelerate

innovation. Digital supply chain management makes easier to plan and manage all

supply chain workflows

5. Optimize company-owned inventory

Check the quantity of the company-owned inventory. Keep exactly what you need;

nothing more than that.

6. Make a supply chain council

The council’s aim is to give directions and align the supply chain strategy with the

company’s core goals. The council helps in removing barriers within the organization.

It also improves the business’s cross-functional communication

7. Mitigating geopolitical tensions

The geopolitical situation has grown more complex it is difficult to maintain open

supply chains as long as geopolitical conflict intensifies and economic and security

risks are high. By building partnerships, engaging in diplomacy, and having realistic

expectations about what is possible, they believe the two countries can maintain a

fruitful relationship that can stabilize global trade, manufacturing, and distribution

8. Improve your visibility.

With full supply chain visibility, you’ll be able to track all of your products and

shipments at all times. This requires the different parts of your supply chain to work

together to prevent confusion. Supply chain visibility also helps you prevent delayed

or incorrect orders.

9. Build Healthy Supplier Relationships

Cultivate and maintain the supplier relationships on an ongoing basis, even after the

deals are finalized. Focus on forming strategies to maintain healthy supplier

relationships. Make goals for continuing value, measuring performance and

maintaining conflict resolution

10. Establish Green Initiatives

Minimize the carbon footprint of your supply chain. In fact, supply chain and logistics

must become sustainable and socially responsible.

You might also like

- SUPPLY CHAIN MANAGEMENT IN HOSPITALITY INDUSTRYE - Dited - 4. Module FinalsDocument25 pagesSUPPLY CHAIN MANAGEMENT IN HOSPITALITY INDUSTRYE - Dited - 4. Module FinalsArmand Padernos100% (9)

- Practising Critical ReflectionDocument234 pagesPractising Critical ReflectionRobert FordNo ratings yet

- John Deere 5520 Tractor Operator's Manual PDFDocument16 pagesJohn Deere 5520 Tractor Operator's Manual PDFfkskefmmseNo ratings yet

- Venky 3Document39 pagesVenky 3Uday GowdaNo ratings yet

- Study of Supply Chain Management at Britannia Industries.Document95 pagesStudy of Supply Chain Management at Britannia Industries.Satender Kumar75% (8)

- Module 8 Managing The Supply ChainDocument6 pagesModule 8 Managing The Supply ChainCharlie MaineNo ratings yet

- Unit 5 - Overcoming Supply Chain ChallengesDocument20 pagesUnit 5 - Overcoming Supply Chain ChallengesMANAV SOLANKINo ratings yet

- SCM and Its EffectsDocument4 pagesSCM and Its EffectsfatimaNo ratings yet

- Research Paper On Supply Chain ManagementDocument6 pagesResearch Paper On Supply Chain Managementp0zikiwyfyb2100% (1)

- Tugas 1 (Supply Chain Management)Document9 pagesTugas 1 (Supply Chain Management)mellyNo ratings yet

- SCM AssignmentDocument8 pagesSCM AssignmentDe BuNo ratings yet

- Unit-12, Supply Chain Management MD Abdur Rouf, St. Id.-OCL1052Document11 pagesUnit-12, Supply Chain Management MD Abdur Rouf, St. Id.-OCL1052S M Abdur RoufNo ratings yet

- Operations 2015 v4Document3 pagesOperations 2015 v4astrosecretszNo ratings yet

- A Test of Resilient LeadershipDocument8 pagesA Test of Resilient LeadershipghaziaNo ratings yet

- Draft Agile SCM PresDocument3 pagesDraft Agile SCM Presadil shahidNo ratings yet

- Avinash Kumar 2241412 - Group 9 Project ReportDocument11 pagesAvinash Kumar 2241412 - Group 9 Project ReportMANOHAR LAKSHMIPATHYNo ratings yet

- Nextgen SCM CiscoDocument13 pagesNextgen SCM CiscoswathiNo ratings yet

- SCM in HCDocument79 pagesSCM in HCNidhin MelethilNo ratings yet

- Adv SCM Assignment - 80012100955Document7 pagesAdv SCM Assignment - 80012100955Nihhar TatedNo ratings yet

- 1.case BriefDocument14 pages1.case Brief16024 Md.Mahbubul Kabir NishatNo ratings yet

- Aditonal Notes - 1Document8 pagesAditonal Notes - 1yeteday615No ratings yet

- Module 6 OMTQMDocument7 pagesModule 6 OMTQMAlisonNo ratings yet

- Network DesignDocument3 pagesNetwork DesignmecyNo ratings yet

- I. The Literature Related To The IssuesDocument25 pagesI. The Literature Related To The Issuesleemyriam5904No ratings yet

- SC & OS - FinalDocument20 pagesSC & OS - FinalPrasad ChamaraNo ratings yet

- SUPPLY CHAIN-M9 - Assign 1Document4 pagesSUPPLY CHAIN-M9 - Assign 1Arcebuche Figueroa FarahNo ratings yet

- Supply Chain Management (Cont.) (Discussed by Video) Basic SC For A ProductDocument11 pagesSupply Chain Management (Cont.) (Discussed by Video) Basic SC For A ProductJulia ChinyunaNo ratings yet

- Sti College Surigao Magallanes ST., Surigao CityDocument6 pagesSti College Surigao Magallanes ST., Surigao Citymae elimancoNo ratings yet

- Case Study-WoodmereDocument7 pagesCase Study-Woodmerealeena9seoNo ratings yet

- Supply CH Log ManDocument13 pagesSupply CH Log ManLissette PlazaNo ratings yet

- Limitations of SCMDocument3 pagesLimitations of SCMAyush ModiNo ratings yet

- Advantages of Supply ChainDocument4 pagesAdvantages of Supply ChainRachel R. AbogatalNo ratings yet

- Collaboration Strategy ContinuumDocument33 pagesCollaboration Strategy ContinuumDavid SantoNo ratings yet

- SCLMDocument45 pagesSCLMkeerthana chandrasekarNo ratings yet

- Supply Chain Management: Name-Diksha Patial CLASS-MBA (4sem) ROLL-NO-1710 Submitted To-Mr. Sachin SharmaDocument16 pagesSupply Chain Management: Name-Diksha Patial CLASS-MBA (4sem) ROLL-NO-1710 Submitted To-Mr. Sachin SharmaShivani KakkerNo ratings yet

- The Food Supply Chain IssuesDocument4 pagesThe Food Supply Chain IssuesNicole DuldulaoNo ratings yet

- Supply Study TvsDocument20 pagesSupply Study TvsSiva RatheeshNo ratings yet

- 55 Kaushan NimeshDocument14 pages55 Kaushan NimeshKaushan NimeshNo ratings yet

- Operations Management 1Document19 pagesOperations Management 1PrerrakNo ratings yet

- Five-Star Case - EditedDocument14 pagesFive-Star Case - EditedAshley WoodNo ratings yet

- Five Star Case - EditedDocument14 pagesFive Star Case - EditedAshley WoodNo ratings yet

- Operation and Supply Chain StrategiesDocument3 pagesOperation and Supply Chain StrategiesMukesh ThakvaniNo ratings yet

- Supply Chain ManagementDocument5 pagesSupply Chain ManagementAce Hulsey TevesNo ratings yet

- SCM Group 12Document17 pagesSCM Group 12Shouvik DuttaNo ratings yet

- Global Supply Chain ManagementDocument31 pagesGlobal Supply Chain ManagementMd.Atiqur Rahman100% (2)

- Supply Chain Management (SCM)Document47 pagesSupply Chain Management (SCM)sean buenaventura100% (1)

- Supply Chain Management: Powerpoint By: Ray A. Decormier, Ph.D. Central Connecticut State UniversityDocument62 pagesSupply Chain Management: Powerpoint By: Ray A. Decormier, Ph.D. Central Connecticut State UniversityAntony LawrenceNo ratings yet

- Time-Based Competition For SCMDocument3 pagesTime-Based Competition For SCMNicole HuangNo ratings yet

- Top 11 Procurement Challenges For 2023: Why Is Procurement Difficult?Document5 pagesTop 11 Procurement Challenges For 2023: Why Is Procurement Difficult?YASH SHELKENo ratings yet

- Expanding A Business Brings Various OpportunitiesDocument6 pagesExpanding A Business Brings Various OpportunitiesCarl Matthew Dela PeñaNo ratings yet

- MSP 530 Assign1Document12 pagesMSP 530 Assign1GIVEN N SIPANJENo ratings yet

- Assignment 2 GreenTech Electronics Case StudyDocument8 pagesAssignment 2 GreenTech Electronics Case StudyArubaNo ratings yet

- Good HabitsDocument9 pagesGood HabitsAman Kumar ThakurNo ratings yet

- SCM 101Document28 pagesSCM 101commandercontentNo ratings yet

- 008Document8 pages008Jonathan SantiagoNo ratings yet

- 113 Final-Team Patrik Jonasson-GS1Document64 pages113 Final-Team Patrik Jonasson-GS1Đặng Quang MinhNo ratings yet

- Assignment 2 GreenTech Electronics Case Study 1 PDFDocument8 pagesAssignment 2 GreenTech Electronics Case Study 1 PDFKNo ratings yet

- Supply Chain ManagementDocument6 pagesSupply Chain Managementmahesadipta86No ratings yet

- Lean Distribution: Applying Lean Manufacturing to Distribution, Logistics, and Supply ChainFrom EverandLean Distribution: Applying Lean Manufacturing to Distribution, Logistics, and Supply ChainRating: 2.5 out of 5 stars2.5/5 (2)

- Military Supply Chain Management: From Deployment to Victory, Mastering the Logistics DanceFrom EverandMilitary Supply Chain Management: From Deployment to Victory, Mastering the Logistics DanceNo ratings yet

- Spiral Flow MethodDocument3 pagesSpiral Flow Methodayesha baberNo ratings yet

- Final HRMDocument40 pagesFinal HRMayesha baberNo ratings yet

- Economics 1Document9 pagesEconomics 1ayesha baberNo ratings yet

- GroupDocument6 pagesGroupayesha baberNo ratings yet

- Strategic Challenges Addressed in ChapterDocument9 pagesStrategic Challenges Addressed in Chapterayesha baberNo ratings yet

- MoldsDocument25 pagesMoldsayesha baberNo ratings yet

- Product PortfolioDocument18 pagesProduct Portfolioayesha baberNo ratings yet

- US April'23 PAKET BDocument12 pagesUS April'23 PAKET BProject P2BanjaranNo ratings yet

- Is Iso 10474 1991Document12 pagesIs Iso 10474 1991chandakweNo ratings yet

- Experiment No.1: Introduction To Lti Representation and Transfer Function ModelDocument7 pagesExperiment No.1: Introduction To Lti Representation and Transfer Function ModelIra CervoNo ratings yet

- Key, Scripts BIG STEP TOEIC 3 - Actual Test 3 - EFIS EnglishDocument7 pagesKey, Scripts BIG STEP TOEIC 3 - Actual Test 3 - EFIS EnglishThao NguyenNo ratings yet

- HKICPA HandbookDocument77 pagesHKICPA Handbookdync100% (1)

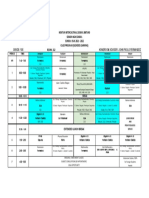

- Grade: 10E ROOM: 212 Homeroom Adviser: John Paolo FernandezDocument1 pageGrade: 10E ROOM: 212 Homeroom Adviser: John Paolo FernandezRangga NarindraNo ratings yet

- MC DonaldDocument65 pagesMC DonaldNeha MishraaNo ratings yet

- 1Document114 pages1Mohamed FathiNo ratings yet

- Tower Crane AccidentDocument37 pagesTower Crane Accidentparawansa muisNo ratings yet

- Single Award End of Feb 2023Document8 pagesSingle Award End of Feb 2023Lone G. MokgalagadiNo ratings yet

- Electronic Immobilizers For The Automotive Industry: U2270B Application NoteDocument19 pagesElectronic Immobilizers For The Automotive Industry: U2270B Application NoteRuslan ValiakhmetovNo ratings yet

- Seminar PresentationDocument16 pagesSeminar PresentationVinay KurkuriNo ratings yet

- Examinations, Medical Treatment and Ship MedicineDocument15 pagesExaminations, Medical Treatment and Ship Medicineanshul_sharma_5No ratings yet

- Chapter 14 - Just in Time SystemsDocument4 pagesChapter 14 - Just in Time Systemshello_khayNo ratings yet

- Climate DLLDocument2 pagesClimate DLLlucky may100% (1)

- A Detailed Study On Loss Processes in Solar CellsDocument11 pagesA Detailed Study On Loss Processes in Solar CellsFernando DiasNo ratings yet

- InfosyspdfDocument30 pagesInfosyspdfBrinda BMNo ratings yet

- MGMT100S2 2019 - With Lecture Schedule PDFDocument8 pagesMGMT100S2 2019 - With Lecture Schedule PDFAkshayScamlattiNo ratings yet

- Ucs617 5Document2 pagesUcs617 5Suprit BeheraNo ratings yet

- Procurement Best Practice GuidelineDocument17 pagesProcurement Best Practice GuidelineA_tarin100% (1)

- Seismic AnalysisDocument6 pagesSeismic AnalysisSharah QuilarioNo ratings yet

- NV-GS11GN NV-GS15GN: Operating InstructionsDocument64 pagesNV-GS11GN NV-GS15GN: Operating InstructionsAmit KaleNo ratings yet

- MV KairosDocument104 pagesMV KairosDominic VillamanteNo ratings yet

- 03 Spring Crochet Along BUNNY GBDocument2 pages03 Spring Crochet Along BUNNY GBkhuyên nguyễnNo ratings yet

- When Textbook RSA Is Used To Protect The Privacy of Hundreds of Millions of UsersDocument9 pagesWhen Textbook RSA Is Used To Protect The Privacy of Hundreds of Millions of UsersShaanan CohneyNo ratings yet

- CC103 Engineering Surveying 1 Chapter 2Document15 pagesCC103 Engineering Surveying 1 Chapter 2Xendra AqeylaaNo ratings yet

- Minnesota Timberwolves (17-28) vs. Indiana Pacers (22-22) : Probable StartersDocument23 pagesMinnesota Timberwolves (17-28) vs. Indiana Pacers (22-22) : Probable Starterstiwari_anunay1689No ratings yet

- Practical-1: AIM: Implement A Program Which Can Decrypt The Original Message From The GivenDocument65 pagesPractical-1: AIM: Implement A Program Which Can Decrypt The Original Message From The GivenprogrammerNo ratings yet