Professional Documents

Culture Documents

Sea Doo GTI Oil Injection Service Manual

Sea Doo GTI Oil Injection Service Manual

Uploaded by

wilsonmoto15Copyright:

Available Formats

You might also like

- BMW X5 E53 V8-4.4 N62 Repair Pages366-381Document17 pagesBMW X5 E53 V8-4.4 N62 Repair Pages366-381rodolfodiazNo ratings yet

- GM Gen III Wiring To JeepsDocument18 pagesGM Gen III Wiring To JeepsRay Zer100% (2)

- Diagnose and Repair Compression Ignition Engine Management SystemsDocument60 pagesDiagnose and Repair Compression Ignition Engine Management Systemslittleprayerbyjacks100% (1)

- Mitsubishi Grandis Wiring Diagram - Configuration DiagramsDocument22 pagesMitsubishi Grandis Wiring Diagram - Configuration Diagramsrodonganjaya22100% (1)

- PJ PDFDocument23 pagesPJ PDFCarlos Diaz100% (6)

- Lubrication (2jz-Ge)Document15 pagesLubrication (2jz-Ge)AlexendraNo ratings yet

- How To Build 4g63tDocument147 pagesHow To Build 4g63tGEEKONo ratings yet

- Qlink Service 150ccDocument37 pagesQlink Service 150ccmasinac91No ratings yet

- Diagrama Cablajului Skoda FabiaDocument610 pagesDiagrama Cablajului Skoda Fabialucian_pil93% (15)

- Howo Chassis 1Document146 pagesHowo Chassis 1tmasaouete hillal100% (3)

- 2GR FE LubricationDocument20 pages2GR FE LubricationNassar Al-EssawiNo ratings yet

- ATV 2008-015 OUTLANDER 400 EFI (Lubrication System) - Shop Manual - 04FXewAAG - SM51Y08S01 - enDocument12 pagesATV 2008-015 OUTLANDER 400 EFI (Lubrication System) - Shop Manual - 04FXewAAG - SM51Y08S01 - enRyan GoebelNo ratings yet

- 2AZ-FE LubricationDocument22 pages2AZ-FE LubricationAdedeji OluwatobilobaNo ratings yet

- Oil and FilterDocument22 pagesOil and FilterAdhi NugrohoNo ratings yet

- Mac Culloch Titan 57Document5 pagesMac Culloch Titan 57robertNo ratings yet

- Toyota Land Cruiser 1998 2007 Lubrication System Service ManualDocument2 pagesToyota Land Cruiser 1998 2007 Lubrication System Service Manualadrienne100% (54)

- Engine Lubrication & Cooling Systems: ZD TD27TiDocument34 pagesEngine Lubrication & Cooling Systems: ZD TD27TiLudo PiętakNo ratings yet

- Engine Lubrication & Cooling Systems: ZD TD27TiDocument34 pagesEngine Lubrication & Cooling Systems: ZD TD27TiRifki AwaludinNo ratings yet

- 5vz Fe LubricationDocument21 pages5vz Fe LubricationHenry SilvaNo ratings yet

- Lubrication System: Lubrication System Diagram OIL Pressure Check Service Information Oil Pump Trouble ShootingDocument159 pagesLubrication System: Lubrication System Diagram OIL Pressure Check Service Information Oil Pump Trouble ShootingpoiufdsapuroiqNo ratings yet

- 1kzte (1) - Sbloccato-Protetto - Parte105Document2 pages1kzte (1) - Sbloccato-Protetto - Parte105lscionti08No ratings yet

- Lubrication System Diagram: CamshaftsDocument12 pagesLubrication System Diagram: CamshaftsgenuineswedeNo ratings yet

- Sistema GAS TB45Document16 pagesSistema GAS TB45nelidaNo ratings yet

- Engine Lubrication & Cooling Systems: PRECAUTIONS AND PREPARATION............................ 1Document22 pagesEngine Lubrication & Cooling Systems: PRECAUTIONS AND PREPARATION............................ 1MortadeloNo ratings yet

- 2AZ FE LubricationDocument22 pages2AZ FE LubricationLuks Fernandez100% (2)

- NimcoDocument5 pagesNimcoomarvicoNo ratings yet

- Cooling Systems: 1TB42 & TD421 Preparation LC-2Document28 pagesCooling Systems: 1TB42 & TD421 Preparation LC-2Msi PCNo ratings yet

- PDI Air-Oil-Block DS-R2Document3 pagesPDI Air-Oil-Block DS-R2AdrianaNo ratings yet

- 1GR FE LubricationDocument19 pages1GR FE LubricationJesus LayaNo ratings yet

- Service Manual Susuki Baleno Sy418Document395 pagesService Manual Susuki Baleno Sy418juanmahepa75% (4)

- Lubrication System (2az Fe) : On Vehicle InspectionDocument2 pagesLubrication System (2az Fe) : On Vehicle InspectionpodlyNo ratings yet

- 2006 cbr1000rrDocument162 pages2006 cbr1000rrIsai OchoaNo ratings yet

- GX610K1 - GX620K1 - GX670 GXV610K1 - GXV620K1 - GXV670 Low Oil PressureDocument8 pagesGX610K1 - GX620K1 - GX670 GXV610K1 - GXV620K1 - GXV670 Low Oil PressureRussell JohnNo ratings yet

- LU - 1NZ-FXE LubricationDocument23 pagesLU - 1NZ-FXE LubricationCarlos MafudNo ratings yet

- Odes 800cc1000cc - WorkshopDocument131 pagesOdes 800cc1000cc - WorkshopIvan RochfordNo ratings yet

- 6.engine Lubrication SystemDocument26 pages6.engine Lubrication Systemalex generalNo ratings yet

- Lubrication PDFDocument32 pagesLubrication PDFn95kNo ratings yet

- GW491QE Petrol Engine Service Manual Lubrication+systemDocument7 pagesGW491QE Petrol Engine Service Manual Lubrication+systemAlbert BriceñoNo ratings yet

- Lubrication System (Hilux/1Kd-Ftv, 2Kd-Ftv (Tasa Made For Argentina) )Document2 pagesLubrication System (Hilux/1Kd-Ftv, 2Kd-Ftv (Tasa Made For Argentina) )grivaskachiswe40No ratings yet

- GT Lube Oil FlushingDocument11 pagesGT Lube Oil Flushingshubham raj bhawsarNo ratings yet

- Section 11 Engine Fuel SystemDocument3 pagesSection 11 Engine Fuel SystemtechnicmerpatipilotschoolNo ratings yet

- SsangYong-Korando 2012 EN US Manual de Taller Sistema de Lubricacion 1b9b8b14fcDocument32 pagesSsangYong-Korando 2012 EN US Manual de Taller Sistema de Lubricacion 1b9b8b14fcRAMON LANDERO PEREZNo ratings yet

- 2011-2019 Hyundai High Fuel Pressure Fuel PumpDocument7 pages2011-2019 Hyundai High Fuel Pressure Fuel PumpJoeNo ratings yet

- S3113 600M411001JV 0 F 9000Document199 pagesS3113 600M411001JV 0 F 9000GeorgiNo ratings yet

- BMW c650gt Oil Filter Change InstructionsDocument3 pagesBMW c650gt Oil Filter Change InstructionsServ Tecn SportourerNo ratings yet

- Graco GL32 - GL43Document8 pagesGraco GL32 - GL43luisNo ratings yet

- Kubota B1700, B2100, B2400 WSM Part 2 - Brake AssemblyDocument233 pagesKubota B1700, B2100, B2400 WSM Part 2 - Brake AssemblyBenoît MARTINNo ratings yet

- 5sfe-Fuel PumpDocument8 pages5sfe-Fuel PumpNato DlAngelesNo ratings yet

- Rcrit 14V647 9581Document43 pagesRcrit 14V647 9581Eko PurwantoNo ratings yet

- Brake SystemDocument8 pagesBrake SystemDomingo BravoNo ratings yet

- SM 9Document10 pagesSM 9EngA7med AmerNo ratings yet

- Introduce LP&MP CompressorDocument61 pagesIntroduce LP&MP Compressorchuminh100% (1)

- 308953EN-S GL-1 Injector ManualDocument6 pages308953EN-S GL-1 Injector ManualeduardoNo ratings yet

- Lubrication System (2Az-Fe) : On-Vehicle InspectionDocument22 pagesLubrication System (2Az-Fe) : On-Vehicle InspectionTung NguyenNo ratings yet

- Engine Oil ServicingDocument2 pagesEngine Oil ServicingPédro GONZALEZNo ratings yet

- Microsoft PowerPoint - BLCP Training Cource F Turbine 4Document27 pagesMicrosoft PowerPoint - BLCP Training Cource F Turbine 4Natthaphon NaosookNo ratings yet

- 2 - A - Manual de Taller Motor D4B Del Hyundai H1 (Inglés) (086-165)Document80 pages2 - A - Manual de Taller Motor D4B Del Hyundai H1 (Inglés) (086-165)Lala CéspedesNo ratings yet

- Section 3 Section 3: Routine MaintenanceDocument2 pagesSection 3 Section 3: Routine MaintenanceСергій БоженкоNo ratings yet

- Oil and Filter: InspectionDocument36 pagesOil and Filter: Inspectionkywheat3306No ratings yet

- Microfilter FinalDocument6 pagesMicrofilter FinalRobs BankNo ratings yet

- 1Nz-Fe Engine: DescriptionDocument59 pages1Nz-Fe Engine: DescriptionAlan Rios Moraga100% (1)

- Lube & Seal SystemDocument83 pagesLube & Seal SystemPraveen ManikandanNo ratings yet

- Dd13 FaultDocument6 pagesDd13 FaultSsNo ratings yet

- Yamaha DS7 (72) RD250 (73) R5C (72) RD350Document113 pagesYamaha DS7 (72) RD250 (73) R5C (72) RD350Igor Majksner100% (5)

- 1998 Sec 7-Manual TransmissionDocument25 pages1998 Sec 7-Manual TransmissionLuis TomboNo ratings yet

- Section 4 Brake SystemDocument5 pagesSection 4 Brake SystemAndré TarginoNo ratings yet

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- Engine RemovalDocument17 pagesEngine RemovalMichael HernandezNo ratings yet

- BHLP027 Error Code List SPN FMIDocument3 pagesBHLP027 Error Code List SPN FMIDtl DiagNo ratings yet

- Safety Instructions and WarningsDocument28 pagesSafety Instructions and WarningsEdson ReisNo ratings yet

- MF 15 4 Techs15583Document58 pagesMF 15 4 Techs15583Tim WorkmanNo ratings yet

- G32D DTCDocument59 pagesG32D DTCPower NguyenNo ratings yet

- 2005 2010 Quick Reference Guide PDFDocument79 pages2005 2010 Quick Reference Guide PDFJOSUE DURAN GRANDENo ratings yet

- Vulcan RemovalDocument21 pagesVulcan Removald4rk3No ratings yet

- 02-01 - Pneumatic Conveying SystemsDocument40 pages02-01 - Pneumatic Conveying SystemsROLAN MACALALAD100% (1)

- Touareg PricelistDocument20 pagesTouareg PricelistWytalikNo ratings yet

- A Micro-Project Report On: " Multipoint Fuel Injection System "Document17 pagesA Micro-Project Report On: " Multipoint Fuel Injection System "Vikram MagarNo ratings yet

- Kohler XT675 Owner's Manual 14 - 590 - 22 - ENDocument8 pagesKohler XT675 Owner's Manual 14 - 590 - 22 - ENbunkmonkeyNo ratings yet

- Operating Instruction PDFDocument43 pagesOperating Instruction PDFnamduong36867% (3)

- BMW N54 Engine Tuning Options (Vishnu Performance)Document2 pagesBMW N54 Engine Tuning Options (Vishnu Performance)bevioNo ratings yet

- Fuel Pump Removal 2Document5 pagesFuel Pump Removal 2ShaqqaNo ratings yet

- Vanguard 18hp - Engine # 3564470373F1Document61 pagesVanguard 18hp - Engine # 3564470373F1Matias Alfredo Contreras KöbrichNo ratings yet

- DT9.9 15Document134 pagesDT9.9 15Nico ObermeyerNo ratings yet

- An Introduction To The M14PDocument11 pagesAn Introduction To The M14PDave MarshNo ratings yet

- Lebm7301 04 PDFDocument94 pagesLebm7301 04 PDFVictor Nunez100% (1)

- E21OwnersManualSections-CareandMaint AndspecsDocument57 pagesE21OwnersManualSections-CareandMaint AndspecsJulio Fernando Gil TubacNo ratings yet

- Yaris ECMDocument1 pageYaris ECMImran MuhammadNo ratings yet

- 205 12Document14 pages205 12carlos maradiagaNo ratings yet

- Service Manual Trucks: MID 249, Bodybuilder Module Fault Codes VHD Version2 From Build Date 11.2002Document28 pagesService Manual Trucks: MID 249, Bodybuilder Module Fault Codes VHD Version2 From Build Date 11.2002Abdelhak EzzahriouiNo ratings yet

Sea Doo GTI Oil Injection Service Manual

Sea Doo GTI Oil Injection Service Manual

Uploaded by

wilsonmoto15Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sea Doo GTI Oil Injection Service Manual

Sea Doo GTI Oil Injection Service Manual

Uploaded by

wilsonmoto15Copyright:

Available Formats

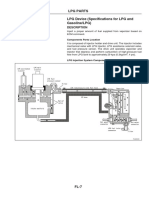

Section 11 LUBRICATION SYSTEM (2-STROKE)

Subsection 01 (OIL INJECTION SYSTEM)

OIL INJECTION SYSTEM

GTI Models

27 Nm

(20 lbfft)

1 3.5 Nm

(31 lbfin)

Dielectric

grease 3.5 Nm

4 (31 lbfin)

1.2 Nm

(11 lbfin)

F17G03S

smr2004-Complete Line Up https://www.boat-manuals.com/ 529

1

Section 11 LUBRICATION SYSTEM (2-STROKE)

Subsection 01 (OIL INJECTION SYSTEM)

XP DI Models

Steering harness

Oil pump

3

Synthetic

injection oil

F08G06S

530 https://www.boat-manuals.com/ smr2004-Complete Line Up

2

Section 11 LUBRICATION SYSTEM (2-STROKE)

Subsection 01 (OIL INJECTION SYSTEM)

GENERAL Disconnect oil tank vent line on PTO side throttle

body.

Whenever repairing the oil injection system, al-

ways verify for water infiltration in reservoir. GTI Models

Also pressure test the oil injection system. Connect pump gauge tester (P/N 529 021 800) to

oil injection reservoir vent check valve.

GTI Models

XP DI Model

Clamp and Hose Connect pump gauge tester (P/N 529 021 800) to

Verify oil filler neck hose no. 2 for damage. disconnected tube at throttle body.

Always ensure that clamps no. 1 are well posi- All Models

tioned and tightened. Torque clamps to 3.5 N•m

(31 lbf•in). NOTE: Use the same pump included in the EN-

GINE LEAK TESTER KIT (P/N 295 500 352).

All Models

1

Check Valve

Black side of the one-way check valve no. 3 is the

valve outlet. It allows air to get in reservoir and

prevent oil to flow out.

NOTE: For proper check valve installation, refer to

appropriate exploded view given at the beginning

of the section.

Oil Filter

Oil filter no. 4 should be replaced annually. F01G0IA

TYPICAL

OIL SYSTEM PRESSURIZATION 1. Connect pump to check valve

WARNING – Pressurize oil system to 21 kPa (3 PSI).

Whenever oil system components are discon-

All Models

nected or replaced, a pressure test must be

done before starting engine. Ensure to veri- – If pressure is not maintained, locate leak and

fy oil line ends for damage. Always cut dam- repair/replace component leaking. To ease leak

aged end before reinstallation. search spray a solution of soapy water on com-

ponents, bubbles will indicate leak location.

XP DI Model

Pressure Test Verify check valve inside vent adapter if pressure

Proceed as follows: does not hold. Also ensure air can enter through

– Fill up oil reservoir. check valve in the opposite direction.

– Install a hose pincher to rotary valve shaft oil All Models

supply hose (except 947 DI engines).

NOTE: The system must maintain a pressure of

– Install a hose pincher to rotary valve shaft oil 21 kPa (3 PSI) for at least 10 minutes. Never pres-

return hose (except 947 DI engines). surize over 21 kPa (3 PSI).

– Install a hose pincher to oil injection pump sup-

ply hose. CAUTION: If any leak is found, do not start the

engine and wipe off any oil leakage.

XP DI Model Disconnect pump gauge tester and remove hose

Install a hose pincher to compressor return line pinchers. On XP DI model, reconnect line at throt-

(lower hose of the vent adapter on top of oil in- tle body.

jection tank).

smr2004-Complete Line Up https://www.boat-manuals.com/ 531

3

Section 11 LUBRICATION SYSTEM (2-STROKE)

Subsection 02 (OIL INJECTION PUMP)

OIL INJECTION PUMP

717 Engines

Synthetic

grease

6 Nm 4

10 Nm (53 lbfin)

(89 lbfin)

5

6 Nm 3

(53 lbfin) Loctite

6 243

Loctite 2

243

8 Nm

(71 lbfin)

8 Nm

(71 lbfin)

4.5 Nm

(40 lbfin) 5 Nm

Loctite (44 lbfin)

243

F00G03T

smr2004-Complete Line Up https://www.boat-manuals.com/ 533

4

Section 11 LUBRICATION SYSTEM (2-STROKE)

Subsection 02 (OIL INJECTION PUMP)

787 RFI Engines

4.5 Nm

(40 lbfin) 1

9

6

3 Nm 6 Nm

(27 lbfin) (53 lbfin)

4.5 Nm

(40 lbfin)

F07G0DS

534 https://www.boat-manuals.com/ smr2004-Complete Line Up

5

Section 11 LUBRICATION SYSTEM (2-STROKE)

Subsection 02 (OIL INJECTION PUMP)

947 DI Engines

6 Nm

(53 lbfin)

6

Loctite

243

6

6 Nm

(53 lbfin)

Loctite

243

1

Oil pump

4.5 Nm 8

(40 lbfin)

Molykote

111

Throttle cable

F12G08S

smr2004-Complete Line Up https://www.boat-manuals.com/ 535

6

Section 11 LUBRICATION SYSTEM (2-STROKE)

Subsection 02 (OIL INJECTION PUMP)

OIL PUMP IDENTIFICATION Remove 2 Allen screws no. 6 with flat washers re-

taining oil injection pump to intake manifold no. 2.

Pump Lever Remove pump.

Different engines need different pumps. See

947 DI Engines

identification on lever.

Remove tuned pipe head. Refer to EXHAUST

CAUTION: Always mount proper pump on en- SYSTEM.

gine.

The cable end has a slight press fit in the lever.

ENGINE TYPE IDENTIFICATION Using a small screwdriver, pry cable end out.

717 105Q-5 787 RFI and 947 DI Engines

787 RFI 06 Disconnect oil injection pump cable no. 7.

Remove 2 Allen screws no. 6 with flat washers

947 DI 01

retaining oil injection pump to magneto housing

NOTE: The following procedures can be done cover.

without removing the engine from hull. Pull pump.

Disconnect oil hoses from fittings of oil injection

REMOVAL pump.

Oil Injection Pump DISASSEMBLY

717 Engines

NOTE: Some oil pump parts are not available

Remove air intake silencer (refer to AIR INTAKE).

in single parts. A gasket set is available for the

Remove carburetor (refer to CARBURETOR). pump. Refer to parts catalog.

Remove rotary valve cover (refer to ROTARY If the pump is found defective, it should be re-

VALVE). placed by a new one.

Remove Allen screws no. 5 retaining intake man-

ifold no. 2 to rotary valve cover. CLEANING

Separate intake manifold from rotary valve cover. Discard all seals and O-rings. Clean metal compo-

To separate oil pump from intake manifold no. 2, nents in a solvent.

remove oil pump gear no. 3 using gear holder

(P/N 420 277 905) and unscrew lock nut no. 4. ASSEMBLY

717 Engines

1

Oil Injection Pump and Intake Manifold

Install oil injection pump no. 1 to intake manifold

no. 2. Torque screws no. 6 to 6 N•m (53 lbf•in).

CAUTION: Whenever oil injection lines are re-

moved, always make the routing as shown.

A00C17B

1. Gear holder

536 https://www.boat-manuals.com/ smr2004-Complete Line Up

7

Section 11 LUBRICATION SYSTEM (2-STROKE)

Subsection 02 (OIL INJECTION PUMP)

947 DI Engines

1

F01D4SA 1

TYPICAL

1. Small oil line

Oil Pump Gear

F12G02A

Install gear no. 3 to oil injection pump shaft.

Torque lock nut no. 4 to 6 N•m (53 lbf•in).

NOTE: Make sure 1 washer is installed on each

side of gear.

Install intake manifold no. 2 to rotary valve cover

and torque screws no. 5 to 10 N•m (89 lbf•in).

F12G03A

F01D4RC A

TYPICAL

A. 10 N•m (89 lbf•in)

787 and 947 DI Engines

Oil Injection Pump and Shaft

Make sure shaft no. 8 is installed in crankshaft

end.

Install pump. Secure with flat washers and

screws no. 6. Torque to 6 N•m (53 lbf•in).

Install oil injection pump cable.

smr2004-Complete Line Up https://www.boat-manuals.com/ 537

8

Section 11 LUBRICATION SYSTEM (2-STROKE)

Subsection 02 (OIL INJECTION PUMP)

717 Engines

1

2

F12G04A 2 1 F01D4RE 3

1. Cable end completely inserted TYPICAL

2. Cable end NOT seated on the steps 1. Jam nut

2. Adjustment nut

CAUTION: Ensure cable end is completely en- 3. Aligned marks

tered in its housing. Ensure it is NOT seated on

the steps. 787 RFI Engines

ADJUSTMENT

CAUTION: As oil injection pump adjustment

is dependent on throttle cable position, make

sure to perform throttle cable adjustment first

except if otherwise specified.

Preliminary Synchronization

NOTE: To check synchronization of pump as a

routine maintenance, see FINAL SYNCHRONIZA-

TION. Make sure idle speed screw on carburetor

is properly set on 717 engines.

Refer to CARBURETOR for throttle cable adjust-

ment procedure.

NOTE: On a twin carburetor engine, make sure F07G02B 1

carburetors are properly synchronized.

1. Aligned marks

Turn oil pump cable adjustment nut to align refer-

ence marks on pump. Loosen jam nut and turn cable adjustment nut to

NOTE: A mirror may be used to facilitate this ver- obtain proper pump setting.

ification. The adjustment nut and jam nut for the oil injection

pump cable are located at the cable support on the

throttle body.

538 https://www.boat-manuals.com/ smr2004-Complete Line Up

9

Section 11 LUBRICATION SYSTEM (2-STROKE)

Subsection 02 (OIL INJECTION PUMP)

F07F0WB 1 2

1. Oil pump cable

2. Adjustment nut

947 DI Engines

Loosen jam nut and turn cable adjustment nut to

obtain pump mark alignment. Refer to following

photos.

The adjustment is located under the throttle body

bracket.

1 2 F16G03B

1. Mark on pump must be facing longest mark on lever

All Engines

Start and bring engine to normal operating temper-

ature.

CAUTION: If watercraft is out of water, engine

must be cooled using the flush kit. If air bub-

bles are present in the oil injection system,

bleed system before operating engine.

Adjust idle speed to specification on 717 Engines.

Refer to CARBURETOR.

NOTE: On RFI and DI engines, there is no idle

F16F01A

speed adjustment to perform.

1. Oil pump cable adjustment

2. Throttle cable Stop engine.

Adjust the cable to the rich position. Use the Final Synchronization

longest mark. Eliminate throttle cable free-play by depressing

throttle lever until a slight resistance is felt. In

this position, marks on pump body and lever must

align.

If necessary, turn cable adjustment nut to obtain

pump mark alignment. Refer to above illustra-

tions.

Tighten jam nut and recheck alignment marks.

smr2004-Complete Line Up https://www.boat-manuals.com/ 539

10

Section 11 LUBRICATION SYSTEM (2-STROKE)

Subsection 02 (OIL INJECTION PUMP)

CAUTION: Proper oil injection pump adjust- 1

ment is very important. Any delay in the

opening of pump can result in serious engine

damage.

Bleeding

CAUTION: Oil injection system must be bled

and adjustment checked before operating en-

gine.

Ensure oil injection reservoir is sufficiently filled.

Install a dry rag below oil injection pump.

Loosen bleed screw to allow oil to flow.

F16G02A

947 DI ENGINES

1. Bleed screw

Keep bleeding until all air has escaped from line.

Make sure no air bubbles remain in oil supply line.

F01D4SC 1 Tighten bleed screw.

717 ENGINES Wipe any oil spillage.

1. Bleed screw

Check small oil lines of the pump. They must be

1 full of oil.

1

F07G02A

F07G06A 2

787 RFI ENGINES 1. Lines must be full of oil

1. Bleed screw 2. Oil pump

If not, proceed as follows.

540 https://www.boat-manuals.com/ smr2004-Complete Line Up

11

Section 11 LUBRICATION SYSTEM (2-STROKE)

Subsection 02 (OIL INJECTION PUMP)

All Engines except 947 DI 2

Run engine at idle speed while manually holding

pump lever in fully open position. Do not activate

throttle lever.

947 DI Engines

– Use the VCK (Vehicle Communication Kit) 1

(P/N 529 035 981). Look in the MONITORING

section of the B.U.D.S software.

– Use the “Oil lines bleeding” function that al-

lows to “lock” the engine RPM in idle speed

while the throttle is fully depressed to ease the

bleeding operation.

– Since oil cannot be seen through the small oil

lines, press and hold the vehicle throttle to wide

open position for 45 seconds.

All Engines 4

CAUTION: If watercraft is out of water, engine

must be cooled using the flush kit. 3

F01G02A

TYPICAL

CHECKING OPERATION 1. Supply oil line to an oil container

2. Hold lever in fully open position

On Watercraft 3. Counterclockwise (reverse) rotating drill

4. Oil must drip here

NOTE: Oil line supply must be full of oil. See

bleeding procedure above. For an accurate test, each port should be checked

separately to ensure equal delivery on both ports.

Start engine and run at idle while holding the pump

lever in fully open position. To obtain a precise result of the oil pump delivery

rate, rotate it counterclockwise at 1500 RPM for a

All Engines except 947 DI total time of 5 minutes.

Oil must advance into small oil lines. NOTE: To ensure accuracy of test, oil lines should

All Engines be completely filled before starting test.

NOTE: The engine should have a rich mixture, Compare the results with the chart below. If oil

idling irregularly and emitting smoke at exhaust pump is out of specification, replace it.

outlet.

OIL PUMP DELIVERY AT

If not, remove pump assembly and check the ENGINE 1500 RPM (pump speed)

pump gear (717 engine) or shaft (787 RFI and 947 FOR 5 MINUTES

DI engines) for defects, replace as necessary.

Test pump as described below: 717 9.9 - 12.1 mL (each port)

NOTE: Through normal use, oil level must not 787 RFI 5.7 - 6.9 mL (each port)

drop in small tubes. If oil drops, verify check valve

947 DI 7.5 - 9.1 mL (each port)

operation. Replace as necessary.

Bench Test

Connect a hose filled with injection oil to main line

fitting. Insert other hose end in an injection oil

container. Using a counterclockwise (reverse po-

sition) rotating drill, rotate pump shaft. Oil must

drip from fittings in parts of rotary valve cover

while holding lever in a fully open position.

smr2004-Complete Line Up https://www.boat-manuals.com/ 541

12

You might also like

- BMW X5 E53 V8-4.4 N62 Repair Pages366-381Document17 pagesBMW X5 E53 V8-4.4 N62 Repair Pages366-381rodolfodiazNo ratings yet

- GM Gen III Wiring To JeepsDocument18 pagesGM Gen III Wiring To JeepsRay Zer100% (2)

- Diagnose and Repair Compression Ignition Engine Management SystemsDocument60 pagesDiagnose and Repair Compression Ignition Engine Management Systemslittleprayerbyjacks100% (1)

- Mitsubishi Grandis Wiring Diagram - Configuration DiagramsDocument22 pagesMitsubishi Grandis Wiring Diagram - Configuration Diagramsrodonganjaya22100% (1)

- PJ PDFDocument23 pagesPJ PDFCarlos Diaz100% (6)

- Lubrication (2jz-Ge)Document15 pagesLubrication (2jz-Ge)AlexendraNo ratings yet

- How To Build 4g63tDocument147 pagesHow To Build 4g63tGEEKONo ratings yet

- Qlink Service 150ccDocument37 pagesQlink Service 150ccmasinac91No ratings yet

- Diagrama Cablajului Skoda FabiaDocument610 pagesDiagrama Cablajului Skoda Fabialucian_pil93% (15)

- Howo Chassis 1Document146 pagesHowo Chassis 1tmasaouete hillal100% (3)

- 2GR FE LubricationDocument20 pages2GR FE LubricationNassar Al-EssawiNo ratings yet

- ATV 2008-015 OUTLANDER 400 EFI (Lubrication System) - Shop Manual - 04FXewAAG - SM51Y08S01 - enDocument12 pagesATV 2008-015 OUTLANDER 400 EFI (Lubrication System) - Shop Manual - 04FXewAAG - SM51Y08S01 - enRyan GoebelNo ratings yet

- 2AZ-FE LubricationDocument22 pages2AZ-FE LubricationAdedeji OluwatobilobaNo ratings yet

- Oil and FilterDocument22 pagesOil and FilterAdhi NugrohoNo ratings yet

- Mac Culloch Titan 57Document5 pagesMac Culloch Titan 57robertNo ratings yet

- Toyota Land Cruiser 1998 2007 Lubrication System Service ManualDocument2 pagesToyota Land Cruiser 1998 2007 Lubrication System Service Manualadrienne100% (54)

- Engine Lubrication & Cooling Systems: ZD TD27TiDocument34 pagesEngine Lubrication & Cooling Systems: ZD TD27TiLudo PiętakNo ratings yet

- Engine Lubrication & Cooling Systems: ZD TD27TiDocument34 pagesEngine Lubrication & Cooling Systems: ZD TD27TiRifki AwaludinNo ratings yet

- 5vz Fe LubricationDocument21 pages5vz Fe LubricationHenry SilvaNo ratings yet

- Lubrication System: Lubrication System Diagram OIL Pressure Check Service Information Oil Pump Trouble ShootingDocument159 pagesLubrication System: Lubrication System Diagram OIL Pressure Check Service Information Oil Pump Trouble ShootingpoiufdsapuroiqNo ratings yet

- 1kzte (1) - Sbloccato-Protetto - Parte105Document2 pages1kzte (1) - Sbloccato-Protetto - Parte105lscionti08No ratings yet

- Lubrication System Diagram: CamshaftsDocument12 pagesLubrication System Diagram: CamshaftsgenuineswedeNo ratings yet

- Sistema GAS TB45Document16 pagesSistema GAS TB45nelidaNo ratings yet

- Engine Lubrication & Cooling Systems: PRECAUTIONS AND PREPARATION............................ 1Document22 pagesEngine Lubrication & Cooling Systems: PRECAUTIONS AND PREPARATION............................ 1MortadeloNo ratings yet

- 2AZ FE LubricationDocument22 pages2AZ FE LubricationLuks Fernandez100% (2)

- NimcoDocument5 pagesNimcoomarvicoNo ratings yet

- Cooling Systems: 1TB42 & TD421 Preparation LC-2Document28 pagesCooling Systems: 1TB42 & TD421 Preparation LC-2Msi PCNo ratings yet

- PDI Air-Oil-Block DS-R2Document3 pagesPDI Air-Oil-Block DS-R2AdrianaNo ratings yet

- 1GR FE LubricationDocument19 pages1GR FE LubricationJesus LayaNo ratings yet

- Service Manual Susuki Baleno Sy418Document395 pagesService Manual Susuki Baleno Sy418juanmahepa75% (4)

- Lubrication System (2az Fe) : On Vehicle InspectionDocument2 pagesLubrication System (2az Fe) : On Vehicle InspectionpodlyNo ratings yet

- 2006 cbr1000rrDocument162 pages2006 cbr1000rrIsai OchoaNo ratings yet

- GX610K1 - GX620K1 - GX670 GXV610K1 - GXV620K1 - GXV670 Low Oil PressureDocument8 pagesGX610K1 - GX620K1 - GX670 GXV610K1 - GXV620K1 - GXV670 Low Oil PressureRussell JohnNo ratings yet

- LU - 1NZ-FXE LubricationDocument23 pagesLU - 1NZ-FXE LubricationCarlos MafudNo ratings yet

- Odes 800cc1000cc - WorkshopDocument131 pagesOdes 800cc1000cc - WorkshopIvan RochfordNo ratings yet

- 6.engine Lubrication SystemDocument26 pages6.engine Lubrication Systemalex generalNo ratings yet

- Lubrication PDFDocument32 pagesLubrication PDFn95kNo ratings yet

- GW491QE Petrol Engine Service Manual Lubrication+systemDocument7 pagesGW491QE Petrol Engine Service Manual Lubrication+systemAlbert BriceñoNo ratings yet

- Lubrication System (Hilux/1Kd-Ftv, 2Kd-Ftv (Tasa Made For Argentina) )Document2 pagesLubrication System (Hilux/1Kd-Ftv, 2Kd-Ftv (Tasa Made For Argentina) )grivaskachiswe40No ratings yet

- GT Lube Oil FlushingDocument11 pagesGT Lube Oil Flushingshubham raj bhawsarNo ratings yet

- Section 11 Engine Fuel SystemDocument3 pagesSection 11 Engine Fuel SystemtechnicmerpatipilotschoolNo ratings yet

- SsangYong-Korando 2012 EN US Manual de Taller Sistema de Lubricacion 1b9b8b14fcDocument32 pagesSsangYong-Korando 2012 EN US Manual de Taller Sistema de Lubricacion 1b9b8b14fcRAMON LANDERO PEREZNo ratings yet

- 2011-2019 Hyundai High Fuel Pressure Fuel PumpDocument7 pages2011-2019 Hyundai High Fuel Pressure Fuel PumpJoeNo ratings yet

- S3113 600M411001JV 0 F 9000Document199 pagesS3113 600M411001JV 0 F 9000GeorgiNo ratings yet

- BMW c650gt Oil Filter Change InstructionsDocument3 pagesBMW c650gt Oil Filter Change InstructionsServ Tecn SportourerNo ratings yet

- Graco GL32 - GL43Document8 pagesGraco GL32 - GL43luisNo ratings yet

- Kubota B1700, B2100, B2400 WSM Part 2 - Brake AssemblyDocument233 pagesKubota B1700, B2100, B2400 WSM Part 2 - Brake AssemblyBenoît MARTINNo ratings yet

- 5sfe-Fuel PumpDocument8 pages5sfe-Fuel PumpNato DlAngelesNo ratings yet

- Rcrit 14V647 9581Document43 pagesRcrit 14V647 9581Eko PurwantoNo ratings yet

- Brake SystemDocument8 pagesBrake SystemDomingo BravoNo ratings yet

- SM 9Document10 pagesSM 9EngA7med AmerNo ratings yet

- Introduce LP&MP CompressorDocument61 pagesIntroduce LP&MP Compressorchuminh100% (1)

- 308953EN-S GL-1 Injector ManualDocument6 pages308953EN-S GL-1 Injector ManualeduardoNo ratings yet

- Lubrication System (2Az-Fe) : On-Vehicle InspectionDocument22 pagesLubrication System (2Az-Fe) : On-Vehicle InspectionTung NguyenNo ratings yet

- Engine Oil ServicingDocument2 pagesEngine Oil ServicingPédro GONZALEZNo ratings yet

- Microsoft PowerPoint - BLCP Training Cource F Turbine 4Document27 pagesMicrosoft PowerPoint - BLCP Training Cource F Turbine 4Natthaphon NaosookNo ratings yet

- 2 - A - Manual de Taller Motor D4B Del Hyundai H1 (Inglés) (086-165)Document80 pages2 - A - Manual de Taller Motor D4B Del Hyundai H1 (Inglés) (086-165)Lala CéspedesNo ratings yet

- Section 3 Section 3: Routine MaintenanceDocument2 pagesSection 3 Section 3: Routine MaintenanceСергій БоженкоNo ratings yet

- Oil and Filter: InspectionDocument36 pagesOil and Filter: Inspectionkywheat3306No ratings yet

- Microfilter FinalDocument6 pagesMicrofilter FinalRobs BankNo ratings yet

- 1Nz-Fe Engine: DescriptionDocument59 pages1Nz-Fe Engine: DescriptionAlan Rios Moraga100% (1)

- Lube & Seal SystemDocument83 pagesLube & Seal SystemPraveen ManikandanNo ratings yet

- Dd13 FaultDocument6 pagesDd13 FaultSsNo ratings yet

- Yamaha DS7 (72) RD250 (73) R5C (72) RD350Document113 pagesYamaha DS7 (72) RD250 (73) R5C (72) RD350Igor Majksner100% (5)

- 1998 Sec 7-Manual TransmissionDocument25 pages1998 Sec 7-Manual TransmissionLuis TomboNo ratings yet

- Section 4 Brake SystemDocument5 pagesSection 4 Brake SystemAndré TarginoNo ratings yet

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- Engine RemovalDocument17 pagesEngine RemovalMichael HernandezNo ratings yet

- BHLP027 Error Code List SPN FMIDocument3 pagesBHLP027 Error Code List SPN FMIDtl DiagNo ratings yet

- Safety Instructions and WarningsDocument28 pagesSafety Instructions and WarningsEdson ReisNo ratings yet

- MF 15 4 Techs15583Document58 pagesMF 15 4 Techs15583Tim WorkmanNo ratings yet

- G32D DTCDocument59 pagesG32D DTCPower NguyenNo ratings yet

- 2005 2010 Quick Reference Guide PDFDocument79 pages2005 2010 Quick Reference Guide PDFJOSUE DURAN GRANDENo ratings yet

- Vulcan RemovalDocument21 pagesVulcan Removald4rk3No ratings yet

- 02-01 - Pneumatic Conveying SystemsDocument40 pages02-01 - Pneumatic Conveying SystemsROLAN MACALALAD100% (1)

- Touareg PricelistDocument20 pagesTouareg PricelistWytalikNo ratings yet

- A Micro-Project Report On: " Multipoint Fuel Injection System "Document17 pagesA Micro-Project Report On: " Multipoint Fuel Injection System "Vikram MagarNo ratings yet

- Kohler XT675 Owner's Manual 14 - 590 - 22 - ENDocument8 pagesKohler XT675 Owner's Manual 14 - 590 - 22 - ENbunkmonkeyNo ratings yet

- Operating Instruction PDFDocument43 pagesOperating Instruction PDFnamduong36867% (3)

- BMW N54 Engine Tuning Options (Vishnu Performance)Document2 pagesBMW N54 Engine Tuning Options (Vishnu Performance)bevioNo ratings yet

- Fuel Pump Removal 2Document5 pagesFuel Pump Removal 2ShaqqaNo ratings yet

- Vanguard 18hp - Engine # 3564470373F1Document61 pagesVanguard 18hp - Engine # 3564470373F1Matias Alfredo Contreras KöbrichNo ratings yet

- DT9.9 15Document134 pagesDT9.9 15Nico ObermeyerNo ratings yet

- An Introduction To The M14PDocument11 pagesAn Introduction To The M14PDave MarshNo ratings yet

- Lebm7301 04 PDFDocument94 pagesLebm7301 04 PDFVictor Nunez100% (1)

- E21OwnersManualSections-CareandMaint AndspecsDocument57 pagesE21OwnersManualSections-CareandMaint AndspecsJulio Fernando Gil TubacNo ratings yet

- Yaris ECMDocument1 pageYaris ECMImran MuhammadNo ratings yet

- 205 12Document14 pages205 12carlos maradiagaNo ratings yet

- Service Manual Trucks: MID 249, Bodybuilder Module Fault Codes VHD Version2 From Build Date 11.2002Document28 pagesService Manual Trucks: MID 249, Bodybuilder Module Fault Codes VHD Version2 From Build Date 11.2002Abdelhak EzzahriouiNo ratings yet