Professional Documents

Culture Documents

Fanuc PLC Syllabus - New

Fanuc PLC Syllabus - New

Uploaded by

Abraham GutierrezCopyright:

Available Formats

You might also like

- Product Specification: Programmable Microprocessor-Based Gen Set Controller For Electronic J1939 CAN Bus Diesel EnginesDocument17 pagesProduct Specification: Programmable Microprocessor-Based Gen Set Controller For Electronic J1939 CAN Bus Diesel EnginesJavierNo ratings yet

- K & H PLC-200Document2 pagesK & H PLC-200syed mohammad ali shahNo ratings yet

- Micom P143 Relay Manual: Read/DownloadDocument2 pagesMicom P143 Relay Manual: Read/Download- witaratamaNo ratings yet

- CNC - MechatronicsDocument93 pagesCNC - Mechatronicskr_abhijeet7235658767% (3)

- CNC MachinesDocument94 pagesCNC Machineskr_abhijeet72356587100% (2)

- 20ME919 - Mechatronics Important Question For ESE NewDocument6 pages20ME919 - Mechatronics Important Question For ESE NewCAD With RaoNo ratings yet

- IADocument9 pagesIAVipul SharmaNo ratings yet

- Literature Review DC MotorDocument24 pagesLiterature Review DC MotorXtremeInfosoftAlwar59% (17)

- Vacon 100 Application Manual DPD00927F UKDocument342 pagesVacon 100 Application Manual DPD00927F UKMiguel CardosoNo ratings yet

- Microchip Motor ControlDocument16 pagesMicrochip Motor ControlOctavio AsNo ratings yet

- Manual Micro B Net DigitalDocument146 pagesManual Micro B Net DigitalingegusNo ratings yet

- Cnc-MachinesNC Machines 1.2 CNC Machines 1.3 DNC MachinesDocument39 pagesCnc-MachinesNC Machines 1.2 CNC Machines 1.3 DNC MachinesRohitash TakNo ratings yet

- Over View On Section MillDocument137 pagesOver View On Section MillMustafa Mahmoud AwwadNo ratings yet

- Subject: Student: Practice Name: Digital Systems 2Document2 pagesSubject: Student: Practice Name: Digital Systems 2Yamil López PérezNo ratings yet

- EE208 Lab ManualDocument38 pagesEE208 Lab Manualsakib shaukatNo ratings yet

- Arico Fa1Document84 pagesArico Fa1vadikcazac67% (3)

- TNC 155 M - InstalDocument119 pagesTNC 155 M - Instalgeorgecotora100% (8)

- MP Electrical Drives Lab ManualDocument37 pagesMP Electrical Drives Lab ManualSoumiya Srinivasan100% (1)

- EE2016 Micropprocessor Lab & Theory July-Nov 2019Document7 pagesEE2016 Micropprocessor Lab & Theory July-Nov 2019Raghu DineshNo ratings yet

- Etap ModulesDocument13 pagesEtap ModulesHasnain yaseenNo ratings yet

- Digital Control of A Stepper Motor: Instructor's PortionDocument13 pagesDigital Control of A Stepper Motor: Instructor's PortionEngr Nayyer Nayyab MalikNo ratings yet

- Submitted To Mr. Amol Purohit ECE Department Submitted by Shivam Varshney EC4 Year Sec b2 11EVJEC089Document20 pagesSubmitted To Mr. Amol Purohit ECE Department Submitted by Shivam Varshney EC4 Year Sec b2 11EVJEC089Malvika DiddeeNo ratings yet

- CNC Overview PresentationDocument50 pagesCNC Overview PresentationVaibhav Vithoba Naik100% (1)

- Fc202 Danfoss Manual ProgramareDocument246 pagesFc202 Danfoss Manual ProgramareRaducan Teodor100% (1)

- 02 Mechatronics & Automation Products PDFDocument58 pages02 Mechatronics & Automation Products PDFShueab MujawarNo ratings yet

- NC, CNC and RoboticsDocument100 pagesNC, CNC and RoboticsGovt Job update - JagadishNo ratings yet

- User Manual For Speed Control of BLDC Motor Using DspicDocument12 pagesUser Manual For Speed Control of BLDC Motor Using DspicTrung TrựcNo ratings yet

- Robot2CNC Basic Edition Haas NGC Installation and Operation 1Document24 pagesRobot2CNC Basic Edition Haas NGC Installation and Operation 1qwerqewrNo ratings yet

- 1 Month Laptop Repairing CourseDocument10 pages1 Month Laptop Repairing CourseChiptroniksInst0% (1)

- ME 1402 - Mechatronics PDFDocument6 pagesME 1402 - Mechatronics PDFnagarajanceNo ratings yet

- 87 Catalog Invertere Ic5Document19 pages87 Catalog Invertere Ic5vga1234No ratings yet

- PLC Training LiteratureDocument45 pagesPLC Training Literaturealex2gustavo2cuevas2No ratings yet

- Servo Motors Q&A Prepared By: Eng. Ahmed SalehDocument4 pagesServo Motors Q&A Prepared By: Eng. Ahmed SalehAhmed AlnagarNo ratings yet

- Microprocessor and Microcontrollers (Credits: Theory-04, Practicals-02) Theory Lectures 60Document4 pagesMicroprocessor and Microcontrollers (Credits: Theory-04, Practicals-02) Theory Lectures 60Jasvinder kourNo ratings yet

- c11gs-r1 5 User ManualDocument21 pagesc11gs-r1 5 User Manualcastellano_rNo ratings yet

- F MC-16F MB90220 Series: 16-Bit Proprietary MicrocontrollerDocument105 pagesF MC-16F MB90220 Series: 16-Bit Proprietary MicrocontrollerTriman TelaumbanuaNo ratings yet

- ABB VFD Operation Manual - v1.2Document22 pagesABB VFD Operation Manual - v1.2Yuriy LobanovNo ratings yet

- The CNC h4 SystemDocument8 pagesThe CNC h4 SystemRobert GiangNo ratings yet

- 4104euen PLC Overview 0Document64 pages4104euen PLC Overview 0ludek_bartakNo ratings yet

- MAN B W ME-C-based Control of The Host AnalysisDocument11 pagesMAN B W ME-C-based Control of The Host AnalysisaloordominicNo ratings yet

- Hritik Baral - ES - CaseStudyDocument10 pagesHritik Baral - ES - CaseStudyHemanga RanaNo ratings yet

- Stepper Motor ReportDocument13 pagesStepper Motor ReportVolda0% (2)

- Specification Intro OverviewDocument2 pagesSpecification Intro OverviewQuantumAutomationNo ratings yet

- 1 - Power Electronics CatalogueDocument83 pages1 - Power Electronics CataloguerockNo ratings yet

- 236 MR-C MitsubishiDocument10 pages236 MR-C MitsubishiemtelesNo ratings yet

- Four-Quadrant: Dynamometer/Power Supply MODEL 8960Document16 pagesFour-Quadrant: Dynamometer/Power Supply MODEL 8960Jose Angel Puente PuenteNo ratings yet

- Dsa 5600 - Fresa CNCDocument12 pagesDsa 5600 - Fresa CNCxemante50% (2)

- Ecu Sensor Simulation mst9000 InstructionDocument9 pagesEcu Sensor Simulation mst9000 InstructionJorge EspinoNo ratings yet

- Komatsu EgseDocument6 pagesKomatsu EgseAllan Rey FernandezNo ratings yet

- ME 1402 - Mechatronics PDFDocument6 pagesME 1402 - Mechatronics PDFHiru Purushothaman HirudayanathanNo ratings yet

- Fanuc Oi PDFDocument16 pagesFanuc Oi PDFGuillermo Ramirez100% (1)

- 1 Cam IntroDocument10 pages1 Cam IntroDarshan SoniNo ratings yet

- Mpc860 Powerquicc™ Family User'S Manual: SupportsDocument1,320 pagesMpc860 Powerquicc™ Family User'S Manual: SupportsNaresh BopparathiNo ratings yet

- MC9S08QE32RMDocument306 pagesMC9S08QE32RMTato527No ratings yet

- CNC IntroductionDocument24 pagesCNC IntroductionaravindanNo ratings yet

- Control System Based On PLC For WindingDocument4 pagesControl System Based On PLC For WindinghanzrizNo ratings yet

- Multivariable Predictive Control: Applications in IndustryFrom EverandMultivariable Predictive Control: Applications in IndustryNo ratings yet

- Multicore DSP: From Algorithms to Real-time Implementation on the TMS320C66x SoCFrom EverandMulticore DSP: From Algorithms to Real-time Implementation on the TMS320C66x SoCNo ratings yet

- AC Electric Motors Control: Advanced Design Techniques and ApplicationsFrom EverandAC Electric Motors Control: Advanced Design Techniques and ApplicationsFouad GiriNo ratings yet

- Model Predictive Control of High Power Converters and Industrial DrivesFrom EverandModel Predictive Control of High Power Converters and Industrial DrivesNo ratings yet

- MAX2021Document20 pagesMAX2021Abraham GutierrezNo ratings yet

- 2022COAZ4027Document123 pages2022COAZ4027Abraham GutierrezNo ratings yet

- Motherboard BatteriesDocument4 pagesMotherboard BatteriesAbraham GutierrezNo ratings yet

- OpenocdDocument232 pagesOpenocdAbraham GutierrezNo ratings yet

- PL Nu'Yua: 'Uq Au) A ' Eybx - (Qabys SqauDocument5 pagesPL Nu'Yua: 'Uq Au) A ' Eybx - (Qabys SqauAbraham GutierrezNo ratings yet

- ComponentesDocument7 pagesComponentesAbraham GutierrezNo ratings yet

- M5L8042 146PDocument7 pagesM5L8042 146PAbraham GutierrezNo ratings yet

- I JTL:: 5HB: F-03 FuseDocument2 pagesI JTL:: 5HB: F-03 FuseAbraham GutierrezNo ratings yet

- 7293-Article Text-10523-1-10-20200601Document12 pages7293-Article Text-10523-1-10-20200601Abraham GutierrezNo ratings yet

- RJK0631JPD RenesasDocument7 pagesRJK0631JPD RenesasAbraham GutierrezNo ratings yet

- STM 32 WB 55 RGDocument8 pagesSTM 32 WB 55 RGAbraham GutierrezNo ratings yet

- Chaves 2016Document67 pagesChaves 2016Abraham GutierrezNo ratings yet

- 27c210a 15Document29 pages27c210a 15Abraham GutierrezNo ratings yet

- HSS60Document6 pagesHSS60Abraham GutierrezNo ratings yet

- Materials 15 00513 v2Document14 pagesMaterials 15 00513 v2Abraham GutierrezNo ratings yet

- As PDF Mitsubishi EdmDocument67 pagesAs PDF Mitsubishi EdmAbraham GutierrezNo ratings yet

- TEMPORALDocument1 pageTEMPORALAbraham GutierrezNo ratings yet

- Wots Wha-217 E2Document8 pagesWots Wha-217 E2Abraham GutierrezNo ratings yet

- Competence Format ExampleDocument10 pagesCompetence Format ExampleAbraham GutierrezNo ratings yet

- Irs2186/Irs21864 (S) PBF: High and Low Side DriverDocument23 pagesIrs2186/Irs21864 (S) PBF: High and Low Side DriverAbraham GutierrezNo ratings yet

- UM1690 User Manual: Discovery Kit For STM32 F0 Series With STM32F072RB MCUDocument31 pagesUM1690 User Manual: Discovery Kit For STM32 F0 Series With STM32F072RB MCUAbraham GutierrezNo ratings yet

- MUR6040 Switchmode Power Rectifier: Ultrafast Rectifier 60 Amperes 400 VOLTSDocument4 pagesMUR6040 Switchmode Power Rectifier: Ultrafast Rectifier 60 Amperes 400 VOLTSAbraham GutierrezNo ratings yet

- Active Gate Voltage Control of Turn-On$di/dt$and Turn-Off$dv/dt$in Insulated Gate TransistorsDocument8 pagesActive Gate Voltage Control of Turn-On$di/dt$and Turn-Off$dv/dt$in Insulated Gate TransistorsAbraham GutierrezNo ratings yet

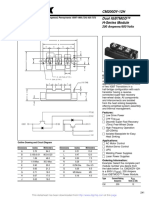

- CM200DY-12H: 200 Amperes/600 VoltsDocument4 pagesCM200DY-12H: 200 Amperes/600 VoltsAbraham GutierrezNo ratings yet

- Page 1 of 15Document15 pagesPage 1 of 15Abraham GutierrezNo ratings yet

- IGBT ThermalDocument14 pagesIGBT ThermalAbraham GutierrezNo ratings yet

- Folding Carton Manufacturing: Intelligent Solutions For State-Of-The-Art Production ProcessesDocument8 pagesFolding Carton Manufacturing: Intelligent Solutions For State-Of-The-Art Production Processesmanuel estradaNo ratings yet

- General Mathematics 11 2019 - 2020Document6 pagesGeneral Mathematics 11 2019 - 2020Dinmar DurendesNo ratings yet

- Cyber Security (Open Elective) ObjectivesDocument2 pagesCyber Security (Open Elective) Objectivessriramganesh81070% (1)

- Min Terms and MaxtermsDocument10 pagesMin Terms and MaxtermsMARUPAKA BHARGAV ANAND BU21CSEN0400111No ratings yet

- Sri Lanka Trade and Information PDFDocument7 pagesSri Lanka Trade and Information PDFDurban Chamber of Commerce and IndustryNo ratings yet

- Output 1 in Third QuarterDocument3 pagesOutput 1 in Third QuarterRodepe CamposanoNo ratings yet

- MBA105 - Almario - Parco - Assignment 1Document14 pagesMBA105 - Almario - Parco - Assignment 1nicolaus copernicusNo ratings yet

- Dbms NotesDocument48 pagesDbms NotesSHIWANI PAL CS-18No ratings yet

- Data Collection GuideDocument16 pagesData Collection GuideŞansal Dikmener100% (1)

- 90.25772-BLMS GDC-051 As BuiltDocument26 pages90.25772-BLMS GDC-051 As BuiltValipireddy Nagarjun100% (1)

- k3fDV2A SheetDocument2 pagesk3fDV2A SheetAlNo ratings yet

- Experiment 8Document19 pagesExperiment 8HAIKAL MUZAFFAR AZAMNo ratings yet

- ProfiLux 3.1T ManualDocument20 pagesProfiLux 3.1T Manualjuanjo19911991No ratings yet

- Yaesu Vertex VRX-1000 VHF Version Service ManualDocument48 pagesYaesu Vertex VRX-1000 VHF Version Service ManualIWNo ratings yet

- AZ 305+Official+Course+Study+GuideDocument14 pagesAZ 305+Official+Course+Study+GuideHeilly JerivethNo ratings yet

- Life, Life - Selected Poems by Arseny TarkovskyDocument5 pagesLife, Life - Selected Poems by Arseny Tarkovskyignoramus83No ratings yet

- DBMS Unit 5Document43 pagesDBMS Unit 5abhivardhan786No ratings yet

- RFQ Index HVDC WolaytaDocument5 pagesRFQ Index HVDC WolaytaS Rao CheepuriNo ratings yet

- DxdiagDocument50 pagesDxdiagJohn DulayNo ratings yet

- 4730-3 BLUM IF59 Installation Instructions 180168 Rev0-2 0-2Document48 pages4730-3 BLUM IF59 Installation Instructions 180168 Rev0-2 0-2Олег ЕфимовNo ratings yet

- TM1 User GuideDocument253 pagesTM1 User GuideJW LeeNo ratings yet

- Vue-Doc-Preview: ImportDocument4 pagesVue-Doc-Preview: ImportLucas DadegnonNo ratings yet

- Geforce 9600 GT: 512Mb (256bit) Graphics CardDocument2 pagesGeforce 9600 GT: 512Mb (256bit) Graphics CardTan Hung LuuNo ratings yet

- Notebook: COD Grupa Producator Descriere Pret Cu Tva Garantie DisponibilitateDocument191 pagesNotebook: COD Grupa Producator Descriere Pret Cu Tva Garantie DisponibilitatenelubobinaNo ratings yet

- IBM - IBM Storage Scale 5.1.9 Problem Determination Guide (2024)Document1,008 pagesIBM - IBM Storage Scale 5.1.9 Problem Determination Guide (2024)Ramon BarriosNo ratings yet

- Kingston SSD Manager User GuideDocument6 pagesKingston SSD Manager User GuideYudi Sintia WijayaNo ratings yet

- Nexus VPCDocument11 pagesNexus VPCNdaru Prakoso100% (1)

- Guia de Inicio Rapido Picus-y-Picus-NxT-Pipetas-electrónicasDocument2 pagesGuia de Inicio Rapido Picus-y-Picus-NxT-Pipetas-electrónicasnimsi encisoNo ratings yet

Fanuc PLC Syllabus - New

Fanuc PLC Syllabus - New

Uploaded by

Abraham GutierrezOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Fanuc PLC Syllabus - New

Fanuc PLC Syllabus - New

Uploaded by

Abraham GutierrezCopyright:

Available Formats

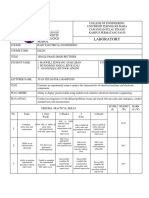

FANUC PLC Online Class – Contents:

Session 1: FANUC CNC controller, Servo amplifier, Spindle amplifier and connections

1. FANUC CNC controller and its connections

2. Fanuc servo amplifier, spindle amplifier and its connections

3. Fanuc PLC I/O units and TBs (Terminal Blocks)

4. FANUC I/O assignment (Group, Base, Slot)

5. CNC machine’s control cabinet components

6. CNC machine’s Electrical Circuit Diagram

Session 2: Number Systems

1. Decimal number system

2. Binary number system

3. Convert Decimal to Binary

4. Bit, Byte, Word and double word

Session 3: Electrical devices used in CNC machine

1. Push Buttons

2. MCB, Contactor, Overload relay and Actuators

3. Limit switches

4. Pressure switches and Float switches

5. Solenoid coils

6. Lamps and LEDs

7. Relay Boards/Relay Modules

8. Terminal Blocks

9. Transformer

10.Digital Input and Digital Output

Session 4: Basics of FANUC PLC

1. Block diagram of FANUC PLC

2. X and Y signal in FANUC PLC

3. G and F signal in FANUC PLC

4. About FANUC ladder software (FAPT LADDER III)

5. Symbols used in FANUC PLC ladder software (NO, NC, coil, Set, Reset)

6. Editing tools in FANUC PLC ladder software

Call for Online Class: +918147200766 Page 1

Session 5: FANUC PLC ladder addressing

1. FANUC PLC addresses (List and ranges)

2. Relay address (R)

3. System relay address (R9000)

4. Message and alarm display address (A)

5. Timer address (T)

6. Counter address (C)

7. Keep relay address (K)

8. Data table address (D)

9. Data table groups and how to create groups?

10.Subprogram (P)

11.Jump and Jump End (JMP and JMPE)

12.JMPB and JMPC instructions

Session 6: How to write your own FANUC PLC for following circuits?

1. Direct online starter (DOL) for motor

2. Start Delta starter for three phase induction motor

3. Elevator Lift (in building)

4. Automatic water level controller

5. Starting and stopping the single motor from four different positions (or locations)

6. Bidirectional rotation of motor (Forward and Reverse rotation)

Session 7: How to write your own FANUC PLC for (CNC Turning, VMC, VTL & HMC)?

1. Ladder for Feedback signals of switch gears (MCB, Overload relay)

2. Ladder for Emergency, machine ready, spindle drive ready

3. Ladder for Mode selection

4. Ladder for M Codes functions

5. Ladder for Spindle motor

6. Ladder for Spindle motor ON in JOG mode

7. Ladder for Spindle orientation function

8. Ladder for Servo motor in JOG movement

9. Ladder for Turret (8 station or 12 station) – PRAGATI make Turret

10.Turret (Hydraulic) using FANUC servo motor with beta amplifier (with I/O link option)

11.Ladder for Servo Turret (Duplomatic)

12.Custom Macro Programming

13.Application of Macro programming

Call for Online Class: +918147200766 Page 2

14.Variables in macro and types of variables

15.Arithmetic expressions

16.Flow control statements

17.GOTO statements

18.Conditional branching

19.Calling macro

20.Ladder for Automatic Tool Changer (ATC)

21.Ladder for Spindle motor (for VMC)

22.Ladder for Rotary table (UCAM with FANUC Servo motor and amplifier)

23.Ladder for Auto Door (Pneumatic)

24.Ladder for Hydraulic motor

25.Ladder for Coolant motor

26.Ladder for Lubrication motor

27.Ladder for Chip conveyor motor

28.Ladder for Hydraulic Chuck and Hydraulic Tailstock

29.Ladder concept for Two Path CNC

30.Ladder for Machine alarms and messages (using address “A”)

31.Ladder for Single block

32.Ladder for Block skips or Block delete

33.Ladder for Optional stop

34.Ladder for Edit key

35.Ladder for Cycle start

36.Ladder for Cycle hold

37.Ladder for Feed hold

38.Ladder for MPG (Manual Pulse Generator)

39.Ladder for Axes rapid override function

40.Ladder for Dry run function

41.Ladder for machine Lock Function

42.Ladder for Axes interlock

43.Ladder for Program Restart

44.Ladder for Cs Contour control

45.Ladder for Feed override switch

46.Ladder for Spindle speed override switch

47.Ladder for Spindle speed override (Increment and Decrement)

48.Ladder and I/O assignment for FANUC MOP

49.Ladder for Cycle start / Cycle stop lamp

50.Ladder for Single block / block delete / optional stop lamps

Call for Online Class: +918147200766 Page 3

51.Ladder for Axes are at home position lamp

52.Ladder for Tool number display

53.Ladder for Power Save Mode

Session 8: Commissioning of New CNC System (FANUC)

1. What is commissioning

2. Procedure for commissioning

3. Procedure to do servo initialization

4. Servo motor tuning

5. Procedure to do spindle initialization

Session 9: FANUC Parameters

1. Basic parameters settings for new FANUC CNC

2. Spindle parameters

3. Servo parameters

4. Homing parameter

5. Fourth axis rotary table parameters

6. Spindle orientation parameters

7. Parameter setting for spindle sensor

8. Parameters setting for 2 path CNC

9. Diagnostic parameters

10.PMC parameters

Session 10: Procedures for machine’s backup

1. Compact Flash (CF) card or memory card, USB (Pen Drive), Ethernet, RS232C

2. Parameters

3. PMC parameters

4. CNC programs

5. PLC Ladder

6. SRAM backup and restore

7. Ethernet setup (Machine Side and PC Side)

8. Ethernet procedure

Call for Online Class: +918147200766 Page 4

Session 11: Maintenance of CNC machine:

1. Different types of machine tools maintenance

2. Best maintenance practices

3. Maintenance tool and accessories required during CNC machine tool maintenance

4. Daily maintenance check list for machines

5. Causes for the failure of Electrical system in the CNC machine tools

6. Precautions to be observed for Electrical system

7. Common reasons for failure and preventive measures

8. Electrical wiring and Electrical panel

9. Types of alarms in FANUC CNC

10.Electrical breakdowns, its types and solutions to breakdowns

11.Analyze problem exist machine

12.Various Alarms categories in FANUC CNC

13.How to solve servo drive and spindle drive alarms

14.How to solve I/O unit faults?

15.Problems related to mechanical systems in CNC

Session 12: How open and display below functions on CNC screen

1. Axes parameters

2. Ladder open and edit the ladder

3. PMCCNF and PMCMNT screens

4. Servo setting screen

5. Spindle setting screen

6. Servo Tuning Procedure

END

Call for Online Class: +918147200766 Page 5

You might also like

- Product Specification: Programmable Microprocessor-Based Gen Set Controller For Electronic J1939 CAN Bus Diesel EnginesDocument17 pagesProduct Specification: Programmable Microprocessor-Based Gen Set Controller For Electronic J1939 CAN Bus Diesel EnginesJavierNo ratings yet

- K & H PLC-200Document2 pagesK & H PLC-200syed mohammad ali shahNo ratings yet

- Micom P143 Relay Manual: Read/DownloadDocument2 pagesMicom P143 Relay Manual: Read/Download- witaratamaNo ratings yet

- CNC - MechatronicsDocument93 pagesCNC - Mechatronicskr_abhijeet7235658767% (3)

- CNC MachinesDocument94 pagesCNC Machineskr_abhijeet72356587100% (2)

- 20ME919 - Mechatronics Important Question For ESE NewDocument6 pages20ME919 - Mechatronics Important Question For ESE NewCAD With RaoNo ratings yet

- IADocument9 pagesIAVipul SharmaNo ratings yet

- Literature Review DC MotorDocument24 pagesLiterature Review DC MotorXtremeInfosoftAlwar59% (17)

- Vacon 100 Application Manual DPD00927F UKDocument342 pagesVacon 100 Application Manual DPD00927F UKMiguel CardosoNo ratings yet

- Microchip Motor ControlDocument16 pagesMicrochip Motor ControlOctavio AsNo ratings yet

- Manual Micro B Net DigitalDocument146 pagesManual Micro B Net DigitalingegusNo ratings yet

- Cnc-MachinesNC Machines 1.2 CNC Machines 1.3 DNC MachinesDocument39 pagesCnc-MachinesNC Machines 1.2 CNC Machines 1.3 DNC MachinesRohitash TakNo ratings yet

- Over View On Section MillDocument137 pagesOver View On Section MillMustafa Mahmoud AwwadNo ratings yet

- Subject: Student: Practice Name: Digital Systems 2Document2 pagesSubject: Student: Practice Name: Digital Systems 2Yamil López PérezNo ratings yet

- EE208 Lab ManualDocument38 pagesEE208 Lab Manualsakib shaukatNo ratings yet

- Arico Fa1Document84 pagesArico Fa1vadikcazac67% (3)

- TNC 155 M - InstalDocument119 pagesTNC 155 M - Instalgeorgecotora100% (8)

- MP Electrical Drives Lab ManualDocument37 pagesMP Electrical Drives Lab ManualSoumiya Srinivasan100% (1)

- EE2016 Micropprocessor Lab & Theory July-Nov 2019Document7 pagesEE2016 Micropprocessor Lab & Theory July-Nov 2019Raghu DineshNo ratings yet

- Etap ModulesDocument13 pagesEtap ModulesHasnain yaseenNo ratings yet

- Digital Control of A Stepper Motor: Instructor's PortionDocument13 pagesDigital Control of A Stepper Motor: Instructor's PortionEngr Nayyer Nayyab MalikNo ratings yet

- Submitted To Mr. Amol Purohit ECE Department Submitted by Shivam Varshney EC4 Year Sec b2 11EVJEC089Document20 pagesSubmitted To Mr. Amol Purohit ECE Department Submitted by Shivam Varshney EC4 Year Sec b2 11EVJEC089Malvika DiddeeNo ratings yet

- CNC Overview PresentationDocument50 pagesCNC Overview PresentationVaibhav Vithoba Naik100% (1)

- Fc202 Danfoss Manual ProgramareDocument246 pagesFc202 Danfoss Manual ProgramareRaducan Teodor100% (1)

- 02 Mechatronics & Automation Products PDFDocument58 pages02 Mechatronics & Automation Products PDFShueab MujawarNo ratings yet

- NC, CNC and RoboticsDocument100 pagesNC, CNC and RoboticsGovt Job update - JagadishNo ratings yet

- User Manual For Speed Control of BLDC Motor Using DspicDocument12 pagesUser Manual For Speed Control of BLDC Motor Using DspicTrung TrựcNo ratings yet

- Robot2CNC Basic Edition Haas NGC Installation and Operation 1Document24 pagesRobot2CNC Basic Edition Haas NGC Installation and Operation 1qwerqewrNo ratings yet

- 1 Month Laptop Repairing CourseDocument10 pages1 Month Laptop Repairing CourseChiptroniksInst0% (1)

- ME 1402 - Mechatronics PDFDocument6 pagesME 1402 - Mechatronics PDFnagarajanceNo ratings yet

- 87 Catalog Invertere Ic5Document19 pages87 Catalog Invertere Ic5vga1234No ratings yet

- PLC Training LiteratureDocument45 pagesPLC Training Literaturealex2gustavo2cuevas2No ratings yet

- Servo Motors Q&A Prepared By: Eng. Ahmed SalehDocument4 pagesServo Motors Q&A Prepared By: Eng. Ahmed SalehAhmed AlnagarNo ratings yet

- Microprocessor and Microcontrollers (Credits: Theory-04, Practicals-02) Theory Lectures 60Document4 pagesMicroprocessor and Microcontrollers (Credits: Theory-04, Practicals-02) Theory Lectures 60Jasvinder kourNo ratings yet

- c11gs-r1 5 User ManualDocument21 pagesc11gs-r1 5 User Manualcastellano_rNo ratings yet

- F MC-16F MB90220 Series: 16-Bit Proprietary MicrocontrollerDocument105 pagesF MC-16F MB90220 Series: 16-Bit Proprietary MicrocontrollerTriman TelaumbanuaNo ratings yet

- ABB VFD Operation Manual - v1.2Document22 pagesABB VFD Operation Manual - v1.2Yuriy LobanovNo ratings yet

- The CNC h4 SystemDocument8 pagesThe CNC h4 SystemRobert GiangNo ratings yet

- 4104euen PLC Overview 0Document64 pages4104euen PLC Overview 0ludek_bartakNo ratings yet

- MAN B W ME-C-based Control of The Host AnalysisDocument11 pagesMAN B W ME-C-based Control of The Host AnalysisaloordominicNo ratings yet

- Hritik Baral - ES - CaseStudyDocument10 pagesHritik Baral - ES - CaseStudyHemanga RanaNo ratings yet

- Stepper Motor ReportDocument13 pagesStepper Motor ReportVolda0% (2)

- Specification Intro OverviewDocument2 pagesSpecification Intro OverviewQuantumAutomationNo ratings yet

- 1 - Power Electronics CatalogueDocument83 pages1 - Power Electronics CataloguerockNo ratings yet

- 236 MR-C MitsubishiDocument10 pages236 MR-C MitsubishiemtelesNo ratings yet

- Four-Quadrant: Dynamometer/Power Supply MODEL 8960Document16 pagesFour-Quadrant: Dynamometer/Power Supply MODEL 8960Jose Angel Puente PuenteNo ratings yet

- Dsa 5600 - Fresa CNCDocument12 pagesDsa 5600 - Fresa CNCxemante50% (2)

- Ecu Sensor Simulation mst9000 InstructionDocument9 pagesEcu Sensor Simulation mst9000 InstructionJorge EspinoNo ratings yet

- Komatsu EgseDocument6 pagesKomatsu EgseAllan Rey FernandezNo ratings yet

- ME 1402 - Mechatronics PDFDocument6 pagesME 1402 - Mechatronics PDFHiru Purushothaman HirudayanathanNo ratings yet

- Fanuc Oi PDFDocument16 pagesFanuc Oi PDFGuillermo Ramirez100% (1)

- 1 Cam IntroDocument10 pages1 Cam IntroDarshan SoniNo ratings yet

- Mpc860 Powerquicc™ Family User'S Manual: SupportsDocument1,320 pagesMpc860 Powerquicc™ Family User'S Manual: SupportsNaresh BopparathiNo ratings yet

- MC9S08QE32RMDocument306 pagesMC9S08QE32RMTato527No ratings yet

- CNC IntroductionDocument24 pagesCNC IntroductionaravindanNo ratings yet

- Control System Based On PLC For WindingDocument4 pagesControl System Based On PLC For WindinghanzrizNo ratings yet

- Multivariable Predictive Control: Applications in IndustryFrom EverandMultivariable Predictive Control: Applications in IndustryNo ratings yet

- Multicore DSP: From Algorithms to Real-time Implementation on the TMS320C66x SoCFrom EverandMulticore DSP: From Algorithms to Real-time Implementation on the TMS320C66x SoCNo ratings yet

- AC Electric Motors Control: Advanced Design Techniques and ApplicationsFrom EverandAC Electric Motors Control: Advanced Design Techniques and ApplicationsFouad GiriNo ratings yet

- Model Predictive Control of High Power Converters and Industrial DrivesFrom EverandModel Predictive Control of High Power Converters and Industrial DrivesNo ratings yet

- MAX2021Document20 pagesMAX2021Abraham GutierrezNo ratings yet

- 2022COAZ4027Document123 pages2022COAZ4027Abraham GutierrezNo ratings yet

- Motherboard BatteriesDocument4 pagesMotherboard BatteriesAbraham GutierrezNo ratings yet

- OpenocdDocument232 pagesOpenocdAbraham GutierrezNo ratings yet

- PL Nu'Yua: 'Uq Au) A ' Eybx - (Qabys SqauDocument5 pagesPL Nu'Yua: 'Uq Au) A ' Eybx - (Qabys SqauAbraham GutierrezNo ratings yet

- ComponentesDocument7 pagesComponentesAbraham GutierrezNo ratings yet

- M5L8042 146PDocument7 pagesM5L8042 146PAbraham GutierrezNo ratings yet

- I JTL:: 5HB: F-03 FuseDocument2 pagesI JTL:: 5HB: F-03 FuseAbraham GutierrezNo ratings yet

- 7293-Article Text-10523-1-10-20200601Document12 pages7293-Article Text-10523-1-10-20200601Abraham GutierrezNo ratings yet

- RJK0631JPD RenesasDocument7 pagesRJK0631JPD RenesasAbraham GutierrezNo ratings yet

- STM 32 WB 55 RGDocument8 pagesSTM 32 WB 55 RGAbraham GutierrezNo ratings yet

- Chaves 2016Document67 pagesChaves 2016Abraham GutierrezNo ratings yet

- 27c210a 15Document29 pages27c210a 15Abraham GutierrezNo ratings yet

- HSS60Document6 pagesHSS60Abraham GutierrezNo ratings yet

- Materials 15 00513 v2Document14 pagesMaterials 15 00513 v2Abraham GutierrezNo ratings yet

- As PDF Mitsubishi EdmDocument67 pagesAs PDF Mitsubishi EdmAbraham GutierrezNo ratings yet

- TEMPORALDocument1 pageTEMPORALAbraham GutierrezNo ratings yet

- Wots Wha-217 E2Document8 pagesWots Wha-217 E2Abraham GutierrezNo ratings yet

- Competence Format ExampleDocument10 pagesCompetence Format ExampleAbraham GutierrezNo ratings yet

- Irs2186/Irs21864 (S) PBF: High and Low Side DriverDocument23 pagesIrs2186/Irs21864 (S) PBF: High and Low Side DriverAbraham GutierrezNo ratings yet

- UM1690 User Manual: Discovery Kit For STM32 F0 Series With STM32F072RB MCUDocument31 pagesUM1690 User Manual: Discovery Kit For STM32 F0 Series With STM32F072RB MCUAbraham GutierrezNo ratings yet

- MUR6040 Switchmode Power Rectifier: Ultrafast Rectifier 60 Amperes 400 VOLTSDocument4 pagesMUR6040 Switchmode Power Rectifier: Ultrafast Rectifier 60 Amperes 400 VOLTSAbraham GutierrezNo ratings yet

- Active Gate Voltage Control of Turn-On$di/dt$and Turn-Off$dv/dt$in Insulated Gate TransistorsDocument8 pagesActive Gate Voltage Control of Turn-On$di/dt$and Turn-Off$dv/dt$in Insulated Gate TransistorsAbraham GutierrezNo ratings yet

- CM200DY-12H: 200 Amperes/600 VoltsDocument4 pagesCM200DY-12H: 200 Amperes/600 VoltsAbraham GutierrezNo ratings yet

- Page 1 of 15Document15 pagesPage 1 of 15Abraham GutierrezNo ratings yet

- IGBT ThermalDocument14 pagesIGBT ThermalAbraham GutierrezNo ratings yet

- Folding Carton Manufacturing: Intelligent Solutions For State-Of-The-Art Production ProcessesDocument8 pagesFolding Carton Manufacturing: Intelligent Solutions For State-Of-The-Art Production Processesmanuel estradaNo ratings yet

- General Mathematics 11 2019 - 2020Document6 pagesGeneral Mathematics 11 2019 - 2020Dinmar DurendesNo ratings yet

- Cyber Security (Open Elective) ObjectivesDocument2 pagesCyber Security (Open Elective) Objectivessriramganesh81070% (1)

- Min Terms and MaxtermsDocument10 pagesMin Terms and MaxtermsMARUPAKA BHARGAV ANAND BU21CSEN0400111No ratings yet

- Sri Lanka Trade and Information PDFDocument7 pagesSri Lanka Trade and Information PDFDurban Chamber of Commerce and IndustryNo ratings yet

- Output 1 in Third QuarterDocument3 pagesOutput 1 in Third QuarterRodepe CamposanoNo ratings yet

- MBA105 - Almario - Parco - Assignment 1Document14 pagesMBA105 - Almario - Parco - Assignment 1nicolaus copernicusNo ratings yet

- Dbms NotesDocument48 pagesDbms NotesSHIWANI PAL CS-18No ratings yet

- Data Collection GuideDocument16 pagesData Collection GuideŞansal Dikmener100% (1)

- 90.25772-BLMS GDC-051 As BuiltDocument26 pages90.25772-BLMS GDC-051 As BuiltValipireddy Nagarjun100% (1)

- k3fDV2A SheetDocument2 pagesk3fDV2A SheetAlNo ratings yet

- Experiment 8Document19 pagesExperiment 8HAIKAL MUZAFFAR AZAMNo ratings yet

- ProfiLux 3.1T ManualDocument20 pagesProfiLux 3.1T Manualjuanjo19911991No ratings yet

- Yaesu Vertex VRX-1000 VHF Version Service ManualDocument48 pagesYaesu Vertex VRX-1000 VHF Version Service ManualIWNo ratings yet

- AZ 305+Official+Course+Study+GuideDocument14 pagesAZ 305+Official+Course+Study+GuideHeilly JerivethNo ratings yet

- Life, Life - Selected Poems by Arseny TarkovskyDocument5 pagesLife, Life - Selected Poems by Arseny Tarkovskyignoramus83No ratings yet

- DBMS Unit 5Document43 pagesDBMS Unit 5abhivardhan786No ratings yet

- RFQ Index HVDC WolaytaDocument5 pagesRFQ Index HVDC WolaytaS Rao CheepuriNo ratings yet

- DxdiagDocument50 pagesDxdiagJohn DulayNo ratings yet

- 4730-3 BLUM IF59 Installation Instructions 180168 Rev0-2 0-2Document48 pages4730-3 BLUM IF59 Installation Instructions 180168 Rev0-2 0-2Олег ЕфимовNo ratings yet

- TM1 User GuideDocument253 pagesTM1 User GuideJW LeeNo ratings yet

- Vue-Doc-Preview: ImportDocument4 pagesVue-Doc-Preview: ImportLucas DadegnonNo ratings yet

- Geforce 9600 GT: 512Mb (256bit) Graphics CardDocument2 pagesGeforce 9600 GT: 512Mb (256bit) Graphics CardTan Hung LuuNo ratings yet

- Notebook: COD Grupa Producator Descriere Pret Cu Tva Garantie DisponibilitateDocument191 pagesNotebook: COD Grupa Producator Descriere Pret Cu Tva Garantie DisponibilitatenelubobinaNo ratings yet

- IBM - IBM Storage Scale 5.1.9 Problem Determination Guide (2024)Document1,008 pagesIBM - IBM Storage Scale 5.1.9 Problem Determination Guide (2024)Ramon BarriosNo ratings yet

- Kingston SSD Manager User GuideDocument6 pagesKingston SSD Manager User GuideYudi Sintia WijayaNo ratings yet

- Nexus VPCDocument11 pagesNexus VPCNdaru Prakoso100% (1)

- Guia de Inicio Rapido Picus-y-Picus-NxT-Pipetas-electrónicasDocument2 pagesGuia de Inicio Rapido Picus-y-Picus-NxT-Pipetas-electrónicasnimsi encisoNo ratings yet