Professional Documents

Culture Documents

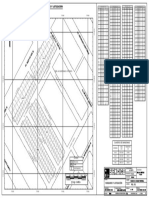

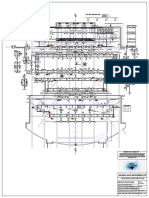

General Construction Notes: Typical Column Elev. Showing Dowels and Ties Spacing

General Construction Notes: Typical Column Elev. Showing Dowels and Ties Spacing

Uploaded by

Christian Kyle BeltranOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

General Construction Notes: Typical Column Elev. Showing Dowels and Ties Spacing

General Construction Notes: Typical Column Elev. Showing Dowels and Ties Spacing

Uploaded by

Christian Kyle BeltranCopyright:

Available Formats

GENERAL NOTES

GENERAL CONSTRUCTION NOTES

NOTES ON CONCRETE MIXES & PLACING

TABLE 'A'

TENSION BARS

TABLE OF LAP SPLICE & ANCHORAGE LENGTH (mm)

TABLE 'B'

COMPRESSION BARS

TABLE OF LAP SPLICE & ANCHORAGE LENGTH (mm)

CONF. REINF.

JOINT HOOP SPACE @ "2Sh" WHEN

1. ALL CONCRETE SHALL DEVELOP A MIN. COMPRESSIVE STRENGTH AT THE END OF TWENTY EIGHT 3. IF SLABS AR E REINFORCED BOTHWAYS BARS ALONG THE SHORTER SPAN SHALL BE PLACED BAR SIZES fc`= 20.7MPa(300psi) fc`= 27.6 MPa (4000psi) BAR SIZES fc`= 20.7MPa(300psi) fc`= 27.6 MPa (4000psi)

1.0 STANDARDS AND REFERENCES THERE ARE BEAMS HAVING WIDTH OF (DEFORMED MM) (DEFORMED MM)

(28) DAYS W/ CORRESPONDING MAXIMUM SIZE AGGREGATE & SLUMP AS FOLLOWS. BELOW THOSE ALONE THE LONG SPAN AT THE CENTER AND OVER THE LONGER SPAN FOR EMBEDMENT LAPPED EMBEDMENT LAPPED EMBEDMENT LAPPED EMBEDMENT LAPPED

D JOINT REINF. D

AT LEAST ONE-HALF THE COLUMN

THE FOLLOWING SHALL GOVERN THE DESIGN FABRICATION AND CONSTRUCTION OF THE PROJECT.

MAX. SIZE OF REINFORCING BARS NEAR THE SUPPORTS. THE SPACING OF THE BARS AT THE COLUMN STRIPS WIDTH & DEPTHS NOT LESS THAN Ø10 300 300 300 300 Ø10 225 300 200 300

1.1 NATIONAL STRUCTURAL CODE OF THE PHILIPPINES (N.S.C.P 2015) VOL. 1, SEVENTH EDITION. LOCATION 28 DAYS STRENGTH MAX SLUMP SHALL NOT BE MORE THAN ONE AND A HALF ( 1 12 ) SLAB THICKNESS. THREE QUARTERS OF THE DEEPEST

AGGREGATE Ø12 300 300 300 300 Ø12 275 300 250 300

BEAM THAT FRAME INTO FOUR

CONF. REINF.

2.0 DESIGN CRITERIA ALL OTHERS, INCLUDING 20 mm 100mm 4. TEMPERATURE BARS FOR SLAB SHALL BE GENERALLY PLACED NEAR THE FACE IN TENSION AND SIDES OF THE COLUMN. ALL OTHER

Ø16 300 400 300 400 Ø16 350 400 325 400

4000 PSI (27.6 MPa) Ø20 400 550 350 500 Ø20 450 500 475 500

2.1 LOADINGS SUSPENDED SLABS SHALL NOT BE LESS THAN 0.0025 X GROSS-SECTIONAL AREA (Ag) OF THE SLAB. CONDITIONS USE HOOPS @ "Sh" CENTERS.

Sh

Ø25 600 800 550 750 Ø25 550 625 550 625

COLUMNS 4000 PSI (27.6 MPa) 20 mm 100mm ( SEE SCHEDULE BELOW)

A. DEAD LOAD

BEAMS 4000 PSI (27.6 MPa) 20 mm 100mm Ø28 750 1000 650 850 Ø28 625 675 625 675

COLUMN TIES AS

3

PER SCHEDULE

CONCRETE 23.56 kN/m 20 mm 100mm Ø32 950 1300 850 1100 Ø32 700 775 700 775

SLAB ON FILL 2500 PSI (17.5 MPa) SCHEDULE OF MINIMUM SLAB REINFORCEMENT FOR COL. BAR SPLICES SEE TABLE

STEEL 76.93 kN/m3

MINIMUM TEMPERATURE BARS OF MIN. LAP SPLICE LENGTH OF

150 mm THK. CHB WALL 2.73 kPa 2. MAINTAIN MINIMUM CONCRETE COVER FOR REINFORCING STEEL AS FOLLOWS. NOTES: NOTES:

COLUMN REINFORCEMENT 1. TOP PLAIN BARS, MULTIPLY VALUE BY 2 1. TOP PLAIN BARS, MULTIPLY VALUE BY 2

100 mm THK. CHB WALL 2.11 kPa SUSPENDED SLABS 20mm 100 mm 10mm Ø @ 250mm EACH WAY 2. NOT MORE THAN 33% OF THE BARS SHALL BE 2. NOT MORE THAN 33% OF THE BARS SHALL BE

40mm

CONF. REINF.

SPLICED WITHIN THE REQUIRED LAP LENGTH SPLICED WITHIN THE REQUIRED LAP LENGTH

B. LIVE LOAD SLAB ON GRADE 125 mm 10mm Ø @ 250mm EACH WAY 3. VALUES GIVEN ABOVE CAN ALSO BE USED FOR COLUMNS

WALLS ABOVE THE GRADE 25mm

Sh

ROOF 1.00 kPa 150 mm 10mm Ø @ 250mm EACH WAY

D JOINT REINF. D

BEAM STIRRUPS AND COLUMN TIES 40mm

CLASSROOMS 1.90 kPa 175 mm 10mm Ø @ 250mm EACH WAY NOTE:

WHERE CONCRETE IS EXPOSED TO

TOILETS 1.90 kPa 200 mm 10mm Ø @ 250mm EACH WAY ALL CONCRETE REINF. DETAIL SHOULD

EARTH BUT POURED AGAINST FORMS 50mm BE DONE IN ACCORDANCE WITH ACI 3. IF THE BEAM REINFORCING BARS END IN A WALL, THE CLEAR DISTANCE FROM THE BAR TO THE FARTHER FACE OF THE

CORRIDORS ABOVE, STAIRS 3.80 kPa

WHERE CONCRETE IS DEPOSITED DETAILING MANUAL (LATEST EDITION) WALL IS NOT LESS THAN 25mm. EMBEDMENT LENGTH SHALL BE SHOWN IN A TABLE 'A' FOR TENSION BARS AND TABLE 'B'

CONF. REINF.

CORRIDORS ON GROUND 4.80 kPa 75mm 5. UNLESS OTHERWISE NOTED IN THE PLANS ALL BEDDED SLABS SHALL BE REINFORCED WITH 10mm Ø

DIRECTLY AGAINST EARTH FOR COMPRESSION BARS UNLESS UNLESS SPECIFIED IN PLAN. TOP BARS AND SHALL NOT BE SPLICED WITHIN THE

C. WIND LOAD AT 250mm O.C. EACH WAY TO CENTER OF SLAB AND CONSTRUCTION JOINTS FOR SAME SHALL

COLUMN OR TWO STIRRUPS SHALL BE PROVED AT ALL SPLICES.

BUILDING CATEGORY = 1 (ESSENTIAL FACILITIES) NOT BE LESS THAN 3.65 METER APART.

3. CONCRETE SHALL BE DEPOSITED IN ITS FINAL POSISITON WITHOUT SEGREGATION. RE-HANDLING 4. IF THERE ARE TWO OR MORE LAYERS OF REINFORCING BARS, USED 25mm BAR SEPARATORS SPACED AT 1.0M ON

OPTION 1 OPTION 2 OR PLACING SHALL BE DONE PREFERABLY WITH BUGGIES , BUCKETS OR WHEELBARROWS, 6. PROVIDE EXTRA REINFORCEMENTS FOR CORNER SLAB ( TWO ADJACENT DISCONTINUOES EDGES) ON CENTER ON NO CASE SHALL THERE BE THAN TWO (2) SEPARATORS BETWEEN LAYERS OF BARS

EXPOSURE CAT. (FLAT UNOBSTRUCTED AREAS AND/OR (URBAN OR SUBURBAN AREAS WITH NO CHUTES WILL BE ALLOWED EXCEPT TO TRANSFER CONCRETE FROM HOPPERS TO BUIGGIES, AS SHOWN BELOW. TYPICAL COLUMN ELEV. SHOWING

D NEAR BODIES OF WATER) B NUMEROUS CLOSELY SPACED OBSTRUCTIONS) 5. MINIMUM CONCRETE PROTECTION FOR REINFORCING BARS OR STEEL SHAPES SHALL BE AS SHOWN IN FIGURE B-2

WHEELBARROWS OR BUCKETS IN WHICH CASE THEY SHALL NOT EXCEED SIX (6) METERS 7. CONCRETE SLAB REINFORCEMENT BE PROPERLY SUPPORTED WITH 10mm STEEL CHAIR

WIND VELOCITY V=340 KPH V=270 KPH DOWELS AND TIES SPACING UNLESS ELSEWHERE.

IN AGGREGATE LENGTH. OR APPROVED EQUIVALENT SPACED AT 1.0 METER ON CENTER BOTHWAYS.

P = qh [(GCpf)-(GCpi)] (DESIGN WIND PRESSURE) Ø12x1000 LONG AT

4. NO DEPOSITING OF CONCRETE SHALL BE ALLOWED WITHOUT THE USE OF VIBRATORS UNLESS MID-DEPTH OF SLAB

WHERE: qh = VELOCITY PRESSURE (kPa) AUTHORIZED IN WRITING DESIGNER AND ONLY FOR UNUSUAL CONDITIONS WHERE VIBRATIONS MAIN REINFORCEMENT MAIN REINFORCEMENT

GCpf = EXTERNAL PRESSURE COFFECIENT ARE EXTREMELY DIFFICULT TO ACCOMPLISH. LAP SPLICE LENGTH:

DOWN INTO EDGE BEAM. EXTENDED AT EACH CORNER

t OR 1/4 D

t OR 1/4 D

GCpf = INTERNAL PRESSURE COFFECIENT 4-Ø 12@ 1800 LONG TOP BARS BEND AT ANY LEVEL NO MORE THAN SLEEVES FOR UTILITY

5. ALL ANCHOR BOLTS, DOWELS, AND OTHER INSERTS SHALL BE PROPERLY POSITIONED & SECURED 1-Ø12 TOP & SLEEVES FOR UTILITY

t

BARS MIN. OF 1,200 (4'-0") INTO BARS. BOTT. BARS ALTERNATE BARS SHOULD BE PIPES MAX. 1/5 D PIPES MAX. 1/5 D

D

D. SEISMIC LOAD IN PLACE PRIOR TO PLACING OF CONCRETE. SPLICED. MIN. DISTANCE BET.

Cvl W 6. ALL CONCRETE SHALL BE KEPT MOST FOR A MINIMUM OF SEVEN CONSECUTIVE DAYS IMMEDIATELY 4-Ø12 BOTT. BARS TWO ADJACENT BARS SPLICES

V= (DESIGN BASE SHEAR) PROVIDE 3-Ø10 EXTRA STIRR. PROVIDE 3-Ø10 EXTRA STIRR.

400

RT AFTER POURING BY THE USE O WET BURLAP, FOG SPRAYING, CURING COMPOUNDS OR OTHER SHALL BE 600mm. EACH SIDE OF SLEEVES EACH SIDE OF SLEEVES

CONF. REINF. TIES LAT. TIES H (CLEAR HEIGHT OF COL.)

APPROVED METHODS.

Vmax = 2.50CaI W Vmin = 0.11 CalW 60

0

L

RT 7. STRIPPING OF FORMS AND SHORES: SLAB 38mm

TYP. DET. FOR SLEEVES TYP. DET. FOR SLEEVES

Vmin = 0.80 ZNvI W

0

CLEAR

WITHIN CENTER

(ZONE 4) 24 HOURS OPENING

60

FOUNDATION

HALF OF "H"

R THRU CONCRETE BEAM THRU CONCRETE BEAM

SUSPENDED SLAB EXCEPT WHEN 8 DAYS 0.25L

WHERE: W = TOTAL DEAD LOAD

400

ADDITIONAL LOADS ARE IMPOSED FIG. B-2 FIG. B-3

T = NATURAL PERIOD = Ct (h) 21 DAYS TOP BARS @ SUPPORT (CONT.)

WALLS

WHERE: C = NUMERICAL COEFFICIENT REQ'D. BOTT. BARS @ SUPPORT

BEAMS 14 DAYS IN TWO WAY SLAB EXTEND

JT. REINF.

h = BUILDING HEIGHT COLUMNS 21 DAYS 60 BARS UP TO BEAM SUPPORT

0

I = IMPORTANCE FACTOR = 1.50 6. WHEN A BEAM CROSSES A GIRDER , REST BEAM ON TOP OF GIRDER BARS, BEAM REINFORCING BARS SHALL BE

8. THE CONTRACTOR SHALL SUBMIT THE SCHEDULE OF POURING AND THE LOCATION OF THE OMIT TRIMMER BARS WHERE

R = NUMERICAL FACTOR = 8.50 OPENING IS FRAMED BY BEAM SYMMETRICAL ABOUT THE CENTER LINE WHENEVER POSSIBLE.

SEISMIC COEFFICIENT Cv = 0.44 Nv CONSTRUCTION JOINTS TO THE STRUCTURAL ENGINEER AT LEAST (4) DAYS PRIOR TO THE TYPICAL CORNER SLAB DETAIL 7. GENERALLY, NO SPLICES SHALL BE PERMITTED AT POINTS WHERE CRITICAL BENDING STRESSES OCCUR, SPLICES

Ca = 0.64 Nv POURING FOR APPROVAL. TYPICAL SLAB BOTTOM BARS WHERE SO PERMITTED SHALL BE INDICATED IN TABLE 'A' AND 'B'. WELDED SPLICES SHALL DEVELOP IN TENSION AT

0.165L SPLICE AT MID SPAN

NEAR SOURCE FACTOR (5 km) Nv = 1.6 9. THE CONTRACTOR SHALL FURNISH AND MAITAIN ADEQUATE FORMS AND SHORINGS UNTIL THE OPENING DET. EXTRA TOP BARS

LEAST 125% OF THE SPLICED YIELD STRENGTH OF THE BAR NOT MORE THAN 50% OF THE BARS AT ANY ONE SECTION

Na = 1.2 0.22L

CONCRETE MEMBERS HAVE ATTAINED THEIR WORKING CONDITION AND STRENGTH. NOTES ON COLUMNS @ SUPPORT IS ALLOWED TO BE SPLICED THEREIN.

Z = SEISMIC ZONE = 0.40 (ZONE 4)

S = SOIL TYPE = D 1. PROVIDE EXTRA SETS OF TIES AT 100 O.C. FOR TIED COLUMN REINFORCEMENT ABOVE

NOTES ON FOOTINGS AND BELOW BEAM-COLUMN CONNECTIONS FOR A DISTANCE FROM FACE OF CONNECTION

2.2 DESIGN STRESSES 1. FOOTINGS ARE DESIGNED FOR AN ALLOWANCE SOIL BEARING PRESSURE OF 96 KPa (2000psf). EQUAL TO GREATER OF THE OVERALL THICKNESS OF COLUMN, 1/6 THE CLEAR HEIGHT OF TYP. DETAIL OF COL. LAP SPLICE NOTES ON CONCRETE HOLLOW BLOCKS WALLS

A. CONCRETE COMPRESSIVE STRENGTH @ 28 DAYS: CONTRACTOR SHALL REPORT TO THE ENGINEER, IN WRITING ,THE ACTUAL SOIL CONDITIONS COLUMN OR 450mm.

a. FOOTINGS, COLUMNS, BEAMS AND SLABS f'c = 27.6 MPa (4,000 psi) UNCOVERED AND CONFIRM ACTUAL BEARING CAPACITY OF SOIL BEFORE DEPOSITING CONCRETE. COLUMN TIES SHALL BE PROTECTED EVERYWHERE BY A COVERING OF CONCRETE CAST

& EXT. GIRDER TO COL. CONNECT. 1. UNLESS OTHERWISE SHOWN IN PLANS ALL CONCRETE HOLLOW BLOCKS AND CERAMIC BLOCKS SHALL BE REINFORCED

2. FOOTING SHALL REST AT LEAST 1500mm BELOW NATURAL GRADE LINE UNLESS OTHERWISE AS SHOWN IN THE SCHEDULE OF CONCRETE HOLLOW BLOCKS AND CERAMIC BLOCK REINFORCEMENT.

b. SLAB ON FILL f'c = 17.5 MPa (2,500 psi) MONOLITHICALLY WIT HTHE CORE WITH A MINIMUM THICKNESS OF 40mm AND NOT LESS

C. SLAB f'c = 27.6 MPa (4,000 psi) INDICATED IN PLANS. NO FOOTING SHALL REST ON FILL 2. THAN 40 TIMES THE MAXIMUM SIZE OF COARSE AGGREGATE IN MILLIMETERS. NOTES ON BEAMS AND GIRDERS 2. PROVIDE 150mm x 300mm STIFFENER COLUMN REINFORCED WITH 4-12mm WITH 10mm Ø TIES AT 150mm ON CENTER

3. MINIMUM CONCRETE PROTECTION FOR REINFORCEMENT SHALL BE 75mm CLEAR FOR CONCRETE WHERE CONCRETE HOLLOW BLOCK TERMINATES AND AT EVERY 3.0M LENGTH OF CONCRETE HOLLOW BLOCK

B. REINFORCING STEEL BARS WHERE COLUMNS CHANGE IN SIZE ,VERTICAL REINFORCEMENT SHALL BE OFFSET AT A 1. UNLESS, OTHERWISE NOTED IN PLANS , CAMBER ALL BEAMS AND GIRDER AT WALLS UNLESS NOTED IN STRUCTURAL PLANS.

DEPOSITED THE GROUND AND 50mm FOR CONCRETE DEPOSITED AGAINST A FORMWORK.

a. FOR BARS 16mm AND GREATER (INTERMEDIATE GRADE DEFORMED BAR) fy = 414 MPa (60,000 psi) SLOPE MONOLITHICALLY WITH THE CORE WITH MINIMUM THICKNESS OF 40mm AND LEAST 6mmØ FOR EVERY 4.5O M OF SPAN , EXCEPT CANTILEVERS FOR WHICH

4. IN CASES WHERE THE SOIL CONDITION IS SUCH THAT THE MINIMUM ALLOWABLE SOIL PRESSURE

b. FOR BARS LESS THAN 16mm (STRUCTURAL GRADE DEFORMED BAR) fy = 275 MPa (40,000 psi) 3. NOT LESS THAN 40 TIMES THE MAXIMUM SIZE COARSE AGGREGATE IN MILLIMETERS THE CAMBER SHALL BE AS NOTED IN PLANS OR AS ORDERED BY THE ENGINEER

OF 96KPa (2000 psf) CAN NOT BE ATTAINED AT A PRACTICAL DEPTHS THE USE OF MICROPILES ,

C. STRUCTURAL STEEL ASTM-A36 UNLESS OTHERWISE INDICATED IN THE PLANS, LAP SPLICES FOR VERTICAL COLUMN BUT IN NO CASE LESS THAN 20 mm FOR EVERY 3.0 M OF FREE SPAN.

BORED PILES, OR DRIVEN PILES MAY BE ADOPTED IN LIEU OF STANDARD ISOLATED FOOTINGS.

FOR TRUSSES, BRACINGS , & STRUTS fy = 248 MPa (36,000 psi) NOTES ON CONCRETE HOLLOW BLOCKS WALLS REINFORCEMENTS

REINFORCEMENT SHALL BE MADE WITHIN THE CENTER HALF OF COLUMN HEIGHT, AND 2. TYPICAL BARS BENDING AND CUTTING DETAILS FOR BEAMS SHALL BE AS

D. PURLINS 4. THE SPLICE LENGTH SHALL BE LESS THAN 40 BAR DIAMETERS. WELDING OR APPROVED SHOWN IN FIG. B-1 BLOCK THICKNESS REINFORCEMENT

COLD FORMED LIGHT fy = 248 MPa (36,000 psi) NOTES ON REINFORCEMENT MECHANICAL DEVICES MAY BE USED PROVIDED THAT NOT MORE THAN ALTERNATE BARS L1 L2

NOTES

E. MASONRY UNIT (CHB) HORIZONTAL LAPPED A. MINIMUM LAPS AT SPLICE= 0.25 M

1. UNLESS OTHERWISE NOTED IN PLANS, THE YIELD STRENGTH OF REINFORCING BARS SHALL BE: ARE WELDED OR MECHANICALLY SPLICED AT ANY LEVEL AND THE VERTICAL DISTANCES 1 1 1 1

NON - LOADING BEARING CHB WALLS fm' = 3.45 MPa (500 psi) fy = 414 MPa ( 60,000 psi ) L1 3 L1 3 L2 3 L2 3

A. FOOTINGS , FOOTING BEAMS AND GIRDERS BETWEEN THESE WELDS OR SPLICES OF ADJACENT BARS IS NOT LESS THAN 600mm. 75 mm 10mm Ø EVERY 3RD LEVEL 10mm Ø @ 600mm O.C. B. PROVIDE RIGHT ANGLED REINFORCEMENT

F. WELDS E - 60XX ELECTRODE fy = 414 MPa ( 60,000 psi ) AT CORNERS 0.92 m LONG

B. COLUMNS AND SHEAR WALLS 125 mm

G. STRUCTURAL BOLTS ASTM- A307 a. Ft = 96.60 mPa (14, 000 psi) 10mm Ø EVERY 3RD LEVEL 10mm Ø @ 600mm O.C.

C. BEAMS AND GIRDER fy = 414 MPa ( 60,000 psi ) C.WHERE CHB OR CER. BLK. WALL DOWELS

b. Fv= 69.00 mPa (10, 000 psi) 150mm 10mm Ø EVERY 3RD LEVEL 10mm Ø @ 600mm O.C. WITH THE SAME SIZE AS VER. OR HOR.

3.0 IN THE INTERPRETATION OF THE DRAWING, INDICATED DIMENSIONS SHALL GOVERN. D. NON-LOAD BEARING WALL PARTITIONS ,BEDDED SLABS , FLOOR & ROOF SLABS,

PARAPETS ,CATCH BASIN,SIDE WALK 4-Ø16 VERT. BARS REINFORCEMENT SHALL BE PROVIDED

fy = 275 MPa ( 40,000 psi ) 200 mm 12mm Ø EVERY 3RD LEVEL 10mm Ø @ 600mm O.C.

DISTANCES AND SIZES SHALL NOT BE SCALED FOR CONSTRUCTIONS PURPOSES 4-Ø16 VERT. BARS

550

2. ALL REINFORCING BARS SIZE 10mm OR LARGER SHALL BE DEFORMED IN ACCORDANCE WITH THE ASTM A-706 1 1 1 1

550

4.0 IN REFERENCES TO OTHER DRAWINGS, SEE ARCHITECTURAL DRAWINGS FOR DEPRESSIONS IN FLOOR BARS SMALLER THAN 10mm MAY BE PLAIN. L1 5 L1 5 L2 5

TOP BARS

L2 5

SLABS , OPENINGS IN THE WALLS AND SLABS , INTERIOR PARTITIONS , LOCATIONS OF DRAINS ETC. 3. SPLICES SHALL BE SECURELY WIRED TOGETHER & SHALL LAP OR EXTEND IN ACCORDANCE w/ TABLE B 2 Ø 12mm SIDE BARS WEB BARS SEE CONSTRUCTION NOTES

5.0 IN CASE OF DISCREPANCIES AS TO THE LAYOUT, DIMENSIONS AND ELEVATIONS BETWEEN THE (TABLE OF LAP SPLICE & ANCHORAGE LENGTH) UNLESS OTHERWISE SHOWNON DRAWINGS , SPLICES SHALL BE BOTTOM BARS FOR MASONRY WALL REIN-

STAGGERED WHENEVER POSSIBLE. 550 FORCEMENTS (TYPICAL)

STRUCTURAL PLANS AND ARCHITECTURAL DRAWINGS, THE CONTRACTORS SHALL NOTIFY BOTH THE 550

FIGURE B-1 FIN. FLR. LVL.

VARIES

6.0 ALL CONCRETE WORKS AND CONCRETE REINFORCEMENTS SHALL BE DONE IN ACCORDANCE WITH THE

ACI.318-14M BUILDING CODE REQUIREMENT AND ALL STRUCTURAL STEEL WORKS ACCORDING WITH THE NOTES ON CONCRETE SLABS TYPICAL CONNECTION DETAIL MAIN BAR END HOOKS NAT. GRD. LVL.

(ALL GRADES) DOWEL BARS TO MATCH

WITH THE AISC-05 IN SOFAR AS THEY DO NOT CONFLICT WITH THE LOCAL BUILDING CODE REQUIREMENT. 1. ALL SLAB REINFORCEMENTS SHALL BE 20mm CLEAR MINIMUM FROM BOTTOM AND FROM THE TOP OF SLAB. CHB VERTICAL BARS

600 (MIN.)

OF R.C. WALL AT CORNERS NOTES ON STIRUPS BAR SIZE DIAMETER 180° HOOK 90° HOOK

Ø10 BOTT. BARS

7.0 ACI REFERS TO AMERICAN CONCRETE INSTITUTE, AISC REFERS TO AMERICAN INSTITUTE OF STEEL 2. UNLESS OTHERWISE SHOWN, REINFORCEMENT IN CONTINUOUS ELEVETED SLAB SHALL BE CUT AS FOLLOWS: (DEFORMED) (mm) @ 300 O.C.

1. ALL REINFORCEMENT SHALL BE BENT COLD UNLESS

250

D+2db L L

CONSTRUCTION AND ASTM REFERS TO AMERICAN SOCIETY FOR TESTING MATERIALS. BENT BAR H 3-Ø10 BOTT. BARS

OTHERWISE PERMITTED BY THE STRUCTURAL ENGINEER. 10 mm Ø 60 75 125 150

8.0 CONSTURCTION NOTES AND TYPICAL DETAILS APPLY TO ALL DRAWINGS UNLESS OTHERWISE SHOWN OR L1 L2 CROSS-TIE NOTES ON WELDS 2. AS SHOWN IN THE DESIGN DRAWINGS OR 12 mm Ø 75 100 150 200

NOTED. MODIFY TYPICAL DETAILS AS DIRECTED TO MEET SPECIAL CONDITIONS. L1/4 L1/4 PERMITTED BY THE STRUCTURAL ENGINEER. 400

350mm. MAX.

L2/4 1. USE E60xx ELECTRODES FOR ALL MEMBERS WELDED. 16 mm Ø 95 125 175 250

TOP BAR 3. TIES & CLOSE STIRRUPS MUST BE AT 135.

9.0 SHOP DRAWING WITH ERECTION AND PLACING DIAGRAMS OF ALL STRUCTURAL STEELS, MISCELLANEOUS 2. WELDS SHALL DEVELOP THE FULL STRENGTH OF MEMBERS JOINED UNLESS 20 mm Ø 115 150 200 300

DOWEL TO MATCH

IRON, PRE-CAST CONCRETE, ETC. SHALL BE SUBMITTED FOR ENGINEERS APPROVAL BEFORE FABRICATION. OTHERWISE SHOWN OR DETAILED IN THE DRAWINGS.

180 DEG. HOOKS 25 mm Ø 150 200 230 450

CHB VERT. BARS

10

10. CONTRACTOR SHALL NOTE AND PROVIDE ALL MISCELLANEUOS CURBS, SILLS , STOOLS EQUIPMENT AND Dbar

dm

300

D+12db

28 mm Ø 240 300 350 550

NOTES ON STRUCTURAL STEEL

in.

MECHANICAL BASES THAT ARE REQUIRED BY THE ARCHITECTURAL , ELECTRICAL AND MECHANICAL DRAWINGS. (TYP.)

DOWEL

32 mm Ø 300 335 450 600

400

11. ALL RESULTS OF THE MATERIAL TESTING FOR CONCRETE, REINFORCING BARS & STRUCTURAL STEEL MUST BOTTOM BAR 1. STRUCTURAL STEEL TO BE USED FOR FABRICATION AND ERECTION OF THIS

FIN. FLR. LVL.

STRUCTURE SHALL COMPLY WITH ALL THE PERTINENT PROVISION OF AISC 4db OR 65mm

BE NOTED & APPROVED BY THE MATERIALS ENGINEER/STRUCTURAL DESIGNER. 135 DEG. HOOKS

250

SPECIFICATION FOR THE DESIGN, FABRICATION AND ERECTION OF STRUCTURAL

VERIFY DEPRESSION

STIRRUP AND THE TIE HOOKS

STEEL FOR BUILDING LATEST EDITION. 90 DEG. HOOKS (ALL GRADES) 6-Ø10 BARS (AS SHOWN)

LE Ø10 BOTT. BARS @ 300 O.C.

2. ALL STRUCTURAL STEEL SHAPES SHALL CONFORM TO ASTM A36 STRUCTURAL Dbar

REINFORCING CONCRETE LINTEL BEAMS IN BAR SIZE DIAMETER

180° HOOK 90° HOOK 400

200 (MIN) 200 (MIN) STEEL UNLESS OTHERWISE INDICATED. 6d (DEFORMED) (mm)

D

D+2db L L

CONCRETE BLOCK WALLS DOWEL BARS TO b

L

12db

FLR. SLAB OR BEAM MATCH VERT. BARS 3. ALL WELDED CONNECTIONS SHALL DEVELOP THE FULL STRENGTH OF THE 10 mm Ø 40 125 85 100

MEMBERS CONNECTED. DOWEL TO MATCH

LINTELS IN BLOCK WALLS Ø10 STIRRUPS D 12 mm Ø 50 165 115 115

(DOWEL)

L1 CHB VERT. BARS

@ 150 O.C. 4. UNLESS OTHERWISE SPECIFIED ALL WELDING RODS SHALL CONFORM WITH

1. ALL JOINTS AND CELLS L

400

WHERE DEPRESSED

VERIFY ARCHITECTURAL

CLEAR TOTAL MIN. HEIGHT OF REINFORCEMENT 16 mm Ø 65 200 140 150

CONTAINING REINFORCING E60 ELECTRODES. 300 SLAB OCCURS

SPAN LENGTH fc' LINTEL

(L) (L+0.40M) (MPa) (mm) BOTTOM TOP STIRRUPS CHB WALL BARS SHALL BE FILLED 5. ALL BOLTS USED UNLESS OTHERWISE SPECIFIED SHALL BE ASTM A 307 BOLTS. 20 mm Ø 115 300 165 300

(TYP.)

DOWEL

FOR SIZE AND SPACING

400

OF HOR. & VERT. BARS WITH CONCRETE GROUT. 32 mm Ø 150 335 230 405

1.20 M 1.60 M 200 1-Ø10 1-Ø10 Ø6 mm @ 200mm SEE CONSTRUCTION NOTES 2. FOR REINFORCEMENTS SEE

OPENING 1-Ø16 VERT. NOTES ON EMBBED PIPES FIN. FLR. LVL.

(DOWEL)

1.50 M 1.90 M 14.0 200 1-Ø10 1-Ø10 Ø6 mm @ 200mm CONSTRUCTION NOTES.

250

BARS TYPICAL

400

1.80 M 2.20 M 200 1-Ø12 1-Ø10 Ø6 mm @ 200mm DOWEL BARS TO MATCH

CHB VERT. BARS 1. ALL EMBEDED PIPES FOR UTILITIES ETC. THAT PASS THRU BEAMS SHALL NOT

(DOWEL)

6-Ø10 BARS (AS SHOWN)

2-Ø12 TOP BARS 1-Ø16 CONT. HOR. BARS EXCEED 100mm IN DIAMETER OR 1/3 BEAM DETPH WHICHEVER IS LESS, UNLESS

400

2.10 M 2.50 M 250 1-Ø12 1-Ø10 Ø6 mm @ 200mm Ø10 BOTT. BARS @ 300 O.C.

FOR FLOOR SLAB ONLY OTHERWISE APPROVED IN WRITING BY THE STRUCTURAL ENGINEER. 400 TYPICAL CHB FOOTING DETAILS

200

2.40 M 2.90 M 17.0 250 1-Ø12 1-Ø10 Ø6 mm @ 200mm FIN. FLR. LVL.

2-Ø12 BOTT. BARS

NOTES ON CONCRETE WALLS

2.70 M 3.10 M 250 1-Ø16 1-Ø12 Ø10mm @ 200mm 2. NO PIPES SHALL BE ALLOWED TO PASS THRU BEAMS VERTICALLY. ( WHERE APPLICABLE )

3. NO PIPES SHALL BE EMBEDDED IN COLUMNS. 1. ALL WALLS SHALL BE REINFORCED ACCORDING TO THE FOLLOWING SCHEDULE OF WALL

3.00 M 3.40 M 300 1-Ø16 1-Ø12 Ø10mm @ 200mm

ELEVATION SECTION NOTE:

3.30 M 3.70 M 20.0 300 1-Ø16 1-Ø12 Ø10mm @ 200mm TYP. SECTION OF MASONRY REINFORCEMENT UNLESS OTHERWISE INDICATED IN THE PLANS.

Ø10mm @ 200mm

PROVIDE THESE ADDITIONAL BARS FOR

3.60 M 4.00 M 300 1-Ø20 1-Ø12

TYP. DET. OF LINTEL BEAM AT CHB WALL OPENING PARTITION REINFORCEMENTS NOTES ON CONSTRUCTION JOINTS IN CONCRETE ALL OPENINGS PLUS BARS (NOT

SHOWN) PARALLEL TO SIDE OF OPENING

WALL REINFORCEMENT VERTICAL

1. WHERE A CONSTRUCTION JOINT IS TO BE MADE, THE SURFACE OF CONCRETE THICKNESS EQUAL TO THE NUMBER OF TERMINATED

HORIZONTAL VERTICAL REMARKS SECTION BARS AT OPENING

SHALL BE CLEANED AND ALL LAITANCE AND STANDING WATER REMOVED SHEAR

TYPICAL CONNECTION DETAIL OF MASONRY WALL KEY SHALL BE PROVIDE AT THE JOINT. 100mm Ø10mm @ 250mm O.C. Ø10mm @ 300mm O.C. HORIZONTAL BARS

VER. BARS SEE ARCHITECTURAL & MECHANICAL

125mm Ø10mm @ 200mm O.C. Ø10mm @ 250mm O.C. AT CENTERS VERTICAL PLANS FOR SLAB OPENING LOCATION.

30 BAR DIA. 30 BAR DIA. MAIN REINFORCEMENTS TO BE

CONTINUOUS (TOP & BOTT. BARS) 150mm Ø12mm @ 250mm O.C. Ø12mm @ 300mm O.C. BARS STAGGED OUT HOR. BARS

(min.) (min.)

12 THK. EXPANSION JOINT

D=FOR BEAM

t=FOR SLAB

WITH MASTIC FILLER CHB WALL R.C. COLUMN OR WALL WHERE JOINTS IS AT POINT OF DOOR

MAIN REINFORCEMENTS

TO BE CONTINUOUS STRESS, PROVIDE SHEAR RODS REINFORCING BARS SHALL HAVE 25mm CLEAR CONCRETE COVER FROM FACE OF WALL EXCEPT FOR OPENING

1-Ø16 VERT. BARS DOWEL BARS TO MATCH WITH ENGINEERS APPROVAL

1-Ø16 VERT. BARS CHB HOR. BARS WALLS IN CONTACT WITH THE GROUND WHERE A MINIMUM OF 60mm SHALL BE PROVIDED AND FOR

Ø10x1000 LONG

(DOWEL)

12 THK. EXPANSION JOINT 12 THK. EXPANSION JOINT EXPOSED FACES OF FORMED WALLS WHERE THE MINIMUM SHALL BE 50mm CLEAR.

CHB WALL WITH MASTIC FILLER @ 300 O.C. 38mm CLEAR

400

WITH MASTIC FILLER 30Ø BAR 30Ø BAR WINDOW

1-Ø16 VERT. BARS 50

FOR SIZE AND SPACING (MIN.) (MIN.) 2. CARRY VERTICAL BARS AT LEAST 60mm ABOVE FLOOR LEVEL TO PROVIDE FOR SPLICES WHEN NECESSARY OPENING

OF HOR. & VERT. BARS 40

D=FOR BEAM STOP AT 50mm BELOW TOP SLAB OR SOLID BAND WHERE THE WALL ENDS VERTICAL AND HORIZONTAL BARS

D/3

SEE CONSTRUCTION NOTES.

(DOWEL)

2t=FOR SLAB

D/3

t/3 t/3

FOR SIZE AND SPACING SHALL BE SPLICED BY LAPPING A DISTANCE EQUAL TO 30 DIAMETERS AND WIRED SECURELY WITH 16 G.I. WIRE

D

t/3

400

OF HOR. & VERT. BARS

t

D/3

SEE CONSTRUCTION NOTES. 30 BAR DIA. (min.) PROVIDED THAT SPLICES IN ADJACENT BARS ARE STAGGERED AT LEAST 1.50M O.C.

FOR SIZE AND SPACING

OF HOR. & VERT. BARS SLAB BEAM

CHB WALL SEE CONSTRUCTION NOTES. 400 TYPICAL DETAIL FOR BEAM 3. UNLESS OTHERWISE NOTED IN THE PLANS, ALL OPENINGS IN WALLS 250mm OR THICKER SHALL BE REINFORCED

(DOWEL) AROUND WITH 2-20mmØ BARS. FOR 225mm, 200mm, 175mm, 150mm THICK WALLS, USE 2-16mmØ. FOR 125mm AND

OPENING OR END WALL OR SLAB CHANGE SOFFIT TYPICAL SLAB & BEAM TYP. EXTERIOR WDW. & DOOR OPENING

CORNER WALL INTERSECTION WALL INTERSECTING R.C. COLUMN OR WALL 100mm THICK WALLS, USE 2-12mmØ BARS. ALL WALLS SPANNING SHALL HAVE VERTICAL REINFORCEMENT BENT

CONSTRUCTION JOINT DET. A U-FORM LIKE STIRRUPS AND SPACED ACCORDING TO THE SCHEDULE UNLESS OTHERWISE NOTED.

PREPARED : PROJECT NAME AND LOCATION: SHEET CONTENTS : SUBMITTED BY : SUBMITTED TO : SET NO.: SHEET NO.

GENERAL NOTES

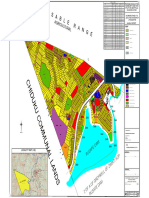

GROUP 5 - CE201 4 - STOREY EDUCATIONAL BUILDING CHRISTIAN KYLE S. BELTRAN MAE ALEXIS S. EMPERADOR SHIENA MARIE T. IGNACIO TEJAY F. MAWAL ANGELINE L. SEGUNDO ENGR. ARNULFO P. DELIMA S-1

PROJECT GROUP NO.

CAPSTONE 2 PROFESSOR

1 5

LOCATION: GUIMBAL NATIONAL HIGH SCHOOL, GUIMBAL, ILOILO

You might also like

- Magia CryptographicaDocument29 pagesMagia CryptographicaazzzNo ratings yet

- Corps - DIV Staff GuideDocument457 pagesCorps - DIV Staff GuideChris WhiteheadNo ratings yet

- EX1200-Electrical Circuit Diagram (Cummins Engine Specification)Document1 pageEX1200-Electrical Circuit Diagram (Cummins Engine Specification)Norman CoetzeeNo ratings yet

- Manzaneo y LotizacionDocument1 pageManzaneo y LotizacionErick FloreanoNo ratings yet

- Amueblado Pottery Barn Leon Plaza MayorDocument1 pageAmueblado Pottery Barn Leon Plaza MayorethelNo ratings yet

- Sense and Sensibility: Lighting Ground PlanDocument1 pageSense and Sensibility: Lighting Ground Planapi-509024597No ratings yet

- TECB RIY3 EQ GF 100 Layout1Document1 pageTECB RIY3 EQ GF 100 Layout1Ahmed AdelNo ratings yet

- Vectorworks Educational Version: Sense and SensibilityDocument1 pageVectorworks Educational Version: Sense and Sensibilityapi-510574946No ratings yet

- System Architecture For Demand Flow SystemDocument1 pageSystem Architecture For Demand Flow SystemDeepu AravindakshanNo ratings yet

- 0815stfrancissch3pln50v4-0815 3 1304 GF LayoutDocument1 page0815stfrancissch3pln50v4-0815 3 1304 GF LayoutPhilip MelemuriyilNo ratings yet

- ODEC Ventilation Layout UKDocument1 pageODEC Ventilation Layout UKsondeepyadav4873No ratings yet

- Revised Utandi Estate 2Document1 pageRevised Utandi Estate 2Bessie SiyadoNo ratings yet

- Pump Foundation Plan Pump Foundation Plan: NotesDocument1 pagePump Foundation Plan Pump Foundation Plan: NotesamitNo ratings yet

- mcc2 PDFDocument1 pagemcc2 PDFSravyaSree100% (2)

- Subdivision Water Mains SampleDocument1 pageSubdivision Water Mains Sampleaggrey noahNo ratings yet

- Section B B Note - : Column Number Column SizeDocument1 pageSection B B Note - : Column Number Column SizeRHUTI NAIKNo ratings yet

- KJPS1J-1J0-SK-0602 - 1 - PS1-J P&ID Main PumpsDocument1 pageKJPS1J-1J0-SK-0602 - 1 - PS1-J P&ID Main PumpsMuhammad rizwanNo ratings yet

- Level 3 MEP ServicesDocument2 pagesLevel 3 MEP ServicesLeyla MoranNo ratings yet

- Bathroom B-17-Elev.2: Master Bathroom Plans & ElevationsDocument1 pageBathroom B-17-Elev.2: Master Bathroom Plans & ElevationsWinmentolMalisaNo ratings yet

- Wind Substation-ModelDocument1 pageWind Substation-ModeldesignNo ratings yet

- Hydraulic GramDocument2 pagesHydraulic Gramerln LimaNo ratings yet

- AR003Document1 pageAR003hossam gabrNo ratings yet

- 2307 Japanexpo Plan StandsDocument1 page2307 Japanexpo Plan StandsAlyciane CendredeauNo ratings yet

- B Block PitDocument1 pageB Block PitAPS DESIGN INFRA PVT.LTD.No ratings yet

- Release / Revision: NW Blvd. & Plum Street VINELAND, NJ 08360Document47 pagesRelease / Revision: NW Blvd. & Plum Street VINELAND, NJ 08360Michael MinisterioNo ratings yet

- Thrusters Fresh Cooling Water SystemDocument1 pageThrusters Fresh Cooling Water SystemAndreas SofianidisNo ratings yet

- Summary: C5Document1 pageSummary: C5Carl Lou BaclayonNo ratings yet

- Ae 104 1Document1 pageAe 104 1ahmed mohameNo ratings yet

- Ce00092-St-Cr3-100 Rev 0Document1 pageCe00092-St-Cr3-100 Rev 0kingmagwalivhaNo ratings yet

- Plans 2Document3 pagesPlans 2rnz mrnNo ratings yet

- Approved Plan 1Document1 pageApproved Plan 1sibusiso.chisi9No ratings yet

- VH Ad 2 VHHH Aoc 4 (Typec)Document1 pageVH Ad 2 VHHH Aoc 4 (Typec)Loïc GIROUDNo ratings yet

- 219090-400-RS-05 Rev 01 Ground Beam ReinforcementDocument1 page219090-400-RS-05 Rev 01 Ground Beam ReinforcementrendaninNo ratings yet

- Notes: FP-1 FP-2 FP-3 FP-4Document1 pageNotes: FP-1 FP-2 FP-3 FP-4Tariq MahmoodNo ratings yet

- Mayfair LOTS 4 & 10 Buildings 4-6: Building 6 Slab Edge PlanDocument1 pageMayfair LOTS 4 & 10 Buildings 4-6: Building 6 Slab Edge PlanEric WilsonNo ratings yet

- PB02-STG-001 Steam Turbine System (A10-P-2001)Document1 pagePB02-STG-001 Steam Turbine System (A10-P-2001)zhangNo ratings yet

- A-121 - BLVD - 1 - Top Roof Floor PlanDocument1 pageA-121 - BLVD - 1 - Top Roof Floor PlanRaghu supertechNo ratings yet

- G3306 Generator Set Electrical System: Control Panel (Emcpii+)Document2 pagesG3306 Generator Set Electrical System: Control Panel (Emcpii+)Mr.Thawatchai hansuwanNo ratings yet

- Cat Dcs Sis ControllerDocument2 pagesCat Dcs Sis ControllerЮрий Шариков100% (5)

- Saudi Arabian Oil Company: 282 A BA-274759 006 0B2Document1 pageSaudi Arabian Oil Company: 282 A BA-274759 006 0B2Mohamed Wasim ShaikhNo ratings yet

- Planta 04 Sin ColorDocument1 pagePlanta 04 Sin ColorDIEGO FERNANDO GARCIA CARMONANo ratings yet

- SLDDocument1 pageSLDkbl11794No ratings yet

- Main WalletDocument1 pageMain Walletshaan.parmar07No ratings yet

- Sequence of Operation: Typical Ahu DDC Control Diagram - (Cav) System - 1Document1 pageSequence of Operation: Typical Ahu DDC Control Diagram - (Cav) System - 1JYOTHEESWARA NAIDU100% (1)

- Basden Steel Corp: Bill of MaterialDocument1 pageBasden Steel Corp: Bill of MaterialsateeshdonkadaNo ratings yet

- Patrakarnagar Chowk (Passport Office Brts Station: Up RampDocument5 pagesPatrakarnagar Chowk (Passport Office Brts Station: Up RamppanikarickyNo ratings yet

- BPS-STR-201-R1-Foundation Plan Other Details For Compound WallDocument1 pageBPS-STR-201-R1-Foundation Plan Other Details For Compound Wallsri projectssNo ratings yet

- Hwy 49 Roadwork2Document1 pageHwy 49 Roadwork2The UnionNo ratings yet

- BR - NO.775 (1X3.00m RCC BOX) 23-08-2019-ModelDocument1 pageBR - NO.775 (1X3.00m RCC BOX) 23-08-2019-Modelgrao vakapalliNo ratings yet

- Subdivision Storm Sewers SampleDocument1 pageSubdivision Storm Sewers Sampleaggrey noahNo ratings yet

- Subdivision Storm Sewers Sample AnnotatedDocument1 pageSubdivision Storm Sewers Sample Annotatedaggrey noahNo ratings yet

- SLD - CBSE Patna - PDF 2Document1 pageSLD - CBSE Patna - PDF 2nbcccbsepatnaNo ratings yet

- Construction Drawing: Legend Notes For Sanitary Piping Installation General Notes NotesDocument1 pageConstruction Drawing: Legend Notes For Sanitary Piping Installation General Notes NotesrajavelNo ratings yet

- StandardDocument1 pageStandardAyesha jabeenNo ratings yet

- Side Shell: Oro Jackson Shell ExpansionDocument1 pageSide Shell: Oro Jackson Shell ExpansionAdly AlandaNo ratings yet

- Elt - Villgio - 0505Document1 pageElt - Villgio - 0505Leandro JampietreNo ratings yet

- 3406, 3406C & 3456 Generator Set Electrical System With EMCP IIDocument4 pages3406, 3406C & 3456 Generator Set Electrical System With EMCP IIKhalifaNo ratings yet

- Notes:: Saudi Arabian Oil CompanyDocument1 pageNotes:: Saudi Arabian Oil Companymohamed esmailNo ratings yet

- Instant Assessments for Data Tracking, Grade 1: Language ArtsFrom EverandInstant Assessments for Data Tracking, Grade 1: Language ArtsNo ratings yet

- 4 3Document3 pages4 3Christian Kyle BeltranNo ratings yet

- Format CoverDocument2 pagesFormat CoverChristian Kyle BeltranNo ratings yet

- Santos Assignment2STEELLECDocument2 pagesSantos Assignment2STEELLECChristian Kyle BeltranNo ratings yet

- Footing ScheduleDocument1 pageFooting ScheduleChristian Kyle BeltranNo ratings yet

- Gantt Final To Print Na ThisDocument6 pagesGantt Final To Print Na ThisChristian Kyle BeltranNo ratings yet

- Beltran Steel Design ProjectDocument35 pagesBeltran Steel Design ProjectChristian Kyle BeltranNo ratings yet

- Beltran-Written#1-Blue ScholarDocument4 pagesBeltran-Written#1-Blue ScholarChristian Kyle BeltranNo ratings yet

- ELECTRICAL CIRCUITS NOTES FINALDocument64 pagesELECTRICAL CIRCUITS NOTES FINALChristian Kyle BeltranNo ratings yet

- Updated With 0.0036 Drift Chap 3Document69 pagesUpdated With 0.0036 Drift Chap 3Christian Kyle BeltranNo ratings yet

- Module 1 AlgebraDocument2 pagesModule 1 AlgebraChristian Kyle BeltranNo ratings yet

- For Bulletin BoardDocument15 pagesFor Bulletin BoardChristian Kyle BeltranNo ratings yet

- Preliminary SizesDocument1 pagePreliminary SizesChristian Kyle BeltranNo ratings yet

- CMTL - Group3 Lab Report 6 DensityDocument5 pagesCMTL - Group3 Lab Report 6 DensityChristian Kyle BeltranNo ratings yet

- CE Election GuidlinesDocument1 pageCE Election GuidlinesChristian Kyle BeltranNo ratings yet

- CMPM Q3 SolutionDocument2 pagesCMPM Q3 SolutionChristian Kyle BeltranNo ratings yet

- CESC GuidelinesDocument5 pagesCESC GuidelinesChristian Kyle BeltranNo ratings yet

- Module 2 Diffrential Calculus P1Document1 pageModule 2 Diffrential Calculus P1Christian Kyle BeltranNo ratings yet

- CE202 grp3 Chap1 5Document50 pagesCE202 grp3 Chap1 5Christian Kyle BeltranNo ratings yet

- Techniques For Problems Involving IncentersDocument4 pagesTechniques For Problems Involving IncentersChristian Kyle BeltranNo ratings yet

- Bill of Quantity 040219Document125 pagesBill of Quantity 040219Christian Kyle BeltranNo ratings yet

- Peer Evaluation Form For Ethnographic Research Paper: N.callado@feudiliman - Edu.ohDocument5 pagesPeer Evaluation Form For Ethnographic Research Paper: N.callado@feudiliman - Edu.ohChristian Kyle BeltranNo ratings yet

- Plane Geometry Notes PDFDocument19 pagesPlane Geometry Notes PDFChristian Kyle BeltranNo ratings yet

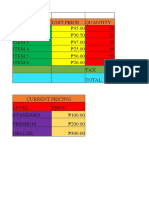

- Menu Item Unit Price Quantity Item 1 35.00 20 Item 2 30.50 15 Item 3 37.00 40 Item 4 25.00 40 Item 5 56.00 35 Item 6 26.00 25 TAX TotalDocument2 pagesMenu Item Unit Price Quantity Item 1 35.00 20 Item 2 30.50 15 Item 3 37.00 40 Item 4 25.00 40 Item 5 56.00 35 Item 6 26.00 25 TAX TotalChristian Kyle BeltranNo ratings yet

- Table 2Document1 pageTable 2Christian Kyle BeltranNo ratings yet

- Tingi - Tingi Cultural Phenomena in The PhilippinesDocument10 pagesTingi - Tingi Cultural Phenomena in The PhilippinesChristian Kyle Beltran100% (1)

- Miguel Ryan R. Arcilla: ObjectivesDocument1 pageMiguel Ryan R. Arcilla: ObjectivesChristian Kyle BeltranNo ratings yet

- Christian Kyle S. Beltran - NU Fairview 06192020Document1 pageChristian Kyle S. Beltran - NU Fairview 06192020Christian Kyle BeltranNo ratings yet

- Chapter 2 Review of Related Literature ADocument17 pagesChapter 2 Review of Related Literature AChristian Kyle BeltranNo ratings yet

- Items PHP Price USD PriceDocument4 pagesItems PHP Price USD PriceChristian Kyle BeltranNo ratings yet

- Hydraulic Actuator Bulldozer Powered by DC Motors: MethodologyDocument3 pagesHydraulic Actuator Bulldozer Powered by DC Motors: MethodologyChristian Kyle BeltranNo ratings yet

- Form ReimbursementDocument10 pagesForm ReimbursementDavid ValentinoNo ratings yet

- Butler Pitch & Putt Disqualification LetterDocument5 pagesButler Pitch & Putt Disqualification LetterAnonymous Pb39klJNo ratings yet

- Syllabus ENTREPRENEURSpring 2013Document8 pagesSyllabus ENTREPRENEURSpring 2013seneca85No ratings yet

- Section 9: FLOW CHART Sr. No. Description Page NoDocument1 pageSection 9: FLOW CHART Sr. No. Description Page NoSudeep NayakNo ratings yet

- QR Code: Male Female This Municipality Other MunicipalityDocument2 pagesQR Code: Male Female This Municipality Other MunicipalityKaius TakashiNo ratings yet

- Master Microservices With Spring, Docker, KubernetesDocument87 pagesMaster Microservices With Spring, Docker, Kuberneteskarthik rNo ratings yet

- Design of A Heat Exchanger Using HTRIDocument4 pagesDesign of A Heat Exchanger Using HTRIcenter010% (1)

- Student's Books, Workbooks, Literature Readers Only For English and Hindi Teacher's ManualsDocument2 pagesStudent's Books, Workbooks, Literature Readers Only For English and Hindi Teacher's Manualslamba lamNo ratings yet

- Digital Static Excitation SystemDocument16 pagesDigital Static Excitation SystemHộpQuà TriÂnNo ratings yet

- Free Speech Coalition Vs Utah "Porn Lawsuit" 2023Document31 pagesFree Speech Coalition Vs Utah "Porn Lawsuit" 2023Michael HouckNo ratings yet

- Service Manual: Harman/kardonDocument229 pagesService Manual: Harman/kardonSang NhNo ratings yet

- Neural Network and Fuzzy SystemDocument189 pagesNeural Network and Fuzzy SystemRenatus GodianNo ratings yet

- The Importance of LogicDocument8 pagesThe Importance of LogicMiyNo ratings yet

- Apana Black Book ProjectDocument35 pagesApana Black Book Projectpradeep dhobiNo ratings yet

- Proposal For Computer Based Exam ApplicationDocument8 pagesProposal For Computer Based Exam ApplicationdaniNo ratings yet

- Gaurav ResumeDocument2 pagesGaurav ResumeMANOJ KUMAR YADAVNo ratings yet

- Introduction To World Class ManufacturingDocument6 pagesIntroduction To World Class ManufacturinganurajNo ratings yet

- Multimaus en 200614 PDFDocument36 pagesMultimaus en 200614 PDFLaur MantescuNo ratings yet

- Osw Assignment 3Document15 pagesOsw Assignment 3DebarchanNo ratings yet

- American National StandardDocument52 pagesAmerican National StandardALEX ROSARIO ANGELESNo ratings yet

- TRIPOLEMDocument11 pagesTRIPOLEMImad BouchaourNo ratings yet

- 0406 Basic Computer Course Book PDFDocument33 pages0406 Basic Computer Course Book PDFSajid AhmadNo ratings yet

- Translate at DuckDuckGoDocument3 pagesTranslate at DuckDuckGotibivipNo ratings yet

- Stockpile Coal Handling - Sec 23Document10 pagesStockpile Coal Handling - Sec 23Muksin SalehNo ratings yet

- Rsac 2023 Soc Findings ReportDocument53 pagesRsac 2023 Soc Findings Reportstr4codeNo ratings yet

- Study Id132426 Retail-Technology-WorldwideDocument32 pagesStudy Id132426 Retail-Technology-WorldwideTamás KozákNo ratings yet

- Digital Design: Design and Implementation of Car Parking System On VHDLDocument11 pagesDigital Design: Design and Implementation of Car Parking System On VHDLHoàng Sơn NguyễnNo ratings yet

- An Introduction To Vijeo Citect: Simon Rooke Team Manager, SCADA and MES Global SupportDocument42 pagesAn Introduction To Vijeo Citect: Simon Rooke Team Manager, SCADA and MES Global Supportyavez andrewNo ratings yet