Professional Documents

Culture Documents

08-3650 - Calc. Report Span 100M P9B-P10B - B - ACI

08-3650 - Calc. Report Span 100M P9B-P10B - B - ACI

Uploaded by

angga fedriantoOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

08-3650 - Calc. Report Span 100M P9B-P10B - B - ACI

08-3650 - Calc. Report Span 100M P9B-P10B - B - ACI

Uploaded by

angga fedriantoCopyright:

Available Formats

Name of Work:

JAKARTA LRT PHASE 1B

VELODROME-MANGGARAI

Client: System:

Simply Supported Composite Box Girder 100m

KSO WASKITA-NK-LRS

JAKARTA LRT PHASE 1B

COMPOSITE SBG SPAN 100M

P9B-P10B

Bentang: 100 m

Rail Gauge: 2 x 1.435

Lebar Beton: 9.150m

LAPORAN PERHITUNGAN

Prepared By : Checked By : Acknowledge By : Approved By :

Ir. Demson Dipl.-Ing. Zdenek

Name : Ragil Kistosi M Sihaloho Fukar

Place/Date : Jakarta, December 2023 Jakarta, December 2023 Jakarta, December 2023

Rev. B

PT. Waagner-Biro Indonesia, Talavera Suite 11th Floor, Jl. Let. Jend. TB. Simatupang Kav 22-26, Jakarta 12430 - Indonesia

Tel : (62-21) 7592 4355 (Hunting) Fax : (62-21) 7592 4358 & 7592 4359 e-mail: sellmebridges@ptwbi.co.id

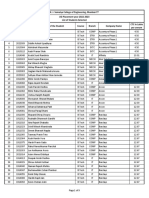

DAFTAR ISI

DAFTAR ISI __________________________________________________________________________________ 1

BAB I DESKRIPSI TEKNIS / TECHNICAL DESCRIPTION ____________________________________ 3

1.1 UMUM / GENERAL __________________________________________________________________ 3

1.2 SISTEM PERANCANGAN STATIS / STATIC DESIGN SYSTEM __________________________ 3

1.3 KONSTRUKSI / CONSTRUCTION ____________________________________________________ 5

BAB II KRITERIA PERENCANAAN / DESIGN CRITERIA ______________________________________ 6

2.1 UMUM / GENERAL __________________________________________________________________ 6

2.2 STANDARD DAN PERATURAN / CODES AND STANDARDS ____________________________ 6

2.3 SPESIFIKASI BEBAN / LOAD SPECIFICATIONS _______________________________________ 7

2.4 ANALISA STRUKTUR DAN STANDAR PERENCANAAN / STRUCTURAL ANALYSIS AND

DESIGN STANDARDS ______________________________________________________________________ 7

2.5 BEBAN RENCANA / DESIGN LOADS _________________________________________________ 7

2.5.1 AKSI dan BEBAN TETAP / PERMANENT LOAD AND ACTIONS ________________________________ 7

2.5.2 BEBAN HIDUP / LIVE LOAD ___________________________________________________________ 8

2.5.3 AKSI LINGKUNGAN / ENVIRONMENT LOAD _____________________________________________ 11

TABEL FAKTOR BEBAN TEMPERATUR / TEMPERATURE LOAD FACTOR ________________________________ 12

TABEL FAKTOR BEBAN ANGIN / WIND LOAD FACTOR ______________________________________________ 12

TABEL FAKTOR BEBAN PENGARUH GEMPA / EARTHQUAKE LOAD FACTOR _____________________________ 18

2.5.4. BEBAN PELAKSANAAN / CONSTRUCTION LOAD__________________________________________ 18

2.5.5 BEBAN LONGITUDINAL / LONGITUDINAL LOAD __________________________________________ 19

2.5.6 BEBAN REL PANJANG / LONG RAIL LOAD _______________________________________________ 21

2.5.7 BEBAN SENTRIFUGAL / CENTRIFUGAL LOAD ____________________________________________ 22

2.5.8 BEBAN HUNTING FORCE / HUNTING FORCE LOAD _______________________________________ 22

2.6 KOMBINASI PEMBEBANAN / LOAD COMBINATION ___________________________________ 23

2.6.1. KOMBINASI PADA KEADAAN BATAS DAYA LAYAN (SLS) / LOAD COMBINATION AT SERVICEABILITY LIMIT

STATE (SLS) ______________________________________________________________________________ 24

2.6.2. KOMBINASI PADA KEADAAN BATAS ULTIMATE (ULS) / LOAD COMBINATION AT ULTIMATE LIMIT STATE

(ULS) ___________________________________________________________________________________ 25

BAB III SPESIFIKASI TEKNIS JEMBATAN LRT 100M / TECHNICAL SPECIFICATION OF LRT

BRIDGE 100M_______________________________________________________________________________ 26

3.1. DATA UMUM / GENERAL DATA _____________________________________________________ 26

3.2. SPESIFIKASI MATERIAL / MATERIAL SPECIFICATIONS ______________________________ 27

3.2.1. Baja Struktural / Structural Steel _______________________________________________________ 27

3.2.2. Baut Struktural / Structural Bolt ________________________________________________________ 29

3.2.3 Beton bertulang (Pelat Lantai) / Reinforced Concrete (Deck Plate) _____________________________ 30

3.3. MUTU TIPE MATERIAL / MATERIAL TYPE QUALITY __________________________________ 30

3.4. BANTALAN / BEARING _____________________________________________________________ 31

3.5. PENCEGAHAN KARAT / CORROSION PROTECTION _________________________________ 31

3.6. PENGELASAN / WELDING __________________________________________________________ 32

BAB IV ANALISA STRUKTUR JEMBATAN LRT 100M / STRUCTURAL ANALYSIS OF LRT

BRIDGE 100M_______________________________________________________________________________ 33

4.1. GAMBARAN UMUM / GENERAL OVERVIEW _________________________________________ 33

4.2. PEMODELAN STRUKTUR / STRUCTURAL MODELLING_______________________________ 34

4.2.1. Properti Material / Material Properties ______________________________________________ 34

4.2.2. Spesifikasi Profil Jembatan / Bridge Elements Section Specification _______________________ 35

4.2.3. Penetapan Perletakan / Bearing Configuration _______________________________________ 37

4.2.4. Pembebanan / Loadings__________________________________________________________ 37

4.3. ANALISA STRUKTUR STEEL BOX GIRDER / STRUCTURAL ANALYSIS OF STEEL BOX

GIRDER __________________________________________________________________________________ 47

4.3.1. Analisa Struktur Kondisi Konstruksi / Construction Stage Analysis ________________________ 47

4.3.2. Analisa Struktur Kondisi Layan / Structural Analysis in Service Condition ___________________ 48

4.3.3. Analisa Struktur Kondisi Beban Terfaktor / Structural Analysis in Ultimate Condition _________ 50

LAPORAN STRUKTUR JALAN LAYANG-LRT JAKARTA FASE 1B | 1

4.3.4. Kontrol Defleksi_________________________________________________________________ 51

4.4. ANALISA GAYA PERLETAKAN / BEARING FORCE ANALYSIS _________________________ 52

4.5. ANALISA CAMBER / CAMBER ANALYSIS ____________________________________________ 59

4.6. ANALISA SAMBUNGAN / CONNECTION ANALYSIS ___________________________________ 60

4.6.1. JOIN 1 ________________________________________________________________________ 60

4.6.2. JOIN 2 ________________________________________________________________________ 68

4.6.3. JOIN 3 ________________________________________________________________________ 76

4.6.4. JOIN 4 ________________________________________________________________________ 84

4.7. ANALISA BRACING/BRACING ANALYSIS ____________________________________________ 92

4.8. ANALISA STIFFENER / STIFFENER ANALYSIS _______________________________________ 94

4.9. ANALISA TORSI / TORSIONAL ANALYSIS ___________________________________________ 94

4.10. ANALISA STUD BOLT / STUD BOLT ANALYSIS _______________________________________ 95

4.11. ANALISA LANTAI BETON / DECK SLAB ANALYSIS ____________________________________ 99

4.12. ANALISA LAS / WELDING ANALYSIS ____________________________________________________ 107

4.13. ANALISA FATIK / FATIGUE ANALYSIS ___________________________________________________ 108

4.14. ANALISA BUCKLING / BUCKLING ANALYSIS ______________________________________________ 110

4.15. ANALISA LATERAL BEAM / LATERAL BEAM ANALYSIS ______________________________________ 113

4.16. ANALISA BEARING STIFFENER / STIFFENER BEARING ANALYSIS _____________________________ 115

LAMPIRAN-A ANALISA DITAIL /ATTACHMENT-A DETAIL ANALYSIS _________________________ 118

First Delivery : December 2023

Revisi / Revision (B) :1. As Per 3VP Comments on 09-01-2024 for detail can see the

respond at the comments

LAPORAN STRUKTUR JALAN LAYANG-LRT JAKARTA FASE 1B | 2

BAB I DESKRIPSI TEKNIS / TECHNICAL DESCRIPTION

1.1 UMUM / GENERAL

Jembatan girder baja komposit ditumpu The composite steel girder bridge is

pada tiap-tiap ujung girder dengan bearing supported at each end of the girder with

yang menahan gaya vertikal utama, bearings that withstand the main vertical,

longitudinal dan lateral sesuai dengan longitudinal and lateral forces according to

konfigurasi bearing yang ada. the existing bearing configuration.

Jembatan direncanakan dapat dilalui 2 The bridge is planned to be able to

(dua) lajur LRT (Light Rapid Transit) withstand 2 (two) LRT (Light Rapid

dengan lebar lantai LRT 2.90 m dan lebar Transit) lanes with an LRT floor width of

beton keseluruhan 9.15 m. 2.90 m and an overall concrete width of

9.15 m.

Panjang bentang jembatan direncanakan

adalah bentang 100 meter, jarak antar The span length of the bridge is planned to

girder adalah 3.80 meter. be 100 meters span, the distance between

girders is 3.80 meters.

Sesuai dengan gambar teknis, ketebalan

lantai beton adalah 250 mm + beton untuk In accordance with the technical drawings,

track 400 mm (sleepers). the thickness of the concrete floor is 250

mm + concrete for 400 mm track

(sleepers).

1.2 SISTEM PERANCANGAN STATIS / STATIC DESIGN SYSTEM

Jembatan direncanakan sebagai struktur The bridge is planned as a free-standing

yang terletak bebas diatas empat structure on four supports. The structural

tumpuan. Metode analisa struktur analysis method is based on the linear

berdasarkan pada anggapan elastic linier elastic assumption and dimensional

dan analisa dimensi komponen dan analysis of components and connections

sambungan-sambungan menggunakan using the limit state approach.

pendekatan kekuatan batas (limit state).

Gaya-gaya internal girder yang dipakai The internal girder forces used in the

pada analisa penampang dan sambungan cross-section and connection analysis are

didasarkan pada beban terfaktor dan based on factored loads and load

kombinasi beban sesuai dengan ACI combinations in accordance with ACI

343.1R-12 (Analysis and Design of 343.1R-12 (Analysis and Design of

Reinforced and Prestressed Concrete Reinforced and Prestressed Concrete

Guideway Structures), beban dan faktor Guideway Structures), the loads and load

beban akan dijelaskan kemudian pada factors will be explained later in the Design

bab Kriteria Desain. Criteria chapter.

LAPORAN STRUKTUR JALAN LAYANG-LRT JAKARTA FASE 1B | 3

Lendutan jembatan akibat beban mati The deflection of the bridge due to dead

dikompensasikan dengan memberikan load is compensated by providing a

lawan lendut awal (fabricated camber) minimum fabricated camber of 100% of

minimum sebesar 100% dari defleksi the deflection due to dead load + 50% of

akibat beban mati+50% beban hidup. live load.

Selama pemasangan tulangan beton dan During concrete reinforcement installation

pengecoran beton, penopang sementara and concrete casting, temporary mid-span

di tengah bentang tidak diperlukan. supports were not required.

Sambungan baut utama direncanakan The main bolted connections are designed

sebagai sambungan tipe slip friksi kritis with critical slip friction type connections,

(critical slip friction), dan diperiksa pada and are checked at the bearing and shear

tipe sambungan tumpu dan geser. connection types. The coefficient of

Koefisien friksi, µ, yang dipergunakan friction, µ, used was Class B = 0.5 for

adalah Kelas B = 0.5 untuk baja yang painted steel on blast-cleaned steel

dipainting/dicat diatas permukaan yang surfaces according to the specification at

dibersihkan sesuai dengan spesifikasi chapter 3.5 based on AISC-RCSC.

perlindungan karat pada bab 3.5

berdasarkan AISC-RCSC.

Struktur dianalisa sebagai girder komposit The structure was analyzed as a

dengan ketebalan beton lantai 250 mm. composite girder with concrete thickness

ketebalan sleeper 400mm sebagai of 250 mm. 400mm sleeper thickness as

superimposed dead load diinputkan superimposed dead load assigned after

setelah aksi komposit. composite action.

Tabel Faktor Gelincir / Slip Factor (RSNI T-03-2005)

LAPORAN STRUKTUR JALAN LAYANG-LRT JAKARTA FASE 1B | 4

Gambar 1.1. Sample Cross Section

1.3 KONSTRUKSI / CONSTRUCTION

Jembatan didesain pada kombinasi beban Bridge is designed with the most critical

yang paling menentukan. Jembatan load combinations. The bridge is assumed

diasumsikan dipasang/ dirangkai diatas to be assembled/ installed using a

penumpu sementara atau disambung temporary support or assembled on land

didarat dan kemudian diangkat ke and lifted to the bearing using crane.

tumpuan dengan menggunakan crane.

Girder utama terbuat dari baja profil Main girder is made of welded Box

penampang “BOX” yang dilas (welded Box section. The girders are connected by a

section). Girder-girder dihubungkan oleh cross bracing in between at the end and

bracing melintang (cross bracing) pada the middle of the girder. Main girder

ujung girder dan pada bagian tengah connection is using bolted connections

girder. Sambungan girder utama and splice plate, with or without filler

menggunakan sambungan baut dan pelat plates.

sambung (splice plate) dengan atau tanpa

pelat pengisi (filler plate).

LAPORAN STRUKTUR JALAN LAYANG-LRT JAKARTA FASE 1B | 5

BAB II KRITERIA PERENCANAAN / DESIGN CRITERIA

2.1 UMUM / GENERAL

Dokumen ini menjelaskan analisa This document explained the static

perhitungan statis yang dipergunakan analysis calculations used in the planning

dalam perencanaan Jembatan Girder of Composite Steel Girder Bridge - LRT

Baja Komposit-LRT Jakarta Phase 1B. Jakarta Phase 1B. Detailed explanation of

Detail penjelasan Beban, Analisa, the loads, analysis, standards, and

Standard dan Asumsi dibuat untuk mudah assumptions is explained in simple terms

dipahami dan diperiksa. so it easy to understand and check.

2.2 STANDARD DAN PERATURAN / CODES AND STANDARDS

1. RSNI T-03-2005 Perencanaan 1. RSNI T-03-2005 Steel Structure

Struktur Baja untuk Jembatan Planning for Bridges

2. PM Perhubungan 60,2012 2. PM Perhubungan 60,2012 General

Perencanaan Umum untuk Jalan Planning for Railroads

Kereta Api 3. SNI 2833-2016, Bridge Design for

3. SNI 2833-2016, Perancangan Earthquake Loads

Jembatan terhadap Beban Gempa 4. AREMA (American Railway

4. AREMA (American Railway Engineering and Maintenance of Way

Engineering and Maintenance of Way Association)

Association) 5. AASHTO 2017 LRFD Bridge Design

5. AASHTO 2017 LRFD Bridge Design Specification

Specification 6. ACI 343.1R-12 Analysys and Design

6. ACI 343.1R-12 Analysys and Design of Reinforced and Prestressed

of Reinforced and Prestressed Concrete Guideway Structures

Concrete Guideway Structures 7. AWS D.1.5 Bridge Welding Code :

7. AWS D.1.5 Bridge Welding Code : Welding Procedure Specifications

Welding Procedure Specifications 8. AISC-RCSC American Institute of

8. AISC-RCSC American Institute of Steel Construction - Research Council

Steel Construction - Research Council on Structural Connection

on Structural Connection

LAPORAN STRUKTUR JALAN LAYANG-LRT JAKARTA FASE 1B | 6

2.3 SPESIFIKASI BEBAN / LOAD SPECIFICATIONS

Dalam perencanaan analisa gempa Earthquake load analysis is using

dipergunakan respons spectrum response spectrum based on SNI-2833-

berdasarkan SNI-2833-2016 di area 2016 in JAKARTA area

JAKARTA.

2.4 ANALISA STRUKTUR dan STANDAR PERENCANAAN / STRUCTURAL

ANALYSIS and DESIGN STANDARDS

Analisa struktur dan perencanaan Planning and structural analysis is based

didasarkan pada Perencanaan struktur on Perencanaan struktur baja untuk

baja untuk jembatan (SK.SNI T-03-2005), jembatan (SK.SNI T-03-2005), AASHTO

AASHTO 2017 LRFD Bridge Design 2017 LRFD Bridge Design Specification,

Specification, dan lain-lain. etc.

2.5 BEBAN RENCANA / DESIGN LOADS

Beban rencana berdasarkan pada PM Design loads is based on PM

Perhubungan, 60, 2012 Perencanaan Perhubungan, 60, 2012 Perencanaan

Umum untuk Jalan Kereta Api, ACI Umum untuk Jalan Kereta Api, ACI

343.1R-12 dan AREMA. 343.1R-12 and AREMA.

2.5.1 AKSI dan BEBAN TETAP / PERMANENT LOAD AND ACTIONS

Beban Mati jembatan terdiri dari berat The Dead Load of a bridge consists of the

masing-masing bagian struktural dan weight of each structural member and

elemen-elemen non-struktural. Masing- non-structural elements. Each of these

masing berat elemen ini harus dianggap element weights should be considered as

sebagai aksi yang terintegrasi pada saat an integrated action when applying normal

menerapkan faktor beban biasa dan and reduced load factors. The self weight

terkurangi. Berat sendiri dari bagian of a structural member is the weight of the

struktur adalah berat bahan dari bagian materials of the member and other

tersebut dan elemen-elemen struktural structural elements. This includes the

lain. Termasuk dalam hal ini adalah berat weight of the materials and parts of the

bahan dan bagian jembatan yang bridge that are structural elements, plus

merupakan elemen struktural, ditambah any non-structural elements that are

dengan elemen non-struktural yang considered permanent. The nominal

dianggap tetap. Berat nominal dan faktor weight and load factors for various

beban untuk berbagai macam material materials commonly used in steel truss

yang umum dipakai dalam jembatan bridges are as shown in the table below.

rangka baja adalah seperti dalam tabel

dibawah ini.

LAPORAN STRUKTUR JALAN LAYANG-LRT JAKARTA FASE 1B | 7

Tabel Berat Nominal Material / Material Weight

Material Jembatan / Bridge Materials Berat Jenis / Specific Gravity

(kN/m3)

Beton Bertulang / Reinforced Concrete 25.0

Lapisan Permukaan Beraspal / Asphalt 22.0

Surface

Baja / Steel 78.5

Cable Tray

Cables

3rd Rail 78.5

Kayu (ringan) / Light timber 7.8

Kayu (keras) / Hardwoods 11.0

Tabel Faktor Beban Tetap dan Berat Sendiri / Permanent Load Factor and Self-weight

Faktor Beban / Load Factor (ɤDL)

Jenis Beban / Load Type Service Limit State Ultimate Limit State

(SLS) (ULS)

Beton dicor ditempat/

1.00 0.9-1.30

Concrete cast in situ

Baja / Steel 1.00 0.9-1.30

2.5.2 BEBAN HIDUP / LIVE LOAD

Struktur akan direncanakan agar dapat The structure will be planned to withstand

menahan beban hidup yang diperoleh dari live loads obtained from the standard

standar spesifikasi light rail (kereta ringan) specifications of the light rail to be used.

yang akan digunakan.

a. Beban Gandar / Axle Load

Beban hidup yang digunakan adalah The live load used is the largest axle load

beban gandar terbesar sesuai rencana according to the planned LRT train to be

sarana LRT yang yang akan dioperasikan operated or the scheme of the load plan.

atau skema dari rencana muatan. Beban The axle load is set as shown below where

gandar diatur seperti gambar dibawah each vehicle axle distributes a load of

dimana tiap as kendaraan 12.50 tons with a distance between the

mendistribusikan beban sebesar 12.50 rails of 1435 mm. Axle loads for Jakarta

ton dengan jarak antar rel adalah sebesar LRT trains are calculated based on the

1435 mm. Beban gandar untuk kereta LRT maximum loads that occur which is the

Jakarta dihitung berdasarkan beban train load plus the passenger load inside.

LAPORAN STRUKTUR JALAN LAYANG-LRT JAKARTA FASE 1B | 8

maksimum yang terjadi. Beban maksimum Therefore, it is important to know the load

yang terjadi adalah beban kereta specifications of the trains used

ditambah dengan beban penumpang yang beforehand. The elevated track structure

berada didalamnya. Oleh karena itu, is designed to be able to withstand 8

spesifikasi beban kereta yang digunakan (eight) cars with 24 axles with each axle

penting untuk diketahui sebelumnya. weight 12.50 tons, where the eight cars

Struktur track elevated dirancang untuk are 2 train sets with each set consisting of

mampu dilewati 8 (delapan) trainset 4 cars.

dengan 24 gandar dengan masing-masing

gandar 12.50 ton, dimana delapan trainset

tersebut merupakan 2 rangkaian kereta

dengan masing-masing rangkaian terdiri

dari 4 trainset.

Spesifikasi kereta dapat dilihat pada The train specifications is as shown in the

gambar berikut: image below:

MC CAR T CAR MC CAR

Gambar 2.2. Kombinasi Rangkaian LRT / LRT Trainset Combinations

LAPORAN STRUKTUR JALAN LAYANG-LRT JAKARTA FASE 1B | 9

Gambar 2.3. Tampak Depan LRT / Front View of the LRT

b. Kecepatan Rencana / Design Velocity

Untuk LRT, kecepatan maksimum adalah As for LRT, the maximum speed is 80

80 km/h, sehingga kecepatan rencana km/h, so the plan speed is 90 km/h.

adalah 90 km/h.

c. Beban Kejut / Impact Load

Beban Impact(I) diambil berdasarkan ACI Impact load (I) is taken based on ACI

343.1R-12 yang bergantung pada 343.1R-12 which depends on the vehicle

kecepatan rencana dan panjang jembatan speed and length of the bridge as shown

seperti pada table berikut: in the following table:

Tabel Beban Kejut/ Impact Load

LAPORAN STRUKTUR JALAN LAYANG-LRT JAKARTA FASE 1B | 10

Dari hasil perhitungan dengan panjang From the calculation results with a span

bentang 100m, Beban kejut diambil length of 100m, the shock load is taken at

sebesar 1.3. 1.3.

2.5.3 AKSI LINGKUNGAN / ENVIRONMENT LOAD

Aksi lingkungan terdiri dari pengaruh Environment load is consist of

temperatur, angin, banjir, gempa dan temperature effects, wind, flood,

penyebab-penyebab alamiah lainnya. earthquake, and other natural causes.

2.5.3.1 Pengaruh Suhu / Temperature Effect

Fluktuasi harian pada suhu udara dan Daily fluctuations in air temperature and

radiasi matahari menimbulkan akibat solar radiation have the following effects

seperti berikut ini pada jembatan: on bridges:

a. Perubahan temperatur secara a. An overall temperature change in the

keseluruhan pada struktur jembatan, bridge structure, referred to as the

yang disebut sebaga suhu efektif effective temperature of the bridge.

jembatan.

b. Perbedaan temperature antara b. The temperature difference between

permukaan atas jembatan dengan the top surface of the bridge and other

bagian lain pada elevasi lain jembatan, parts at other elevations of the bridge,

yang disebut sebagai perbedaan which is referred to as the temperature

temperature yang mengakibatkan difference which results in the

timbulnya gaya dan/atau pengaruh generation of forces and / or the effect

gaya didalam struktur. of forces in the structure.

Didalam buku “The employer’s In the reference book of “The employer’s

requirement : section 9 : Design Cirteria” requirement : section 9 : Design Cirteria”,

temperatur jembatan rata-rata minimum the minimum average bridge temperature

adalah 23oC dan maksimum temperature is 23oC and the maximum average bridge

jembatan rata-rata adalah 37oC. Dengan temperature is 30oC. Thus obtained ±ΔT

demikian didapat ±ΔT sebesar 7oC. of 7oC.

LAPORAN STRUKTUR JALAN LAYANG-LRT JAKARTA FASE 1B | 11

Tabel Faktor Beban Temperatur / Temperature Load Factor

Faktor Beban / Load Factor (ɤTMP)

Ultimate Limit

Jenis Beban / Load Type Service Limit State

State

(SLS)

(ULS)

Temperature Range 0.30-1.00 1.00-1.50

2.5.3.2 Beban Angin / Wind Load

Beban angin bekerja tegak lurus rel, Wind load acting perpendicular to the rail,

secara horisontal, tipikal nilainya adalah: horizontally, typical values are:

a. 3.0 kN/m2 pada areal proyeksi vertikal a. 3.0 kN/m2 in the vertical projection area

jembatan tanpa kereta di atasnya. of bridges without trains above.

Namun demikian, 2.0 kN/m2, pada However, 2.0 kN/m2, in the area of the

areal proyeksi rangka batang pada truss projection in the direction of the

arah datangnya angin, tidak termasuk wind, excluding the area of the floor

areal sistem lantai. system.

b. 1.5 kN/m2 pada areal kereta dan b. 1.5 kN/m2 in the area of trains and

jembatan, dengan kereta di atasnya, bridges, with trains on them, with the

pengecualian 1.2 kN/m2 untuk exception of 1.2 kN/m2 for bridges

jembatan selain gelagar dek/rasuk atau other than deck girders or composite

jembatan komposit, sedangkan 0.8 bridges, and 0.8 kN/m2 for the area of

kN/m2 untuk areal proyeksi rangka truss projections in the wind direction.

batang pada arah datangnya angin.

Tabel Faktor Beban Angin / Wind Load Factor

Faktor Beban / Load Factor (ɤWL)

Jenis Beban / Load Type Service Limit State Ultimate Limit State

(SLS) (ULS)

Beban angin pada struktur /

0.30-1.00 1.00-1.50

Wind on Structure

Beban angin pada kendaraan /

0.30-1.00 1.00-1.50

Wind on Vehicle

LAPORAN STRUKTUR JALAN LAYANG-LRT JAKARTA FASE 1B | 12

2.5.3.3 Pengaruh Gempa / Earthquake

Beban gempa direncanakan dengan Earthquake loads are planned using the

menggunakan SNI gempa untuk jembatan earthquake for bridges SNI (SNI 2833 -

(SNI 2833 – 2016). Wilayah gempa di 2016). The earthquake region in Indonesia

Indonesia telah dibagi menjadi beberapa has been divided into several regions

wilayah berdasarkan pergerakan muka based on ground surface movement

tanah (PGA) dan percepatan respons (PGA) and acceleration response

spectrum (Ss dan S1). Gambar di bawah spectrum (Ss and S1). The figure below

memperlihatkan pembagian wilayah shows the division of earthquake regions

gempa di Indonesia. in Indonesia.

Peta percepatan puncak di batuan dasar (PGA) untuk probabilitas terlampaui 7% dalam

75 tahun / Map of peak acceleration at bedrock (PGA) for 7% probability of exceedance

in 75 years

LAPORAN STRUKTUR JALAN LAYANG-LRT JAKARTA FASE 1B | 13

Peta respon spektra percepatan 0.2 detik di batuan dasar untuk probabilitas terlampaui

7% dalam 75 tahun / Response spectrum map of 0.2 s acceleration in bedrock for 7%

probability of exceedance in 75 years

Peta respon spektra percepatan 1 detik di batuan dasar untuk probabilitas terlampaui

7% dalam 75 tahun / Response spectra map of 1-second acceleration in bedrock for 7%

probability of exceedance in 75 years

Penentuan klasifikasi situs diperoleh Determination of site classification is

berdasarkan hasil penyelidikan tanah based on the results of field soil

lapangan. Hasil analisis menunjukan investigation. The results of the analysis

bahwa kelas situs di lokasi yang ditinjau shows that the site class at the location

termasuk kategori tanah lunak. Faktor reviewed falls under the soft soil category.

LAPORAN STRUKTUR JALAN LAYANG-LRT JAKARTA FASE 1B | 14

amplifikasi harus ditentukan untuk Amplification factors must be determined

menghasilkan respon spekrum. Tabel di to generate the spectral response. The

bawah memperlihatkan faktor amplifikasi table below shows the amplification

untuk FPGA, Fa dan Fv. factors for FPGA, Fa and Fv.

Faktor Amplifikasi untuk PGA - 0,2 detik / Amplification Factor for PGA - 0.2 seconds

Besarnya nilai faktor amplifikasi untuk periode 1 detik (Fv) / The value of the

amplification factor for a period of 1 second (Fv)

Berdasarkan 3 variabel yang telah Based on the 3 variables previously

dijelaskan sebelumnya, maka design described, the design response spectrum

response spectrum dapat ditentukan can be determined using the following

dengan menggunakan persamaan equation:

berikut:

As = FPGA ´ PGA As = FPGA ´ PGA

SDS = Fa ´ Ss SDS = Fa ´ Ss

SD1 = Fv ´ S1 SD1 = Fv ´ S1

Klasifikasi situs tanah dapat dilihat pada The soil site classification can be seen in

tabel di bawah ini, untuk perencanaan the table below, for LRT planning in

LRT di Jakarta digunakan kelas situs Jakarta, the medium soil site class is used.

tanah Sedang.

LAPORAN STRUKTUR JALAN LAYANG-LRT JAKARTA FASE 1B | 15

Klasifikasi Situs Tanah / Soil Classification

Rata-rata harmonic

Bore Situs Tanah /

No / harmonic average

Hole Soil Type

(Ň)

Tanah Sedang /

1 DB 1 25.55

Medium Soil

Tanah Sedang /

2 DB 2 20.93

Medium Soil

Tanah Sedang /

3 DB 3 21.05

Medium Soil

Tanah Sedang /

4 DB 4 24.29

Medium Soil

Tanah Sedang /

5 DB 5 24.35

Medium Soil

Tanah Sedang /

6 DB 6 17.70

Medium Soil

Tanah Sedang /

7 DB 7 17.27

Medium Soil

Tanah Lunak /

8 DB 8 8.66

Soft Soil

Tanah Lunak /

9 DB 9 3.61

Soft Soil

Tanah Lunak /

10 DB 10 6.77

Soft Soil

Tanah Lunak /

11 DB 11 2.84

Soft Soil

Tanah Lunak /

12 DB 12 6.4

Soft Soil

Berdasarkan peraturan gempa Indonesia Based on Indonesian earthquake

untuk jembatan (RSNI 2833 2016). regulations for bridges (RSNI 2833 2016).

Percepatan muka tanah untuk daerah The ground acceleration for the Jakarta

Jakarta adalah 0.3 g. Berdasarkan area is 0.3 g. Based on the ground

percepatan muka tanah tersebut, maka acceleration, it can be concluded that the

dapat disimpulkan bahwa koefiesien yang coefficients used for the calculation of

digunakan untuk perhitungan beban earthquake loads are as follows:

gempa adalah sebagai berikut:

Ss = 0.6 g

S1 = 0.25 g

FPGA = 0.3

LAPORAN STRUKTUR JALAN LAYANG-LRT JAKARTA FASE 1B | 16

Design Response Spectrum

Struktur LRT diklasifikasikan kedalam LRT structures are classified into the

kategori jembatan lainya (other bridges). “other bridges” category. Based on the

Berdasarkan tabel dibawah, nilai R yang table below, the R-value used for a single

digunakan untuk kolom tunggal pada column in the “other bridges” category is 3.

kategori jembatan lainya adalah 3. Berarti This means that the R-value for the LRT

nilai R untuk pier (struktur atas) LRT, pier (superstructure), for example, can be

semisal, dapat diambil sebesar 3, baik taken as 3, in both longitudinal and

untuk arah longitudinal maupun transverse directions. As for the

transversal. Sedangkan untuk desain foundation design (lower structure), the R-

pondasi (struktur bawah), nilai R dapat value can be taken as half of the R-value

diambil setengah dari nilai R struktur atas of the upper structure R=1. For the

R=1. Untuk struktur atas (girder baja superstructure (composite steel girders),

komposit) diambil R=1 sehingga R=1 is taken so that melting is expected at

pelelehan diharapkan terjadi pada kolom the pier column.

pier.

LAPORAN STRUKTUR JALAN LAYANG-LRT JAKARTA FASE 1B | 17

Faktor modifikasi respon (R) untuk bangunan bawah / Response modification factor (R)

for sub-buildings

Tabel Faktor Beban Pengaruh Gempa / Earthquake Load Factor

Faktor Beban / Load Factor (ɤEQ)

Ultimate Limit

Jenis Beban / Load Type Service Limit State

State

(SLS)

(ULS)

Pengaruh Gempa /

0.7 1.00

Earthquake Effect

2.5.4. BEBAN PELAKSANAAN / CONSTRUCTION LOAD

Beban pelaksanaan terdiri dari: Construction load consist of:

Beban yang disebabkan oleh aktivitas Loads caused by the construction

pelaksanaan itu sendiri; dan, activity itself; and,

Aksi lingkungan yang mungkin timbul Environmental actions that may arise

selama waktu pelaksanaan. during the construction period.

Selama waktu pelaksanaan jembatan, tiap During the construction of the bridge, any

aksi lingkungan dapat terjadi bersamaan environmental action may occur together

dengan beban pelaksanaan seperti: with the construction loads such as:

beban pengaruh temperature dan beban temperature influence loads and wind

angin pada struktur jembatan. loads on the bridge structure.

Adalah tidak perlu untuk

mempertimbangkan pengaruh gempa It is not necessary to consider earthquake

selama pelaksanaan konstruksi. effects during construction.

LAPORAN STRUKTUR JALAN LAYANG-LRT JAKARTA FASE 1B | 18

2.5.5 BEBAN LONGITUDINAL / LONGITUDINAL LOAD

a. Beban lepas-rel / Derailment Loads

Beban lepas-rel adalah beban yang Derailment loads is the load generated by

dihasilkan dengan menempatkan placing LRT carriage with their

gerbong LRT dengan sumbu longitudinal axes parallel to the rail

longitudinalnya parallel dengan arah rel. direction. Vertical off-rail loads are

Beban lepas-rel vertical ditentukan determined by placing two or three

dengan menempatkan dua atau tiga carriage placed along their longitudinal

gerbong yang ditempatkan sepanjang axis parallel to the rail axis. The off-rail

sumbu longitudinal nya parallel terhadap load shall be imposed on all

sumbu rel. Beban lepas-rel harus superstructure and substructure elements

dibebankan pada semua struktur atas subjected to the LRT.

dan elemen struktur bawah yang

terbeban LRT.

Beban lepas-rel vertical diasumsikan The vertical derailment load is assumed

sbb: as follows:

1) Bila rel dipasang dengan rel 1) When the rail is installed with

pembatas kecelakaan (emergency emergency guardrail placed every

guardrail) yang ditempatkan 25cm 25cm on rail length, the loading is

pada setiap panjang rel, pembebanan carried out between the emergency

dilakukan antara rel pembatas guardrail every 10cm up to 25cm.

kecelakaan (emergency guardrail) Guardrails installed to reduce the

10cm sampai 25cm. Rel penahan wear of LRT wheels shall not be used

yang dipasang untuk mengurangi aus as guardrails.

roda LRT tidak boleh dipakai sebagai

rel pembatas kecelakaan.

2) Untuk rel tangensial dan rel lengkung 2) For tangential rails and curved rails

dengan radius lebih bsar dari 1500m with a radius greater than 1500m and

dan tidak tersedia rel pembatas no crash guardrail is available, the

kecelakaan, penempatan beban placement of the load varies between

bervariasi antara 10cm sampai 10cm up to a maximum of 100cm.

maksimum 100cm

LAPORAN STRUKTUR JALAN LAYANG-LRT JAKARTA FASE 1B | 19

3) Untuk radius rel yang lebih kecil, 3) For smaller radius rails, where the

dimana jarak antara rel dan pelat dek distance between the rail and the deck

lebih kecil dari 120cm, posisi beban plate is smaller than 120cm, the

maksimum harus diatur sehingga maximum load position should be set

posisi roda yang terlepas berada so that the disengaged wheel position

20cm dari muka rel dari batas rel is 20cm away from the rail face of the

terdekat. nearest rail boundary.

4) Pengecekan pada komponen struktur 4) Checks on superstructure or

atas atau struktur bawah yang substructure components supporting

menopang dua atau lebih rel (track), two or more rails (tracks), only one

hanya satu track yang dianggap lepas track is considered derailed, the other

(derailed), track lainnya dianggap tracks are considered full or empty

penuh atau kosong tergantung control depending on the calculated stability

stabilitas element yang dihitung. control element.

Sedangkan untuk beban lepas-rel The horizontal off-rail loads are assumed

horizontal diasumsikan sbb: as follows:

1) Pada bagian yang tidak memiliki rel 1) In sections without emergency

pembatas kecelakaan (emergency guardrail, with a maximum carriage

guardrail), dengan kecepatan speed between 70 and 100 km/h, the

gerbong maximum antara 70 sampai horizontal off-rail load should be taken

100 km/jam, beban horizontal akibat as 30 percent of the weight of a

lepas-rel harus diambil sebesar 30 carriage working 60cm above the rail

persen dari berat sebuat gerbong and perpendicular to the structure axis

yang bekerja 60cm diatas rel dan by 300cm.

tegak lurus terhadap sumbu struktur

sebesar 300cm.

2) Pada bagian yang tidak memiliki rel 2) In sections without emergency

pembatas kecelakaan (emergency guardrail, with a maximum carriage

guardrail), dengan kecepatan speed of less than 70 km/h, the

gerbong maximum kurang dari 70 horizontal load due to off-rail should

km/jam, beban horizontal akibat be taken as 10 percent of the weight

lepas-rel harus diambil sebesar 10 of a carriage acting 60cm above the

persen dari berat sebuat gerbong

LAPORAN STRUKTUR JALAN LAYANG-LRT JAKARTA FASE 1B | 20

yang bekerja 60cm diatas rel dan rail and perpendicular to the structure

tegak lurus terhadap sumbu struktur axis by 300cm.

sebesar 300cm.

3) Pada bagian yang memiliki rel 3) In sections with emergency guardrail,

pembatas kecelakaan (emergency with a maximum carriage speed equal

guardrail), dengan kecepatan to or less than 100 km/h, the

gerbong maximum sama dengan atau horizontal load due to off-rail should

kurang dari 100 km/jam, beban be taken as 10 percent of the weight

horizontal akibat lepas-rel harus of a carriage acting 60cm above the

diambil sebesar 10 persen dari berat rail and perpendicular to the structure

sebuat gerbong yang bekerja 60cm axis by 300cm.

diatas rel dan tegak lurus terhadap

sumbu struktur sebesar 300cm.

b. Beban Longitudinal Lainnya/ Other Longitudinal Load

Selain kedua metode diatas maka In addition to the above two methods,

beban longitudinal yang diakibatkan the resulting longitudinal load can also

dapat juga dirujuk sebagai berikut: be referred to as follows:

1) Beban akibat pengereman (LFn), 1) Load due to braking (LFn), equal to

adalah sama dengan 15% dari 15% of the live load without impact

beban hidup tanpa beban impact, load, and acting 2.5m from the top of

dan bekerja 2.5 m dari atas rel. the rail.

2) Beban akibat pengereman darurat 2) Load due to emergency braking

(LFe), adalah sama dengan 30% (LFe), equal to 30% of live load

dari beban hidup tanpa beban without impact load, and acting 0.9

impact, dan bekerja 0.9 m dari atas m from the top of the rail.

rel.

2.5.6 BEBAN REL PANJANG / LONG RAIL LOAD

Berdasarkan PM Perhubungan 60,2012, According to PM Perhubungan 60,2012,

bebean rel panjang longitudinal (LF) pada longitudinal long rail loads (LF) are

dasarnya 10 kN/m, maksimum 2000 kN. basically 10 kN/m, maximum 2000 kN.

LAPORAN STRUKTUR JALAN LAYANG-LRT JAKARTA FASE 1B | 21

2.5.7 BEBAN SENTRIFUGAL / CENTRIFUGAL LOAD

Beban sentrifugal, diambil berdasarkan Centrifugal load, according to ACI 343.1R-

ACI 343.1R-12 sebagai berikut: 12 as follows:

Dimana: Where:

V = Kecepatan rencana (m/s) V = Design speed (m/s)

LL = Beban vertikal kereta (kN), tanpa LL= Vertical train load (kN), without impact

faktor kejut factor

R = Radius trek (m) R = radius trek, (m)

g = Percepatan gravitasi (m/s2) g = percepatan gravitasi (m/s2)

Bekerja secara horizontal pada pusat Work horizontally at the center of the

gaya kereta. Gaya sentrifugal harus train's force. Centrifugal force must be

diterapkan bersamaan dengan kombinasi applied in conjunction with other load

beban lain yang menghasilkan gaya combinations that generate maximum

maksimum pada struktur. Gaya sentrifugal force on the structure. This centrifugal

ini diasumsikan bekerja 1.8 m (6 ft) di atas force is assumed to act 1.8 m (6 ft) above

rel. the rails.

2.5.8 BEBAN HUNTING FORCE / HUNTING FORCE LOAD

Hunting force merupakan beban hidup Hunting force is a horizontal live load

horizontal yang disebabkan oleh interaksi caused by the lateral interaction of the

lateral kendaraan dan jalur pemandu vehicle and the guide way (nosing force).

(nosing force). Jika gaya sentrifugal dan If centrifugal and hunting force act

hunting force bekerja secara bersamaan, simultaneously, only the larger force must

hanya gaya yang lebih besar yang harus be considered.

dipertimbangkan.

Berdasarkan ACI 343.1R-12, gaya HF ini According to ACI 343.1R-12, HF force

harus diambil sebesar 8% untuk beban shall be taken as 8% for the non-factored

kendaraan standar vertikal vertical standard vehicle load.

LAPORAN STRUKTUR JALAN LAYANG-LRT JAKARTA FASE 1B | 22

2.6 KOMBINASI PEMBEBANAN / LOAD COMBINATION

Semua beban permanent pada jembatan All permanent loads on the bridge are

dasumsikan akan bekerja secara assumed to act simultaneously. However,

bersamaan. Namun demikian, bilamana where a reduced permanent load exerts

beban permanen terkurangi memberikan the total maximum force on a structural

pengaruh gaya maksimum total pada element, the load combination should

elemen struktur, kombinasi beban harus consider the effect of this reduced load as

mempertimbangan pengaruh beban long as the reduced load is logically

terkurangi ini selama beban terkurangi ini acceptable.

dapat diterima secara logis.

Faktor beban untuk keadaan batas ultimit The load factors for the ultimate limit state

didasarkan kepada umur rencana are based on a bridge plan life of 100

jembatan 100 tahun. years.

Aksi rencana ditentukan dari aksi nominal The plan action is determined from the

yaitu mengalikan aksi nominal dengan nominal action by multiplying the nominal

factor beban yang sesuai. Seluruh action by the appropriate load factor. All

pengaruh aksi rencana harus mengambil effects of the plan action should take the

fackor beban yang sama, dan keadaan same load factor, and the most dangerous

paling berbahaya harus diambil. condition should be taken.

Berikut kelompok beban yang digunakan: The following load groups are used:

DL = Beban mati DL = Dead load

SDL = Beban mati tambahan SDL = Additional dead load

LL+IM = Beban hidup + impact LL+IM = Live load + impact

LFn = Beban longitudinal (normal braking) LFn = Longitudinal load (normal braking)

LFe = Beban longitudinal (emergency LFe = Longitudinal load (emergency

braking) braking)

LF = Beban longitudinal (Long Rail Load) LF = Longitudinal load (Long Rail Load)

WL = Beban angin pada beban hidup WL = Wind load on live load

WS = Beban angin pada struktur WS = Wind load on the structure

CE = Beban sentrifugal CE = Centrifugal load

LAPORAN STRUKTUR JALAN LAYANG-LRT JAKARTA FASE 1B | 23

HF = Beban hunting force HF = Hunting force load

T = Beban temperatur T = Temperature load

SH+CR = Beban lainnya (seperti SH+CR = Other loads (such as shrinkage,

shrinkage, settlement, efek pemuaian rail settlement, rail expansion effect and rail

dan rail break) break)

DR = Beban derailment DR = Derailment load

EQ = Beban gempa EQ = Earthquake load

2.6.1. KOMBINASI PADA KEADAAN BATAS DAYA LAYAN (SLS) / LOAD

COMBINATION AT SERVICEABILITY LIMIT STATE (SLS)

Pada keadaan batas daya layan In the serviceability limit state (SLS), more

(serviceability limit state/SLS), lebih dari than one transient action can occur

satu aksi transient bisa terjadi secara simultaneously.

bersamaan. The combination in the primary

Kombinasi pada keadaan batas daya serviceability limit state consists of the

layan primer terdiri dari jumlah pengaruh sum of the effects of a fixed action with one

aksi tetap dengan satu aksi transient. transient action.

Kombinasi beban daya layan yang lazim Typical serviceability load combinations

seperti tabel dibawah ini: are shown in the table below:

Kombinasi Pembebanan Service / ACI Service Load Combination (ACI 343.1R-12) (SLS)

No. Name DL+SDL LL+IM LFn LF CE/HF WL+WS TU SH+CR EQX EQY

1 SLS 1 1 1 1 1 1

2 SLS 2 1 1 1 1 1 0.3

3 SLS 3 1 1 1 1 1 0.3 1 1

4 SLS 4 1 1 1 1

5 SLS 4-1 1 0.8 0.8 0.8 0.8 1 1 0.7 0.21

6 SLS 4-2 1 0.8 0.8 0.8 0.8 1 1 0.7 -0.21

7 SLS 4-3 1 0.8 0.8 0.8 0.8 1 1 -0.7 0.21

8 SLS 4-4 1 0.8 0.8 0.8 0.8 1 1 -0.7 -0.21

9 SLS 4-5 1 0.8 0.8 0.8 0.8 1 1 0.21 0.7

10 SLS 4-6 1 0.8 0.8 0.8 0.8 1 1 -0.21 0.7

11 SLS 4-7 1 0.8 0.8 0.8 0.8 1 1 0.21 -0.7

12 SLS 4-8 1 0.8 0.8 0.8 0.8 1 1 -0.21 -0.7

LAPORAN STRUKTUR JALAN LAYANG-LRT JAKARTA FASE 1B | 24

2.6.2. KOMBINASI PADA KEADAAN BATAS ULTIMATE (ULS) / LOAD COMBINATION

AT ULTIMATE LIMIT STATE (ULS)

Kombinasi pada keadaan batas ultimate The combination in the ultimate limit state

(ultimate limit state/ULS) terdiri dari jumlah (ULS) consists of the sum of fixed action

pengaruh aksi tetap dengan satu effects with one transient effect. Some

pengaruh transient. Beberapa aksi actions may occur at the serviceability

kemungkinan dapat terjadi pada tingkat level at the same time as others occur at

daya layan pada waktu yang sama the ultimate level. The possibility of such

dengan aksi lainnya terjadi pada tingkat combinations occurring must be taken into

ultimate. Kemungkinan terjadinya account, but only one action at the

kombinasi seperti ini harus serviceability level is included in the

diperhitungkan, tetapi hanya satu aksi loading combination.

pada tingkat daya layan yang dimasukkan

pada kombinasi pembebanan.

Kombinasi Pembebanan Ultimate / ACI Ultimate Load Combination (ACI 343.1R-12) (ULS)

No. Name DL+SDL LL(FULL)+IM LL(EMPTY)+IM LFe LF CE/HF WL+WS TU SH+CR DR EQX EQY

1 ULS 0 1.3 1.7 1.7 1 1

2 ULS 0-A 0.9 1.7 1.7 1 1

3 ULS 1 1.3 1.4 1.4 1.5 1

4 ULS 1-A 0.9 1.4 1.4 1.5 1

5 ULS 3-1 1 0.8 0.8 0.8 0.8 1 1 1 0.3

6 ULS 3-2 1 0.8 0.8 0.8 0.8 1 1 1 -0.3

7 ULS 3-3 1 0.8 0.8 0.8 0.8 1 1 -1 0.3

8 ULS 3-4 1 0.8 0.8 0.8 0.8 1 1 -1 -0.3

9 ULS 3-5 1 0.8 0.8 0.8 0.8 1 1 0.3 1

10 ULS 3-6 1 0.8 0.8 0.8 0.8 1 1 -0.3 1

11 ULS 3-7 1 0.8 0.8 0.8 0.8 1 1 0.3 -1

12 ULS 3-8 1 0.8 0.8 0.8 0.8 1 1 -0.3 -1

13 ULS 5 1.3 1.4 1.4 1.5 1 1.4

14 ULS 5-A 0.9 1.4 1.4 1.5 1 1.4

15 ULS 5-B 1.3 1.4 1.4 1.5 1 1.4

16 ULS 5-C 0.9 1.4 1.4 1.5 1 1.4

LAPORAN STRUKTUR JALAN LAYANG-LRT JAKARTA FASE 1B | 25

BAB III SPESIFIKASI TEKNIS JEMBATAN LRT 100M /

TECHNICAL SPECIFICATION OF LRT BRIDGE 100M

Spesifikasi Material yang digunakan Material specifications used in the

dalam perencanaan jembatan ini planning of this bridge use materials that

menggunakan material yang sudah dapat can already be available in the country, so

tersedia di dalam negeri, sehingga that it is expected to provide more value

diharapkan dapat memberikan nilai lebih than this building itself.

dari bangunan ini sendiri.

3.1. DATA UMUM / GENERAL DATA

Tipe : Jembatan Girder Baja Komposit- Type : Composite-Simple Span Steel

Simple Span Girder Bridge

Bentang : 99.290m (pusat ke pusat Span : 99.290 m (center to center bearing)

bearing) Overall length = Span + 0.71m (approx)

Panjang keseluruhan = Bentang + 0.71m Width :

(approx) LRT traffic lane = 2 x 2.9m

Lebar : LRT rail width = 2 x 1.435m

Jalur lalu lintas LRT = 2 x 2.9 m Reinforced concrete floor width = 9.15m

Lebar Rail LRT = 2 x 1.435 m Distance between center girder = 3.80m

Lebar lantai beton bertulang = 9.15m Height :

Jarak antar center girder = 3.80m Girder height = 4.075m (outside top flange

Tinggi : - outside bottom flange)

Tinggi girder = 4.075 m (luar sayap atas - Vertical free height = 5.2m

luar sayap bawah)

Tinggi bebas vertical = 5.2 m

LAPORAN STRUKTUR JALAN LAYANG-LRT JAKARTA FASE 1B | 26

Gambar 3.1. Tampak Atas dan Tampak Samping

Gambar 3.2. Potongan Melintang

3.2. SPESIFIKASI MATERIAL / MATERIAL SPECIFICATIONS

3.2.1. Baja Struktural / Structural Steel

Baja Mutu SS 400 sesuai JIS G 3101 Steel Grade SS 400 as per JIS G

atau ekivalen: 3101 or equivalent:

Minimum kuat tarik: Minimum tensile strength:

fu = 400 MPa fu = 400 MPa

Minimum kuat leleh: Minimum yield strength:

fy = 245 MPa fy = 245 MPa

Ketebalan: Thickness:

t ≤ 40 mm t ≤ 40 mm

Modulus elastisitas: Modulus of Elasticity:

E = 210000 MPa E = 210000 MPa

LAPORAN STRUKTUR JALAN LAYANG-LRT JAKARTA FASE 1B | 27

Modulus Geser: Shear Modulus:

G = 80770 MPa G = 80770 MPa

Poisson’s ratio: Poisson’s ratio:

= 0.3 = 0.3

Koefisient muai linier: Linear expansion coefficient:

=11.7 10-6 / oC =11.7 10-6 / oC

Berat jenis: Specific Gravity:

w = 7850 kg/m3 w = 7850 kg/m3

Baja Mutu SM 490 YA/YB sesuai JIS Steel SM 490 YA/YB as per JIS G

G 3106 atau ekivalen: 3106 or equivalent:

Minimum kuat tarik: Minimum tensile strength:

fu = 490 MPa fu = 490 MPa

Minimum kuat leleh: Minimum yield strength:

fy = 355 MPa fy = 355 MPa

Ketebalan: Thickness:

t ≤ 40 mm t ≤ 40 mm

Modulus elastisitas: Modulus of Elasticity:

E = 210000 MPa E = 210000 MPa

Modulus Geser: Shear Modulus:

G = 80770 MPa G = 80770 MPa

Poisson’s ratio: Poisson’s ratio:

= 0.3 = 0.3

Koefisient muai linier: Linear expansion coefficient:

= 11.7 10-6 / oC = 11.7 10-6 / oC

Berat jenis: Specific Gravity:

w = 7850 kg/m3 w = 7850 kg/m3

Baja Mutu SM 570 sesuai JIS G Steel SM 570 as per JIS G 3106 or

3106 atau ekivalen: equivalent:

Minimum kuat tarik: Minimum tensile strength:

fu = 570 Mpa fu = 570 Mpa

LAPORAN STRUKTUR JALAN LAYANG-LRT JAKARTA FASE 1B | 28

Minimum kuat leleh: Minimum yield strength:

fy = 450 MPa fy = 450 MPa

Ketebalan: Thickness:

t ≤ 40 mm t ≤ 40 mm

Modulus elastisitas: Modulus of Elasticity:

E = 210000 MPa E = 210000 MPa

Modulus Geser: Shear Modulus:

G = 80770 MPa G = 80770 MPa

Poisson’s ratio: Poisson’s ratio:

= 0.3 = 0.3

Koefisient muai linier: Linear expansion coefficient:

= 11.7 10-6 / oC = 11.7 10-6 / oC

Berat jenis: Specific Gravity:

w = 7850 kg/m3 w = 7850 kg/m3

3.2.2. Baut Struktural / Structural Bolt

Baut struktural untuk sambungan sistem Structural bolts for the connection of the

struktur utama dan sekunder didisain main and secondary structural systems

menggunakan Baut High Strength are designed using High Strength Friction

Friction Grip: Grip Bolts:

Mutu Baut : Bolt Quality:

Grade 8.8F/T JIS B1180-1994 atau Grade 8.8F/T JIS B1180-1994 or

ekivalen equivalent

Minimum kuat tarik: Minimum tensile strength:

fuf = 800 MPa fuf = 800 MPa

Faktor Slip untuk permukaan Cat: Slip Factor for Paint surface:

= 0.5 = 0.5

Reduction factor: Reduction factor:

KSR = 0.70 KSR = 0.70

Faktor tipe lubang: Hole type factor:

kh = 1.00 untuk lubang standar kh = 1.00 for standard holes

LAPORAN STRUKTUR JALAN LAYANG-LRT JAKARTA FASE 1B | 29

3.2.3 Beton bertulang (Pelat Lantai) / Reinforced Concrete (Deck Plate)

Mutu beton untuk pelat lantai (dicor Quality of concrete for floor slabs (cast in

ditempat): place):

Kuat tekan karakteristik beton Compressive strength of concrete

f’c = 35 MPa atau K-430 f’c = 35 MPa or K-430

Berat jenis: Specific gravity:

w = 2500 kg/m3 w = 2500 kg/m3

Baja tulangan. Reinforcing steel.

Minimum kuat leleh: Minimum yield strength:

fy = 420 Mpa fy = 420 Mpa

Modulus elastisitas: Modulus of elasticity:

E = 200000 MPa E = 200000 MPa

Modulus geser: Shear modulus:

G = 80770 MPa G = 80770 MPa

Poisson’s ratio: Poisson's ratio:

= 0.3 = 0.3

Berat jenis: Specific gravity:

w = 7850 kg/m3 w = 7850 kg/m3

3.3. MUTU TIPE MATERIAL / MATERIAL TYPE QUALITY

Girder Utama atau Splice > 8mm Main Girder or Splice > 8mm

: SM570 atau ekivalen : SM570 or equivalent

Stiffener atau pelat > 8mm Stiffener atau pelat > 8mm

: SM490 YA/YB atau ekivalen : SM490 YA/YB or equivalent

filler < 8mm dan hot rolled filler < 8mm and hot rolled

: SS400 : SS400

Baut, mur, washer Bolt, nut, washer

: M24 Grade 8.8 F/T, Galvanis. : M24 Grade 8.8 F/T, Galvanized.

Lantai beton Concrete floor

: Minimum f’c = 35 Mpa atau K-430 : Minimum f’c = 35 Mpa or K-430

Deck Plate (CSD) Deck Plate (CSD)

: JIS G3302 Fy = 550 Mpa h=50mm : JIS G3302 Fy = 550 Mpa h=50mm

t=1mm t=1mm

LAPORAN STRUKTUR JALAN LAYANG-LRT JAKARTA FASE 1B | 30

3.4. BANTALAN / BEARING

Vertikal / Main bearing : Will be Provide In Separate Documents

3.5. PENCEGAHAN KARAT / CORROSION PROTECTION

Perlindungan korosi dirancang untuk The corrosion protection is designed for

kategori korosivitas C4 = Tinggi, Kawasan corrosivity category C4 = High, Industrial

industry dan area pantai dengan salinitas and coastal areas with moderate salinity

sedang menurut EN ISO 12944 Part 2. according to EN ISO 12944 Part 2.

Sistem cat yang dipilih didasarkan pada The selected paint system is based on

sistem S4.13 menurut EN ISO 12944 system S4.13 according to EN ISO 12944

Bagian 5:2007 Tabel A.4, ketebalan total Part 5:2007 Table A.4, total thickness 240

240 mikron. microns.

Sistem S4.13 memiliki daya tahan tertinggi The S4.13 system has the highest

yang diharapkan selama 15 tahun expected durability of 15 years according

menurut perkiraan. Pasal 5.5 EN ISO to estimates. Article 5.5 EN ISO 12944

12944 Bagian 5 dan EN ISO 12944 Part 5 and EN ISO 12944 Part 1.

Bagian 1.

Tabel 3.1. Sistem Proteksi Korosi / Corrosion Protection System

LAPORAN STRUKTUR JALAN LAYANG-LRT JAKARTA FASE 1B | 31

3.6. PENGELASAN / WELDING

Pengelasan sesuai pada semua aspek Welding conforms to all aspects listed in

yang tercantum dalam AWS D.1.5 Bridge AWS D.1.5 Bridge Welding Code: Welding

Welding Code : Welding Procedure Procedure Specifications.

Specifications.

LAPORAN STRUKTUR JALAN LAYANG-LRT JAKARTA FASE 1B | 32

BAB IV ANALISA STRUKTUR JEMBATAN LRT 100M /

STRUCTURAL ANALYSIS OF LRT BRIDGE 100M

Hasil perancangan dari tipe jembatan box The design results of this type of

girder komposit ini hanya dapat digunakan composite box girder bridge can only be

untuk tujuan awal yang tercantum dalam used for the original purpose stated in this

dokumen ini. Penggunaan isi dokumen document. Use of the contents of this

atau laporan ini untuk tujuan lain dilarang document or report for any other purpose

tanpa pemberitahuan dan otorisasi is prohibited without prior notice and

sebelumnya dari PT. WAAGNER BIRO authorization from PT. WAAGNER BIRO

INDONESIA. INDONESIA.

4.1. GAMBARAN UMUM / GENERAL OVERVIEW

Gambar 4.1. Tampak Memanjang Jembatan / Bridge Longitudinal View

Gambar 4.2. Tampak Atas Jembatan / Bridge Top View

Gambar 4.3. Tampak Melintang Jembatan / Bridge Cross Sectional View

LAPORAN STRUKTUR JALAN LAYANG-LRT JAKARTA FASE 1B | 33

4.2. PEMODELAN STRUKTUR / STRUCTURAL MODELLING

4.2.1. Properti Material / Material Properties

Berdasarkan pada pembahasan bab Based on the explanation in the previous

sebelumnya, material yang digunakan chapter, the material used for steel is

untuk baja adalah SM570. Material Fc’35 / SM570. The Fc'35 / K - 430 material will

K - 430 akan diinputkan kedalam section be inputted into the concrete section using

concrete dengan menggunakan model the model from CEB-FIP to obtain the

dari CEB-FIP untuk mendapakan curva compressive strength curves of the

kuat tekan dari mutunya, dan time- quality, and the time-dependent

dependent koefisien dari susut dan coefficients of shrinkage and creep are

rangkak diinputkan menggunakan model inputted using CEB-FIP model.

CEB-FIP.

LAPORAN STRUKTUR JALAN LAYANG-LRT JAKARTA FASE 1B | 34

Gambar 4.4 – Grafik Creep & Shrinkage Beton / Concrete Creep & Shrinkage Graph

Gambar 4.5 – Grafik Kuat Tekan Beton / Concrete Compressive Strength Graph

4.2.2. Spesifikasi Profil Jembatan / Bridge Elements Section Specification

Girder utama dimodelkan sebagai Main girder is modelled as a composite

komposit untuk mempertimbangkan efek section to consider its effects during the

selama analisa tahapan konstruksi construction stage analysis

LAPORAN STRUKTUR JALAN LAYANG-LRT JAKARTA FASE 1B | 35

LAPORAN STRUKTUR JALAN LAYANG-LRT JAKARTA FASE 1B | 36

Gambar 4.6 – Profil Box Girder / Box Girder Profile

4.2.3. Penetapan Perletakan / Bearing Configuration

Gambar 4.7 – Penetapan Perletakan / Girder Configuration

4.2.4. Pembebanan / Loadings

BEBAN MATI SENDIRI / SELF WEIGHT LOAD (SWL)

Baut dan sambungan dimasukan Bolts and connections are included in

dalam faktor 1,2 x SWL, dihitung oleh a factor of 1.2 x SWL, calculated by the

program menggunakan luas program using the cross-sectional area

penampang baja dikalikan berat of the steel multiplied by the specific

spesifik baja. weight of the steel.

LAPORAN STRUKTUR JALAN LAYANG-LRT JAKARTA FASE 1B | 37

Gambar 4.8 – Beban Sendiri / Self Weight Load (GZ -1,2)

BEBAN CORRUGATED STEEL DECK (CSD) / CSD LOAD

CSD = H = 50 mm ; t = 1 mm = 0.15 kN/m2

Gambar 4.9 – Beban Corrugated Steel Deck / CSD Load

BEBAN BETON SEGAR (SDL) / FRESH CONCRETE LOAD

Deck = G1 = 0.25m x 4.575m x 25 KN/m3 = 28.594 KN/m

Gambar 4.10 – Beban Beton Segar / Fresh Concrete Load

LAPORAN STRUKTUR JALAN LAYANG-LRT JAKARTA FASE 1B | 38

BEBAN MATI TAMBAHAN (SIDL) / SUPERIMPOSED DEAD LOAD

Beban SIDL diaplikasikan setelah SIDL load is applied when the age of

umur beton lantai 28 hari the concrete exceeding 28 days

Slab Track = 0.7876 m2 x 25 kN/m3 = 19.69 kN/m

Embedded Sleeper = 0.5045 m2 x 25 kN/m3 = 12.61 kN/m

Rail + Fastener Load = 2.5 kN/m

Third Rail = 0.073 m2 x 78.5 kN/m3 = 6.0 kN/m

Parapet Load = 15 kN/m

Cable Box = 3 kN/m

Cable Tray & Cable = 10.5 kN/m

Gambar 4.11 – Beban SIDL / SIDL Load

LAPORAN STRUKTUR JALAN LAYANG-LRT JAKARTA FASE 1B | 39

BEBAN SUHU / TEMPERATURE LOAD

Temp = 40 oC - 15 oC = 25 oC

Gambar 4.12 – Beban Suhu / Temp. Load

BEBAN HIDUP / LIVE LOAD

LAPORAN STRUKTUR JALAN LAYANG-LRT JAKARTA FASE 1B | 40

Gambar 4.13 – Beban Hidup Kereta 8 Gerbong / Live Load 8 Trainset

BEBAN AKIBAT PENGEREMAN / BRAKE LOAD

Beban akibat pengereman adalah Load due to braking is 15% of the live

15% dari beban hidup tanpa beban load without impact load

impact

Beban gandar (Axle load) = 125 kN x 24

Jumlah lajur (Lane number) = 2 Lajur (Lane)

Total = 6000 kN

Beban Rem (Brake Load) = 0.15 x 6000 = 900kN/Bridge

= 4.5 kN/m/girder

Lengan Kantilever (Cantilever) = 2.5 m (Dari atas rel/ from top of rail)

Gambar 4.14 – Beban akibat Pengereman / Brake Load)

LAPORAN STRUKTUR JALAN LAYANG-LRT JAKARTA FASE 1B | 41

BEBAN AKIBAT CENGKRAMAN / GRIP LOAD

Beban akibat cengkraman adalah 30% Load due to grip is 30% of the live

dari beban hidup tanpa beban impact load without impact load

Beban gandar (Axle Load) = 125 kN x 24

Jumlah lajur (Lane Number) = 2 Lajur (Lane)

Total = 6000 kN

Beban Cengkram (Grip Load) = 0.3 x 6000 = 1800kN/Bridge

= 9 kN/m/girder

Lengan Kantilever (Cantilever) = 0.9 m (Dari atas rel/ from top of rail)

Gambar 4.15 – Beban akibat Cengkraman / Grip Load

BEBAN HUNTING FORCE / HUNTING FORCE LOAD

Beban akibat hunting force adalah 8% Load due to hunting force is 8% of the

dari beban hidup tanpa beban impact live load without impact load

Beban gandar (Axle Load) = 125 kN x 24

Jumlah lajur (Lane Number) = 2 Lajur (Lane)

Total = 6000 kN

Beban Hunting Force = 0.08 x 6000 = 480 kN/Bridge

= 2.4 kN/m/girder

LAPORAN STRUKTUR JALAN LAYANG-LRT JAKARTA FASE 1B | 42

Gambar 4.16 – Beban Hunting Force / Hunting Force Load

BEBAN LONG RAIL / LONG RAIL LOAD

Beban pada dasarnya 10 kN/m, Base load 10 kN/m, with a maximum

maksimum 2000 kN of 2000 kN

Jumlah lajur (Lane number) = 2 Lajur (Lane)

Total = 2000 kN

Beban Long Rail = 10 kN/m/girder

Gambar 4.17 – Beban Long Rail / Long Rail Load

BEBAN AKIBAT DERAILMENT / DERAILMENT LOAD

Beban akibat derailment adalah 10% Load due to derailment is 10% of the

dari beban hidup tanpa beban impact live load without impact load

Beban gandar (Axle Load) = 125 kN x 24

Jumlah lajur (Lane Number) = 2 Lajur (Lane)

Total = 6000 kN

Beban Derailment = 0.1 x 6000 = 600kN/Bridge

= 3.0 kN/m/girder

Lengan Kantilever (Cantilever) = 3.0 m (Dari atas rel)

LAPORAN STRUKTUR JALAN LAYANG-LRT JAKARTA FASE 1B | 43

Gambar 4.18 – Beban akibat Derailment / Derailment Load

BEBAN ANGIN STRUKTUR (WS) / WIND LOAD ON STRUCTURE

Beban angin struktur diinputkan Wind load on structure is applied

secara horizontal dengan intensitas : horizontally with the intensity of:

WLS = 3 KN/m2 x (h girder+parapet)

= 19.014 kN/m

Gambar 4.19 – Beban Angin Struktur / Wind Load on Structure

LAPORAN STRUKTUR JALAN LAYANG-LRT JAKARTA FASE 1B | 44

BEBAN ANGIN KERETA (WL) / WIND LOAD ON VEHICLE

Beban angin kendaraan bekerja pada Wind load on vehicle is applied at

1800 mm diatas permukaan jalan 18000 mm above road surface

WLV = 1.5 KN/m2 x (h girder+parapet+train) = 12.85 KN/m

Lengan Kantilever = 2.1 m (Dari atas rel/ from top of rail)

Gambar 4.20 – Beban Angin pada Kereta / Wind Load on Vehicle

LAPORAN STRUKTUR JALAN LAYANG-LRT JAKARTA FASE 1B | 45

BEBAN GEMPA DINAMIS (EQ) / DYNAMIC EARTHQUAKE LOAD

PGA = 0.3 Ss = 0.6

S1 = 0.25 Soil class =D

Gambar 4.21 – Respon Spektrum

LAPORAN STRUKTUR JALAN LAYANG-LRT JAKARTA FASE 1B | 46

4.3. ANALISA STRUKTUR STEEL BOX GIRDER / STRUCTURAL ANALYSIS

OF STEEL BOX GIRDER

4.3.1. Analisa Struktur Kondisi Konstruksi / Construction Stage Analysis

Kondisi final struktur setelah construction The final condition of the structure after

stage analisis adalah kondisi “inisial” untuk construction stage analysis is the "initial"

post construction stage analysis dengan condition for post construction stage

memperhitungkan perubahan modulus analysis by taking into account the change

elastisitas akibat efek time-dependent in modulus of elasticity due to the time-

material. dependent effect of materials.

Kondisi berat baja sendiri (tanpa dek, curb, dan barrier) / Condition with steel self-

weight only (without deck, curb, and barrier)

Gambar 4.22 – My Kondisi Baja Sendiri (My maks = 73708 kN.m)

Kondisi saat pengecoran berat baja + beton segar (tanpa SIDL) / Condition with steel

self-weight + fresh concrete

Gambar 4.23 – My Kondisi Saat Pengecoran (My maks = 108944 kN.m)

LAPORAN STRUKTUR JALAN LAYANG-LRT JAKARTA FASE 1B | 47

Kondisi saat pemasangan ballast-rail-parapet setelah 28 hari (berat baja + beton

segar + SIDL)

Gambar 4.24 – My Kondisi Saat SIDL (My maks = 194007 kN.m)

4.3.2. Analisa Struktur Kondisi Layan / Structural Analysis in Service Condition

Kondisi layan (SLS) dibawah adalah The service condition (SLS) below is a

kondisi pada saat jembatan sudah condition when the bridge is more than 28

berumur lebih dari 28 hari, dan 10000 hari days old, and 10000 days or 25 years with

atau 25 tahun dengan asumsi bahwa the assumption that creep and shrinkage

creep dan shrinkage sudah have affected the bridge so that planning in

mempengaruhi jembatan sehingga planning is safer.

perencanaan dalam perencanan lebih The service condition (SLS) is in

aman. accordance with the Subchapter 2.6 loading

Kondisi layan (SLS) sesuai dengan combination where the load has been

kombinasi pembebanan Sub BAB 2.6 combined with various conditions.

dimana sudah beban sudah

dikombinasikan dengan berbagai kondisi.

Gambar 4.25 – My Kombinasi Layan SLS 10000 hari (My Maks = 247074 kN.m)

LAPORAN STRUKTUR JALAN LAYANG-LRT JAKARTA FASE 1B | 48

Gambar 4.26 – Tegangan Serat Atas Kombinasi SLS 10000 hari (Maks = -286 MPa)

Gambar 4.27 – Tegangan Serat Bawah Kombinasi SLS 10000 hari (Maks= 286 MPa)

Gambar 4.28 – Tegangan Beton SLS 10000 hari (Maks = -24 MPa)

LAPORAN STRUKTUR JALAN LAYANG-LRT JAKARTA FASE 1B | 49

4.3.3. Analisa Struktur Kondisi Beban Terfaktor / Structural Analysis in Ultimate

Condition

Kondisi struktur kondisi beban terfaktor The structural condition of the factored

(ULS) sesuai dengan kombinasi load condition (ULS) corresponds to the

pembebanan Sub BAB 2.6 dimana sudah loading combination of Subchapter 2.6

beban sudah dikombinasikan dengan where the loads have been combined with

berbagai kondisi. various conditions.

Gambar 4.29 – My Kombinasi Kuat ULS (My = 335163 kN.m)

Gambar 4.30 – Tegangan Serat Atas ULS (Maks = -354 MPa < 430 Mpa t>40mm)

Gambar 4.31 – Tegangan Serat Bawah ULS (Maks = 353 MPa <430 Mpa t>40mm)

LAPORAN STRUKTUR JALAN LAYANG-LRT JAKARTA FASE 1B | 50

4.3.4. Kontrol Defleksi

Gambar 4.32 –Lendutan Akibat LL 80 mm < L/700 V<100km/h (100000/700=142mm)

(OK)

LAPORAN STRUKTUR JALAN LAYANG-LRT JAKARTA FASE 1B | 51

4.4. ANALISA GAYA PERLETAKAN / BEARING FORCE ANALYSIS

LAPORAN STRUKTUR JALAN LAYANG-LRT JAKARTA FASE 1B | 52

LAPORAN STRUKTUR JALAN LAYANG-LRT JAKARTA FASE 1B | 53

LAPORAN STRUKTUR JALAN LAYANG-LRT JAKARTA FASE 1B | 54

LAPORAN STRUKTUR JALAN LAYANG-LRT JAKARTA FASE 1B | 55

LAPORAN STRUKTUR JALAN LAYANG-LRT JAKARTA FASE 1B | 56

LAPORAN STRUKTUR JALAN LAYANG-LRT JAKARTA FASE 1B | 57

LAPORAN STRUKTUR JALAN LAYANG-LRT JAKARTA FASE 1B | 58

4.5. ANALISA CAMBER / CAMBER ANALYSIS

Gambar 4.33 –Lendutan Akibat Berat Sendiri+Pengecoran+SIDL 429 mm

Gambar 4.34 –Lendutan P1-P2 Akibat LL 68 mm

DL Deflection (mm) 0 145 277 371 422 429 422 371 277 145 0

rem camber, DL (mm) 0 12 22 29 33 34 33 29 22 12 0

LL Deflection (mm) 0 23 43 58 66 68 66 58 43 23 0

rem camber, LL (mm) 0 -12 -22 -29 -33 -34 -33 -29 -22 -12 0

Fabrikasi Camber (mm) 0 156.5 298.5 400 455 463 455 400 298.5 156.5 0

Camber Graphic

500

450

400

350

300

250

200

150

100

50

0

0 10000 20000 30000 40000 50000 60000 70000 80000 90000 100000 110000

Fabrikasi Camber (mm) rem camber, DL (mm)

LAPORAN STRUKTUR JALAN LAYANG-LRT JAKARTA FASE 1B | 59

4.6. ANALISA SAMBUNGAN / CONNECTION ANALYSIS

JOIN 1 JOIN 2 JOIN 3 JOIN 4 JOIN 4 JOIN 3 JOIN 2 JOIN 1

4.6.1. JOIN 1

Steel Dimension Concrete Dimension

Top Flange Concrete

bit bo = 2600 mm bc = 4,575 mm

to to = 40 mm tc, avrg = 250 mm

bit = 2100 mm hc = 250 mm

Web Material Data

s= 40 mm Concrete

h= 4075 mm f'c = 40 Mpa

h

s D= 3995 mm wc = 2,500 kg/m3

Ec = 33,994 Mpa

Bottom Flange Steel

bu = 2600 mm Fy = 450 Mpa

tu = 40 mm Fu = 570 Mpa

tu

bib = 2100 mm Es = 200,000 Mpa

G= 80,000 Mpa

bib Weld n = Es/Ec = 5.88

aw,ft = 9 mm 3n = 17.65

bu Lw,ft = 12.728 mm

Section Properties aw,fb = 9 mm

Lw,fb = 12.728 mm

Strong axis

Girder Composite Composite Section Area - steel Section Area - concrete

Only (n) (3n) Af,top = 208000 mm2 Ac,tr (n) = 194405.96 mm2

2

Area [cm ] 6316.0 8260.1 6964.0 Aweb = 319600 mm2 Ac,tr (3n) = 64801.99 mm2

2

Centroid [cm] 237.0 280.0 254.0 Af,bot = 104000 mm g,con = 2859.38 kg/m

4

Ix,tot [cm ] 162534279 212433453 182324055 g,stl = 4958.06 kg/m

Yb,steel [cm] 237.0 280.0 254.0

Yt,steel [cm] 170.5 127.5 153.5 Weak axis

Yt,slab [cm] --- 152.5 178.5 Flange Top Web Bot Total

3 4 4 4 4

Wx,b,steel [cm ] 685884.3 758561.9 717806.2 [cm ] [cm ] [cm ] [cm ]

3

Wx,t,steel [cm ] 953114.7 1666767.3 1187792.5 Iy,c,steel 34649333 35240161 5858667 75748161

3

Wx,t,slab [cm ] --- 1393441.4 1021433.4 Iy,comp(n) 35628975 35240161 5858667 76727803

P.N.A = 5335.00 mm from bottom of steel Iy,comp(3n) 34685616 35240161 5858667 75784444

Section Properties - Each Element Stress and Force Distribution to FLANGES and WEB due to N + M

Concrete steel (n)

2 TOTAL

Ac = 1944 cm TOTAL SLS

3 ULS

Wx,c = 8100 cm

Yc,top = -152 cm MAX N [kN]

Yc,bott = -127 cm MAX V-2 [kN]

Wx,c,top = -1393441 cm3 MAX V-3 [kN]

Wx,c,bot = -1666767 cm3 MAX M-2 [kN-m]

MAX M-3 [kN-m]

2

Top Flange σM+N,top [kN/cm ] 0.00 0.00

2 2

Atf = 1040 1040 cm σM+N,bot [kN/cm ] 0.00 0.00

Concrete

3

Wx,tf = 693 693 cm N M+N [kN] 0.00 0.00

Ytf,top = -171 -127 cm QV [kN] 0.00 0.00

Ytf,bott = -167 -123 cm MY [kN.m] 0.00 0.00

Wx,tf,top = -953115 -1666767 cm3 MZ [kN.m] 0.00 0.00

Wx,tf,bot = -976008 -1720772 cm3 σM+N,top [kN/cm ]

2

-12.28 -17.65

Steel Top Flange

2

σM+N,bot [kN/cm ] -12.28 -17.65

Web N M+N [kN] -12771.20 -18356.00

2

Aw = 1598 1598 cm QV [kN] 0.00 0.00

3

Wx,w = 106400 106400 cm MY [kN.m] 0.00 0.00

Yw,top = -167 -123 cm MZ [kN.m] 0.00 0.00

2

Yw,bott = 233 276 cm σM+N,top [kN/cm ] -12.28 -17.65

3 2

Wx,w,top = -976008 -1720772 cm σM+N,bot [kN/cm ] 12.35 20.56

Steel Web

3

Wx,w,bot = 697661 769554 cm N M+N [kN] 55.93 2325.09

QV [kN] 3514.50 6053.50

Bot. Flange MY [kN.m] 13103.18 20327.75

2

Abf = 1040 1040 cm MZ [kN.m] 0.00 0.00

3 2

Wx,bf = 693 693 cm σM+N,top [kN/cm ] 12.35 20.56

Steel Bottom Flange

2

Ybf,top = 233 276 cm σM+N,bot [kN/cm ] 12.35 20.56

Ybf,bott = 237 280 cm N M+N [kN] 12844.00 21382.40

3

Wx,bf,top = 697661 769554 cm QV [kN] 0.00 0.00

3

Wx,bf,bot = 685884 758562 cm MY [kN.m] 0.00 0.00

MZ [kN.m] 0.00 0.00

LAPORAN STRUKTUR JALAN LAYANG-LRT JAKARTA FASE 1B | 60

SPLICE PLATE DESIGN (AASHTO LRFD Article 6.13.6)

1. DETERMINATION OF CONTROLLING FLANGE

- Summary of Stresses

LIMIT STATES LOCATION STRESS [Mpa]

Top Flange -176.5 → Stress at extreme fiber of the plate

STRENGTH I

Bottom Flange 205.6 → Stress at extreme fiber of the plate

Top Flange -122.8 → Stress at extreme fiber of the plate

SERVICE II

Bottom Flange 123.5 → Stress at extreme fiber of the plate

Controlling Flange = Bottom Flange…OK → Note that this calculation is made with the approach of bottom flange as the controlling flange.!!

2. BOTTTOM FLANGE SPLICE DESIGN

2.1 Minimum Flexural Resistance: Strength Limit State

Rh = 1.0 (Hybrid factor)

α= 1.0 (1.0, except that a lower value equal to [F n/F yf] maybe use for flanges where F n is less than F yf)

Φf = 1.0 (Resistance factor for flexure)

F yf = 450.0 Mpa (Specified minimum yield strength of the flange)

fcf = 205.600 Mpa (Maximum flexural stress due to the factored loads at the midthickness of controlling flange at the point of splice)

F cf = 337.500 MPa (Minimum flexural stress resistance, F cf = 1/2[|fcf/Rh| + αΦfF yf] ≥ 0.75αΦ fF yf)

- Section Properties of Bottom Flange: (Article 6.8.2.1)

Φy = 0.95 (Resistance factor for yielding of tensioned member) 2 1

Φu = 0.80 (Resistance factor for fracture of tensioned member)

s

Fy = 450 MPa (Yield stress of the connected material)

Fu = 570 MPa (Tensile strength of the connected material) g

tbot = 40 mm (Girder's thickness)

B P

Bbot = 2600 mm (Width of the girder)

dHole = 26 mm (Hole's diameter) g

s= 75 mm (Pitch of any two consecutive holes)

g= 100 mm (Gage of the same two holes)

Ag = 104000.00 mm2 (Gross Area) 2 1

For line 1-1:

nbolts = 26 Pcs (Number of bolts in line 1-1)

Ns = 0 Pcs (Number of inclined lines in line 1-1)

Anet1-1 = 76960.00 mm2 (Nett area based on line 1-1)

For line 2-2:

nbolts = 26 Pcs (Number of bolts in line 2-2)

Ns = 0 Pcs (Number of inclined lines in line 2-2)

Anet2-2 = 76960.00 mm2 (Nett area based on line 2-2)

Anet = 76960.00 mm2 (Nett area)

Aeffective = 82090.67 mm2 (Effective area, taken as minimum of Anett and Agross)

Pcf = 27705.60 kN (Minimum Design force, Pcf = F cfAg for compression force and Pcf = F cfAeffective for tension force)

2.2 Determination of Flange Bolts (Article 6.13.2)

2.2.1 Shear Resistance : Strength Limit State

Grade = 8.8/TF (Bolts Grade)

Øbolt = 24 mm (Diameter of bolts)

Ns = 2 Planes (Number of shear planes)

Rr = 103.14 kN/plane (Factor resistance of a bolt in shear at the strength limit state)

Rr = 206.29 kN (Factor resistance of a bolt in shear at the strength limit state)

Nreq1 = 134.30 Pcs (Number of the minimum required bolts at strength limit state, N req = Pcf/R r)

2.2.2 Slip Resistance: Permanent Deflection Service Limit State and For Constructibility

F fs = 123.50 Mpa (Minimum flexural stress resistance on service limit state, F fs = fs/R h)

Pfs = 12844.00 kN (Minimum design force at service limit state, Pfs = F fsAg)

Ns = 2 Planes (Number of slip planes)

R r-slip = 67.73 kN/plane (Factor resistance of a bolt in shear at the permanent deflection service limit state)

R r-slip = 135.45 kN (Factor resistance of a bolt in shear at the permanent deflection service limit state)

Nreq2 = 94.82 Pcs (Number of the minimum required bolts at service limit state, Nreq = Pfs/Rr)

Nused = 134 Pcs (Number of bolts used) → 1.00 OK

LAPORAN STRUKTUR JALAN LAYANG-LRT JAKARTA FASE 1B | 61

2.3 Tensile Resistance of Splice Plates: Strength Limit State (Article 6.13.6.1.4c and 6.13.5.2)

Φy = 0.95 (Resistance factor for yielding of tensioned member) (Article 6.8.2.1)

Φu = 0.80 (Resistance factor for fracture of tensioned member)

Fy = 450 MPa (Yield stress of the splice material)

Fu = 570 MPa (Tensile strength of the splice material)

U= 1.0 (Reduction factor to account for shear lag)

BS-wide = 2600 mm (Width of splice plate - outside part - wider splice)

tS-wide = 20 mm (Thickness of splice plate - outside part - wider splice)

BS-small = 2600 mm (Width of splice plate - inside part - smaller splice)

tS-small = 20 mm (Thickness of splice plate - inside part - smaller splice)

Ag-wide = 52000.0 mm2 (Gross area of outside splice - wider splice)

Ag-small = 52000.0 mm2 (Gross area of inside splice - smaller splice, counted as 2 Pcs already)

- Yielding on gross section of inside and outside splice plates:

Rry-Out = 22230.0 kN → Rry-Out > Pcf/2 → 0.623 OK

Rry-Ins = 22230.0 kN → Rry-Ins > Pcf/2 → 0.623 OK

- Fracture on net section of inside and outside splice plates:

Anet-Out = 38480.0 mm2 (Nett area of the outside splice, taken from configuration of nett area on the connected material)

Anet-Ins = 38480.0 mm2 (Nett area of the inside splice, counted as 2 Pcs already)

RrU-Out = 17546.9 kN → RrU-Out > Pcf/2 → 0.789 OK

RrU-Ins = 17546.9 kN → RrU-Ins > Pcf/2 → 0.789 OK

2.4 Tensile Resistance of Girder's Plates: Strength Limit State (Article 6.8.2.1)

Φy = 0.95 (Resistance factor for yielding)

Φu = 0.80 (Resistance factor for fracture)

Fy = 450 MPa (Yield stress)

Fu = 570 MPa (Tensile strength)

U= 1.0 (Reduction factor for shear lag)

dHole = 26 mm (Hole's diameter)

tbot = 40 mm (Girder's thickness)

Bbot = 2600 mm (Width of the girder)

P1 bolt [kN] = 117.5 kN (Actual force in one bolt)

....

nrequired = 134 Pcs (Number of required bolts)

C1 C C3 Cn

2

nused = 182 Pcs (Number of used bolts)

utility = 0.74

No = 1 2 3 4 5 6 7 0 0 0

Norow = 26 26 26 26 26 26 26 0 0 0 (No. of bolts row)

Ntot-bolt = 26 52 78 104 130 156 182 182 182 182 (No. of total bolts)

Pi-bolt [kN] = 3054.6 3054.6 3054.6 3054.6 3054.6 3054.6 3054.6 0.0 0.0 0.0 (Bolt's force per line)

Pi [kN] = 21382.4 18327.8 15273.1 12218.5 9163.9 6109.3 3054.6 0.0 0.0 0.0 (Force in line C-i)

2

Ahole [mm ] = 27040.0 27040.0 27040.0 27040.0 27040.0 27040.0 27040.0 0.0 0.0 0.0 (Hole's area)

2

ANett [mm ] = 76960.0 76960.0 76960.0 76960.0 76960.0 76960.0 76960.0 0.0 0.0 0.0 (Line's netto area)

Pr-U [kN] = 35093.8 35093.8 35093.8 35093.8 35093.8 35093.8 35093.8 0.0 0.0 0.0 (Fracture resistance)

Pr-y [kN] = 44460.0 44460.0 44460.0 44460.0 44460.0 44460.0 44460.0 0.0 0.0 0.0 (Yielding resistance)

Pr [kN] = 35093.8 35093.8 35093.8 35093.8 35093.8 35093.8 35093.8 0.0 0.0 0.0 (Tensile resistance)

Utility = 0.61 0.52 0.44 0.35 0.26 0.17 0.09 0.00 0.00 0.00 (Design Utility ratio)

- First "zig-zag" line facture checking (see illustration of line 2-2 above):