Professional Documents

Culture Documents

QAR-QD#419-2 Single Parts

QAR-QD#419-2 Single Parts

Uploaded by

Irwanto ManafCopyright:

Available Formats

You might also like

- The 9 Centers Human DesignDocument14 pagesThe 9 Centers Human Designmonicabors100% (11)

- The Woman Speaks To The Man Who Has Employed Her SonDocument3 pagesThe Woman Speaks To The Man Who Has Employed Her SonSerena SulawammotNo ratings yet

- LTHEDocument5 pagesLTHEMohit Goswami100% (1)

- ITP For Boiler ErectionDocument6 pagesITP For Boiler ErectionUmair Awan100% (2)

- Holistic Self Health CareDocument80 pagesHolistic Self Health Careadkittipong100% (1)

- Fotocopias Ingles Tema Climate 1º EsoDocument6 pagesFotocopias Ingles Tema Climate 1º EsoMayOrdóñezNo ratings yet

- Carbon Footprint of Organic FertilizerDocument5 pagesCarbon Footprint of Organic FertilizerSteve Savage100% (6)

- QAR-QD#419-15 Feed Cylinder GPDocument8 pagesQAR-QD#419-15 Feed Cylinder GPIrwanto ManafNo ratings yet

- QAR-QD#419-14 Grapple Cylinder GPDocument6 pagesQAR-QD#419-14 Grapple Cylinder GPIrwanto ManafNo ratings yet

- QAR-QD#419-21 Boom Cylinder GPDocument2 pagesQAR-QD#419-21 Boom Cylinder GPIrwanto ManafNo ratings yet

- QAR-QD#419-24 Edmo Jack Cylinder GPDocument2 pagesQAR-QD#419-24 Edmo Jack Cylinder GPIrwanto ManafNo ratings yet

- QAP K-HouseDocument4 pagesQAP K-HouseAbhinash TamangNo ratings yet

- Material Inspection SheetDocument3 pagesMaterial Inspection Sheetrahid iqubalNo ratings yet

- E13. Sample Inspection Release Certificate IRCDocument2 pagesE13. Sample Inspection Release Certificate IRCMohamedNo ratings yet

- INCR New Format 2021Document1 pageINCR New Format 2021Khan ZamanNo ratings yet

- IVR-HAL-ONGC-L&T-CBE-003-Dt 25-11 - 019Document6 pagesIVR-HAL-ONGC-L&T-CBE-003-Dt 25-11 - 019Harish GundaNo ratings yet

- Field Inspection & Test Plan (F-Itp) : DOC. NO.: I-T3108-QAQC-006Document7 pagesField Inspection & Test Plan (F-Itp) : DOC. NO.: I-T3108-QAQC-006bernardNo ratings yet

- Civil FormatsDocument46 pagesCivil Formatsaftabshekh624462No ratings yet

- RamprasadDocument2 pagesRamprasadRagul0042No ratings yet

- Qaqc Cir Civil Material PillingDocument1 pageQaqc Cir Civil Material PillingFirman Indra JayaNo ratings yet

- QAR-QD404-1 Liquid Penetrant Testing Report-GeneralDocument1 pageQAR-QD404-1 Liquid Penetrant Testing Report-GeneralIrwanto ManafNo ratings yet

- Liquid Penetrant Inspection Report: Industrial Proforma FormDocument1 pageLiquid Penetrant Inspection Report: Industrial Proforma FormJohn DolanNo ratings yet

- Inspection and Test PlanDocument6 pagesInspection and Test PlanReduddboy100% (1)

- 2412- IRN FormatDocument2 pages2412- IRN FormatFahad AhmadNo ratings yet

- LOG-563-03 Receiving Inspection Checklist Rev.1Document1 pageLOG-563-03 Receiving Inspection Checklist Rev.1Emy SumartiniNo ratings yet

- TST IR Clair P 575 Bought Out Items BAGS DT 22.07.2019Document2 pagesTST IR Clair P 575 Bought Out Items BAGS DT 22.07.2019MOUNESH REDDYNo ratings yet

- Quality Control Manual of PT Sarku Enjinering Utama (ASME JR)Document110 pagesQuality Control Manual of PT Sarku Enjinering Utama (ASME JR)herlan100% (1)

- Inspection & Test Plan (Itp) : Mechanical (Machine & Equipment)Document2 pagesInspection & Test Plan (Itp) : Mechanical (Machine & Equipment)ikramNo ratings yet

- PP-FR-03 Route CardDocument1 pagePP-FR-03 Route Cardchandra100% (2)

- QA ProcessDocument4 pagesQA Processmadhu krishnaNo ratings yet

- 6 PTJ QA FRM 004 Receiving Inspection ReportDocument1 page6 PTJ QA FRM 004 Receiving Inspection ReportAhmed NagyNo ratings yet

- 05-01 ITPDocument2 pages05-01 ITPMo ZeroNo ratings yet

- ITP Sample For Steet Strucute WorksDocument7 pagesITP Sample For Steet Strucute WorksTee Klong RungNo ratings yet

- Bluskies Engineering PVT LTD: Acp Panel Inpection ReportDocument7 pagesBluskies Engineering PVT LTD: Acp Panel Inpection ReportRavi Shankar KolluruNo ratings yet

- 01 - Asf-Qc-Itp-002Document4 pages01 - Asf-Qc-Itp-002Sherif YehiaNo ratings yet

- FQP Format Cqa-IV-r2 DT 200510Document2 pagesFQP Format Cqa-IV-r2 DT 200510sheb20040% (1)

- Quality Control Plan / Inspecting and Testing Plan - (Discipline) Structure Erection and InstallationDocument1 pageQuality Control Plan / Inspecting and Testing Plan - (Discipline) Structure Erection and InstallationTarun PatelNo ratings yet

- Vendor Fabrication Shop Site Construction: QA/QC Inspections: Inspection Test PlanDocument2 pagesVendor Fabrication Shop Site Construction: QA/QC Inspections: Inspection Test PlanSuraj ShettyNo ratings yet

- KLD 00 4500399734 ZV P23 00030 0000 02 Fabrication, Installation & Testing of Structural SteelDocument5 pagesKLD 00 4500399734 ZV P23 00030 0000 02 Fabrication, Installation & Testing of Structural SteelRana AsifNo ratings yet

- S 000 16B0 0011V - 0 PDFDocument33 pagesS 000 16B0 0011V - 0 PDFChung TrịnhNo ratings yet

- TST IR Clair P 575 CAGES Bought Out Items DT 22.07.2019Document2 pagesTST IR Clair P 575 CAGES Bought Out Items DT 22.07.2019MOUNESH REDDYNo ratings yet

- Itp STR Slpg-Q-0000-24001-032-001-4-ADocument11 pagesItp STR Slpg-Q-0000-24001-032-001-4-AsivagnanamNo ratings yet

- Pumps ItpDocument3 pagesPumps Itpkokod9757No ratings yet

- QIP of Boiler For ErectionDocument6 pagesQIP of Boiler For ErectionUmair Awan100% (2)

- Receiving Inspection Checklist Details & Sub-AssemblyDocument7 pagesReceiving Inspection Checklist Details & Sub-AssemblyMohamedNo ratings yet

- NGWK PK 0001 VDQC Plit 0006Document7 pagesNGWK PK 0001 VDQC Plit 0006stdshopNo ratings yet

- ITP Civil and Structure Moly ProjectDocument34 pagesITP Civil and Structure Moly ProjectYosses Sang NahkodaNo ratings yet

- Inspection Report: F-084/09 R-VM23-0012-LV-052 Rev.00Document5 pagesInspection Report: F-084/09 R-VM23-0012-LV-052 Rev.00Navid HashemiNo ratings yet

- Inspection and Test Plan: JS19-010 Haddadin Engineering Co. AISC & AWS D1.1 2015Document3 pagesInspection and Test Plan: JS19-010 Haddadin Engineering Co. AISC & AWS D1.1 2015Khaled GamalNo ratings yet

- QCP 23-196 Rev.1Document4 pagesQCP 23-196 Rev.1ARKA technocorpNo ratings yet

- Tank Erection Itp Org ChartDocument34 pagesTank Erection Itp Org Chartvasantha kumar100% (1)

- ITP For Batteries Chargers and UPSDocument7 pagesITP For Batteries Chargers and UPSaryan_iustNo ratings yet

- Quality Assurance Plan: MPL QAP No.Document13 pagesQuality Assurance Plan: MPL QAP No.Varun MalhotraNo ratings yet

- Inspection Report: CPP-RM-PO-0180Document4 pagesInspection Report: CPP-RM-PO-0180ANIL PLAMOOTTIL0% (1)

- Qality Assurance Inspection and Test Plan: Piping Fabrication & InstallationDocument16 pagesQality Assurance Inspection and Test Plan: Piping Fabrication & Installationmanoj thakkarNo ratings yet

- Inspection and Test Plan: S. H. Joo D. H. YounDocument2 pagesInspection and Test Plan: S. H. Joo D. H. YounfitriatitisariNo ratings yet

- ITP Sample For Piping Assembly WorksDocument7 pagesITP Sample For Piping Assembly WorksTee Klong RungNo ratings yet

- Cyl Suspensi Tr-3034 MTN MhuDocument1 pageCyl Suspensi Tr-3034 MTN MhuM Ferry AnwarNo ratings yet

- Itr Ew 05a - EngDocument1 pageItr Ew 05a - Engwassim nasriNo ratings yet

- 149-158 - Zug-Header-Malinau-Sc 12 016 Rev 1 Unit 2Document58 pages149-158 - Zug-Header-Malinau-Sc 12 016 Rev 1 Unit 2Muhammad Fitransyah Syamsuar PutraNo ratings yet

- Itp Tank RappDocument4 pagesItp Tank Rapprizky youlandaNo ratings yet

- EG.02.J.96.053.102NM 03 1 PublicationDocument6 pagesEG.02.J.96.053.102NM 03 1 Publicationfhairuz.wahidNo ratings yet

- Air Balance Test QCDD FormDocument2 pagesAir Balance Test QCDD FormSamir AminNo ratings yet

- PDI ReportDocument2 pagesPDI ReportPreetam GiteNo ratings yet

- The Sarbanes-Oxley Section 404 Implementation Toolkit: Practice Aids for Managers and AuditorsFrom EverandThe Sarbanes-Oxley Section 404 Implementation Toolkit: Practice Aids for Managers and AuditorsNo ratings yet

- HOUSING SWING EX-3600 (Before)Document7 pagesHOUSING SWING EX-3600 (Before)Irwanto ManafNo ratings yet

- Carrier Diff Eh 1700Document2 pagesCarrier Diff Eh 1700Irwanto ManafNo ratings yet

- Centricity Pto Ex 2500Document3 pagesCentricity Pto Ex 2500Irwanto ManafNo ratings yet

- Case Pto Only IdDocument5 pagesCase Pto Only IdIrwanto ManafNo ratings yet

- Case Pto 3600Document2 pagesCase Pto 3600Irwanto ManafNo ratings yet

- Spindle Center JointDocument2 pagesSpindle Center JointIrwanto ManafNo ratings yet

- Carrier Ex 2500Document6 pagesCarrier Ex 2500Irwanto ManafNo ratings yet

- Casing Travel MotorDocument2 pagesCasing Travel MotorIrwanto ManafNo ratings yet

- Flange Grease Ex 2500aDocument1 pageFlange Grease Ex 2500aIrwanto ManafNo ratings yet

- Concentricity PtoDocument3 pagesConcentricity PtoIrwanto ManafNo ratings yet

- Casing Travel Motor 2Document3 pagesCasing Travel Motor 2Irwanto ManafNo ratings yet

- QAR-QD418-79 Housing As-Rear SuspensionDocument6 pagesQAR-QD418-79 Housing As-Rear SuspensionIrwanto ManafNo ratings yet

- Bucket Re BushingDocument2 pagesBucket Re BushingIrwanto ManafNo ratings yet

- QAR-QD418-78 Housing As-Rear SuspensionDocument6 pagesQAR-QD418-78 Housing As-Rear SuspensionIrwanto ManafNo ratings yet

- QAR-QD418-207 Piston-ParkingDocument5 pagesQAR-QD418-207 Piston-ParkingIrwanto ManafNo ratings yet

- QAR-QD418-50 Rod As-Rear SuspensionDocument5 pagesQAR-QD418-50 Rod As-Rear SuspensionIrwanto ManafNo ratings yet

- QAR-QD418-51 Rod As-Rear SuspensionDocument5 pagesQAR-QD418-51 Rod As-Rear SuspensionIrwanto ManafNo ratings yet

- QAR QD418 115 Rod As Lift CylinderDocument5 pagesQAR QD418 115 Rod As Lift CylinderIrwanto ManafNo ratings yet

- QAR-QD418-5 Rod-Front Susp 797 (191-8043)Document6 pagesQAR-QD418-5 Rod-Front Susp 797 (191-8043)Irwanto ManafNo ratings yet

- QAR-QD#419-24 Edmo Jack Cylinder GPDocument2 pagesQAR-QD#419-24 Edmo Jack Cylinder GPIrwanto ManafNo ratings yet

- Chapter #06 - Three YearsDocument41 pagesChapter #06 - Three YearsIrwanto ManafNo ratings yet

- 5 6264764972983651383Document1 page5 6264764972983651383Irwanto ManafNo ratings yet

- Form-Qc-001-616 Washer Pin Pivot StopDocument1 pageForm-Qc-001-616 Washer Pin Pivot StopIrwanto ManafNo ratings yet

- QAR-QD#407-19 Line Shaft (697-LINE SHAFT)Document2 pagesQAR-QD#407-19 Line Shaft (697-LINE SHAFT)Irwanto ManafNo ratings yet

- QAR-QD403-2 Magnetic Particle Inspection ReportDocument2 pagesQAR-QD403-2 Magnetic Particle Inspection ReportIrwanto ManafNo ratings yet

- QAR-QD#419-15 Feed Cylinder GPDocument8 pagesQAR-QD#419-15 Feed Cylinder GPIrwanto ManafNo ratings yet

- QAR-QD#407-7 Hollow Printing RollsDocument2 pagesQAR-QD#407-7 Hollow Printing RollsIrwanto ManafNo ratings yet

- 003 - Dye Penetrant Testing Report - Rev00 - 02122015Document2 pages003 - Dye Penetrant Testing Report - Rev00 - 02122015Irwanto ManafNo ratings yet

- Jedec Standard: Els ServiçosDocument18 pagesJedec Standard: Els ServiçosEverton LuizNo ratings yet

- The Winnipeg Foundation 2014 Annual ReportDocument76 pagesThe Winnipeg Foundation 2014 Annual ReportChrisDcaNo ratings yet

- Gujarat Cancer and Research Institute RatesDocument33 pagesGujarat Cancer and Research Institute RatesNimhans HospitalNo ratings yet

- GRES Integrated Energy Storage SystemDocument33 pagesGRES Integrated Energy Storage SystemVadim PopovichNo ratings yet

- ME Lab 2 LectureDocument5 pagesME Lab 2 LectureIan Paul TongolNo ratings yet

- MCN KweenDocument4 pagesMCN KweenAngelo SigueNo ratings yet

- Long Quiz Earth Sci 11Document2 pagesLong Quiz Earth Sci 11Jesha mae MagnoNo ratings yet

- 1 jISHADocument5 pages1 jISHAFirman MufidNo ratings yet

- Case Study On A Highway Project: Environmental Impact AssesmentDocument10 pagesCase Study On A Highway Project: Environmental Impact AssesmentSRUTHI FRANCIS M.Tech Environmental Engineering 2020-2022No ratings yet

- Notes-Nutrition in PlantsDocument3 pagesNotes-Nutrition in PlantsADHIL MOHAMMEDNo ratings yet

- PSP Assignment1Document25 pagesPSP Assignment1B BasitNo ratings yet

- Furnace SoftwareDocument7 pagesFurnace SoftwareolaNo ratings yet

- Sago Pudding - Recipes - Poh's KitchenDocument2 pagesSago Pudding - Recipes - Poh's KitchenXuxu TooNo ratings yet

- Barron's Bigbook Special WordDocument123 pagesBarron's Bigbook Special WordArif Al MamunNo ratings yet

- Hospital Management System: Dept. of CSE, GECRDocument30 pagesHospital Management System: Dept. of CSE, GECRYounus KhanNo ratings yet

- Muscular Triangles of The NeckDocument3 pagesMuscular Triangles of The NeckSam TagardaNo ratings yet

- T N M M T N M M: HE EW Essies Anual HE EW Essies AnualDocument8 pagesT N M M T N M M: HE EW Essies Anual HE EW Essies AnualMunna100% (1)

- Training - Cga ApplicationDocument34 pagesTraining - Cga ApplicationSubhan Muhammad100% (1)

- Nanoengineered Silica-Properties PDFDocument18 pagesNanoengineered Silica-Properties PDFkevinNo ratings yet

- Ethics in HRMDocument7 pagesEthics in HRMVinay RamaneNo ratings yet

- Acupressure Points GuidelinesDocument6 pagesAcupressure Points Guidelinesshahisk100% (1)

- Phason FHC1D User ManualDocument16 pagesPhason FHC1D User Manuale-ComfortUSANo ratings yet

- Workload ManagementDocument25 pagesWorkload Managementdex adecNo ratings yet

- Environmental Geotechniques: Theories of Ion ExchangeDocument21 pagesEnvironmental Geotechniques: Theories of Ion ExchangeTenkurala srujanaNo ratings yet

- Wear Solutions BrochureDocument16 pagesWear Solutions BrochureOkan KalendarNo ratings yet

QAR-QD#419-2 Single Parts

QAR-QD#419-2 Single Parts

Uploaded by

Irwanto ManafOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

QAR-QD#419-2 Single Parts

QAR-QD#419-2 Single Parts

Uploaded by

Irwanto ManafCopyright:

Available Formats

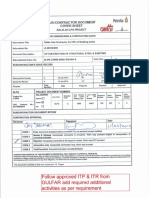

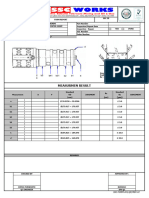

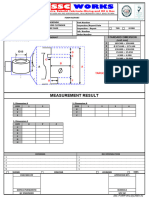

Document No.

: QAR-QD#419-2

Revision : 00

FINAL INSPECTION REPORT Date : 22-Jan-07

PT. Sanggar Sarana Baja Responsibility : QC Department

Remanufacturing Division

Page : 1 of 1

No. : Customer : Part Name :

PO. No. : Cust. WO. No. : Model :

NRC ID : Packing List No. : Part No. :

INSPECTION TEST PLAN

Checklist

No Description Signature

Ö/X

1. Ensure Receive Packing List before final inspect the finished components & record the number

2. Ensure Green OK Tag is attached on finished components

3. Items that need to be checked in final inspection :

*) Visual Inspection

*) Check PO & Part Number, Model and record it (see part information section above)

*) Check the NRC Identification (ID) and record the numbers (see 2nd page for group

components and part information section above for single components)

*) Ensure NRC Indentification Plate was installed on the component and check the contents

(ONLY applied on group components and Non-CAT single components)

*) Take a pictures

- Groups : NRC ID & Plate, Front / Rear / Left / Right view of the overall component, Stand,

Packing Sling (for Wheel Gp), Control Valve & Gear Pump (for Transmission),

Eye Bearing in Housing As (for Hoist Cylinder Gp), Wiper seal (Hydraulics Gp)

- Single : NRC ID & Plate, Front / Rear / Left / Right view of the overall component

*) Put the Yellow QC Pass Sticker (for finished components) and Red Reject Sticker (for

"Return to Customer" components)

*) Ensure all pictures were downloaded to its PO folders and rename the pictures file name to

finalinspectionX.jpg (X : pictures taken sequence)

4. Sign Packing List document and send to Shipping and Receiving Officer

5. Make Inspection Release Certificate (IRC), update IRC Monitoring and ask QC Manager

for approval. Please double check for NRC ID in IRC Monitoring

6. Copy IRC to 5 copies :

- The original & 1 copy of IRC were sent to Sales Admin Officer

- Two (2) copies were sent to Shipping and Receiving Officer

- And the remain documents, will be sent to Cost Controlling Officer and QC archives

7. For group components, find the testing report → ask QC Manager for approval → Copy it

and attached to the component. Don't forget to scan the testing report then send to customer

by email

8. Take pictures of component box / pack (overall and packing list view) and downloaded to

its folder

STATUS : ACCEPT RETURN TO CUSTOMER

TIME TAKEN : HRS

Reviewed by Prepared by

QC Engineer : Inspector :

Signature : Date : Signature : Date :

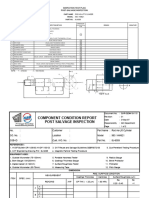

Document No. : QAR-QD#419-2

Revision : 01

FINAL INSPECTION REPORT Date : 19-Feb-07

PT. Sanggar Sarana Baja Responsibility : QC Department

Remanufacturing Division

Page : 1 of 1

No. : Customer : Part Name :

SO. No. : Cust. WO. No. : Model :

SSB ID : Packing List No. : - Part No. :

INSPECTION TEST PLAN

Checklist

No Description Signature

Ö/X

1. Ensure Green OK Tag is attached on finished components

2. Items that need to be checked in final inspection :

*) Visual Inspection

*) Check SO & Part Number, Model and record it (see part information section above)

*) Check the SSB Identification (ID) and record the numbers (see part information section

above)

*) Ensure SSB Identification Plate was installed on the component and check the contents

(ONLY applied on external component)

*) Take a pictures

- SSB ID & Plate, Front / Rear / Left / Right view of the overall component

*) Put the Yellow QC Pass Sticker (for finished components) and Red Reject Sticker (for

"Return to Customer" components)

*) Ensure all pictures were downloaded to its PO folders and rename the pictures file name to

finalinspectionX.jpg (X : pictures taken sequence)

3. Find the testing report. Copy it and attached to the component. DON'T FORGET to scan the

testing report then send to customer by email (if required)

4. Ensure Receive Packing List before create Inspection Release Certificate (IRC) & record

the number. Please double check the Packing List contents with final inspection result

5. Sign Packing List document and send to Shipping and Receiving Officer

6. Take pictures of component box / pack (overall and packing list view) and downloaded to

its folder

7. Make Inspection Release Certificate (IRC) and update IRC Monitoring. Please double

check for SSB ID in IRC Monitoring

8. Copy IRC to 5 copies :

- The original & 1 copy of IRC were sent to Sales Admin Officer

- One (1) copy were sent to Shipping and Receiving Officer

- And the remain documents, will be sent to Cost Controlling Officer and QC archives

STOCK : YES NO

STATUS : ACCEPT RETURN TO CUSTOMER

TIME TAKEN : HRS

Reviewed by Prepared by

QC Engineer : Inspector :

Signature : Date : Signature : Date :

You might also like

- The 9 Centers Human DesignDocument14 pagesThe 9 Centers Human Designmonicabors100% (11)

- The Woman Speaks To The Man Who Has Employed Her SonDocument3 pagesThe Woman Speaks To The Man Who Has Employed Her SonSerena SulawammotNo ratings yet

- LTHEDocument5 pagesLTHEMohit Goswami100% (1)

- ITP For Boiler ErectionDocument6 pagesITP For Boiler ErectionUmair Awan100% (2)

- Holistic Self Health CareDocument80 pagesHolistic Self Health Careadkittipong100% (1)

- Fotocopias Ingles Tema Climate 1º EsoDocument6 pagesFotocopias Ingles Tema Climate 1º EsoMayOrdóñezNo ratings yet

- Carbon Footprint of Organic FertilizerDocument5 pagesCarbon Footprint of Organic FertilizerSteve Savage100% (6)

- QAR-QD#419-15 Feed Cylinder GPDocument8 pagesQAR-QD#419-15 Feed Cylinder GPIrwanto ManafNo ratings yet

- QAR-QD#419-14 Grapple Cylinder GPDocument6 pagesQAR-QD#419-14 Grapple Cylinder GPIrwanto ManafNo ratings yet

- QAR-QD#419-21 Boom Cylinder GPDocument2 pagesQAR-QD#419-21 Boom Cylinder GPIrwanto ManafNo ratings yet

- QAR-QD#419-24 Edmo Jack Cylinder GPDocument2 pagesQAR-QD#419-24 Edmo Jack Cylinder GPIrwanto ManafNo ratings yet

- QAP K-HouseDocument4 pagesQAP K-HouseAbhinash TamangNo ratings yet

- Material Inspection SheetDocument3 pagesMaterial Inspection Sheetrahid iqubalNo ratings yet

- E13. Sample Inspection Release Certificate IRCDocument2 pagesE13. Sample Inspection Release Certificate IRCMohamedNo ratings yet

- INCR New Format 2021Document1 pageINCR New Format 2021Khan ZamanNo ratings yet

- IVR-HAL-ONGC-L&T-CBE-003-Dt 25-11 - 019Document6 pagesIVR-HAL-ONGC-L&T-CBE-003-Dt 25-11 - 019Harish GundaNo ratings yet

- Field Inspection & Test Plan (F-Itp) : DOC. NO.: I-T3108-QAQC-006Document7 pagesField Inspection & Test Plan (F-Itp) : DOC. NO.: I-T3108-QAQC-006bernardNo ratings yet

- Civil FormatsDocument46 pagesCivil Formatsaftabshekh624462No ratings yet

- RamprasadDocument2 pagesRamprasadRagul0042No ratings yet

- Qaqc Cir Civil Material PillingDocument1 pageQaqc Cir Civil Material PillingFirman Indra JayaNo ratings yet

- QAR-QD404-1 Liquid Penetrant Testing Report-GeneralDocument1 pageQAR-QD404-1 Liquid Penetrant Testing Report-GeneralIrwanto ManafNo ratings yet

- Liquid Penetrant Inspection Report: Industrial Proforma FormDocument1 pageLiquid Penetrant Inspection Report: Industrial Proforma FormJohn DolanNo ratings yet

- Inspection and Test PlanDocument6 pagesInspection and Test PlanReduddboy100% (1)

- 2412- IRN FormatDocument2 pages2412- IRN FormatFahad AhmadNo ratings yet

- LOG-563-03 Receiving Inspection Checklist Rev.1Document1 pageLOG-563-03 Receiving Inspection Checklist Rev.1Emy SumartiniNo ratings yet

- TST IR Clair P 575 Bought Out Items BAGS DT 22.07.2019Document2 pagesTST IR Clair P 575 Bought Out Items BAGS DT 22.07.2019MOUNESH REDDYNo ratings yet

- Quality Control Manual of PT Sarku Enjinering Utama (ASME JR)Document110 pagesQuality Control Manual of PT Sarku Enjinering Utama (ASME JR)herlan100% (1)

- Inspection & Test Plan (Itp) : Mechanical (Machine & Equipment)Document2 pagesInspection & Test Plan (Itp) : Mechanical (Machine & Equipment)ikramNo ratings yet

- PP-FR-03 Route CardDocument1 pagePP-FR-03 Route Cardchandra100% (2)

- QA ProcessDocument4 pagesQA Processmadhu krishnaNo ratings yet

- 6 PTJ QA FRM 004 Receiving Inspection ReportDocument1 page6 PTJ QA FRM 004 Receiving Inspection ReportAhmed NagyNo ratings yet

- 05-01 ITPDocument2 pages05-01 ITPMo ZeroNo ratings yet

- ITP Sample For Steet Strucute WorksDocument7 pagesITP Sample For Steet Strucute WorksTee Klong RungNo ratings yet

- Bluskies Engineering PVT LTD: Acp Panel Inpection ReportDocument7 pagesBluskies Engineering PVT LTD: Acp Panel Inpection ReportRavi Shankar KolluruNo ratings yet

- 01 - Asf-Qc-Itp-002Document4 pages01 - Asf-Qc-Itp-002Sherif YehiaNo ratings yet

- FQP Format Cqa-IV-r2 DT 200510Document2 pagesFQP Format Cqa-IV-r2 DT 200510sheb20040% (1)

- Quality Control Plan / Inspecting and Testing Plan - (Discipline) Structure Erection and InstallationDocument1 pageQuality Control Plan / Inspecting and Testing Plan - (Discipline) Structure Erection and InstallationTarun PatelNo ratings yet

- Vendor Fabrication Shop Site Construction: QA/QC Inspections: Inspection Test PlanDocument2 pagesVendor Fabrication Shop Site Construction: QA/QC Inspections: Inspection Test PlanSuraj ShettyNo ratings yet

- KLD 00 4500399734 ZV P23 00030 0000 02 Fabrication, Installation & Testing of Structural SteelDocument5 pagesKLD 00 4500399734 ZV P23 00030 0000 02 Fabrication, Installation & Testing of Structural SteelRana AsifNo ratings yet

- S 000 16B0 0011V - 0 PDFDocument33 pagesS 000 16B0 0011V - 0 PDFChung TrịnhNo ratings yet

- TST IR Clair P 575 CAGES Bought Out Items DT 22.07.2019Document2 pagesTST IR Clair P 575 CAGES Bought Out Items DT 22.07.2019MOUNESH REDDYNo ratings yet

- Itp STR Slpg-Q-0000-24001-032-001-4-ADocument11 pagesItp STR Slpg-Q-0000-24001-032-001-4-AsivagnanamNo ratings yet

- Pumps ItpDocument3 pagesPumps Itpkokod9757No ratings yet

- QIP of Boiler For ErectionDocument6 pagesQIP of Boiler For ErectionUmair Awan100% (2)

- Receiving Inspection Checklist Details & Sub-AssemblyDocument7 pagesReceiving Inspection Checklist Details & Sub-AssemblyMohamedNo ratings yet

- NGWK PK 0001 VDQC Plit 0006Document7 pagesNGWK PK 0001 VDQC Plit 0006stdshopNo ratings yet

- ITP Civil and Structure Moly ProjectDocument34 pagesITP Civil and Structure Moly ProjectYosses Sang NahkodaNo ratings yet

- Inspection Report: F-084/09 R-VM23-0012-LV-052 Rev.00Document5 pagesInspection Report: F-084/09 R-VM23-0012-LV-052 Rev.00Navid HashemiNo ratings yet

- Inspection and Test Plan: JS19-010 Haddadin Engineering Co. AISC & AWS D1.1 2015Document3 pagesInspection and Test Plan: JS19-010 Haddadin Engineering Co. AISC & AWS D1.1 2015Khaled GamalNo ratings yet

- QCP 23-196 Rev.1Document4 pagesQCP 23-196 Rev.1ARKA technocorpNo ratings yet

- Tank Erection Itp Org ChartDocument34 pagesTank Erection Itp Org Chartvasantha kumar100% (1)

- ITP For Batteries Chargers and UPSDocument7 pagesITP For Batteries Chargers and UPSaryan_iustNo ratings yet

- Quality Assurance Plan: MPL QAP No.Document13 pagesQuality Assurance Plan: MPL QAP No.Varun MalhotraNo ratings yet

- Inspection Report: CPP-RM-PO-0180Document4 pagesInspection Report: CPP-RM-PO-0180ANIL PLAMOOTTIL0% (1)

- Qality Assurance Inspection and Test Plan: Piping Fabrication & InstallationDocument16 pagesQality Assurance Inspection and Test Plan: Piping Fabrication & Installationmanoj thakkarNo ratings yet

- Inspection and Test Plan: S. H. Joo D. H. YounDocument2 pagesInspection and Test Plan: S. H. Joo D. H. YounfitriatitisariNo ratings yet

- ITP Sample For Piping Assembly WorksDocument7 pagesITP Sample For Piping Assembly WorksTee Klong RungNo ratings yet

- Cyl Suspensi Tr-3034 MTN MhuDocument1 pageCyl Suspensi Tr-3034 MTN MhuM Ferry AnwarNo ratings yet

- Itr Ew 05a - EngDocument1 pageItr Ew 05a - Engwassim nasriNo ratings yet

- 149-158 - Zug-Header-Malinau-Sc 12 016 Rev 1 Unit 2Document58 pages149-158 - Zug-Header-Malinau-Sc 12 016 Rev 1 Unit 2Muhammad Fitransyah Syamsuar PutraNo ratings yet

- Itp Tank RappDocument4 pagesItp Tank Rapprizky youlandaNo ratings yet

- EG.02.J.96.053.102NM 03 1 PublicationDocument6 pagesEG.02.J.96.053.102NM 03 1 Publicationfhairuz.wahidNo ratings yet

- Air Balance Test QCDD FormDocument2 pagesAir Balance Test QCDD FormSamir AminNo ratings yet

- PDI ReportDocument2 pagesPDI ReportPreetam GiteNo ratings yet

- The Sarbanes-Oxley Section 404 Implementation Toolkit: Practice Aids for Managers and AuditorsFrom EverandThe Sarbanes-Oxley Section 404 Implementation Toolkit: Practice Aids for Managers and AuditorsNo ratings yet

- HOUSING SWING EX-3600 (Before)Document7 pagesHOUSING SWING EX-3600 (Before)Irwanto ManafNo ratings yet

- Carrier Diff Eh 1700Document2 pagesCarrier Diff Eh 1700Irwanto ManafNo ratings yet

- Centricity Pto Ex 2500Document3 pagesCentricity Pto Ex 2500Irwanto ManafNo ratings yet

- Case Pto Only IdDocument5 pagesCase Pto Only IdIrwanto ManafNo ratings yet

- Case Pto 3600Document2 pagesCase Pto 3600Irwanto ManafNo ratings yet

- Spindle Center JointDocument2 pagesSpindle Center JointIrwanto ManafNo ratings yet

- Carrier Ex 2500Document6 pagesCarrier Ex 2500Irwanto ManafNo ratings yet

- Casing Travel MotorDocument2 pagesCasing Travel MotorIrwanto ManafNo ratings yet

- Flange Grease Ex 2500aDocument1 pageFlange Grease Ex 2500aIrwanto ManafNo ratings yet

- Concentricity PtoDocument3 pagesConcentricity PtoIrwanto ManafNo ratings yet

- Casing Travel Motor 2Document3 pagesCasing Travel Motor 2Irwanto ManafNo ratings yet

- QAR-QD418-79 Housing As-Rear SuspensionDocument6 pagesQAR-QD418-79 Housing As-Rear SuspensionIrwanto ManafNo ratings yet

- Bucket Re BushingDocument2 pagesBucket Re BushingIrwanto ManafNo ratings yet

- QAR-QD418-78 Housing As-Rear SuspensionDocument6 pagesQAR-QD418-78 Housing As-Rear SuspensionIrwanto ManafNo ratings yet

- QAR-QD418-207 Piston-ParkingDocument5 pagesQAR-QD418-207 Piston-ParkingIrwanto ManafNo ratings yet

- QAR-QD418-50 Rod As-Rear SuspensionDocument5 pagesQAR-QD418-50 Rod As-Rear SuspensionIrwanto ManafNo ratings yet

- QAR-QD418-51 Rod As-Rear SuspensionDocument5 pagesQAR-QD418-51 Rod As-Rear SuspensionIrwanto ManafNo ratings yet

- QAR QD418 115 Rod As Lift CylinderDocument5 pagesQAR QD418 115 Rod As Lift CylinderIrwanto ManafNo ratings yet

- QAR-QD418-5 Rod-Front Susp 797 (191-8043)Document6 pagesQAR-QD418-5 Rod-Front Susp 797 (191-8043)Irwanto ManafNo ratings yet

- QAR-QD#419-24 Edmo Jack Cylinder GPDocument2 pagesQAR-QD#419-24 Edmo Jack Cylinder GPIrwanto ManafNo ratings yet

- Chapter #06 - Three YearsDocument41 pagesChapter #06 - Three YearsIrwanto ManafNo ratings yet

- 5 6264764972983651383Document1 page5 6264764972983651383Irwanto ManafNo ratings yet

- Form-Qc-001-616 Washer Pin Pivot StopDocument1 pageForm-Qc-001-616 Washer Pin Pivot StopIrwanto ManafNo ratings yet

- QAR-QD#407-19 Line Shaft (697-LINE SHAFT)Document2 pagesQAR-QD#407-19 Line Shaft (697-LINE SHAFT)Irwanto ManafNo ratings yet

- QAR-QD403-2 Magnetic Particle Inspection ReportDocument2 pagesQAR-QD403-2 Magnetic Particle Inspection ReportIrwanto ManafNo ratings yet

- QAR-QD#419-15 Feed Cylinder GPDocument8 pagesQAR-QD#419-15 Feed Cylinder GPIrwanto ManafNo ratings yet

- QAR-QD#407-7 Hollow Printing RollsDocument2 pagesQAR-QD#407-7 Hollow Printing RollsIrwanto ManafNo ratings yet

- 003 - Dye Penetrant Testing Report - Rev00 - 02122015Document2 pages003 - Dye Penetrant Testing Report - Rev00 - 02122015Irwanto ManafNo ratings yet

- Jedec Standard: Els ServiçosDocument18 pagesJedec Standard: Els ServiçosEverton LuizNo ratings yet

- The Winnipeg Foundation 2014 Annual ReportDocument76 pagesThe Winnipeg Foundation 2014 Annual ReportChrisDcaNo ratings yet

- Gujarat Cancer and Research Institute RatesDocument33 pagesGujarat Cancer and Research Institute RatesNimhans HospitalNo ratings yet

- GRES Integrated Energy Storage SystemDocument33 pagesGRES Integrated Energy Storage SystemVadim PopovichNo ratings yet

- ME Lab 2 LectureDocument5 pagesME Lab 2 LectureIan Paul TongolNo ratings yet

- MCN KweenDocument4 pagesMCN KweenAngelo SigueNo ratings yet

- Long Quiz Earth Sci 11Document2 pagesLong Quiz Earth Sci 11Jesha mae MagnoNo ratings yet

- 1 jISHADocument5 pages1 jISHAFirman MufidNo ratings yet

- Case Study On A Highway Project: Environmental Impact AssesmentDocument10 pagesCase Study On A Highway Project: Environmental Impact AssesmentSRUTHI FRANCIS M.Tech Environmental Engineering 2020-2022No ratings yet

- Notes-Nutrition in PlantsDocument3 pagesNotes-Nutrition in PlantsADHIL MOHAMMEDNo ratings yet

- PSP Assignment1Document25 pagesPSP Assignment1B BasitNo ratings yet

- Furnace SoftwareDocument7 pagesFurnace SoftwareolaNo ratings yet

- Sago Pudding - Recipes - Poh's KitchenDocument2 pagesSago Pudding - Recipes - Poh's KitchenXuxu TooNo ratings yet

- Barron's Bigbook Special WordDocument123 pagesBarron's Bigbook Special WordArif Al MamunNo ratings yet

- Hospital Management System: Dept. of CSE, GECRDocument30 pagesHospital Management System: Dept. of CSE, GECRYounus KhanNo ratings yet

- Muscular Triangles of The NeckDocument3 pagesMuscular Triangles of The NeckSam TagardaNo ratings yet

- T N M M T N M M: HE EW Essies Anual HE EW Essies AnualDocument8 pagesT N M M T N M M: HE EW Essies Anual HE EW Essies AnualMunna100% (1)

- Training - Cga ApplicationDocument34 pagesTraining - Cga ApplicationSubhan Muhammad100% (1)

- Nanoengineered Silica-Properties PDFDocument18 pagesNanoengineered Silica-Properties PDFkevinNo ratings yet

- Ethics in HRMDocument7 pagesEthics in HRMVinay RamaneNo ratings yet

- Acupressure Points GuidelinesDocument6 pagesAcupressure Points Guidelinesshahisk100% (1)

- Phason FHC1D User ManualDocument16 pagesPhason FHC1D User Manuale-ComfortUSANo ratings yet

- Workload ManagementDocument25 pagesWorkload Managementdex adecNo ratings yet

- Environmental Geotechniques: Theories of Ion ExchangeDocument21 pagesEnvironmental Geotechniques: Theories of Ion ExchangeTenkurala srujanaNo ratings yet

- Wear Solutions BrochureDocument16 pagesWear Solutions BrochureOkan KalendarNo ratings yet