Professional Documents

Culture Documents

CN DISPONIBLE D6888 - 4082mthd

CN DISPONIBLE D6888 - 4082mthd

Uploaded by

wcenttiCopyright:

Available Formats

You might also like

- The Relay Testing Handbook-Generator Relay Protection Testing TOC-ToF-BibDocument36 pagesThe Relay Testing Handbook-Generator Relay Protection Testing TOC-ToF-BibMartin Goodnough100% (1)

- Boylan - The Spiritual Life of The PriestDocument63 pagesBoylan - The Spiritual Life of The Priestpablotrollano100% (1)

- Norma ASTM D 2036-09 para Determinación de CianuroDocument20 pagesNorma ASTM D 2036-09 para Determinación de Cianurotesiscianuro2014100% (3)

- 355 SCDDocument4 pages355 SCDJuan Ramón RincónNo ratings yet

- Advanced Pharmaceutical analysisFrom EverandAdvanced Pharmaceutical analysisRating: 4.5 out of 5 stars4.5/5 (2)

- Flow Solution FS 3700 Automated Chemistry AnalyzerDocument16 pagesFlow Solution FS 3700 Automated Chemistry AnalyzerMiguel Angel Hanco ChoqueNo ratings yet

- Wad Cyanide OIA1677Document13 pagesWad Cyanide OIA1677wcenttiNo ratings yet

- WS3700 Method Abstract ASTM 7237Document4 pagesWS3700 Method Abstract ASTM 7237sewan48762No ratings yet

- Cianeto Total - SFADocument4 pagesCianeto Total - SFAAndré SchikierskiNo ratings yet

- Tot Cyanid ASTM D7511 091Document36 pagesTot Cyanid ASTM D7511 091maruf amaludinNo ratings yet

- CN WAD FS3000 A002966 OIA1677 FS 3k - UpdatedDocument33 pagesCN WAD FS3000 A002966 OIA1677 FS 3k - Updatedsergioalex1430No ratings yet

- Method Oia-1677-09 2010Document28 pagesMethod Oia-1677-09 2010sergioalex1430No ratings yet

- 2538 A New Approach For Nitrate Cadmium Reduction by Discrete Analysis-SDocument8 pages2538 A New Approach For Nitrate Cadmium Reduction by Discrete Analysis-SClaudio AppollonioNo ratings yet

- 1203 Total Cyanide UV Digestion Segmented FIADocument1 page1203 Total Cyanide UV Digestion Segmented FIAmiguel008No ratings yet

- AppNote AAS 0016 en ZEEnit Toxics Surface Drinking WaterDocument6 pagesAppNote AAS 0016 en ZEEnit Toxics Surface Drinking WaterAlberto HernándezNo ratings yet

- Available Cyanide With Ligand Displacement and Flow Injection Analysis (FIA) Utilizing Gas Diffusion Separation and Amperometric DetectionDocument7 pagesAvailable Cyanide With Ligand Displacement and Flow Injection Analysis (FIA) Utilizing Gas Diffusion Separation and Amperometric Detectionasma hamzaNo ratings yet

- Total Cyanide Using UV Digestion and Amperometric Detection (ASTM D7511 09e Equivalent Method)Document6 pagesTotal Cyanide Using UV Digestion and Amperometric Detection (ASTM D7511 09e Equivalent Method)maruf amaludinNo ratings yet

- A Green Chemistry Approach To Mercury ControlDocument7 pagesA Green Chemistry Approach To Mercury ControlDennis Daniel Condori EspilcoNo ratings yet

- CN Total New 3837mthdDocument36 pagesCN Total New 3837mthdYean CarlosNo ratings yet

- 353.2 No3, No2Document8 pages353.2 No3, No2nguyenngoc209No ratings yet

- WAD Cynoprobe PDFDocument9 pagesWAD Cynoprobe PDFGerehNo ratings yet

- Technology Guide 15: SSPC: The Society For Protective CoatingsDocument16 pagesTechnology Guide 15: SSPC: The Society For Protective CoatingsIris Carmen100% (1)

- Method For Nitrate Determination by Cadmium Reduction, Version 2.3Document8 pagesMethod For Nitrate Determination by Cadmium Reduction, Version 2.3KhalidOfqirNo ratings yet

- AppNote AAS 0017 en contrAA Wastewater Sewage SlugdeDocument7 pagesAppNote AAS 0017 en contrAA Wastewater Sewage SlugdeAlberto HernándezNo ratings yet

- Method Abstract: ScopeDocument6 pagesMethod Abstract: ScopeMIGUEL ANGEL MEJIA SANDOVALNo ratings yet

- Test Method: Subject: ApprovedDocument4 pagesTest Method: Subject: ApprovedLucky KhanNo ratings yet

- Astm D 2036-98 CianuroDocument20 pagesAstm D 2036-98 CianuroGianinaRoncalChávezNo ratings yet

- ASTM D7511 12 Total Cyanide by FIADocument10 pagesASTM D7511 12 Total Cyanide by FIAGiuliana Katia Morales FuertesNo ratings yet

- 7601 - Crystallin Silica PDFDocument6 pages7601 - Crystallin Silica PDFAmalia NurbandiniNo ratings yet

- Cianuro Wad ASTM D6888-16Document8 pagesCianuro Wad ASTM D6888-16Gabriel Apaza SánchezNo ratings yet

- Removal of Silver From Photographic SolutionsDocument10 pagesRemoval of Silver From Photographic SolutionsMinh Tiến TrầnNo ratings yet

- Analytical Method For Hydrated LimeDocument60 pagesAnalytical Method For Hydrated LimeFadly FaradhilaNo ratings yet

- EPA 202.1 - AlDocument2 pagesEPA 202.1 - AlAristaNo ratings yet

- Method - 200-2 - Rev - 2-8 - 1994 Elementos RecuperablesDocument13 pagesMethod - 200-2 - Rev - 2-8 - 1994 Elementos RecuperablesPablo MéndezNo ratings yet

- 2 SO2-Air Cyanide OxydationDocument8 pages2 SO2-Air Cyanide OxydationbazanvlNo ratings yet

- Whitepaper: Overcoming Challenges of Sulfur Analysis in Natural Gas and Gaseous FuelsDocument8 pagesWhitepaper: Overcoming Challenges of Sulfur Analysis in Natural Gas and Gaseous FuelsSiti Fajar karinaNo ratings yet

- Cod 3715Document4 pagesCod 3715shaukat786.No ratings yet

- GB 15892-2009Document25 pagesGB 15892-2009dewi wulansariNo ratings yet

- 355 S DetectorDocument4 pages355 S DetectorFaizal ThelordImmortal100% (1)

- D 4193 - 95 - RdqxotmtukveDocument6 pagesD 4193 - 95 - RdqxotmtukveTHANGVUNo ratings yet

- 245.2 Mercury by Cold Vapor TechniqueDocument6 pages245.2 Mercury by Cold Vapor TechniquedcardonasterNo ratings yet

- Hydrometallurgical Process: Analysis of Free, Total & WAD Cyanide in Gold Leach Slurry & WastewaterDocument1 pageHydrometallurgical Process: Analysis of Free, Total & WAD Cyanide in Gold Leach Slurry & WastewaterJUNIORNo ratings yet

- Iso 9227 PDFDocument13 pagesIso 9227 PDFMario AguillonNo ratings yet

- Agilent FPD-Low Level Sulfur Detection in CO2Document4 pagesAgilent FPD-Low Level Sulfur Detection in CO2amittal111No ratings yet

- 5989 9234enDocument4 pages5989 9234enAngela MoraNo ratings yet

- AppNote AAS novAA 800 0008 en Industrial EffluentsDocument4 pagesAppNote AAS novAA 800 0008 en Industrial EffluentsAlberto HernándezNo ratings yet

- Unit 9 Applications of Polarography Amperometric Titrations and Voltammetry PDFDocument15 pagesUnit 9 Applications of Polarography Amperometric Titrations and Voltammetry PDFAranga100% (1)

- Solvent Extraction PD Dari CyanideDocument6 pagesSolvent Extraction PD Dari CyanideAdeNo ratings yet

- Determination of Cu (II) in Beer by Derivative Potentiometric Stripping AnalysisDocument5 pagesDetermination of Cu (II) in Beer by Derivative Potentiometric Stripping AnalysisPicha PichoNo ratings yet

- Methods BeerDocument62 pagesMethods BeerTruong Anh TuanNo ratings yet

- AppNote AAS 0009 en novAA800 Sewage SludgeDocument4 pagesAppNote AAS 0009 en novAA800 Sewage SludgemariholzNo ratings yet

- Breuer 09Document6 pagesBreuer 09Jesus ParedesNo ratings yet

- Unit 9 Applications of Polarography, Amperometric Titrations and VoltammetryDocument15 pagesUnit 9 Applications of Polarography, Amperometric Titrations and VoltammetryNathanian100% (9)

- Determination of Sodium and Potassium Content For Silver-Cadmium Oxide Contact MaterialsDocument2 pagesDetermination of Sodium and Potassium Content For Silver-Cadmium Oxide Contact MaterialstsliaNo ratings yet

- Determination of Sodium in Foods PDFDocument6 pagesDetermination of Sodium in Foods PDFGiu Ali Mamani PacoNo ratings yet

- 10 1021@acsreagents 4012Document3 pages10 1021@acsreagents 4012Quercus AlbaNo ratings yet

- Gas-Liquid Separator Integrated To HG-QFAAS Method For Determination of Tin at Trace Levels in The Water SamplesDocument11 pagesGas-Liquid Separator Integrated To HG-QFAAS Method For Determination of Tin at Trace Levels in The Water SamplesGanjar OfficialNo ratings yet

- Senseor For T50Document100 pagesSenseor For T50hienda09hhNo ratings yet

- 13 Epa Cianuro Wad Fia 1677-2004 AcreditadoDocument26 pages13 Epa Cianuro Wad Fia 1677-2004 AcreditadoErick Leonardo Valle MendozaNo ratings yet

- Acids Org Sb-Aq 5989-1265Document8 pagesAcids Org Sb-Aq 5989-1265pacocurroNo ratings yet

- Application of IC-MS and IC-ICP-MS in Environmental ResearchFrom EverandApplication of IC-MS and IC-ICP-MS in Environmental ResearchRajmund MichalskiNo ratings yet

- Chapter 03Document40 pagesChapter 03AC BañaresNo ratings yet

- Vanilla Icebox CookiesDocument2 pagesVanilla Icebox CookiesmadduxdavidNo ratings yet

- Interviw With Martin DavisDocument12 pagesInterviw With Martin DavisraktimddkNo ratings yet

- Galvafroid Data SheetDocument13 pagesGalvafroid Data SheetAdam HughesNo ratings yet

- Star Holman 210HX Conveyor OvenDocument2 pagesStar Holman 210HX Conveyor Ovenwsfc-ebayNo ratings yet

- Specifications Battery Chargers For Rail VehiclesDocument2 pagesSpecifications Battery Chargers For Rail VehiclesPirata ScribNo ratings yet

- Research Report - Aakanksha MistryDocument19 pagesResearch Report - Aakanksha MistryAakanksha MistryNo ratings yet

- FIN V1 Chap4 EconDocument15 pagesFIN V1 Chap4 EconV I S W A L S HNo ratings yet

- Volumetric Rotary Piston Meter Asm LXH SA1508 15mm, 20mm & 25mmDocument19 pagesVolumetric Rotary Piston Meter Asm LXH SA1508 15mm, 20mm & 25mmGreen FarmersNo ratings yet

- MP900 and MP9000 Series Kool-Pak Power Film Resistors: TO-126, TO-220 and TO-247 StyleDocument3 pagesMP900 and MP9000 Series Kool-Pak Power Film Resistors: TO-126, TO-220 and TO-247 StyleManoel HenriqueNo ratings yet

- AASHTO - LRFD - Construction Specs-2nd Edition-2 PDFDocument664 pagesAASHTO - LRFD - Construction Specs-2nd Edition-2 PDFSharfaraz Hossain100% (1)

- Mesología BERQUEDocument6 pagesMesología BERQUEPanchita PonisioNo ratings yet

- Lab File of Ad Hoc and Sensor Networks Lab (ETEC - 458) : Department of Information TechnologyDocument39 pagesLab File of Ad Hoc and Sensor Networks Lab (ETEC - 458) : Department of Information TechnologyswatiNo ratings yet

- RPLL NewDocument74 pagesRPLL NewMeta learnNo ratings yet

- SSC Teaching QualificationDocument3 pagesSSC Teaching QualificationSasikalaNo ratings yet

- Biological Bases of BehaviorDocument7 pagesBiological Bases of BehaviorSANTHOSH KUMAR T MNo ratings yet

- FirePro Technical Prospectus PDFDocument28 pagesFirePro Technical Prospectus PDFRANJITHNo ratings yet

- No More War PDF - Pauling, Linus, 1901Document260 pagesNo More War PDF - Pauling, Linus, 1901pdf ebook free downloadNo ratings yet

- Computational Methods: Test Program For Chasing Method Developed in MatlabDocument6 pagesComputational Methods: Test Program For Chasing Method Developed in MatlabMujtaba MujahidNo ratings yet

- Type 4536 Oscillator-Divider ICDocument13 pagesType 4536 Oscillator-Divider ICRoscoeDog718No ratings yet

- 11thMachAutoExpo 2022Document112 pages11thMachAutoExpo 2022Priyanka KadamNo ratings yet

- Saturn Quad QSDSSDocument1 pageSaturn Quad QSDSSniall.godleyNo ratings yet

- Chap 11Document3 pagesChap 11Flia Diaz ZunigaNo ratings yet

- Lesson 3Document4 pagesLesson 3Justin Kean HakeemNo ratings yet

- Chapter 4 - Structural Imperfections Kingery Introducción A Los Materiales CerámicosDocument27 pagesChapter 4 - Structural Imperfections Kingery Introducción A Los Materiales CerámicosLaura BárbaroNo ratings yet

- DER Vol III DrawingDocument50 pagesDER Vol III Drawingdaryl sabadoNo ratings yet

- Cooper Ls Brochure Industrial Led Lighting Product CatalogueDocument68 pagesCooper Ls Brochure Industrial Led Lighting Product CataloguecarlosmandopintoNo ratings yet

- ISO 00426-1-1983 ScanDocument5 pagesISO 00426-1-1983 ScanthangNo ratings yet

CN DISPONIBLE D6888 - 4082mthd

CN DISPONIBLE D6888 - 4082mthd

Uploaded by

wcenttiOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CN DISPONIBLE D6888 - 4082mthd

CN DISPONIBLE D6888 - 4082mthd

Uploaded by

wcenttiCopyright:

Available Formats

Method

Available Cyanide by ASTM D 6888

Document #40821214

Flow Solution™ FS 3700 Automated Chemistry Analyzer

Available Cyanide by Automated Ligand Exchange

ASTM D 6888, Flow Injection Analysis (FIA)

Cartridge Part Number 330091CT

Scope and Application

This method is used for determining available cyanide in water and wastewater by automated ligand exchange, flow

injection analysis, and amperometric detection according to ASTM Method D 6888-09 (Reference 2). This method is

approved for use in the USEPA’s data gathering and monitoring programs associated with the Clean Water Act.

Cyanide ion (CN–), hydrogen cyanide in water (HCN(aq)), and cyano-complexes of zinc, copper, cadmium, mercury, nickel,

and silver can be determined by this method. The presence of polysulfides and colloidal material may prove intractable for

application of this method.

Method Performance

Range 5.0 µg/L–0.5 mg/L

Rate 30 samples/hour

Precision at 50 µg/L <2% RSD

Method Detection Limit (MDL) 1.0 µg/L

The range may be extended to analyze other concentrations by changing the size of the sample loop. The quality of the

analysis is assured through reproducible calibration and testing of the Flow Injection Analysis (FIA) system.

A general flow diagram of the Flow Injection Analysis (FIA) system is shown below (see Figure 1 for a detailed flow

diagram).

Flow Solution™ 3700 Method

Part Number 330098 1

Available Cyanide by ASTM D 6888

Reagents and Calibrants

Chemical Name CAS # Chemical Formula Part Number

Acetic acid, glacial 64-19-7 C2H4O2

Acetone 67-64-1 C 3H 6O

Bismuth nitrate pentahydrate 10035-06-0 Bi(NO3)3 • 5H2O

Water, deionized H 2O

5-[4-(Dimethylamino) benzylidene] rhodanine 536-17-4 C12H12N2OS2

DOWFAX 2A1 12626-49-2 A000080

Ethylenediamine 107-15-3 C2 H 8 N 2

Ligand exchange reagent, available cyanide A001416

(WAD) reagent A

Ligand exchange reagent, available cyanide A001417

(WAD) reagent B

Mercury (II) cyanide 594-04-1 Hg(CN)2

Nickel potassium cyanide 14220-17-8 K2Ni(CN)4

Potassium cyanide 151-50-8 KCN

Silver nitrate 7761-58-3 AgNO3

Sodium acetate 127-09-3 C2H3O2Na

Sodium arsenite 7784-46-5 NaAsO2

Sodium hydroxide 1310-73-2 NaOH

Sulfuric acid, concentrated 7664-93-9 H2SO4

Sulfuric acidification reagent (SAR) A001872

Summary of ASTM D 6888

ASMT D 6888 summarizes the method and interferences as follows below (Reference 6).

Method

l Prior to analysis, treat the sample to remove potential interferences. Ligand exchange reagents form

thermodynamically stable complexes with the transition metal ions, releasing the cyanide ion from the cyano-complex-

es. Addition of acid converts the cyanide ion to hydrogen cyanide gas (HCN), which passes under a gas diffusion mem-

brane. The hydrogen cyanide gas diffuses through the membrane into an alkaline receiving solution where it converts

back to cyanide ion. The cyanide ion is monitored amperometrically with a silver working electrode, silver/silver chloride

reference electrode, and platinum/stainless steel counter electrode at an applied potential of zero volt. The current gen-

erated is proportional to the cyanide concentration present in the original sample.

Interferences

l Method interferences can be caused by contaminants in the reagents, reagent water, and glassware, which may bias

the results. Take care to keep all such items free of contaminants.

l Sulfide, at concentrations greater than 50 ppm, is a positive interferant in this method (Reference 11). When sulfide is

acidified, it forms hydrogen sulfide, which passes through the gas diffusion membrane and produces a signal at the

silver electrode. In addition, sulfide ion reacts with cyanide ion in solution to reduce its concentration over time.

l Treat samples containing water soluble aldehydes, such as formaldehyde or acetaldehyde, by adding ethylenediamine

solution, at the time of sampling.

l Remove oxidizing agents that decompose cyanides by adding ascorbic acid if analysis is to be within 24 hours,

otherwise use sodium arsenite.

Flow Solution™ 3700 Method

Part Number 330098 2

Available Cyanide by ASTM D 6888

l High concentrations of carbonate can result in a negative response in the amperometric detector when carbon dioxide

diffuses across the gas diffusion membrane into the alkaline receiving solution, reducing its pH. Treat effluents from

high-carbonate containing wastes, such as coal gasification waste and atmospheric emission scrub water, with

hydrated lime to stabilize the sample (Reference 11).

l Tests conducted on samples containing large amounts of colloids indicate rapid cyanide losses. Filter turbid or colloidal

samples.

l Nitrate and nitrite do not interfere in this method.

l Thiocyanate, sulfite, and thiosulfate do not interfere with this method.

Safety

WARNING: Cyanide solutions may produce toxic hydrogen cyanide gas when acidified. For these reasons, any method

involving cyanide in a sample or reagent should only be performed by properly trained personnel wearing adequate

personal protective equipment.

WARNING: Two separate waste bottles should be used: one clearly marked “Cyanide Waste” and another marked “Acid

Waste”. The waste line from the amperometric flow cell must go to the Cyanide Waste bottle. The waste line from the gas

diffusion module must go to the Acid Waste bottle.

WARNING: Cyanide ion, hydrocyanic acid, all cyanide salts, and most metal-cyanide complexes are extremely danger-

ous. As a contact poison, cyanide does not need to be ingested to produce toxicity. Also, cyanide solutions produce fatally

toxic hydrogen cyanide gas when acidified. For these reasons, any method involving cyanide in a sample or reagent

should only be performed by properly trained personnel wearing adequate personal protective equipment.

1. The toxicity or carcinogenicity of each compound or reagent used in this method has not been fully established. Each

chemical should be treated as a potential health hazard. Exposure to these chemicals should be reduced to the

lowest possible level.

2. For reference purposes, a file of Material Safety Data Sheets (MSDS) for each chemical used in this method should

be available to all personnel involved in this chemical analysis. The preparation of a formal safety plan is also

advisable.

3. Chemicals used in this method may be highly toxic or hazardous and should be handled with extreme caution at all

times. Consult the appropriate MSDS before handling.

4. Unknown samples may be potentially hazardous and should be handled with extreme caution at all times.

5. Proper personal protective equipment (PPE) should be used when handling or working in the presence of chemicals.

6. This method does not address all safety issues associated with its use. The laboratory is responsible for maintaining a

safe work environment and a current awareness file of OSHA regulations regarding the safe handling of the chemicals

specified in this method.

Sample Handling and Preservation

1. Collect samples in amber glass bottles with minimal headspace that have been thoroughly cleaned and rinsed with

reagent water.

2. Ensure the volume of sample collected is sufficient to obtain a representative sample, analyze replicates, and

minimize waste disposal. 40 mL amber VOA vials have been found sufficient.

3. Add NaOH solution to pH 11 and cool samples to 2-6 °C.

4. Do not add NaOH if the cyanide concentration would change as a result of the addition.

Flow Solution™ 3700 Method

Part Number 330098 3

Available Cyanide by ASTM D 6888

5. Treat samples containing sulfide ion.

a. Test samples with lead acetate test paper to determine the presence or absence of sulfide ion. Note that the lead

acetate test paper can be unreliable and is typically not usable for sulfide concentrations below approximately

50 ppm.

i. If sulfide is detected by the lead acetate test strip (sulfide > 50 ppm), dilute sample so that sulfide is below

amount detected by test strips. Record dilution factor on chain of custody/ sample bottle analyze samples

within 24 hours.

ii. Lead acetate test paper should be tested for minimum level of sulfide detection by spiking reagent water

aliquots with decreasing levels of sulfide. The spiked samples are tested with lead acetate test paper

moistened with acetate buffer. Test each new batch of test paper or acetate buffer to determine the lowest

level of sulfide ion detection prior to use.

b. If the sample contains particulate matter that would be removed with filtration, filter the sample. Available CN

species are soluble in water, so particulate matter need not be analyzed.

6. Treat samples containing or suspected to contain formaldehyde, acetaldehyde, or other water-soluble aldehydes with

20 mL of 3.5% ethylenediamine solution per liter of sample.

NOTE: Samples that have been disinfected by UV irradiation are likely to contain aldehydes.

7. Oxidizing agents such as chlorine can destroy most of the cyanide during storage and manipulation. Destroy the

oxidizing agent at the time of sample collection so the test result reflects an accurate cyanide concentration in the

source at the time of collection. Treat samples containing chlorine, hypochlorite, or sulfite with 0.1 g sodium arsenite

per 100 mL sample. Sodium thiosulfate may be used in place of sodium arsenite.

a. Using a plastic pipette, place a drop of sample on a strip of potassium iodide-starch test paper.

b. If observing a bluish discoloration on the paper, add a few crystals of sodium arsenite to the sample with a

spatula. Continue to add crystals and testing a drop of sample on the test paper until color is no longer produced

on the test paper.

NOTE: Do not add an excess of reducing agent.

8. High concentrations of carbonate can result in a negative response in the amperometric detector when carbon dioxide

diffuses across the membrane into the alkaline acceptor reagent, reducing its pH. The high buffer capacity of the

acceptor reagent largely eliminates sensitivity to carbonate. Nevertheless, Standard Methods recommend using

hydrated lime to stabilize samples such as effluents from coal gasification wastes, atmospheric emission scrub waters,

and other high carbonate-containing wastes.

a. Slowly add hydrated lime while stirring to raise the pH of the sample to 12.0–12.5.

b. Decant the sample after the precipitate settles.

Configuration and Start-Up

Refer to the Flow Solution™ 3700 Operator Manual (Reference 3) and/or the FlowView Quick Start Reference Guide

(Reference 14) for assistance configuring the FS 3700 and FlowView.

1. Instrument Configuration

a. Verify that the cartridge is configured as illustrated in the cartridge schematic shown in Figure 1.

b. Connect the appropriate pump tubes to the cartridge and to their appropriate reagent containers according to the

flow diagram.

c. Create and Save Method in FlowView, as follows:

Flow Solution™ 3700 Method

Part Number 330098 4

Available Cyanide by ASTM D 6888

Primary Chassis Pump at Start 40%

Valve Load Inject (sec) 35

Cycle Duration (sec) 120

Heater Setpoint (°C) Not Used

UV Lamp Not Used

Detector Detector Mode Amperometric

Sample Gain 1X

Applied Potential 0

Polarity Normal

Calibration Settings Calibrant Units ppm

Final Units ppm

Conversion Factor 1.00

Calibration Curve Fitting Method 2nd Order

Include Origin as a Calibration Point? No

Peak Measurement Measure Peaks by Height

Baseline Value for Peak Marking Sync Peak Starts as Baseline (Default)

Apply Carryover Correction? No

Smoothing Smoothing Mode (#points) Moving Average (5 points)

Sync-Peak Marking Recognize Sync Peak Start by a rise 100

of

Total Counts within 5 seconds

Sync Peak Ignore Time (sec) 50

Use Return to Baseline? √

Return to Baseline (%) 99

Minimum Peak Height 400

Minimum Peak Width 60

Use 1st derivative? √

Minimum Return to Baseline (%) 90

Cutoff Counter Value for End of Peak 4

2. Instrument Stabilization

a. Start the pump, allowing the solution to flow through the entire system.

b. Make sure that the flow cell of each detector is purged of all bubbles and the flow is stable and free from surging.

c. For trace level analysis, OI Analytical recommends calibrating from 2.00-100 µg/L.

3. Amperometric Cell Conditioning

Perform the following after servicing the amperometric cell, or as needed.

a. Load a 5 mg/L cyanide standard into the sampling valve and inject it into the segmented FIA system.

b. Continue to inject 5 mg/L cyanide standard until three successive peak heights or area results are within 5% RSD,

indicating a stable electrode system.

c. Following stabilization, or to demonstrate stability of the electrode system, inject the 0.5 mg/L cyanide calibrant until

three successive peak heights or area results are within 3% RSD.

Flow Solution™ 3700 Method

Part Number 330098 5

Available Cyanide by ASTM D 6888

4. Start the Run

a. Select Sample Table and specify Result File prior to starting the run. For help on creating a Sample Table, refer to

the FlowView Software Quick Start Guide (Reference 14).

b. Press Start to begin to collecting baseline data. Verify that the baseline does not drift and is free from large

fluctuations. When ready, click Run.

NOTE: Very sharp fluctuations in the baseline and/or consistent drifting are typically signs of bubbles in the flowcell. The

flowcell must be free of bubbles prior to beginning analysis.

5. Operating Notes

a. Sensitivity and performance at the low end may be enhanced by:

i. Increasing the size of the sample loop.

ii. Decreasing the range of calibrants to closer fit the concentration of the samples being run.

b. Performance may be enhanced and the range extended on the high end by:

i. Decreasing the size of the sample loop.

ii. Making the shortest possible connection between the cartridge and the detector.

iii. Increasing the cycle duration time in “Cartridge configuration”.

iv. Moving the calibrant range up so that the calibrants are closer to the concentration of the actual samples.

6. After the Run

a. Disconnect the lead from the working electrode.

b. Place acid reagent pump tubes into reagent water and pump reagent water through the system for at least

10–15 minutes. Do not pump reagent water in place of base reagent.

c. Stop the pump, and wait for flow to stop.

d. Release tension on all pump tubes.

e. Store the Gel Polymer Reference Electrode (PN 325348) in electrode storage solution when not in use with

Reference Electrode Storage Kit (PN 326133).

f. Power off the system.

NOTE: For short-term and overnight shutdowns, simply turn off the pump and release tension on the pump tubes.

Flow Solution™ 3700 Method

Part Number 330098 6

Available Cyanide by ASTM D 6888

References

1. Wilmont, J.C.; Solujic, L.; Milosavljevic, E. B.; Hendrix, J.L.; Rader, W.S. Formation of Thiocyanate During Removal of

Sulfide as Lead Sulfide Prior to Cyanide Determination. Analyst 1996, 121, 799–801.

2. Standard Test Methods for Cyanides in Water. Annual Book of ASTM Standards Volume 11.02, ASTM International;

ASTM D 6888-09.

3. Flow Solution™ 3700 Operator’s Manual (part number 329998). Available from OI Analytical, P.O. Box 9010, College

Station, TX, 77842–9010.

4. Milosavljevic, E.B.; Solujic, L. How to Analyze for Cyanide. Cyanide: Social Industrial and Economic Aspects. The

Minerals, Metals, and Materials Society. 2001, 125–128.

5. Ingersol, D.; Harris, W.R.; Bomberger, D.C.; Coulson, D.M. Development and Evaluation Procedures for the Analysis

of Simple Cyanides, Total Cyanides, and Thiocyanate in Water and Waste Water: 1983; EPA-600/4-83-054; U.S.

Environmental Protection Agency, Environmental Monitoring Systems Laboratory, U.S. Government Printing Office:

Washington, DC, 1983.

6. Milosavljevic, E.B.; Solujic, L.; Hendrix, J.L. Environ. Sci. Technol. 1995, 29 (No. 2), 426–430.

7. Federal Register, CFR Title 40, Part 136, Appendix B, U.S. Government Printing Office: Washington, DC, 1994.

8. Guide to Method Flexibility and Approval of EPA Water Methods. Available from the National Technical Information

Service (PB97-117766).

9. Handbook for Analytical Quality Control in Water and Wastewater Laboratories: 1979; EPA-600/4-79-019; U.S.

Environmental Protection Agency, Environmental Monitoring Systems Laboratory, U.S. Government Printing Office:

Washington, DC, 1979.

10. Less is Better: Laboratory Chemical Management for Waste Reduction. Available from the American Chemical

Society, Department of Government Regulations and Science Policy, 1155 16th Street, NW, Washington, DC 20036.

11. ASTM D 7365-09a Standard Practice for Sampling, Preservation and Mitigating Interferences in Water Samples for

Analysis of Cyanide.

12. Report of the Draft Method OIA-1677 Interlaboratory Validation Study, March 1997. Available from OI Analytical, Box

9010, College Station, TX 77842-9010.

13. Report of the Draft Method OIA-1677 Single Laboratory Validation Study, November 1996. Available from OI

Analytical, Box 9010, College Station, TX 77842-9010.

14. Flow Solution™ 3700 ACA Flow Analyzer Software Quick Start Guide (part number 327069). Available from OI

Analytical, P.O. Box 9010, College Station, TX, 77842–9010.

Flow Solution™ 3700 Method

Part Number 330098 7

Available Cyanide by ASTM D 6888

Figures

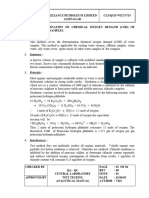

Figure 1. Diagram of 330091CT Available Cyanide Cartridge

Flow Solution™ 3700 Method

Part Number 330098 8

Available Cyanide by ASTM D 6888

Figure 2. Available Cyanide Calibration Series

Figure 3. Calibration Curve and Statistics

Flow Solution™ 3700 Method

Part Number 330098 9

Available Cyanide by ASTM D 6888

Figure 4. Method MDL, Accuracy & Precision

Calibrant Calibrant Calibrant Calibrant

0.002 mg/L 0.010 mg/L 0.050 mg/L 0.100 mg/L

Replicate 1 0.0014 0.0108 0.0532 0.1044

Replicate 2 0.0016 0.0108 0.0520 0.1044

Replicate 3 0.0016 0.0107 0.0517 0.1036

Replicate 4 0.0013 0.0106 0.0515 0.1037

Replicate 5 0.0010 0.0105 0.0514 0.1032

Replicate 6 0.0013 0.0104 0.0514 0.1033

Replicate 7 0.0015 0.0102 0.0510 0.1027

Replicate 8 0.0014 0.0108 0.0513 0.1029

Replicate 9 — 0.0104 0.0514 0.1035

Replicate 10 — 0.0102 0.0508 0.1039

Mean 0.0014 0.0105 0.0516 0.1036

Standard Deviation 0.000196 0.000237 0.000669 0.000570

%RSD 14.12% 2.25% 1.30% 0.55%

%Accuracy — — — —

MDL 0.000587 — — —

Flow Solution™ 3700 Method

Part Number 330098 10

Available Cyanide by ASTM D 6888

Appendix A - Prep Guide

Reagent Preparation

NOTE: For best results, filter and degas all reagents prior to use.

WARNING: Do not add surfactants to reagents as their presence could severely hinder or impede proper

diffusion of cyanide thorugh the gas diffusion membrane.

Reagent Water

1. Prepare degassed and deionized reagent water using one of the following methods:

2. Place distilled/deionized water under a strong vacuum for 15–20 minutes. Magnetic stirring or sonification

aids in the degassing process.

3. Purge distilled/deionized water with nitrogen gas (or other inert gas) through a glass frit for approximately

5 minutes.

4. Boil distilled/deionized water in an Erlenmeyer flask for 15–20 minutes. Remove the flask from the heat

source, cover it with an inverted beaker, and allow it to cool to room temperature. After preparing degassed

reagent water, store it in a tightly-sealed container to protect it from reabsorbing atmospheric gases. For best

results, store degassed reagent water under a slight vacuum when not used.

Stock base reagent, 10 M sodium hydroxide

1. While stirring, carefully add 400 g of sodium hydroxide in 700 mL of reagent water in a 1 L volumetric

flask.

2. Cool to room temperature.

3. Dilute to volume with reagent water and mix well.

4. Store in an amber bottle at room temperature.

NOTE: CO2 from atmosphere absorbs into NaOH solution. Do not shake or mix stock reagent prior to pipeting.

Always pipet from top.

Sodium Hydroxide, 1 M

1. While stirring, carefully add 40 g of sodium hydroxide in 700 mL of reagent water in a 1 L volumetric

flask.

2. Cool to room temperature.

3. Dilute to volume with reagent water and mix well.

4. Store at room temperature.

Sample Preservation Reagents

a. Acetate Buffer

1. Dissolve 146 g of sodium acetate in 400 mL of reagent water in a 1 L volumetric flask.

2. Add 480 g of glacial acetic acid.

3. Dilute to volume with reagent water and mix well.

b. Ethylenediamine Solution, 3.5% (v/v)

1. Add 3.5 mL of ethylenediamine to a 100 mL volumetric flask.

2. Dilute to volume with reagent water and mix well.

c. Ascorbic Acid—Crystals

d. Sodium Arsenite—Crystals

Flow Solution™ 3700 Method

Part Number 330098 11

Available Cyanide by ASTM D 6888

FIA Reagents

Carrier - Reagent Water

Sulfuric Acidification Reagent SAR

1. Weigh 1.00 g of bismuth nitrate pentahydrate into a 1 L volumetric flask.

2. Add 55 mL of reagent water.

3. Carefully add 55 mL of concentrated sulfuric acid. Gently swirl the flask to dissolve the bismuth nitrate

pentahydrate.

4. Dilute to volume with reagent water and mix well.

NOTE: Directions must be followed exactly or the bismuth nitrate will not dissolve.

Base reagent, 0.1 M sodium hydroxide

1. Dilute 10 mL of acceptor stock solution to 1 L in a volumetric flask. and mix well.

2. Dilute to volume with reagent water and mix well.

Mixed ligand exchange reagent, available cyanide

1. Transfer 0.125 mL of (WAD) reagent A and 0.250 mL of (WAD) reagent B into a 100 mL volumetric

flask containing about 50 mL of reagent water.

2. Dilute to volume with reagent water and mix well.

3. Store at 4 °C. Keep the bottle closed, unless in use. If stored properly, available cyanide Mixed Ligand

Reagent is stable for approximately six months.

4. Check available cyanide mixed ligand reagent monthly after preparation, by adjusting the mixed

D 6888 LCS solution.

Calibrant Preparation

Stock Solutions

Standard Silver Nitrate Solution, 0.0192 N

a. Dissolve 3.27 g of silver nitrate in 700 mL of reagent water in a 1 L volumetric flask.

b. Dilute to volume with reagent water and mix well.

c. Store in an amber bottle at room temperature.

Rhodanine Solution, 0.2 mg/mL in Acetone

a. Dissolve 20 mg of 5-[4-(dimethylamino)benzylidene]rhodanine in 80 mL of acetone in a 100 mL volumetric

flask.

b. Dilute to volume with acetone and mix well.

Potassium Cyanide Stock Solution, 1,000 mg/mL

a. Dissolve 2 g of sodium hydroxide in 500 mL of reagent water in a 1 L volumetric flask.

b. Add 2.51 g of potassium cyanide.

c. Dilute to volume with reagent water and mix well.

d. Store in an amber bottle at 4 °C. If stored properly, this reagent is typically stable for two months.

NOTE: This stock solution can be purchased from a reputable supplier.

Standardized Potassium Cyanide Stock Solution

a. Add 0.5 mL of rhodanine solution to 25 mL of potassium cyanide stock solution.

b. Titrate with silver nitrate solution until the color changes from canary yellow to a salmon hue.

c. Based on the determined potassium cyanide concentration, dilute the potassium cyanide stock solution to

a final concentration of 1.00 g/L. If the concentration is not 1.00 g/L, correct the intermediate and working

calibration concentrations accordingly.

d. Store in an amber bottle at 4 °C. If stored properly, this reagent is typically stable for two months.

Stock Nickel (II) cyanide stock solution, 1,000 mg/L

1. Dissolve 0.2488 g of potassium tetracyanonickelate in 25 mL of reagent water and 1 mL of 1 M sodium

hydroxide in a 100 mL volumetric flask.

Flow Solution™ 3700 Method

Part Number 330098 12

2. Dilute to volume with reagent water and mix well.

Stock Mercury (II) cyanide solution, 1,000 mg/L

1. Dissolve 0.486 g of mercury (II) cyanide in 25 mL of reagent water and 1 mL of 1 M sodium hydroxide

in a 100 mL volumetric flask.

2. Dilute to volume with reagent water and mix well.

Mixed D 6888 LCS Solution (0.2 mg/L CN)

1. Pipet 0.1 mL of Nickel (II) cyanide and mercury (II) cyanide intermediate solution into 25 mL of reagent

water and 1 mL of 1M sodium hydroxide in a 100 mL volumetric flask.

2. Dilute to volume with reagent water and mix well.

3. Store in brown glass or plastic at 2-6 °C.

4. The mixed D 6888 LCS solution evaluates the efficiency of the mixed ligand reagent addition. To

evaluate efficiency of each ligand, prepare separate nickel (II) cyanide and mercury (II) cyanide LCD solutions.

Intermediate Standards – 100 mg/L

1. Using a volumetric pipette, transfer 10 mL of stock standard to a 100 mL volumetric flask that contains

1 mL of 1 M sodium hydroxide and 40 mL of reagent water.

2. Dilute to volume with reagent water and mix well.

3. Store in an amber bottle at 4 °C. If stored properly, this reagent is typically stable for one month.

Calibration series

1. A calibration series may be prepared in 100 mL volumetric flasks containing 1 mL of 1 M sodium hydroxide

using the table below.

2. Dilute and mix well.

3. Store in an amber bottle at 4 °C.

4. Prepare fresh calibrants daily.

Final Concentration (mg/L) 0.01 0.10 0.25 0.50 1.00 5.00

Volume of Intermediate Standard to Transfer (µL) 100 1000 2500 5000 10000 5000

Flow Soution™ 3700 Method

Part Number 330098 13

You might also like

- The Relay Testing Handbook-Generator Relay Protection Testing TOC-ToF-BibDocument36 pagesThe Relay Testing Handbook-Generator Relay Protection Testing TOC-ToF-BibMartin Goodnough100% (1)

- Boylan - The Spiritual Life of The PriestDocument63 pagesBoylan - The Spiritual Life of The Priestpablotrollano100% (1)

- Norma ASTM D 2036-09 para Determinación de CianuroDocument20 pagesNorma ASTM D 2036-09 para Determinación de Cianurotesiscianuro2014100% (3)

- 355 SCDDocument4 pages355 SCDJuan Ramón RincónNo ratings yet

- Advanced Pharmaceutical analysisFrom EverandAdvanced Pharmaceutical analysisRating: 4.5 out of 5 stars4.5/5 (2)

- Flow Solution FS 3700 Automated Chemistry AnalyzerDocument16 pagesFlow Solution FS 3700 Automated Chemistry AnalyzerMiguel Angel Hanco ChoqueNo ratings yet

- Wad Cyanide OIA1677Document13 pagesWad Cyanide OIA1677wcenttiNo ratings yet

- WS3700 Method Abstract ASTM 7237Document4 pagesWS3700 Method Abstract ASTM 7237sewan48762No ratings yet

- Cianeto Total - SFADocument4 pagesCianeto Total - SFAAndré SchikierskiNo ratings yet

- Tot Cyanid ASTM D7511 091Document36 pagesTot Cyanid ASTM D7511 091maruf amaludinNo ratings yet

- CN WAD FS3000 A002966 OIA1677 FS 3k - UpdatedDocument33 pagesCN WAD FS3000 A002966 OIA1677 FS 3k - Updatedsergioalex1430No ratings yet

- Method Oia-1677-09 2010Document28 pagesMethod Oia-1677-09 2010sergioalex1430No ratings yet

- 2538 A New Approach For Nitrate Cadmium Reduction by Discrete Analysis-SDocument8 pages2538 A New Approach For Nitrate Cadmium Reduction by Discrete Analysis-SClaudio AppollonioNo ratings yet

- 1203 Total Cyanide UV Digestion Segmented FIADocument1 page1203 Total Cyanide UV Digestion Segmented FIAmiguel008No ratings yet

- AppNote AAS 0016 en ZEEnit Toxics Surface Drinking WaterDocument6 pagesAppNote AAS 0016 en ZEEnit Toxics Surface Drinking WaterAlberto HernándezNo ratings yet

- Available Cyanide With Ligand Displacement and Flow Injection Analysis (FIA) Utilizing Gas Diffusion Separation and Amperometric DetectionDocument7 pagesAvailable Cyanide With Ligand Displacement and Flow Injection Analysis (FIA) Utilizing Gas Diffusion Separation and Amperometric Detectionasma hamzaNo ratings yet

- Total Cyanide Using UV Digestion and Amperometric Detection (ASTM D7511 09e Equivalent Method)Document6 pagesTotal Cyanide Using UV Digestion and Amperometric Detection (ASTM D7511 09e Equivalent Method)maruf amaludinNo ratings yet

- A Green Chemistry Approach To Mercury ControlDocument7 pagesA Green Chemistry Approach To Mercury ControlDennis Daniel Condori EspilcoNo ratings yet

- CN Total New 3837mthdDocument36 pagesCN Total New 3837mthdYean CarlosNo ratings yet

- 353.2 No3, No2Document8 pages353.2 No3, No2nguyenngoc209No ratings yet

- WAD Cynoprobe PDFDocument9 pagesWAD Cynoprobe PDFGerehNo ratings yet

- Technology Guide 15: SSPC: The Society For Protective CoatingsDocument16 pagesTechnology Guide 15: SSPC: The Society For Protective CoatingsIris Carmen100% (1)

- Method For Nitrate Determination by Cadmium Reduction, Version 2.3Document8 pagesMethod For Nitrate Determination by Cadmium Reduction, Version 2.3KhalidOfqirNo ratings yet

- AppNote AAS 0017 en contrAA Wastewater Sewage SlugdeDocument7 pagesAppNote AAS 0017 en contrAA Wastewater Sewage SlugdeAlberto HernándezNo ratings yet

- Method Abstract: ScopeDocument6 pagesMethod Abstract: ScopeMIGUEL ANGEL MEJIA SANDOVALNo ratings yet

- Test Method: Subject: ApprovedDocument4 pagesTest Method: Subject: ApprovedLucky KhanNo ratings yet

- Astm D 2036-98 CianuroDocument20 pagesAstm D 2036-98 CianuroGianinaRoncalChávezNo ratings yet

- ASTM D7511 12 Total Cyanide by FIADocument10 pagesASTM D7511 12 Total Cyanide by FIAGiuliana Katia Morales FuertesNo ratings yet

- 7601 - Crystallin Silica PDFDocument6 pages7601 - Crystallin Silica PDFAmalia NurbandiniNo ratings yet

- Cianuro Wad ASTM D6888-16Document8 pagesCianuro Wad ASTM D6888-16Gabriel Apaza SánchezNo ratings yet

- Removal of Silver From Photographic SolutionsDocument10 pagesRemoval of Silver From Photographic SolutionsMinh Tiến TrầnNo ratings yet

- Analytical Method For Hydrated LimeDocument60 pagesAnalytical Method For Hydrated LimeFadly FaradhilaNo ratings yet

- EPA 202.1 - AlDocument2 pagesEPA 202.1 - AlAristaNo ratings yet

- Method - 200-2 - Rev - 2-8 - 1994 Elementos RecuperablesDocument13 pagesMethod - 200-2 - Rev - 2-8 - 1994 Elementos RecuperablesPablo MéndezNo ratings yet

- 2 SO2-Air Cyanide OxydationDocument8 pages2 SO2-Air Cyanide OxydationbazanvlNo ratings yet

- Whitepaper: Overcoming Challenges of Sulfur Analysis in Natural Gas and Gaseous FuelsDocument8 pagesWhitepaper: Overcoming Challenges of Sulfur Analysis in Natural Gas and Gaseous FuelsSiti Fajar karinaNo ratings yet

- Cod 3715Document4 pagesCod 3715shaukat786.No ratings yet

- GB 15892-2009Document25 pagesGB 15892-2009dewi wulansariNo ratings yet

- 355 S DetectorDocument4 pages355 S DetectorFaizal ThelordImmortal100% (1)

- D 4193 - 95 - RdqxotmtukveDocument6 pagesD 4193 - 95 - RdqxotmtukveTHANGVUNo ratings yet

- 245.2 Mercury by Cold Vapor TechniqueDocument6 pages245.2 Mercury by Cold Vapor TechniquedcardonasterNo ratings yet

- Hydrometallurgical Process: Analysis of Free, Total & WAD Cyanide in Gold Leach Slurry & WastewaterDocument1 pageHydrometallurgical Process: Analysis of Free, Total & WAD Cyanide in Gold Leach Slurry & WastewaterJUNIORNo ratings yet

- Iso 9227 PDFDocument13 pagesIso 9227 PDFMario AguillonNo ratings yet

- Agilent FPD-Low Level Sulfur Detection in CO2Document4 pagesAgilent FPD-Low Level Sulfur Detection in CO2amittal111No ratings yet

- 5989 9234enDocument4 pages5989 9234enAngela MoraNo ratings yet

- AppNote AAS novAA 800 0008 en Industrial EffluentsDocument4 pagesAppNote AAS novAA 800 0008 en Industrial EffluentsAlberto HernándezNo ratings yet

- Unit 9 Applications of Polarography Amperometric Titrations and Voltammetry PDFDocument15 pagesUnit 9 Applications of Polarography Amperometric Titrations and Voltammetry PDFAranga100% (1)

- Solvent Extraction PD Dari CyanideDocument6 pagesSolvent Extraction PD Dari CyanideAdeNo ratings yet

- Determination of Cu (II) in Beer by Derivative Potentiometric Stripping AnalysisDocument5 pagesDetermination of Cu (II) in Beer by Derivative Potentiometric Stripping AnalysisPicha PichoNo ratings yet

- Methods BeerDocument62 pagesMethods BeerTruong Anh TuanNo ratings yet

- AppNote AAS 0009 en novAA800 Sewage SludgeDocument4 pagesAppNote AAS 0009 en novAA800 Sewage SludgemariholzNo ratings yet

- Breuer 09Document6 pagesBreuer 09Jesus ParedesNo ratings yet

- Unit 9 Applications of Polarography, Amperometric Titrations and VoltammetryDocument15 pagesUnit 9 Applications of Polarography, Amperometric Titrations and VoltammetryNathanian100% (9)

- Determination of Sodium and Potassium Content For Silver-Cadmium Oxide Contact MaterialsDocument2 pagesDetermination of Sodium and Potassium Content For Silver-Cadmium Oxide Contact MaterialstsliaNo ratings yet

- Determination of Sodium in Foods PDFDocument6 pagesDetermination of Sodium in Foods PDFGiu Ali Mamani PacoNo ratings yet

- 10 1021@acsreagents 4012Document3 pages10 1021@acsreagents 4012Quercus AlbaNo ratings yet

- Gas-Liquid Separator Integrated To HG-QFAAS Method For Determination of Tin at Trace Levels in The Water SamplesDocument11 pagesGas-Liquid Separator Integrated To HG-QFAAS Method For Determination of Tin at Trace Levels in The Water SamplesGanjar OfficialNo ratings yet

- Senseor For T50Document100 pagesSenseor For T50hienda09hhNo ratings yet

- 13 Epa Cianuro Wad Fia 1677-2004 AcreditadoDocument26 pages13 Epa Cianuro Wad Fia 1677-2004 AcreditadoErick Leonardo Valle MendozaNo ratings yet

- Acids Org Sb-Aq 5989-1265Document8 pagesAcids Org Sb-Aq 5989-1265pacocurroNo ratings yet

- Application of IC-MS and IC-ICP-MS in Environmental ResearchFrom EverandApplication of IC-MS and IC-ICP-MS in Environmental ResearchRajmund MichalskiNo ratings yet

- Chapter 03Document40 pagesChapter 03AC BañaresNo ratings yet

- Vanilla Icebox CookiesDocument2 pagesVanilla Icebox CookiesmadduxdavidNo ratings yet

- Interviw With Martin DavisDocument12 pagesInterviw With Martin DavisraktimddkNo ratings yet

- Galvafroid Data SheetDocument13 pagesGalvafroid Data SheetAdam HughesNo ratings yet

- Star Holman 210HX Conveyor OvenDocument2 pagesStar Holman 210HX Conveyor Ovenwsfc-ebayNo ratings yet

- Specifications Battery Chargers For Rail VehiclesDocument2 pagesSpecifications Battery Chargers For Rail VehiclesPirata ScribNo ratings yet

- Research Report - Aakanksha MistryDocument19 pagesResearch Report - Aakanksha MistryAakanksha MistryNo ratings yet

- FIN V1 Chap4 EconDocument15 pagesFIN V1 Chap4 EconV I S W A L S HNo ratings yet

- Volumetric Rotary Piston Meter Asm LXH SA1508 15mm, 20mm & 25mmDocument19 pagesVolumetric Rotary Piston Meter Asm LXH SA1508 15mm, 20mm & 25mmGreen FarmersNo ratings yet

- MP900 and MP9000 Series Kool-Pak Power Film Resistors: TO-126, TO-220 and TO-247 StyleDocument3 pagesMP900 and MP9000 Series Kool-Pak Power Film Resistors: TO-126, TO-220 and TO-247 StyleManoel HenriqueNo ratings yet

- AASHTO - LRFD - Construction Specs-2nd Edition-2 PDFDocument664 pagesAASHTO - LRFD - Construction Specs-2nd Edition-2 PDFSharfaraz Hossain100% (1)

- Mesología BERQUEDocument6 pagesMesología BERQUEPanchita PonisioNo ratings yet

- Lab File of Ad Hoc and Sensor Networks Lab (ETEC - 458) : Department of Information TechnologyDocument39 pagesLab File of Ad Hoc and Sensor Networks Lab (ETEC - 458) : Department of Information TechnologyswatiNo ratings yet

- RPLL NewDocument74 pagesRPLL NewMeta learnNo ratings yet

- SSC Teaching QualificationDocument3 pagesSSC Teaching QualificationSasikalaNo ratings yet

- Biological Bases of BehaviorDocument7 pagesBiological Bases of BehaviorSANTHOSH KUMAR T MNo ratings yet

- FirePro Technical Prospectus PDFDocument28 pagesFirePro Technical Prospectus PDFRANJITHNo ratings yet

- No More War PDF - Pauling, Linus, 1901Document260 pagesNo More War PDF - Pauling, Linus, 1901pdf ebook free downloadNo ratings yet

- Computational Methods: Test Program For Chasing Method Developed in MatlabDocument6 pagesComputational Methods: Test Program For Chasing Method Developed in MatlabMujtaba MujahidNo ratings yet

- Type 4536 Oscillator-Divider ICDocument13 pagesType 4536 Oscillator-Divider ICRoscoeDog718No ratings yet

- 11thMachAutoExpo 2022Document112 pages11thMachAutoExpo 2022Priyanka KadamNo ratings yet

- Saturn Quad QSDSSDocument1 pageSaturn Quad QSDSSniall.godleyNo ratings yet

- Chap 11Document3 pagesChap 11Flia Diaz ZunigaNo ratings yet

- Lesson 3Document4 pagesLesson 3Justin Kean HakeemNo ratings yet

- Chapter 4 - Structural Imperfections Kingery Introducción A Los Materiales CerámicosDocument27 pagesChapter 4 - Structural Imperfections Kingery Introducción A Los Materiales CerámicosLaura BárbaroNo ratings yet

- DER Vol III DrawingDocument50 pagesDER Vol III Drawingdaryl sabadoNo ratings yet

- Cooper Ls Brochure Industrial Led Lighting Product CatalogueDocument68 pagesCooper Ls Brochure Industrial Led Lighting Product CataloguecarlosmandopintoNo ratings yet

- ISO 00426-1-1983 ScanDocument5 pagesISO 00426-1-1983 ScanthangNo ratings yet