Professional Documents

Culture Documents

Reciprocating Air Compressor Report Bme

Reciprocating Air Compressor Report Bme

Uploaded by

Kartik JadhavOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Reciprocating Air Compressor Report Bme

Reciprocating Air Compressor Report Bme

Uploaded by

Kartik JadhavCopyright:

Available Formats

Annexure-1

Micro-Project proposal

(Format for Micro Project proposal about 1-2 pages)

Title of Micro -Project

Title of project: - Reciprocating Air Compressor

Aims Benefits of Micro Project (minimum 30-50 words)

Reciprocating Air Compressor is a type of positive displacement type of air

compressor in which air is sucked into a chamber and compressed with the help

of a reciprocating piston. The basic working principle of a reciprocating

compressor is similar to that of a crankshaft piston. The air flows into the

compressing cylinder after passing through the air filter and via a suction valve.

The air is then compressed using a crankshaft and a piston and leaves through a

discharge valve. The compressed air is then stored in a storage tank.

There are four kinds of reciprocating compressors:

1. SINGLE ACTING RECIPROCATING AIR COMPRESSOR

Only one side of the piston is used for the compression of the air and the

other side is connected to the crankshaft and not used for the compression.

2. DOUBLE ACTING RECIPROCATING AIR COMPRESSOR

Both the sides of the piston is used for the compression of the air. As the

piston moves, one side compressors the air while the other side sucks in

more air from the atmosphere.

3. SINGLE STAGE RECIPROCATING AIR COMPRESSOR

In this air compressor, the compression of the air takes place in a single

cylinder

4. DOUBLE STAGE RECIPROCATING AIR COMPRESSOR

In this types of compressor, the compression of the air takes place in two stages

i.e. the air is first compressed to some extent in one cylinder and is then

transferred to the second cylinder for further compression

2.0 Courses Outcomes Addressed

• Understand the operating principles of air compressors

• Identify the common types of compressors and their application

• Understand the use of air compressors in thermal power plant

• Understand the operating principles of screw compressor

• Understand the operating principal of reciprocating compressor

• Understand the operating and maintenance of compressor

• Understand the importance of lubrication in compressors

• Know the most common faults in compressors and troubleshooting

• Know the safe working method with compressors

3.0 Proposed Methodology (Producers in brief that will be followed to do

the micro project) in about 100 to 200 words).

i. First of all search information on mobile.

ii. Then collect the information about micro project. iii. Then give

the laptop/ computer and prepare report on project.

4.0 Action plan (Sequence and time require for major activity)

Sr.No. Details of Planned Planned Names of

Activity start Date Finished Responsible

Date

Team

Members

1 Collect 26/4/2022 27/4/2022 JADHAV

information KARTIK

on topic BALIRAM

(322)

MAHARASTRA STATE BOARD OF TECHNICAL EDUCATION

2 Prepare 26/4/2022 27/4/2022 PANGUDWALE

format YASH

SANTOSH (339)

3 Prepare 26/4/2022 27/4/2022 SAYYAD

format ABUJAR EJAJ

ALI (346)

4 Write 26/4/2022 27/4/2022 BORA OMKAR

report SANJAY (313)

5.0 Resources Required (major resources such as raw material, some machining

facility, software etc.)

Sr.No. Names of Resources Specification Qty. Remark

/materials

1 Internet service - 1 -

2 pc - 1 -

3 Sheet paper - 1 -

4 Colour pen - 5 -

Names of Team Members with Roll no.

1. JADHAV KARTIK BALIRAM (322)

2. PANGUDWALE YASH SANTOSH (339)

3. SAYEYAD ABUJAR EJAJ ALI (346)

4. BORA OMKAR SANJAY (313)

MAHARASTRA STATE BOARD OF TECHNICAL EDUCATION

MAHARASTRA STATE BOARD OF TECHNICAL EDUCATION

Annexure-2

Micro-Project Report

Format for Micro-Project Report (Minimum 4 pages)

Title of Micro -Project

1.0 Rationale (Importance of the project, in about 30 to 50 words. This is a

modified version of the earlier one written after the work)

Air compressors work by forcing atmospheric air under pressure to create

potential energy that can be stored in a tank for later use. Just like an open

balloon, the pressure builds up when the compressed air is deliberately

released, converting the potential energy into usable kinetic energy. From

there, this energy transfer can be harnessed to power various pneumatic tools.

Industrial air compressors work similarly to combustion engines. Generally,

air compressor operation requires a pump cylinder, piston and crankshaft to

transfer energy for a wide variety of tasks. These basic components can help

supply air for filling up objects like tires or inflatable pool toys, or they can

supply power for operating tools such as drills, nail guns, grinders, sanders

and spray guns.

From impact wrenches to AC units, many versatile air-powered tools and

machines are responsible for the comfort, shelter, automation and efficiency of

everyday life. The compressors themselves are more compact and lightweight

than other centralized power sources. They are also long-lasting, require less

maintenance and are easier to move than other old-fashioned machinery

2.0 Aims/Benefits of the Micro -Project:

An air compressor is a pneumatic device that converts power (using an electric

motor, diesel or gasoline engine, etc.) into potential energy stored in pressurized

air (i.e., compressed air). By one of several methods, an air compressor forces

more and more air into a storage tank, increasing the pressure. When the tank's

pressure reaches its engineered upper limit, the air compressor shuts off. The

compressed air, then, is held in the tank until called into use. [1] The energy

contained in the compressed air can be used for a variety of applications,

utilizing the kinetic energy of the air as it is released and the tank depressurizes.

When tank pressure reaches its lower limit, the air compressor turns on again

and re-pressurizes the tank. An air compressor must be differentiated from a

pump because it works for any gas/air, while pumps work on a liquid.

Compressed air is air that is pressurised to greater than atmospheric pressure. It

is exactly the same as the air that you breathe only it has been forced to a

smaller volume and kept under pressure. Air is made up of 78% nitrogen,

2021% oxygen and around 1-2% of other gases as well as water vapour. When

compressed, the air is still made up of the same mixture of gases, however, it

will have been forced into a smaller space, bringing the molecules closer

together.

Compressed air can be stored at a high pressure and is a fantastic medium for

transmitting energy. Compressed air is a popular energy source as it is safer and

easier than alternative options like steam and batteries. Steam can be dangerous

as it gets extremely hot whereas batteries can run out of charge, making both

options unfavorable.

Compressed air is safe to use, easy to store and has many versatile uses.

3.0 Course Outcomes Achieved (Add to the earlier list if more COs are

addressed)

Identify the force systems for given conditions by applying

the basic of mechanics

Check the broad based working Reciprocating air

compressors

Apply the principle of friction in various conditions for

useful purposes

select the

MAHARASTRA STATE BOARD OF TECHNICAL EDUCATION

4.0 Literature Review

Dr. D. D. Jadhav Reference book of basic mechanical engineering

In this book describe detail information on Reciprocating Air Compressor.

Reciprocating air compressor are a set of familiar words within a person’s

language. Reciprocating air compressor usually developed with age, services as

a useful and fundamental tool for communication and acquiring knowledge.

5.0 Actual Methodology Followed (Write step wise work done, data collected

and its analysis (if any). The contribution of individual member may also be

noted.)

First of all, search information on mobile.

Then collect the information about micro project.

Then give the laptop/ computer and prepare report on project.

MAHARASTRA STATE BOARD OF TECHNICAL EDUCATION

6.0 Actual Resources Used (Mentione the actual resources used).

Sr. Name of Specification Qty. Remarks

no. Resources/Material

1 mobile - - -

2 Sheet paper A4 size 1 -

3 colour pen 15cm 5 -

7.0 Outputs of the Micro-Projects (Drawings of the prototype, drawing of

survey, presentation of collected data, findings etc.)

• onveyors that move feed or grain between silos and other destinations

• Ventilation systems in greenhouses or hydroponic systems

• Crop spraying to deliver pesticides or fertilizer

• Powering different types of material handling machinery

• Powering various dairy machines from milking to material transportation

• Air tools and automated machinery

• Welding or cutting equipment

• Component ejection from molds

• Production monitoring devices

• Feed and roller machinery adjustments

• Molding gas tanks and plastic bottles

• Positioners, air knives, clamps and air chucks

• Pneumatic finishing and packaging devices

MAHARASTRA STATE BOARD OF TECHNICAL EDUCATION

8.0 Skill Developed/Learning outcome of the Micro-Project

• Operation Monitoring - Watching gauges, dials, or other indicators to

make sure a machine is working properly.

• Operation and Control - Controlling operations of equipment or systems.

• Critical Thinking - Using logic and reasoning to identify the strengths and

weaknesses of alternative solutions, conclusions or approaches to

problems

• Active Listening - Giving full attention to what other people are saying,

taking time to understand the points being made, asking questions as

appropriate, and not interrupting at inappropriate times.

• Repairing - Repairing machines or systems using the needed tools.

• Management of Personnel Resources - Motivating, developing, and

directing people as they work, identifying the best people for the job.

•

Instructing - Teaching others how to do something.

9.0 Applications of this Micro-Project.

• Air compressors are found in a wide range of environments for an even

wider range of uses. You’ll see gas stations offering compressed air to

inflate your vehicle’s tires and your tire shop using compressed air with

an air tool to remove your tires. You may have seen small desktop air

compressors used with an airbrush or a trailer-style gas-powered air

compressor at a construction site powering jackhammers and concrete

compactors.

• In fact, you’ve likely been around many different kinds of air

compressors and didn’t even know it — they may be hidden away in your

refrigerator or the HVAC system at your local arena.

• Air compressors have a multitude of uses for leisure and maintenance at

home or in businesses to get work done efficiently and safely. The

pressure that comes from compressed air has so many uses that we’re

sure to leave out a few applications.

• Still, we have compiled a lengthy list that will widen your knowledge

about the various ways that air compressors are used in a multitude of

environments.

• Different applications call for different types of air compressors.

MAHARASTRA STATE BOARD OF TECHNICAL EDUCATION

• While there are many types of compressors in size and power supply, you

will find two main designs for the majority of air compressors:

reciprocating piston air compressors and rotary screw air compressors.

• In these two designs, you’ll find several models offering a selection

ranging from the low-pressure air in a small storage tank, sufficient to

pump up your bike or car tires, to the ultimate power of pressurized air

that will supply a heavy manufacturing facility with constant and reliable

air for plant operations.

• Unless you work in manufacturing or another industrial environment,

you’re probably most familiar with reciprocating piston air compressors.

• However, you may not have seen all the variations of this air compressor

design.

• The tank can be vertical or horizontal, can be a single cylinder tank or

double cylinder and can be a portable design with wheels to easily move

around or a stationary model that stays in one place.

• Air compressors can be grouped into three classifications:

consumergrade, professional-grade and industrial-grade.

*******************

MAHARASTRA STATE BOARD OF TECHNICAL EDUCATION

MAHARASTRA STATE BOARD OF TECHNICAL EDUCATION

MAHARASTRA STATE BOARD OF TECHNICAL EDUCATION

MAHARASTRA STATE BOARD OF TECHNICAL EDUCATION

You might also like

- BioConsole 560 Operator and Reference Manual PDFDocument150 pagesBioConsole 560 Operator and Reference Manual PDFIsai Lara OsoriaNo ratings yet

- Machine Design Project Report UNITENDocument58 pagesMachine Design Project Report UNITENSyafiq Fauzi100% (4)

- NASA Systems Engineering Handbook: NASA/SP-2016-6105 Rev2 - Full Color VersionFrom EverandNASA Systems Engineering Handbook: NASA/SP-2016-6105 Rev2 - Full Color VersionNo ratings yet

- Sucker Rods HandbookDocument14 pagesSucker Rods HandbookJaime Andres Trujillo86% (7)

- MMK 11603 Computer Aided DesignDocument13 pagesMMK 11603 Computer Aided DesignFATHI HAKIMI BIN ANWAR STUDENTNo ratings yet

- Career Episode 3 Design and Analysis of Spray Drying PlantDocument7 pagesCareer Episode 3 Design and Analysis of Spray Drying PlantNishar Alam Khan 19MCD0042No ratings yet

- Final Seminar DocumentDocument15 pagesFinal Seminar Documentworku teklearegayNo ratings yet

- Rac Part 1Document13 pagesRac Part 1PrathmeshNo ratings yet

- Check Sheet For B. Sc. Thesis Proposal and Topic ApprovalDocument9 pagesCheck Sheet For B. Sc. Thesis Proposal and Topic ApprovalZeshan SarwarNo ratings yet

- Fabrication of Universal Tapping MachineDocument67 pagesFabrication of Universal Tapping MachineMuhammed Hashirkk0% (1)

- Shelland Tube Heat ExchangerDocument23 pagesShelland Tube Heat ExchangerAditya YadavNo ratings yet

- Analysis of Air Ow in An Empty Room Due To Single and Double Ceiling FanDocument22 pagesAnalysis of Air Ow in An Empty Room Due To Single and Double Ceiling FanFrancisco A. LotufoNo ratings yet

- Shell and Tube Heat Exchanger: January 2018Document23 pagesShell and Tube Heat Exchanger: January 2018gamailkabaaaapNo ratings yet

- Industrial Centrifugal Compressors Design Validation, Using Rapid Method Evolutionary Algorithms To Predict Map Characteristics EvaluationDocument12 pagesIndustrial Centrifugal Compressors Design Validation, Using Rapid Method Evolutionary Algorithms To Predict Map Characteristics EvaluationMustafa AliosmanoğluNo ratings yet

- Designing, Analysis, Selection, Drafting and Modeling of HVAC System and Its Component (For Mechanical Engineering Department)Document18 pagesDesigning, Analysis, Selection, Drafting and Modeling of HVAC System and Its Component (For Mechanical Engineering Department)Akash Srivastava100% (1)

- ShellandTubeHeatExchanger ProjectDocument23 pagesShellandTubeHeatExchanger Projectmanish sengarNo ratings yet

- Nature of The Project: TH THDocument4 pagesNature of The Project: TH THSyed YousufuddinNo ratings yet

- Engineering & Technology Surat) : (C.K.Pithawala College ofDocument23 pagesEngineering & Technology Surat) : (C.K.Pithawala College of19006 Sahel GamitNo ratings yet

- Pneumatic Can Crushing MachineDocument22 pagesPneumatic Can Crushing MachineBoopathi KalaiNo ratings yet

- Fluid Machineries SW - 4Document9 pagesFluid Machineries SW - 4Napoleon Russell QueNo ratings yet

- PROJECT REPORT 2017-2018 Submitted by (Team Name) : Manual and Motorized BlowerDocument53 pagesPROJECT REPORT 2017-2018 Submitted by (Team Name) : Manual and Motorized Blowerimran kadriNo ratings yet

- Turbine Blade PaperDocument23 pagesTurbine Blade PaperÖğüt CumaNo ratings yet

- University Institute of Engineering: Plant Utilities CHF-451Document15 pagesUniversity Institute of Engineering: Plant Utilities CHF-451metaliNo ratings yet

- Drying Software ArticleDocument12 pagesDrying Software ArticleIonut VelescuNo ratings yet

- Design and Analysis of Gas Turbine Rotor Blade Using Finite Element MethodDocument23 pagesDesign and Analysis of Gas Turbine Rotor Blade Using Finite Element MethodFITAS MOUNIRNo ratings yet

- Drying Software ArticleDocument20 pagesDrying Software ArticleFA AyNo ratings yet

- Discovery: Pneumatic Metal Sheet Cutting MachineDocument7 pagesDiscovery: Pneumatic Metal Sheet Cutting MachineStella RaphaelNo ratings yet

- PREPARE A Report Port of Various Pneumatic Hand Tools and Its AttachmentsDocument9 pagesPREPARE A Report Port of Various Pneumatic Hand Tools and Its AttachmentsMe Samarth BadsalNo ratings yet

- Redesign of Desk FanDocument50 pagesRedesign of Desk FanartiedalarripaadrianNo ratings yet

- Design of Air Conditioning System For Residential/Office BuildingDocument5 pagesDesign of Air Conditioning System For Residential/Office BuildingmuskanNo ratings yet

- Synopsis For Btech4 YearDocument5 pagesSynopsis For Btech4 YearAkash SrivastavaNo ratings yet

- Pneumatic Multipurpose Press (Report)Document86 pagesPneumatic Multipurpose Press (Report)shivapalanipedNo ratings yet

- Air JetDocument12 pagesAir JetSajib Iglesias100% (1)

- Air Blower Using HouseDocument6 pagesAir Blower Using HouseShahzaib GulNo ratings yet

- Air Blower Using HouseDocument6 pagesAir Blower Using HouseShahzaib GulNo ratings yet

- Engineering Design ProcessDocument7 pagesEngineering Design ProcessMuhd AriffNo ratings yet

- Design of Air Conditioning System For Residential/Office BuildingDocument5 pagesDesign of Air Conditioning System For Residential/Office BuildingDareyoss NegussieNo ratings yet

- Automatic Copper Wire Cutting MachineDocument79 pagesAutomatic Copper Wire Cutting Machinephoenixsiva100% (2)

- CFD Analysis of Solar Flat Plate CollectorDocument6 pagesCFD Analysis of Solar Flat Plate CollectorDimuthu Prasad WijethungeNo ratings yet

- Nature of The Project: ND RDDocument5 pagesNature of The Project: ND RDSyed YousufuddinNo ratings yet

- CFD Based Simulation Model For Design of Fixed NozzleDocument11 pagesCFD Based Simulation Model For Design of Fixed NozzleeseNo ratings yet

- BKF3463 - Unit Operation (Integrated Project Overview) 20151016-1 LatestDocument3 pagesBKF3463 - Unit Operation (Integrated Project Overview) 20151016-1 LatestNor HidayahNo ratings yet

- Guidelines For Btech Industrial Training EedDocument6 pagesGuidelines For Btech Industrial Training EedhimanshuNo ratings yet

- Design and Fabrication of Solar Powered Air PurifierDocument7 pagesDesign and Fabrication of Solar Powered Air PurifierKala JattNo ratings yet

- Performance Analysis of Desiccant DehumidifierDocument18 pagesPerformance Analysis of Desiccant DehumidifierTotoh HanafiahNo ratings yet

- Executive Summary For Aarti Industries - Ishaan MehtaDocument2 pagesExecutive Summary For Aarti Industries - Ishaan MehtaritikNo ratings yet

- 2017Document12 pages2017subhadhali1998No ratings yet

- Modeling and Designing of Wind Turbine Blade: September 2020Document70 pagesModeling and Designing of Wind Turbine Blade: September 2020Karthik JNo ratings yet

- Pneumatic Trainer KitDocument19 pagesPneumatic Trainer Kitfidianty hutasoitNo ratings yet

- HVAC Course PreviewDocument8 pagesHVAC Course PreviewMohammed MechNo ratings yet

- Analisa Pengaruh Diameter Impeller Terhadap Kapasitas Dan Penurunan Tekanan Blower SentrifugalDocument10 pagesAnalisa Pengaruh Diameter Impeller Terhadap Kapasitas Dan Penurunan Tekanan Blower SentrifugalMuwafiqah MarwaNo ratings yet

- A Seminar Report On Vocational Training at SNC Power Corporation (P) Ltd. Jaipur (20-03-2014 TO 20-04-2014)Document55 pagesA Seminar Report On Vocational Training at SNC Power Corporation (P) Ltd. Jaipur (20-03-2014 TO 20-04-2014)Sonu LovesforuNo ratings yet

- TurbinebladepaperDocument23 pagesTurbinebladepaperJuan Bernardo AlonsoNo ratings yet

- Literature Review of Reciprocating CompressorDocument8 pagesLiterature Review of Reciprocating Compressorc5qx9hq5100% (1)

- Industrial Training Format CivilDocument12 pagesIndustrial Training Format CivilBhat TalhaNo ratings yet

- Emeraldf1a4b4d2 88a0 20140220065003Document8 pagesEmeraldf1a4b4d2 88a0 20140220065003Sbaa SbaaNo ratings yet

- Fabrication of Pneumatic Auto Feed Punching MachineDocument73 pagesFabrication of Pneumatic Auto Feed Punching MachineVinayaga ProjectinstituteNo ratings yet

- Mon-52 p1 Milestone1Document17 pagesMon-52 p1 Milestone1api-529470340No ratings yet

- Research and Design of Snow Hydrology Sensors and Instrumentation: Selected Research PapersFrom EverandResearch and Design of Snow Hydrology Sensors and Instrumentation: Selected Research PapersNo ratings yet

- Understanding Aerodynamics: Arguing from the Real PhysicsFrom EverandUnderstanding Aerodynamics: Arguing from the Real PhysicsRating: 4.5 out of 5 stars4.5/5 (2)

- Mechatronics - Unit-Iii (Iv B.Tech I Sem Mech) : (Hydraulic Systems)Document36 pagesMechatronics - Unit-Iii (Iv B.Tech I Sem Mech) : (Hydraulic Systems)Radha KrishnaNo ratings yet

- ha2Pyfaduh12Ezcakdb4Iyaxpx1J2Ljenqghlodczgttdh8Yi5Kga Io-Device?Skuid 35709Document6 pagesha2Pyfaduh12Ezcakdb4Iyaxpx1J2Ljenqghlodczgttdh8Yi5Kga Io-Device?Skuid 35709Mahmoud AhmedNo ratings yet

- Technical Data: Uni en 12845 Fire-Fighting Sets With Vertical PumpsDocument11 pagesTechnical Data: Uni en 12845 Fire-Fighting Sets With Vertical PumpsEmanuel CezarNo ratings yet

- Check List API RP 14c: DownloadDocument2 pagesCheck List API RP 14c: DownloadtunlinooNo ratings yet

- en WHB Hatz W35 PDFDocument76 pagesen WHB Hatz W35 PDFpricopdaniel100% (3)

- Saep 365 PDFDocument32 pagesSaep 365 PDFRami ElloumiNo ratings yet

- 85633Document24 pages85633RZ EmiNo ratings yet

- Axial Piston Variable Pump A10VG Series 10: RE 92750/2020-03-03 Replaces: 2019-12-12Document60 pagesAxial Piston Variable Pump A10VG Series 10: RE 92750/2020-03-03 Replaces: 2019-12-12Omar OsmanNo ratings yet

- Live Graving Dry DockDocument36 pagesLive Graving Dry DockAshiq AbdullahNo ratings yet

- Sample Problem - Pump Power Calculations - EnggcyclopediaDocument6 pagesSample Problem - Pump Power Calculations - EnggcyclopediaMuhammadObaidullahNo ratings yet

- DG - Datasheet Heat Exchanger TypeDocument9 pagesDG - Datasheet Heat Exchanger TypeCoral bhaiNo ratings yet

- Äktabasic Systems: A New Way of WorkingDocument8 pagesÄktabasic Systems: A New Way of WorkingCarlos Alberto Ramirez GarciaNo ratings yet

- Pompa Grease Trap 326,16 LPM @13,2mDocument1 pagePompa Grease Trap 326,16 LPM @13,2mAndreas B KresnawanNo ratings yet

- Fire Pump Proposal Summary: WeightDocument3 pagesFire Pump Proposal Summary: WeightDerkung Benowat100% (1)

- Grant Cooled Water Baths R-Series Operating Instructions ManualDocument24 pagesGrant Cooled Water Baths R-Series Operating Instructions ManualvalruxNo ratings yet

- WaterGems Output Clear Water Design-Reamal Block-20.10.2020Document5 pagesWaterGems Output Clear Water Design-Reamal Block-20.10.2020Milan NayekNo ratings yet

- Lebw4957 05Document50 pagesLebw4957 05PhamLeDanNo ratings yet

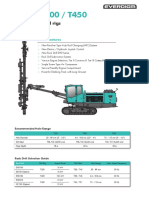

- Top-Hammer Drill Rigs: Main FeaturesDocument2 pagesTop-Hammer Drill Rigs: Main FeaturesGeorge HarrisonburgNo ratings yet

- Nash Liquid Ring Vacuum Pumps - CompressDocument6 pagesNash Liquid Ring Vacuum Pumps - Compressabu omarNo ratings yet

- Cat 416DDocument24 pagesCat 416DJulio MeesNo ratings yet

- Design Criteria & Tech Spec. For Water SupplyDocument25 pagesDesign Criteria & Tech Spec. For Water Supplyuhudhu.ahmedNo ratings yet

- Wartsila O Pumps Svanehoj BallastDocument4 pagesWartsila O Pumps Svanehoj BallastBoris SitorusNo ratings yet

- DS 6HH-CCDocument2 pagesDS 6HH-CCJose UllauriNo ratings yet

- WS-01 - Flow SwitchDocument1 pageWS-01 - Flow SwitchSHARAB IMTIAZNo ratings yet

- 04 Gambar Alat 171220Document57 pages04 Gambar Alat 171220rendra syamNo ratings yet

- Remove Transmission Oil Pump and Control Valve As A UnitDocument3 pagesRemove Transmission Oil Pump and Control Valve As A UnitAnonymous cS9UMvhBqNo ratings yet

- Room Air Conditioner: Service ManualDocument42 pagesRoom Air Conditioner: Service ManualUlfran MedinaNo ratings yet

- KLINGER Gland Packing Selection GuideDocument1 pageKLINGER Gland Packing Selection Guidesf wNo ratings yet