Professional Documents

Culture Documents

Inst263 - Reponses 68 - 69

Inst263 - Reponses 68 - 69

Uploaded by

NGASSAKI ATONGUI Christ HubertOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Inst263 - Reponses 68 - 69

Inst263 - Reponses 68 - 69

Uploaded by

NGASSAKI ATONGUI Christ HubertCopyright:

Available Formats

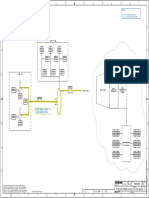

Answer 68

Fault Possible Impossible

√

No AC power to VFD

√

Controller has dead 4-20 mA output

√

Level transmitter out of calibration

√

Level switch contacts failed shorted

√

Level switch contacts failed open

√

250 ohm resistor failed open

√

Cable between TB12 and TB13 failed open

√

Cable between TB13 and LSL failed open

Answer 69

If the screw on JB1-4 were to come loose, it would interrupt the current to the I/P transducer, thus

making its pneumatic output fail low. We know this because the upward-pointing arrow next to FY-42b

denotes it as direct-acting (more mA = more air pressure out). With low air pressure to the bypass valve,

the valve will fail open (as indicated by the arrow on the valve stem symbol). This will bypass flow from

output to input on the compressor, reducing the amount of gas flow to the process.

For your information, compressor surge is a fluid dynamic phenomenon whereby the blades in a non-

positive-displacement compressor (e.g. axial or centrifugal vane) “stall” just like the wings of an airplane

flying too slowly and/or at too great an angle of attack. When the blades of a compressor stall, they lose

“traction” on the compressed gas, unloading the mechanical driver (engine, motor, or turbine) and allowing

the compressor to gain speed, then the blades will “un-stall” and re-load the driver, continuing the cycle.

The following passage is taken from Francis Shinskey’s excellent book Energy Conservation and Control,

published by Academic Press in 1978, describing compressor surge:

“The most demanding aspect of controlling compressors is surge protection. The problem

lies in being unable to determine with absolute certainty the degree of approach to surge. Once a

compressor begins to surge, it will continue until corrective action is applied, so automatic protection

is mandatory. A small centrifugal compressor may surge several times without damage, but a

100,000-hp axial could require reblading after a single incident.”

“When a compressor begins to surge, the suction flow falls to zero within a few milliseconds,

reverses momentarily, and begins to recover in less than a half second. If the situation is not

corrected, the cycle repeats immediately, resulting in a series of thunderclaps less than a second

apart. The sudden fall in suction flow can be detected and used to open a recirculating valve, but

not before at least one surge cycle is sustained. To prevent surge from developing at all requires a

control system which skirts the unstable area altogether.”

136

You might also like

- TTi TS Series Power Supplies ManualDocument27 pagesTTi TS Series Power Supplies Manualj.bycroft126No ratings yet

- Error Amplifier Design and ApplicationsDocument6 pagesError Amplifier Design and ApplicationsGhulam Abbas100% (1)

- 4-Pin GM HEI Module NotesDocument6 pages4-Pin GM HEI Module Noteszampardi100% (2)

- ADTEk - RX PDFDocument43 pagesADTEk - RX PDFedilbertos_4100% (1)

- SL39ADocument14 pagesSL39ALuz Analía Valdez CandiaNo ratings yet

- Equivalent Length & Pressure Losses in Fittings & Valves PDFDocument1 pageEquivalent Length & Pressure Losses in Fittings & Valves PDFbilal almelegyNo ratings yet

- Astron TroubleshootingDocument7 pagesAstron TroubleshootingLuis CarlosNo ratings yet

- PIX Catalog 2011-17-18Document2 pagesPIX Catalog 2011-17-186A EntertainmentNo ratings yet

- 3 - RM Electrical TroubleshootingDocument26 pages3 - RM Electrical TroubleshootingAlexandre SilvaNo ratings yet

- Inverter Troubleshooting ChecksDocument4 pagesInverter Troubleshooting ChecksTarak BenslimaneNo ratings yet

- Distance RelaysDocument14 pagesDistance RelaysSoham LohiyaNo ratings yet

- Unit 3 OpampDocument64 pagesUnit 3 Opamprudranshvsingh4705No ratings yet

- Transformadores Parte 2Document29 pagesTransformadores Parte 2Carolina PulidoNo ratings yet

- Power Transformer Protection ... PresentationDocument17 pagesPower Transformer Protection ... Presentationsandeepy_27100% (3)

- DK 105 1 RGM 12S - enDocument26 pagesDK 105 1 RGM 12S - enMuhammad Akmal RafiqueNo ratings yet

- E3 Chapter 14Document14 pagesE3 Chapter 14Ahmed Sami El SharkawiNo ratings yet

- ENC10 Tamping Depth TransducerDocument4 pagesENC10 Tamping Depth Transducerbravi14141No ratings yet

- High Current Switching Regulators: DescriptionDocument22 pagesHigh Current Switching Regulators: DescriptionClaudio MartinsNo ratings yet

- Unit 5Document59 pagesUnit 5vbarath58No ratings yet

- 11 TroubleshootingDocument6 pages11 TroubleshootingWajaht AliNo ratings yet

- Presentation On Transformer ProtectionDocument28 pagesPresentation On Transformer ProtectionSushil Sharma100% (1)

- Annex-I Off-Load TransformersDocument2 pagesAnnex-I Off-Load Transformerssami ul haqNo ratings yet

- 555 TimerDocument28 pages555 TimerNisha Kotyan G RNo ratings yet

- OpampDocument51 pagesOpampMitesh BhagoraNo ratings yet

- Danfoss Warning CodesDocument2 pagesDanfoss Warning CodesAtindra TiwariNo ratings yet

- Ard TPS-25 PDFDocument7 pagesArd TPS-25 PDFNguyễn Thân67% (3)

- Generator Protection: Presented by D G Pattanayak Dy MGR (Electrical) Operation DeptDocument36 pagesGenerator Protection: Presented by D G Pattanayak Dy MGR (Electrical) Operation DeptDUVASU UPNo ratings yet

- Signal Conditioning For Resistive, Rectance Varian and Self Generating SensorsDocument74 pagesSignal Conditioning For Resistive, Rectance Varian and Self Generating SensorsYash BhattNo ratings yet

- Trouble Shooting Capacitor Regulated Pancake Light Tower GeneratorsDocument7 pagesTrouble Shooting Capacitor Regulated Pancake Light Tower GeneratorsBilly MecanizadoNo ratings yet

- 9 Post NotesDocument8 pages9 Post NotesHansrajNo ratings yet

- Short Circuit Test On Power Transformer: ProcedureDocument4 pagesShort Circuit Test On Power Transformer: Proceduresaurabhjerps231221No ratings yet

- 15 MVA Transformer-S012-2-12Document30 pages15 MVA Transformer-S012-2-12Neeraj SinghNo ratings yet

- Clipper:: Date: AIM: To Observe The Performance of Clippers and Clampers. TheoryDocument2 pagesClipper:: Date: AIM: To Observe The Performance of Clippers and Clampers. TheoryDharmistha VishwakarmaNo ratings yet

- Buchholz RelayDocument9 pagesBuchholz RelaytubolytNo ratings yet

- Samsung Microwave TrainingDocument23 pagesSamsung Microwave Trainingbody2030No ratings yet

- Buchholz RelaysDocument9 pagesBuchholz RelaysAngel StragliatiNo ratings yet

- 555 TimerDocument14 pages555 TimernathmanojNo ratings yet

- LRF-3 Transformer Comparision (SMS-1)Document2 pagesLRF-3 Transformer Comparision (SMS-1)SOUMENNo ratings yet

- DEE20023 Chapter 3 (C) BIPOLAR JUNCTION TRANSISTOR SESI II 20222023Document23 pagesDEE20023 Chapter 3 (C) BIPOLAR JUNCTION TRANSISTOR SESI II 20222023Muhd ZarifNo ratings yet

- Comparison Between BJT, FET & Thyristor: Intruder AlarmDocument26 pagesComparison Between BJT, FET & Thyristor: Intruder AlarmRojan Pradhan100% (1)

- Transformer Protection FinalDocument72 pagesTransformer Protection FinalAvnish Bhasin100% (2)

- Applications of Op Amp: Unit-IiDocument79 pagesApplications of Op Amp: Unit-Iimanoj1316kumar_63152No ratings yet

- High Current Switching Regulator: DescriptionDocument13 pagesHigh Current Switching Regulator: DescriptionEfrain PadronNo ratings yet

- Thyristors: Semiconductor Devices (Dr. Mohamad Alam Saeed)Document31 pagesThyristors: Semiconductor Devices (Dr. Mohamad Alam Saeed)Azwin HamdanNo ratings yet

- Paia 9505 Theremax Assembly and User Manual With Schematic 200dpiDocument36 pagesPaia 9505 Theremax Assembly and User Manual With Schematic 200dpiTomas J. GallardoNo ratings yet

- LTC 3124Document28 pagesLTC 3124m3rishorNo ratings yet

- 1ZUA549200-505 VRLTC Technical Guide Rev2Document20 pages1ZUA549200-505 VRLTC Technical Guide Rev2Mạnh Nguyễn VănNo ratings yet

- Unit 2 PECADocument18 pagesUnit 2 PECAtechranaytNo ratings yet

- Boletin QSC rmx2450Document2 pagesBoletin QSC rmx2450Joseph Manny Spanish100% (1)

- L5 - Diodes 2Document26 pagesL5 - Diodes 2amonNo ratings yet

- Troubleshooting and Service Information For Voltmaster GeneratorsDocument15 pagesTroubleshooting and Service Information For Voltmaster GeneratorsMd Rodi Bidin100% (1)

- OP AMP - OL ConnectionDocument10 pagesOP AMP - OL ConnectionPrithak PodderNo ratings yet

- H / P P S E Man Alpha One/7R/8R/8P Amplifier Service ManualDocument16 pagesH / P P S E Man Alpha One/7R/8R/8P Amplifier Service Manual王军No ratings yet

- 8700 Troubleshooting GuideDocument8 pages8700 Troubleshooting GuideJULIO CESAR GASPAR SANCHEZNo ratings yet

- HV Equipment File 4 of 5Document26 pagesHV Equipment File 4 of 5MohammedSaadaniHassaniNo ratings yet

- Elec SMPS2Document4 pagesElec SMPS2Victor D'souzaNo ratings yet

- Lm723 Linear Power Supply: GeneralDocument9 pagesLm723 Linear Power Supply: Generalsyed_hafeez_2No ratings yet

- 1 Transformer ProtectionDocument19 pages1 Transformer Protectionknowledge engineeringNo ratings yet

- A 120 Watt Solid State Amp: Accoutrement: More SimpleDocument12 pagesA 120 Watt Solid State Amp: Accoutrement: More SimpleFarooq AhmadNo ratings yet

- Lect 2 - Electronics and InstrumentationDocument25 pagesLect 2 - Electronics and Instrumentationahmedabousree4No ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- Interview Questions and Answers On Safety Systems Instrumentation ToolsDocument7 pagesInterview Questions and Answers On Safety Systems Instrumentation ToolsNGASSAKI ATONGUI Christ HubertNo ratings yet

- DenizenDocument2 pagesDenizenNGASSAKI ATONGUI Christ HubertNo ratings yet

- Inst263 - Question 68aDocument1 pageInst263 - Question 68aNGASSAKI ATONGUI Christ HubertNo ratings yet

- How To Become A Highly Skilled Instrument Engineer and Instrument Technician Learning Instrumentation and Control EngineeringDocument3 pagesHow To Become A Highly Skilled Instrument Engineer and Instrument Technician Learning Instrumentation and Control EngineeringNGASSAKI ATONGUI Christ HubertNo ratings yet

- Fire Alarm System Commissioning ProcedureDocument3 pagesFire Alarm System Commissioning ProcedureNGASSAKI ATONGUI Christ HubertNo ratings yet

- Normally-Closed Contacts For Stop ButtonsDocument9 pagesNormally-Closed Contacts For Stop ButtonsNGASSAKI ATONGUI Christ HubertNo ratings yet

- Kalwakurthy Segment Gate Valve Chambers Kalwakurthy MandalDocument1 pageKalwakurthy Segment Gate Valve Chambers Kalwakurthy MandalKumar KingslyNo ratings yet

- Tabla de Pruebas Tarea Pruebas BCIDocument3 pagesTabla de Pruebas Tarea Pruebas BCIGIAN FRANCO ALBERTO ARENAS VARGASNo ratings yet

- TG Filter 2012Document142 pagesTG Filter 2012SergNo ratings yet

- Spare Parts Inventory MEADocument161 pagesSpare Parts Inventory MEAGrupo ValoracionNo ratings yet

- Directional Control ValvesDocument18 pagesDirectional Control Valvesdoan luc100% (1)

- NPSH and CavitationDocument1 pageNPSH and CavitationSofiane HalimiNo ratings yet

- Turbines - New Module Hay PDFDocument191 pagesTurbines - New Module Hay PDFThái Mai Đình100% (2)

- PART 87 - 1 Flow Direction of Valve - Part 4 (Globe Valve)Document7 pagesPART 87 - 1 Flow Direction of Valve - Part 4 (Globe Valve)ravindra_jivaniNo ratings yet

- Dense Phase Pneumatic Conveying SystemDocument1 pageDense Phase Pneumatic Conveying SystemH3mantNo ratings yet

- Indra: Piping & Equipment Flowsheet Symbols Speciality Items Valves EquipmentDocument1 pageIndra: Piping & Equipment Flowsheet Symbols Speciality Items Valves EquipmentnadirNo ratings yet

- Hydraulic Schematic Reading PDFDocument18 pagesHydraulic Schematic Reading PDFNoureddine AdjNo ratings yet

- Pe1024-Mb-Mfb030-011200 25 GT#1 MBH 2Document1 pagePe1024-Mb-Mfb030-011200 25 GT#1 MBH 2Aldo Quispe HuarachiNo ratings yet

- Introduction To Gas Turbine: 1. Operating PrincipleDocument6 pagesIntroduction To Gas Turbine: 1. Operating PrincipleMuhammad Ridhwan100% (2)

- Grundfos Fire PumpDocument4 pagesGrundfos Fire PumpMuhammad YusriNo ratings yet

- Orifice and Venturi Meter - PrelabDocument6 pagesOrifice and Venturi Meter - Prelableo besaNo ratings yet

- LNGC Q-Flex Al Thumama - Imo 9360843 - Cargo Operating ManualDocument415 pagesLNGC Q-Flex Al Thumama - Imo 9360843 - Cargo Operating Manualseawolf50100% (1)

- SC4379-461-02 Fo Transfer SystemDocument13 pagesSC4379-461-02 Fo Transfer SystemChandni JhaNo ratings yet

- Codes & Standards - ROTARYDocument2 pagesCodes & Standards - ROTARYUmair PervaizNo ratings yet

- Booster Pump Submittal PackageDocument5 pagesBooster Pump Submittal PackageMohammad Mustafa AkbariNo ratings yet

- Model YutingDocument2 pagesModel YutingSayyid AbulkhairNo ratings yet

- Valves and Fittings Losses in Equivalent Feet of Pipe: Y-StrainerDocument3 pagesValves and Fittings Losses in Equivalent Feet of Pipe: Y-Strainerthilina lakhithaNo ratings yet

- 325CDocument9 pages325CSanchez DlcNo ratings yet

- Engineering Data CompAir F4HS-F59HS-50Hz ISODocument10 pagesEngineering Data CompAir F4HS-F59HS-50Hz ISODragoslav DzolicNo ratings yet

- Week One Homework Problems PDFDocument2 pagesWeek One Homework Problems PDFRajesh YNo ratings yet

- ASME VIII Unfired Vessel Relief ValvesDocument53 pagesASME VIII Unfired Vessel Relief Valvessaid530No ratings yet

- LECTURASDocument117 pagesLECTURASBRUCE DARWIN PACHAS TALLANo ratings yet

- Tecman TMB5 Web Spec V160921Document1 pageTecman TMB5 Web Spec V160921thomas.templierNo ratings yet

- Fundamentos de Compresores, Curvas PerformanceDocument116 pagesFundamentos de Compresores, Curvas Performancejowar100% (5)