Professional Documents

Culture Documents

Digital Transformation in Oil and Gas Companies-A Case Study of Bien Dong POC

Digital Transformation in Oil and Gas Companies-A Case Study of Bien Dong POC

Uploaded by

beriOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Digital Transformation in Oil and Gas Companies-A Case Study of Bien Dong POC

Digital Transformation in Oil and Gas Companies-A Case Study of Bien Dong POC

Uploaded by

beriCopyright:

Available Formats

See discussions, stats, and author profiles for this publication at: https://www.researchgate.

net/publication/345572096

Digital Transformation in Oil and Gas Companies-A case study of Bien Dong

POC

Article · October 2020

DOI: 10.47800/PVJ.y2020v10-07

CITATIONS READS

5 6,030

4 authors, including:

Tung V. Tran Trung Ngọc Tran

Biendong Petroleum Operating Company 16 PUBLICATIONS 21 CITATIONS

29 PUBLICATIONS 104 CITATIONS

SEE PROFILE

SEE PROFILE

Ngô Hữu Hải

27 PUBLICATIONS 373 CITATIONS

SEE PROFILE

All content following this page was uploaded by Tung V. Tran on 09 November 2020.

The user has requested enhancement of the downloaded file.

RESEARCH & DISCUSSION

PETROVIETNAM JOURNAL

Volume 10/2020, p. 68 - 81

ISSN 2615-9902

DIGITAL TRANSFORMATION IN OIL AND GAS COMPANIES -

A CASE STUDY OF BIEN DONG POC

Tran Vu Tung, Tran Ngoc Trung, Ngo Huu Hai, Nguyen Thanh Tinh

Bien Dong Petroleum Operating Company

Email: tungtv@biendongpoc.vn

https://doi.org/10.47800/PVJ.y2020v10-07

Summary

The fourth industrial revolution (Industry 4.0) with the breakthrough of internet and artificial intelligence has had a strong impact,

changing all aspects of global socio-economic life. Digital transformation in the spread of Industry 4.0 is no longer a choice but has become

an inevitable development trend for businesses to truly stand up to the times. Digital transformation is the transformation of business

activities, processes, products, and models to fully leverage the opportunities of digital technologies, characterised by development,

growth, innovation, and disruption. In particular, "digital disruption" is the situation when new technology competes with the traditional

business way that we now often refer to under the concepts of cloud computing, big data, and internet of things (IoT). This competition

will help businesses utilise digitised data and processes to create a new model that is more efficient and convenient. Digital technologies

in oil and gas companies can have a significant business impact as it contributes to increasing hydrocarbon recovery, ensuring safety

across the business ecosystem, and improving operational reliability. This paper addresses the oil and gas industry’s trends in digital

transformation and the initiatives at Bien Dong POC.

Key words: Digital transformation, oil and gas industry, big data, AI, digitalisation.

1. Introduction tools that combine data science, smart sensors and data

communications can help prevent machine failures and

The oil and gas industry is undergoing a fundamen-

improve productivity.

tal digitalisation era to unlock more energy at lower costs

and delivers significant performance improvements. With - Product quality and parameters are monitored

real-time insights, improving equipment availability and throughout the entire manufacturing process.

getting ahead of obstacles become less challenging. To - Operational costs of production when automated,

remain competitive, companies are adapting and trans- intelligent and visualised production segments can

forming their trial and error models to take advantage of reduce personnel involved in field monitoring, machine

current paradigm shift to implement modern solutions operation, technology systems, and logistics.

and accelerate the impact of going digital.

- Workplace safety is better ensured.

Digitalisation is the integration of digital technologies

and business models through applications such as big 2. Opportunities for digital transformation in oil and

data, internet of things (IoT), cloud storage, connection, gas industry

and artificial intelligence (AI), etc., in order to create ma-

Energy consumption continues to increase over the

jor changes in the operational scheme and enhance the

years. As shown in Figure 1, although renewables will in-

company’s value [1].

crease sharply, oil and natural gas will continue to be the

The benefits from digital transformation can be sum- biggest energy source used by the world's population,

marised in four groups: accounting for about 55% of total annual energy con-

- Productivity improvement using maintenance sumption. Since current oil and gas exploitation activities

have naturally declined, the continuous growth of pe-

Date of receipt: 1/10/2020. Date of review and editing: 1-16/10/2020. troleum fuels will only be possible when there are tech-

Date of approval: 18/10/2020. nological leaps in exploration and production activities.

68 PETROVIETNAM - JOURNAL VOL 10/2020

PETROVIETNAM

The deployment of industrial revolution 4.0 applications levels. It can drive substantial enhancements for worker

is one of the necessary measures to increase production productivity, and data-driven decision making, thereby

at lower costs. accelerating a creative digital innovation. It also helps in

promoting operational excellence by transforming the

Today, digital technologies in oil and gas focus on

federated legacy operating environment into a lean, agile,

two aspects of IT optimisation and business optimisation.

and high performance computing business platform. Dig-

Digitalisation helps in creating a lean and agile IT service

ital technologies can also facilitate combining data from

environment that concentrates on operational excellence.

financial, transactional, geophysical, and other systems.

New IT technologies such as advanced analytics, data cen-

Thus, businesses are able to unleash business value by

tre automation, and cloud computing are explored and

means of new forms of advanced analytics. Digital tech-

employed. Meanwhile, digitalisation helps in enhancing

nologies can range from simple visualisations systems

business performance by implementing digital capabili-

to complex simulation models that can reliably predict

ties such as business simulation, integrated planning, and

future performance, all the way to highly automated ma-

asset performance management.

chine learning analytics.

It is showed that digitalisation amplifies business op-

Thus, implementation of digital technologies can fa-

timisation by creating seamless integration across organ-

cilitate operational excellence, thereby allowing oil and

isational silos, thereby enabling operational agility at high

End-use energy consumption by sector, world End-use energy consumption by fuel, world

quadrillion British thermal units quadrillion British thermal units

350 350

Industrial

300 300

History Projections

250 250 Petroleum and other

liquids

200 200

Transportation

150 150 Electricity

Natural gas

100 100

Residential Coal

50 Commercial 50

Renewables

0 0

2010 2020 2030 2040 2050 2010 2020 2030 2040 2050

Primary energy consumption by energy source, world

quadrillion British thermal units Share

300 100 Renewables

History Projections

Renewables 90

250 Petroleum and other 80 Petroleum and

liquids other liquids

70

200 Natural gas

Coal 60

150 50

Coal

%

40

100

30

20 Natural gas

50

Nuclear 10

0 Nuclear

0

2010 2020 2030 2040 2050 2018 2050

Figure 1. World annual energy consumption reported in International Energy Outlook 2019 [2].

PETROVIETNAM - JOURNAL VOL 10/2020 69

RESEARCH & DISCUSSION

Figure 2. Applications based on digital platform in petroleum industry [4].

gas leaders to effectively prove that they are running their ticular, digitisation is the first step and also plays the most

assets safely, sustainably, reliably, and cost-effectively. important role because it can significantly increase pro-

ductivity, save time and make the system more secure. In

In fact, recently, there are a few sectors in the oil and

other words, the result of the digitisation process is the

gas industry that can afford new technologies, but they are

condition required to perform the digital transformation.

just separate solutions in field management, production,

and maintenance. According to Deloitte's report in 2015, In the 1980s, oil and gas companies began to apply

digitalisation in the petroleum industry was rated 4.68 on a digital technology to accurately estimate the reserves

10-point scale [3]. Only a few leading oil and gas companies and potential production of the hydrocarbon resources as

are highly digitalised and are developing towards smartisa- well as to improve operational efficiency of the oil and gas

tion. Therefore, in order to become a “4.0 company”, a com- fields in the world [4]. However, over the years, the oil and

pany needs to take advantage of the following factors: gas industry has not fully seized the opportunity to use

data and technology in a meaningful way. For example, an

- New technologies with smart sensors, IoT and

oil and gas platform can generate trillions of bytes of data

intelligent technologies enable workers to work remotely,

per day [4], but only a small portion is used for decision

- High-speed bandwidth connection improves data making. The reason is that the data processing technol-

transmission between on-shore and off-shore platforms, ogy has not met the requirements, the information tech-

- Big data and large data storage capacity becomes nology infrastructure system of the oil and gas industry

available at a much cheaper cost. Cloud computing is going slowly compared to the times. Modern central

technology and cloud storage platform make the cost of distributed control systems still use infrastructure with

operation, maintenance and upgrade much cheaper than slow transmission speeds such as Supervisory Control and

on-premise database server systems, Data Acquisition (SCADA), Highway Addressable Remote

Transducer (HART) Protocol, and Fieldbus, etc. Therefore,

- Advanced analytical methods and advanced

digitalisation in the oil and gas upstream industry is still in

simulation greatly assist in making timely and accurate oil

the early stage.

and gas field operating decisions.

In the future, digital transformation in oil and gas

- New business models and smarter workflow

should focus on the following four topics: asset life cycle

processes help improve productivities.

digital management, the concept of "beyond the barrel",

The digital transformation process undergoes three the circular collaborative ecosystem and energy optimisa-

key steps: (1) digitisation, (2) digitalisation of the process tion [4]. Different themes will create respective applicable

(digitalisation), and (3) digital transformation (DT). In par- innovations and technologies (Figure 2):

70 PETROVIETNAM - JOURNAL VOL 10/2020

PETROVIETNAM

Table 1. Amount of generated data in petroleum engineering disciplines [4]

Section The amount of data

Drilling data 0.3 GB/well/day

Electric submersible pump monitoring 0.4 GB/well/day

Wireline data 5 GB/well/day

Fiber optic data 0.1 GB/well/day

Seismic data 100 GB/survey

Plant process data 4 - 6 GB/day

Pipeline inspection 1.5 TB/600 km

Plant atmospheric data 0.1 GB/day

Plant operational data 8 GB/year

Vibration data 7.5 GB/year/customer

- Asset life cycle digital management is the process directors as well as all technical team and support staffs of

of digital transformation and equipment operation the oil and gas company need to ensure continuous and

modelling and improvement of strategic decision-making multidisciplinary involvement throughout the project life

based on data science. The process relies on dedicated cycle. Continuous feedback will assist in shaping timely

sensors to collect real-time information from physical and accurate project planning and implementation. Sec-

assets, and on analytical tools to process data. Companies ond is the lack of training and retraining of personnel

make decisions and strategies to advance business in the development of smart oilfield projects. Third, the

performance as well as operating model. shortage of skilled labour in the oil and gas industry and

- The circular collaboration ecosystem uses an the lack of experience in similar projects are equally a

integrated digital platform to better collaboration challenge. People with knowledge and experience from

among stakeholders in the petroleum ecosystem, while successful implementation of digital transformation proj-

accelerating innovation, reducing costs, and improving ects are very rare even in the world.

transparency in governance and administration. For process and improvement, one challenge is the

- The concept of "beyond the barrel" refers to the large number of traditional processes that need to be

application of a customer model, supplier participation re-evaluated and digitised into digital processes that re-

in innovation and flexibility, using expert knowledge and quire huge amounts of time, manpower, and technologi-

opening new opportunities for petroleum operation. cal factors. The second one is the inertia or resistance to

non-traditional change. Meanwhile, for the application of

- Energy optimisation refers to the use of advanced

new technologies, the two biggest challenges are limited

technologies to improve the efficiency and effectiveness

budget and limited expertise. In the current period with

of production systems.

the constant and unpredictable fluctuations of oil and

3. Challenges and opportunities in digital transformation gas prices, budget for technology application becomes a

challenge. Besides, the continuous change and improve-

The implementation of digital transformation in an oil ment of technology also have a significant impact on the

and gas company consists of three main pillars: human, immediate investment decisions or are waiting for more

process (corporate culture, administration, digital strat- effective and smarter solutions in the near future.

egy and process improvement) and new technologies ap-

plication. For the culture and digital strategy, the human Analysis and data management poses many chal-

factor is the biggest challenge. First, defining the busi- lenges for the oil and gas engineering team. The first is the

ness’s Mission - Vision - Core value and digital strategy are ability to analyse, synthesise and process a large amount

restructuring, changing the mindset, working method of of fragmented data in many places with many different

the entire enterprise in the direction of digitisation. In ad- technical disciplines. The second challenge is security

dition, when experience is weak, leaders should also pro- when data needs to be centralised, strictly confidential

vide learning opportunities to project team or divide the and decentralised to access. Real-time data retrieval and

project into different phases with separate milestones. response to oil and gas facilities are also a major challenge

The lack of feedback loops (Plan-Do-Check-Act) is a chal- as most people in complex geographic locations find it

lenge in the development of Oil and gas 4.0. The board of difficult to secure a continuous broadband connection.

PETROVIETNAM - JOURNAL VOL 10/2020 71

RESEARCH & DISCUSSION

Table 2. Lists of major challenges in digital transformation

Challenges Description Solution

System safety Interaction and integration of different Companies in different technology sectors will work together

technologies can lead to errors. The supporting to overcome existing technical challenges and limitations.

platforms and facilities are yet to be deployed.

Digitalisation Poor alignment between real project goals and Defining the Mission - Vision - Core value of the business and

strategy the needs and operating status of the company. defining the digital strategy are restructuring, changing the

The goals are becoming outdated in terms of mindset, working method of the entire enterprise towards

technology that is constantly changing. digitalisation.

Geography New oil and gas fields are increasingly in remote 1. Upgrade communication and connection to meet the new

locations. Limited bandwidth between offshore needs.

platforms and onshore headquarters because 2. It is necessary to focus on digital data soon. As a premise for

offshore platforms are often located in remote advanced analysis and artificial intelligence.

locations, out to sea. 3. Research and deploy edge computing applications.

The data is fragmented due to the nature of the

work and is not synchronised.

Macro policy Lack of government policy and planning. Governments will coordinate with businesses to make policy,

propaganda, and guidance planning. Oil and gas, computer

science, automation and other engineering disciplines will be

linked together based on the master plan and the guidelines

of each country.

In Vietnam, the following resolutions and action plans are

available:

1. Resolution No. 52-NQ/TW, dated September 27, 2019 of the

Politburo on several guidelines and policies to actively

participate in the Fourth Industrial Revolution.

2. Directive 16/CT-TTg dated May 4, 2017 of the Prime Minister

on strengthening access capacity to the Industrial Revolution

4.0.

3. Contents of the Action Plan in Decision No. 4246/QD-BCT

dated November 10, 2017 of the Minister of Industry and

Trade.

Traditional With everything digitally connected, we no Businesses need a modern and comprehensive digital

process longer have to rely on traditional paper-based solution that replaces outdated, error-prone paper processes

processes and operate in silos; There will be no and takes advantage of this digitised data.

more room for manual and time-consuming

processes.

Resistance to Where is the organisation on the changes? Most 1. Companies should have the best digital solution to

change employees are entrenched in traditional daily minimise time-consuming processes, improve employee

mission processes. When it comes to improving efficiency and reduce work pressure by allowing access to

processes and incorporating new technologies, work from anywhere, at any time, regardless of location.

they resist. They see change management as a 2. The era of "Oil and gas 4.0" must be initiated from the

challenge to their roles/responsibilities and a leadership level. Company management needs to deliver the

threat to their job safety. Many people resist the highest level of commitment and be passed on to each

change of their working environment because employee as part of the digital transformation process.

digital disruption is seen as a threat to many 3. Transparency and effective communication are essential to

employees in the profession. Besides, a new and keep people motivated about the potential of this new

difficult problem is always sceptical and technology.

uncooperative. 4. Improve employees' capacity and awareness.

Outdated Businesses are very comfortable in their existing 1. Manufacturers need to leave their comfort zones, revamp

business systems. The need for upgrading is not clear their business models, and move towards more efficient,

model without seeing the results of pioneering accurate, and fast business processes using modern digital

projects. technologies instead of current generation of outdated systems.

2. If there is an early awareness of Industry 4.0 and assessment

of advantages and disadvantages of the current model, it is

the choice. If it is late, it is a life-and-death decision, vital to the

business.

Limited Many repetitive, redundant, and time- Organisations can automate or reduce manual tasks, allowing

automation consuming tasks that are performed manually for faster product updates and response times by embracing

by a group of employees consume a large the right digital solution.

amount of work time resulting in high costs.

72 PETROVIETNAM - JOURNAL VOL 10/2020

PETROVIETNAM

Challenges Description Solution

Budget A substantial investment in a manufacturing 1. Companies will gradually realise the great benefits of digital

limitation facility is required during the digital transformation and increase their investments.

transformation journey. The benefits are many, 2. Appropriate planning of the investment process is required,

both short term and long term, but it is and no two digital transformation schemes are alike.

important for each company to have a strategy 3. Having a long-term vision is crucial to achieving a truly

that matches its business model, revenue, and valuable future goal. Avoid short-term influences such as

total operating costs. Covid-19 or oil prices slump that could interrupt or stop the

programme.

4. Solid solutions (return on investment - ROI) should be

selected and considered as a proof-of-concept method (POC).

Lack of Without the right expertise, the introduction of 1. In case the company's existing expertise is inadequate, a

knowledge the technology alone is not enough to make it partnership with outside consultants or hiring new staff

work. Increasing employee knowledge is an should be considered.

essential part of the application of digital 2. The digital transformation programme responsibility

technologies into production. should be a common goal of the entire organisation and

Lack of experience from doing a similar project is should not be limited to just a few employees or departments.

equally a challenge. 3. Universities offer interdisciplinary courses.

Lack of interdisciplinary talent, the current

education system focuses too much on

cultivating a single specialty.

Unsuitable Lack of training and retraining of personnel in 1. The leaders should also provide learning opportunities to

training developing smart oilfield projects; shortage of the project team or break the project into small sections with

programme skilled workers in the oil and gas industry. separate milestones. The lack of feedback loops (Plan-Do-

Check-Act) is a challenge in the development of Oil and gas

4.0. Ensuring continuous and multidisciplinary involvement

throughout the life of the project between the project team,

the board of directors as well as all technical and support

personnel of the oil and gas company.

2. Need a methodical and scientific training programme to

develop smart oilfield projects. This helps to add knowledge

that is lacking and is not usually found in oil and gas operating

businesses such as cloud computing, data mining, or artificial

intelligence.

Inflexible - The introduction of the Industrial Internet of 1. To solve this problem, it is necessary to form a project team

structure Things (IIoT) or AI into an offshore platform is from many disciplines including engineers, operating

not just a small improvement. The organisation technicians, data analysts and experts into the team

needs a new technological background, people, responsible for the transformation. The team will nurture

and business model. If necessary, the structure ideas, research new technologies, and then develop

must be established and reorganised to meet execution plans promoting collective strength and wisdom.

the changing needs of Industry 4.0. 2. Large and multinational oil and gas companies have been

- The application of new technologies takes a at the forefront of the pilot work. The models and benefits

certain amount of time to evaluate, and to adjust have been clearly indicated and documented, companies

the existing strategy according to the new with a smaller model will build their own digital

environment. transformation model.

Security Cyber security is a major concern for any digital 1. Vulnerable issues should be identified and recorded.

transformation project as the network works and 2. Several layers of protections and insecure mechanisms

control systems will be connected to the need to be in place to ensure the system is safe, secure, and

internet. reliable.

The major challenges in digital transformation can be cy. Oil prices are highly volatile and extraction costs often

identified in Table 2. rise in more challenging environments, such as deep and

arctic waters and unconventional resources (e.g. oil and

4. Digital transformation in oil and gas upstream

shale gas). Mature fields need to optimise exploitation

industry

costs; efficiency and competitiveness in finding and sup-

Oil and gas upstream is characterised by strong com- plying oil and gas for domestic and global markets have

petition in terms of area, capital and market; therefore all to be improved.

oil and gas producers must focus on production efficien- According to Korovin and Tkachenko, the Oil and

PETROVIETNAM - JOURNAL VOL 10/2020 73

RESEARCH & DISCUSSION

gas 4.0 programmes focus on the integration of produc- companies, smart oil fields can increase production by 2

tion operations, decision making and the application of - 7% and reduce operating costs by 5 - 20%. In addition,

modern information technology [5]. From an application according to the practice of smart oil field projects, smart

perspective, the smart oil and gas field not only replaces oil fields need to have the following functions: (1) real-

repetitive human work, but also replaces human analy- time data accessing and sharing; (2) ability to analyse the

sis, which is a knowledge creation process. The process current state, predict future trends and make optimisation

is: Awareness → Analysis and Alerts → Decision → Imple- decisions; (3) ability to achieve operational integration;

mentation → Optimisation). and (4) automatic control capabilities.

In recent years, smart oil fields have grown rapidly and In addition, Table 3 addresses the opportunities for

many large companies are working on them. For example: applications implemented in the oil and gas industry.

BP's "Field of the future" uses smart sensors and automa-

5. Digital transformation at Bien Dong POC

tion process to transmit real-time data from the field to

a remote centre for rapid analysis and decision-making Facing the oil price slump in recent years, the task of

[6]. This programme started in 2003 and BP deployed this oil and gas companies is to optimise exploration and pro-

programme for 80 wells around the world in 2012. They duction costs, improve efficiency and competitiveness in

also established the "Advanced Collaboration Centre" finding and supplying oil and gas for domestic and world

worldwide to allow remote co-operation in many fields of markets. Bien Dong POC has made efforts to look for the

oil and gas engineering and exchange expertise between potential oil and gas prospect and focused on research-

locations. At the beginning of project implementation, a ing solutions to maximise the amount of recovered oil

programme structure was proposed, consisting of three and gas in the Hai Thach - Moc Tinh fields, improving effi-

layers: digital infrastructure and IT architecture, remote ciency of oil and gas production activities. However, it can

performance management, and system optimisation. be seen that traditional approaches for search and explo-

In Shell's "Smart Fields" programme, sensors and ration of oil and gas fields, especially condensate fields, as

control valves in complex reservoir environments are so far employed in Vietnam have reached the boundary

connected to improve operational efficiency through of economic efficiency, forcing us to consider using mod-

real-time monitoring [7]. According to estimates by large ern and non-traditional technologies, particularly digital

Table 3. Industrial Revolution 4.0 applications in oil and gas industry [4]

Area Application Reference

Exploration - Geological data [8 - 11]

- Seismic interpretation.

- Geological maps 1D, 2D, and 3D.

Drilling - Rig optimisation. [12 - 16]

- Productivity.

- Non-production time reduction (NPT).

- Risk reduction.

- Characterising the drill string dynamics.

Reservoir Engineering - Reservoir management. [17 - 23]

- Closed-loop reservoir management-CLRM), (Integrated asset modelling - IAM).

- Heavy oil reservoir optimisation.

- Unconventional reservoir characterisation.

- Improved hydraulic fracturing.

- Improved enhanced oil recovery projects.

Production Engineering - Improved decline curve analysis. [24 - 30]

- Production back allocation.

- Electric submersible pump (ESP) optimisation

- (Rod pump optimisation.

- Improved hydraulic fracturing operation.

- Improved reservoir surveillance.

Maintenance - Asset management. [31 - 32]

- Well completion optimisation.

Health and Safety - Effective HSE management. [33 - 36]

Environment - HSE) - Improved risk assessment method.

74 PETROVIETNAM - JOURNAL VOL 10/2020

PETROVIETNAM

transformation, application of big data processing technology, auto- Third, the company conducts research-

mation and development of artificial intelligence systems to support es develops goals and action plans in the

decision-making. Accurate determination to improve the efficiency of coming time for oil and gas field manage-

management and exploitation of oil and gas fields has become a real ment and operation programmes, includ-

need in the development of production. ing: (1) predictive maintenance programme

(predictive maintenance - PdM); (2) pro-

In recent years, having identified the core values that can bring

gramme asset performance management

return on investment (ROI), Bien Dong POC is implementing an action

and technology system optimisation (pro-

plan for the Industry 4.0 programme in the following main directions.

cess optimisation); and (3) enterprise perfor-

First, Bien Dong POC starts to build a digital project, a centralised mance management programme. This helps

data platform for the whole company (digital platform). The data can to optimise maintenance run times; mini-

be used for the intelligent oil and gas management system (oil and gas mises unplanned breakdown or well closing

business intelligence); and bring oil and gas field management, analy- times; ensures the safe and continuous op-

sis, and operations tools to cloud computing and mobile platforms. eration of the technology system and helps

Second, the company replaces traditional processes with electron- to minimise equipment maintenance costs.

ic, digital, software-based application, and centralised database-based Bien Dong POC has so far applied the Solar

working methods; builds a corporate culture based on digital ideology, turbine operation parameter monitoring

innovate creative thinking towards the application of digital technol- system to monitor the performance of the

ogy to increase cohesion, develop expertise, improve productivity, and equipment, make predictions, early warn-

ensure continuity. Tools and softwares are deployed to support team- ings and corrective plans for the failure-po-

work and online meetings, manage work assignments, and share data. tential parts before machine damages.

The online approval process (e-approval) is built and implemented to Fourth, researching and planning are

increase efficiency and work consistency. This helps simplify, streamline, conducted to apply artificial intelligence

and ease text-approval processes. tools to support the process of analysing

and linking geological documents, well geo-

physics and exploitation data to improve

the efficiency of management, operation

and exploration of Hai Thach - Moc Tinh con-

densate gas fields.

Fifth, in order to successfully carry out

digital transformation towards the global

trend, the digital human resources devel-

opment program must go one step ahead,

and focus on investment in human resourc-

es. The strategy is to attract and develop

high-tech talents with digital thinking, vi-

sion, and skills. For that reason, Bien Dong

POC has established a research team on

Industry 4.0, specialising in monitoring and

updating opportunities for development

and application of digital technology in

management and business. In addition, the

company also focuses on developing and

training to improve working capabilities for

all employees in the context of the Indus-

trial Revolution 4.0 (Empowering Industrial

4/0 Workforce).

Figure 3. The components of digital oil field [37].

PETROVIETNAM - JOURNAL VOL 10/2020 75

RESEARCH & DISCUSSION

Midnight to 4 a.m.

- Automated analytics on op’s data

- Intelligent alerting 3 p.m. to 4 p.m.

- Gas lift and rod pump - Afternoon meeting

- Opportunity mapping - Track and document FO actions

- Actual vs target analytics - Track and document

- Automated downtime and codes - Maintenance, WO teams

- Review optimisation opportunities

7 a.m. to 9 a.m. - Update targets

- Morning meetings - Assess actions

- FO assignments - Assign night Crew FO actions

- Opportunity assessment for PbE

- Actual vs target assessment

- HSE issues

8 a.m. to 3 p.m. 4 p.m. to Midnight

- Continuous monitor of alarms - Update data base and analytics

and field activities - Close tickets

- Monitor wells (dynacards) - Uplift tracking

- Well reviews as indicated - Automated updating of data-driven

- Monitor FO activity analytic models

- Communication with FO staff

- Communication with maintenance,

WO teams

- Opportunity execution

- Opportunity assessment for PbE

- Optimisation strategy

Figure 4. Continuous processes in oil and gas industry [37].

6. Bien Dong POC digital transformation strategy the digitalisation programme. The lack of staff with pas-

sion for technology and ambition poses challenges to the

Bien Dong POC's digital transformation strategy is

deployment of digital transformation. Staff with passion

based on the three main pillars of People, Technology and

and motivation are the key to project success [37]. In ad-

Systems Process (Figure 3).

dition, being able to form up a team with different areas

6.1. People of expertise from reservoir management, production and

operation, IT or data science engineers also brings a great

People management is a challenging task. The obsta- challenge to implementing digitalisation.

cle one can see in human nature is “resistance to change”.

This is very common due to feelings of personal interests 6.2. Technologies

being affected; new ways of doing things will require em-

In the past, the oil and gas industry applied high tech-

ployees to change and adapt, and scepticism about the

nology in several specific technical disciplines. For exam-

feasibility and benefits of Industry 4.0 does exist among

ple, the reservoir operation simulation models were built

them. However, these barriers to the implementation

and the production model analysis was developed very

of the digitalisation programme can be overcome by a

early. Over the years, technology has matured. Many new

bottom-up approach, with which stakeholders are fully

technologies have emerged, enabling oil and gas compa-

engaged from the start. The benefits of digitalisation pro-

nies to apply and integrate them into the field manage-

grammes need to be consistent with the production and

ment and operation. Some of the latest technologies we

business goals of the company, and directly attached to

have discussed here - such as big data, cloud computing

each employee in developing personal capacity, thus im-

and IIoT or artificial intelligence and machine learning

proving efficiency.

allow us to build truly smart solutions to be able to self-

Projects are easily accepted when you absorb the monitor, learn and intelligently control the comprehen-

team's intrinsic dynamics. The corporate cultural environ- sive operations at fields.

ment needs to be reviewed and adjusted if necessary. A

These technologies provide an open environment for

modification to the organisational model should also be

smart solutions with a comprehensive workflow through

taken into account when implementing it.

all stages. Therefore, the development of digitalisation

In most oil and gas operating companies, there is programmes has never been so favourable and support-

no pre-project staff training programme, especially with ed. But advanced technologies also require more com-

76 PETROVIETNAM - JOURNAL VOL 10/2020

PETROVIETNAM

a.m.

a.m.

a.m.

p.m.

a.m.

a.m.

Well uptime Volume Interventions

a.m.

Figure 5. Offshore maintenance process [37].

petent human resources and higher costs to be able to arises, the other activities must also be adjusted. These

develop and maintain these systems. are continuous daily activities consuming manpower time

and each decision greatly affects environmental health

6.3. Process

and safety, production efficiency and costs.

As technology develops, it is increasingly involved in The development of these workflows requires exten-

oil and gas field management and operation processes. sive knowledge of many areas in oil and gas engineer-

Technologies are built and used to support smarter and ing, modern corporate governance practices, as well as

automated management of oil and gas field operations. data-driven, science-based and systematic approaches.

Oil and gas field management and operation is a In addition, digital transformation also requires the ap-

closed loop of processes such as validation, stock update plication of modern technologies to transform work pro-

reporting, field and production monitoring, processing cesses to improve labour efficiency and safety, and create

systems and equipment maintenance. When any change more value from an asset. Figure 4 illustrates an example

PETROVIETNAM - JOURNAL VOL 10/2020 77

RESEARCH & DISCUSSION

reliable simulation models. Figures 5 and

a.m. a.m.

6 show some examples of the oil and gas

field governance workflows applied in Bien

Dong POC. It is the result of automatic activ-

ities and expert knowledge of many depart-

ments. The goal is to be able to make accu-

rate and fast decisions based on raw data.

7. Conclusions

, Digital transformation is a large-scale

business shift. The opportunity for the over-

a.m. all digital transformation is driven by large

database of oil and gas field operations,

and advanced management tools by com-

panies.

The scope of Bien Dong POC’s digital

transformation project is to lay out founda-

p.m.

tions for a digital platform, that can be lev-

p.m. eraged to deliver digital services. All data

will be standardised, examined and linked

on a centralised, flexible and scalable digital

platform, meeting current needs and future

growth of Bien Dong POC. It involves con-

siderable costs as this necessitates invest-

ment in IT as well as engineering initiatives.

Figure 6. Gas and condensate off-spec monitoring process [37].

This opportunity is of strategic importance

of a continuous process applying modern IT technology and advanced because it is targeted to improve the effi-

workflow in well monitoring and surveillance. ciency of operation and management pro-

cess.

The production and operation outputs can be measured with differ-

ent well openings through well test activities and at the outputs of the The digital transformation programme

oil and gas processing systems. Being able to accurately calculate the has exploited important opportunities

production output at different well openings and across the entire pro- through the timely application of digitalisa-

duction network is extremely important for oil and gas field manage- tion and mine dynamics analysis to promote

ment and operations to maximise economic potential of the reservoir. capture and create high value in oil and gas

In addition, incorrect forecasting of yield can lead to false reservoir es- operations. With collected data converted

timates and make erroneous decisions about well exploitation regime. into decisive information, Bien Dong POC

The construction of non-parametric reservoir models based on pressure has safely, effectively and continuously op-

and temperature data has proven to be a valid and cost-effective solu- erated production over the years. Future

tion [37]. forecasts, management reports such as as-

set monitoring, production performance

The "Production Performance Monitoring” (PPM) process has been

diagnostics and production optimisation

successfully implemented in Bien Dong POC. The PPM goal is to create

are performed accurately and promptly for

automated workflows to improve productivity, data and process man-

investors and stakeholders. Operating data

agement methodology, and data standardisation. The components of

is systematically exploited, stored and man-

this solution consists of (1) building a monitoring infrastructure system

aged in the corporate office, and synchro-

of operational activities; (2) collecting and storing real-time data; (3)

nised with Microsoft Azure cloud server to

standardising the production activity and allocation process; (4) track-

ensure data consistency, reliability and ac-

ing and evaluating allocation results automatically; and (5) building

78 PETROVIETNAM - JOURNAL VOL 10/2020

PETROVIETNAM

curacy. Applying digital technology, deploying real-time [6] Jeff Dickens, David Michael Latin, Graeme Verra,

connectivity technology solutions is a response to unfore- William R. Blosser, Greg A. Edmonds, and Greg Grimshaw,

seen events such as natural disasters and epidemics to en- "The BP field of the future programme: The continuing

sure a continuous connection. During the peak period of mission to deliver value", SPE Intelligent Energy Conference

the Covid-19 epidemic in Vietnam, when the measures of and Exhibition, Utrecht, The Netherlands, 23 - 25 March

social isolation and isolation were applied, the Bien Dong 2010. DOI: 10.2118/128672-MS.

POC office was still operating based on the digital plat-

[7] Frans Gijsbert Van den Berg, "Smart fields -

form and centralised-digitalised central database.

Optimising existing fields", Digital Energy Conference and

The trade-off involved in the implementation is con- Exhibition, Houston, Texas, USA, 11 - 12 April 2007. DOI:

sidered the extensive training to engage employees and 10.2118/108206-MS.

drive adaption and a broader cultural change. Leadership

[8] Abdulhamed Alfaleh, Yuhe Wang, Bicheng

development is needed to foster an aspirational outlook,

Yan, John Killough, Hongqing Song, and Chenji Wei,

with managers acting as change agents. In addition, the

"Topological data analysis to solve big data problem

digital transformation programme is also a prerequisite

in reservoir engineering: Application to inverted 4D

for research, goal development and future action plans for

seismic data", SPE Annual Technical Conference and

the future advanced oil and gas field management pro-

Exhibition, Houston, Texas, 28 - 30 September 2015. DOI:

grammes in Bien Dong POC, such as: (1) predictive main-

10.2118/174985-MS.

tenance programme (predictive maintenance - PdM); (2)

programme asset performance management and tech- [9] Rocky Roden, "Seismic interpretation in the

nology system optimisation (process optimisation); and age of big data", SEG International Exposition and Annual

(3) enterprise performance management programme. Meeting, Dallas, Texas, 16 - 21 October 2016.

[10] P. Joshi, R. Thapliyal, A. A. Chittambakkam, R.

References

Ghosh, S. Bhowmick, and S. N. Khan, "Big data analytics

[1] Mariam Helmy Ismail Abdelaal, Mohamed Khater, for micro-seismic monitoring", Offshore Technology

and Mohamed Zaki, "Digital business transformation Conference Asia, Kuala Lumpur, Malaysia, 20 - 23 March,

and strategy: What do we know so far?", University of 2018. DOI: 10.4043/28381-MS.

Cambridge, 2018. DOI: 10.13140/RG.2.2.36492.62086.

[11] Tatiana Olneva, Dmitryi Kuzmin, Svetlana

[2] U.S. Energy Information Administration, Rasskazova, and Azamat Timirgalin, "Big data approach

"International energy outlook 2019 with projections to for geological study of the big region West Siberia", SPE

2050", 2019. [Online]. Available: https://www.eia.gov/ Annual Technical Conference and Exhibition, Dallas, Texas,

outlooks/ieo/pdf/ieo2019.pdf. USA, 24 - 26 September 2018. DOI: 10.2118/191726-MS.

[3] Gerald C. Kane, Doug Palmer, Anh Nguyen [12] W. Duffy, J. Rigg, and E. Maidla, "Efficiency

Phillips, David Kiron, and Natasha Buckley, "Strategy not improvement in the bakken realized through drilling

technology, drives digital transformation", MIT Sloan data processing automation and the recognition and

Management Review and Deloitte University Press, 2015. standardization of best safe practices", SPE/IADC Drilling

[Online]. Available: https://www2.deloitte.com/cn/en/ Conference and Exhibition, The Hague, The Netherlands, 14 -

pages/technology-media-and-telecommunications/ 16 March, 2017. DOI: 10.2118/184724-MS.

ar ticles/strategy-not-technology- drives- digital-

[13] Eric Maidla, William Maidla, John Rigg, Michael

transformation.html.

Crumrine, and Philipp Wolf-Zoellner, "Drilling analysis

[4] Hongfang Lu, Lijun Guo, Mohammadamin Azimi, using big data has been misused and abused," IADC/SPE

and Kun Huang, "Oil and Gas 4.0 era: A systematic review Drilling Conference and Exhibition, Fort Worth, Texas, USA,

and outlook", Computers in Industry, Vol. 111, pp. 68 - 90, 6 - 8 March 2018. DOI: 10.2118/189583-MS.

2019. DOI: 10.1016/j.compind.2019.06.007.

[14] Qishuai Yin, Jin Yang, Bo Zhou, Menglei Jiang,

[5] I.S. Korovin and M.G. Tkachenko, "Intelligent Xiaoliang Chen, Chao Fu, Li Yan, Lei Li, Yatao Li and Zhengli

oilfield model", Procedia Computer Science, Vol. 101, pp. Liu, "Improve the drilling operations efficiency by the big

300 - 303, 2016. DOI: 10.1016/j.procs.2016.11.035. data mining of Real-Time logging," SPE/IADC Middle East

PETROVIETNAM - JOURNAL VOL 10/2020 79

RESEARCH & DISCUSSION

Drilling Technology Conference and Exhibition, Abu Dhabi, EOR projects," SPE Offshore Europe Conference & Exhibition,

UAE, 29 - 31 January 2018. DOI: 10.2118/189330-MS. Aberdeen, United Kingdom, 5 - 8 September 2017. DOI:

10.2118/186159-MS.

[15] J. Johnston and A. Guichard, "New findings

in drilling and wells using big data analytics," Offshore [24] D. Seemann, M. Williamson, and S. Hasan,

Technology Conference, Houston, Texas, USA, 4 - 7 May, "Improving reservoir management through big data

2015. DOI: 10.4043/26021-MS. technologies", SPE Middle East Intelligent Energy Conference

and Exhibition, Manama, Bahrain, 28 - 30 October 2013.

[16] Mark Hutchinson, Ben Thornton, Philippe Theys,

DOI: 10.2118/167482-MS.

and Harald Bolt, "Optimizing drilling by simulation and

automation with big data", SPE Annual Technical Conference [25] Beau. T. Rollins, Andy Broussard, Billy Cummins,

and Exhibition, Dallas, Texas, USA, 24 - 26 September 2018. Akim Smiley, and Nelson Dobbs, "Continental Production

DOI: 10.2118/191427-MS. allocation and analysis through big data", SPE/AAPG/

SEG Unconventional Resources Technology Conference,

[17] Oladele Bello, Don Yang, Sony Lazarus, Xiaowei

Austin, Texas, USA, 24 - 26 July 2017. DOI: 10.15530/

Shawn Wang, and Tommy Denney, "Next generation

URTEC-2017-2678296.

downhole big data platform for dynamic data-driven well

and reservoir management", SPE Reservoir Characterisation [26] N.P. Sarapulov and R.A. Khabibullin, "Application

and Simulation Conference and Exhibition, Abu Dhabi, UAE, of big data tools for unstructured data analysis to

5 May 2017. DOI: 10.2118/186033-MS. improve ESP operation efficiency", SPE Russian Petroleum

Technology Conference, Moscow, Russia, 16 - 18 October,

[18] M. R. Brulé, "The data reservoir: How big data

2017. DOI: 10.2118/187738-MS.

technologies advance data management and analytics

in E&P", SPE Digital Energy Conference and Exhibition, [27] Supriya Gupta, Luigi Saputelli, and Michael

The Woodlands, Texas, USA, 3 - 5 March 2015. DOI: Nikolaou, "Big data analytics workflow to safeguard ESP

10.2118/173445-MS. operations in real-time", SPE North America Artificial Lift

Conference and Exhibition, The Woodlands, Texas, USA, 25 -

[19] Andrei S.Popa, Eli Grijalva, Steve Cassidy, Juan

27 October 2016. DOI: 10.2118/181224-MS.

Medel, and Andrew Cover, "Intelligent use of big data for

heavy oil reservoir management," SPE Annual Technical [28] Tyler Palmer and Mark Turland, "Proactive rod

Conference and Exhibition, Houston, Texas, USA, 28 - 30 pump optimization: Leveraging big data to accelerate

September 2015. DOI: 10.2118/174912-MS. and improve operations", SPE North America Artificial Lift

Conference and Exhibition, The Woodlands, Texas, USA, 25 -

[20] Avi Lin, "Principles of big data algorithms and

27 October 2016. DOI: 10.2118/181216-MS.

application for unconventional oil and gas resources", SPE

Large Scale Computing and Big Data Challenges in Reservoir [29] Jack Betz, "Low oil prices increase value of big

Simulation Conference and Exhibition, Istanbul, Turkey, 15 - data in fracturing", Journal of Petroleum Technology, Vol.

17 September, 2014. DOI: 10.2118/172982-MS. 67, No. 4, pp. 60 - 61, 2015. DOI: 10.2118/0415-0060-JPT.

[21] Charalampos Chelmis, Jing Zhao, Vikrambhai [30] Matthew Ockree, Kenneth G. Brown, Joseph

S.Sorathia, Suchindra Agarwal, and Viktor Prasanna, Frantz, Micheal Deasy, and Ramey John, "Integrating

"Semiautomatic, semantic assistance to manual curation big data analytics into development planning

of data in smart oil fields", SPE Western Regional Meeting, optimization", SPE/AAPG Eastern Regional Meeting,

Bakersfield, California, USA, 21 - 23 March 2012. DOI: Pittsburgh, Pennsylvania, USA, 7 - 11 October 2018. DOI:

10.2118/153271-MS. 10.2118/191796-18ERM-MS.

[22] Egbadon Udegbe, Eugene Morgan, and Sanjay [31] Moritz von Plate, "Big data analytics for

Srinivasan, "From face detection to fractured reservoir prognostic foresight", SPE Intelligent Energy International

characterization: Big data analytics for restimulation Conference and Exhibition, Aberdeen, Scotland, UK, 6 - 8

candidate selection", SPE Annual Technical Conference and September 2016. DOI: 10.2118/181037-MS.

Exhibition, San Antonio, Texas, USA, 9 - 11 October 2017.

[32] Daria Khvostichenko and Sergey Makarychev-

DOI: 10.2118/187328-MS.

Mikhailov, "Effect of fracturing chemicals on well

[23] Jie Xiao and Xin Sun, "Big data analytics drive productivity: Avoiding pitfalls in big data analysis", SPE

80 PETROVIETNAM - JOURNAL VOL 10/2020

PETROVIETNAM

International Conference and Exhibition on Formation [36] Luca Cadei, Danilo Loffreno, Giuseppe Camarda,

Damage Control, Lafayette, Louisiana, USA, 7 - 9 February Marco Montini, Gianmarco Rossi, Piero Fier, Davide Lupica,

2018. DOI: 10.2118/189551-MS. Andrea Corneo, Lorenzo Lancia, Diletta Milana, Marco

Carrettoni, Elisabetta Purlalli, Francesco Carduccu and

[33] Mohammadali Tarrahi and Arash Shadravan,

Gustavo Sophia, "A data driven management strategy to

"Advanced Big Data Analytics Improves HSE Management",

reduce the environmental impact of upstream production

SPE Bergen One Day Seminar, Grieghallen, Bergen, Norway,

plants", SPE Norway One Day Seminar, Bergen, Norway, 14

20 April 2016. DOI: 10.2118/180032-MS.

May 2019. DOI: 10.2118/195615-MS.

[34] Mohammadali Tarrahi and Arash Shadravan,

[37] Gustavo Carvajal, Marko Maucec, and Stan

"Intelligent HSE big data analytics platform promotes

Cullick, "Chapter 8: Transitioning to effective DOF enabled

occupational safety", SPE Annual Technical Conference

by collaboration and management of change", in Intelligent

and Exhibition, Dubai, UAE, 26 - 28 September, 2016. DOI:

Digital Oil and Gas Fields, Gustavo Carvajal, Marko Maucec

10.2118/181730-MS.

and Stan Cullick, Eds. Boston: Gulf Professional Publishing,

[35] Kim Hua Tan, Victor G. Ortiz-Gallardo, and Robert 2018, pp. 291 - 319. DOI: 10.1016/B978-0-12-804642-

K. Perrons, "Using Big Data to manage safety-related risk 5.00008-6.

in the upstream oil & gas industry: A research agenda",

Energy Exploration & Exploitation, Vol. 34, No. 2, pp. 282 -

289, 2016. DOI: 10.1177/0144598716630165.

PETROVIETNAM - JOURNAL VOL 10/2020 81

View publication stats

You might also like

- Digital Transformation in Oil & Gas WhitepaperDocument9 pagesDigital Transformation in Oil & Gas WhitepaperLuiz100% (1)

- Accenture Driving Unconventional Growth Through IIoT PDFDocument20 pagesAccenture Driving Unconventional Growth Through IIoT PDFkikita2911*100% (1)

- VAILLANT Combi Compact and Thermocompact Logical Fault FindingDocument16 pagesVAILLANT Combi Compact and Thermocompact Logical Fault Findingacw285100% (1)

- Digital Transformation in Oil and Gas Companies-A Case Study of Bien Dong POCDocument15 pagesDigital Transformation in Oil and Gas Companies-A Case Study of Bien Dong POCtejaNo ratings yet

- An Ocean of Opportunity: PerspectiveDocument1 pageAn Ocean of Opportunity: PerspectiveRoger BustosNo ratings yet

- Whitepaper Digital Transformation in Oil and GasDocument13 pagesWhitepaper Digital Transformation in Oil and GasDaniel ComeglioNo ratings yet

- Harnessing Volatility Technology Transformation in Oil and GasDocument6 pagesHarnessing Volatility Technology Transformation in Oil and GassajjadkarbalaeiNo ratings yet

- From Bytes To BarrelsDocument28 pagesFrom Bytes To BarrelsJohanNo ratings yet

- NextPlant Handbook 0Document16 pagesNextPlant Handbook 0Alessio MohamedNo ratings yet

- Untapped Potential Digital Transformation in Mid & Downstream Industries 10th Oct 19 - FinalDocument2 pagesUntapped Potential Digital Transformation in Mid & Downstream Industries 10th Oct 19 - FinalashispNo ratings yet

- Untapped Potential Digital Transformation in Mid & Downstream Industries 10th Oct 19 - FinalDocument2 pagesUntapped Potential Digital Transformation in Mid & Downstream Industries 10th Oct 19 - FinalashispNo ratings yet

- Digital Transformation For Production and Reservoir: The Voice of The Oilfield ApproachDocument12 pagesDigital Transformation For Production and Reservoir: The Voice of The Oilfield ApproachPromoservicios CANo ratings yet

- WhitePaper AVEVA ClosedLoopProcessofBigDataandAnalytics 07-18Document11 pagesWhitePaper AVEVA ClosedLoopProcessofBigDataandAnalytics 07-18karlGGNo ratings yet

- Testbirds Whitepaper New HorizonsDocument12 pagesTestbirds Whitepaper New HorizonsJoao VictorNo ratings yet

- Top 10 Oil and Gas Trends in 2021 - GartnerDocument5 pagesTop 10 Oil and Gas Trends in 2021 - Gartnerashutosh chauhanNo ratings yet

- Advances in Digitalization ofDocument16 pagesAdvances in Digitalization ofkeyachemNo ratings yet

- Peter G. Martin - Profiting From The IIoT (White Paper) - Schneider Electric (2016)Document10 pagesPeter G. Martin - Profiting From The IIoT (White Paper) - Schneider Electric (2016)AKRAMNo ratings yet

- Why Digital Transformation in Manufacturing Is Imperative - PTC - PTCDocument6 pagesWhy Digital Transformation in Manufacturing Is Imperative - PTC - PTCEkin TazegülNo ratings yet

- Petrotechnics Oil and Gas 4.0Document12 pagesPetrotechnics Oil and Gas 4.0sddrlNo ratings yet

- Profiting From The IIoT White Paper 998-19887854 US SDocument10 pagesProfiting From The IIoT White Paper 998-19887854 US SjamujamuNo ratings yet

- Digital Transformation in Process IndustriesDocument60 pagesDigital Transformation in Process IndustriesNicolae Visan100% (4)

- Atos Lookout Discrete ManufacturingDocument8 pagesAtos Lookout Discrete ManufacturingDhanya ArumughomNo ratings yet

- 1 s2.0 S2212827117312039 Main PDFDocument6 pages1 s2.0 S2212827117312039 Main PDFjoel zapanaNo ratings yet

- MEOS21 Infographic v2Document1 pageMEOS21 Infographic v2nikhil0123456789No ratings yet

- Sylthe 2018Document15 pagesSylthe 2018amanda.sanchesNo ratings yet

- Navigating The Digital Future The Disruption of Capital Projects PDFDocument12 pagesNavigating The Digital Future The Disruption of Capital Projects PDFGustavo AHNo ratings yet

- The Digital Transformation of BusinessDocument19 pagesThe Digital Transformation of BusinessjungkleinianNo ratings yet

- The Hitchhikers Guide To The Subsurface Universe - 11dec 2019 - EbookDocument14 pagesThe Hitchhikers Guide To The Subsurface Universe - 11dec 2019 - EbookJose Luis Becerril BurgosNo ratings yet

- Digital Transformation Is Redefining Oil & Gas: FeaturesDocument1 pageDigital Transformation Is Redefining Oil & Gas: FeaturesMinh Phuong100% (1)

- Capturing The True Value of Industry 4.0Document8 pagesCapturing The True Value of Industry 4.0jerry tuNo ratings yet

- Influence de La Capacit de Transformation Numrique Sur La Performance OprationnelleDurabilit SuisseDocument20 pagesInfluence de La Capacit de Transformation Numrique Sur La Performance OprationnelleDurabilit SuissetgistaNo ratings yet

- Usingof Digital Applicationsto TransformprojectmanagementDocument15 pagesUsingof Digital Applicationsto TransformprojectmanagementJean CarloNo ratings yet

- Accelerating Digital Transformations: A Playbook For UtilitiesDocument11 pagesAccelerating Digital Transformations: A Playbook For UtilitiesPaola Andrea Mejia MejiaNo ratings yet

- Cloud's Trillion-Dollar Prize Is Up For GrabsDocument16 pagesCloud's Trillion-Dollar Prize Is Up For GrabsRishabh DabasNo ratings yet

- Digital Transformation For Oil and Gas PDFDocument23 pagesDigital Transformation For Oil and Gas PDFAcid BurnsNo ratings yet

- Accenture IT Cost Reduction Using New TechnologyDocument6 pagesAccenture IT Cost Reduction Using New TechnologyAlexanderNo ratings yet

- How To Maximize Operations Productivity in Mining IndustryDocument4 pagesHow To Maximize Operations Productivity in Mining Industryharishkumar.ravichandranNo ratings yet

- Unlock The Power of Industrial Iot With AnalyticsDocument19 pagesUnlock The Power of Industrial Iot With AnalyticsPablo D. RigoNo ratings yet

- Hexagon MI Aerospace Smart Manufacturing Ebook A4 WEBDocument26 pagesHexagon MI Aerospace Smart Manufacturing Ebook A4 WEBLuis7929No ratings yet

- DELOITTE DI CIO CIO Insider Maximizing The Impact of Tech Investments in The New NormalDocument20 pagesDELOITTE DI CIO CIO Insider Maximizing The Impact of Tech Investments in The New NormalLuis Paulo Senra HuberNo ratings yet

- The Internet of Things in The Oil and Gas Industry: A Systematic ReviewDocument21 pagesThe Internet of Things in The Oil and Gas Industry: A Systematic ReviewمحمدNo ratings yet

- DXTX in The Industrial Machinery IndustryDocument20 pagesDXTX in The Industrial Machinery IndustryCarlos Andres Méndez CórdovaNo ratings yet

- Final Report Group 4Document31 pagesFinal Report Group 4thien anhNo ratings yet

- Digitalization in Chemical IndustryDocument3 pagesDigitalization in Chemical IndustryjournalNo ratings yet

- Transforming The Energy Industry With AIDocument18 pagesTransforming The Energy Industry With AIPiero RaurauNo ratings yet

- Digitalization in Maintenance PDFDocument22 pagesDigitalization in Maintenance PDFFran jimenezNo ratings yet

- Point of View On Digital ConstructionDocument16 pagesPoint of View On Digital ConstructionIrsyad RabbaniNo ratings yet

- Opex 2019 The Drive Towards Operational Excellence in Oil and Gas Oil and Gas iqRNIFb0AhUSeZzZ1Z9WwJIZAWN3fSM6XmxOQCtOiG PDFDocument10 pagesOpex 2019 The Drive Towards Operational Excellence in Oil and Gas Oil and Gas iqRNIFb0AhUSeZzZ1Z9WwJIZAWN3fSM6XmxOQCtOiG PDFnaveenNo ratings yet

- Reimagining Construction - ADSK CIOB - Discussion Paper - ReleasedDocument28 pagesReimagining Construction - ADSK CIOB - Discussion Paper - ReleasedWan Yusoff Wan MahmoodNo ratings yet

- Digitally Transforming Offshore Oil and Gas Production With Topsides 4.0Document10 pagesDigitally Transforming Offshore Oil and Gas Production With Topsides 4.0Mrudula SurveNo ratings yet

- Artikel 2 (Pendukung) Preparing-For-The-Next-Normal-Via-Digital-Manufacturings-Scaling-PotentialDocument10 pagesArtikel 2 (Pendukung) Preparing-For-The-Next-Normal-Via-Digital-Manufacturings-Scaling-PotentialErik GunawanNo ratings yet

- Accenture 804893 Smart Production POV FinalDocument20 pagesAccenture 804893 Smart Production POV FinalPraneeth BakkiNo ratings yet

- ARCHANA LENKA - MBA HR - Industry 4.0Document7 pagesARCHANA LENKA - MBA HR - Industry 4.0mitaNo ratings yet

- Mckinsey - Transforming Advanced Manufacturing Through Industry 4 Point 0 - 2022Document7 pagesMckinsey - Transforming Advanced Manufacturing Through Industry 4 Point 0 - 2022Victor Cervantes ANo ratings yet

- E2-E3 MGMTDocument257 pagesE2-E3 MGMTJTONo ratings yet

- Digital Transformation Initiative - Accenture 2018Document75 pagesDigital Transformation Initiative - Accenture 2018Thang Nguyen100% (1)

- AT-06376 HP Article Black Swans PMorseDocument2 pagesAT-06376 HP Article Black Swans PMorseShamsMohdNo ratings yet

- ManufacturingDocument20 pagesManufacturingBalwant SinghNo ratings yet

- 998-22344999 - IoF Software Manifesto - GMA - Ebrochure - WEB - FINALDocument30 pages998-22344999 - IoF Software Manifesto - GMA - Ebrochure - WEB - FINALFrancoNo ratings yet

- The Digital Transformation of the Automotive Industry: Catalysts, Roadmap, PracticeFrom EverandThe Digital Transformation of the Automotive Industry: Catalysts, Roadmap, PracticeNo ratings yet

- IoT Standards with Blockchain: Enterprise Methodology for Internet of ThingsFrom EverandIoT Standards with Blockchain: Enterprise Methodology for Internet of ThingsNo ratings yet

- HSE PlanDocument52 pagesHSE PlanberiNo ratings yet

- 3M™ PELTOR™ WS™ LiteCom Pro III Ex HeadsetDocument2 pages3M™ PELTOR™ WS™ LiteCom Pro III Ex HeadsetberiNo ratings yet

- BF CMT Diesel Fume ShowDocument12 pagesBF CMT Diesel Fume ShowberiNo ratings yet

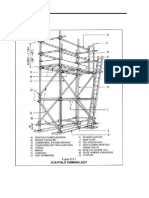

- ScaffoldingDocument54 pagesScaffoldingberiNo ratings yet

- Layout Saluran Drainase & Oil Trap WorkshopDocument1 pageLayout Saluran Drainase & Oil Trap WorkshopberiNo ratings yet

- Worksho Pencegahan Dan Pengendalian Penyakit MonkeypoxDocument64 pagesWorksho Pencegahan Dan Pengendalian Penyakit MonkeypoxberiNo ratings yet

- NickelDocument134 pagesNickelberiNo ratings yet

- 3M Protecta Comfort Belt StyleDocument2 pages3M Protecta Comfort Belt StyleberiNo ratings yet

- 7 Steps To IH Success - EbookDocument18 pages7 Steps To IH Success - EbookberiNo ratings yet

- Guidance Noise Control Practicability Assessment 2023Document19 pagesGuidance Noise Control Practicability Assessment 2023beriNo ratings yet

- Hazard Control - High Risk Electrical TasksDocument7 pagesHazard Control - High Risk Electrical TasksberiNo ratings yet

- FSQ in Food Storage and Distribution PracticesDocument19 pagesFSQ in Food Storage and Distribution PracticesberiNo ratings yet

- Hazard Identification and Risk Assessments Sample (HIRARC)Document8 pagesHazard Identification and Risk Assessments Sample (HIRARC)beriNo ratings yet

- Manual On Ambient Water Quality MonitoringDocument231 pagesManual On Ambient Water Quality MonitoringberiNo ratings yet

- Root Cause Analysis Presentation (RCA)Document21 pagesRoot Cause Analysis Presentation (RCA)beriNo ratings yet

- Heat Stroke Safety PosterDocument4 pagesHeat Stroke Safety PosterberiNo ratings yet

- Validation of The Bahasa Version of The COPSOQ IIIDocument39 pagesValidation of The Bahasa Version of The COPSOQ IIIberiNo ratings yet

- Pengembangan Aplikasi Monitoring Penyakit Hipertensi Dan Diabetes Mellitus TerintegrasiDocument15 pagesPengembangan Aplikasi Monitoring Penyakit Hipertensi Dan Diabetes Mellitus TerintegrasiberiNo ratings yet

- Regional Framework For NATECH - FinalDocument64 pagesRegional Framework For NATECH - FinalberiNo ratings yet

- All Essential NFPA CodesDocument29 pagesAll Essential NFPA CodesberiNo ratings yet

- Meat HygieneDocument50 pagesMeat HygieneberiNo ratings yet

- Physics: Chapter - Alternating Current Chapterwise Practise Problems (CPP) For NEETDocument21 pagesPhysics: Chapter - Alternating Current Chapterwise Practise Problems (CPP) For NEETsoyel afridiNo ratings yet

- R22 220V-240V 50Hz 9000-28000BTU Panasonic Rotary Compressor Contact SupplierDocument9 pagesR22 220V-240V 50Hz 9000-28000BTU Panasonic Rotary Compressor Contact Supplierأبو زينب المهندسNo ratings yet

- Aristotig 400: Instruction ManualDocument22 pagesAristotig 400: Instruction ManualGurkan ÇetinkayaNo ratings yet

- Underwater Windmill: A Seminar Report OnDocument50 pagesUnderwater Windmill: A Seminar Report OnaaronNo ratings yet

- Installation, Operation and Maintenance Instructions: FEM67 FEM107 FEM207 Fem67Sc FEM107SC FEM207SCDocument21 pagesInstallation, Operation and Maintenance Instructions: FEM67 FEM107 FEM207 Fem67Sc FEM107SC FEM207SCRadwan AL TrougNo ratings yet

- Pioneering Efficient Energy Solutions: SHV India SHV IndiaDocument41 pagesPioneering Efficient Energy Solutions: SHV India SHV Indiaatripathi2009No ratings yet

- Analysis of Triazine in Crude - Raman SpectrosDocument4 pagesAnalysis of Triazine in Crude - Raman SpectroscbrittaivNo ratings yet

- Velux Roof Lights CatalogueDocument43 pagesVelux Roof Lights CataloguecordooleyNo ratings yet

- 7.4 HomeostasisDocument19 pages7.4 HomeostasisJunkNo ratings yet

- Practical 7: AIM: Study The Maintenance and Troubleshooting of UpsDocument2 pagesPractical 7: AIM: Study The Maintenance and Troubleshooting of UpsVasundharaNo ratings yet

- Cable Size CalculatorDocument13 pagesCable Size CalculatorSamer ChahroukNo ratings yet

- Matter and Energy 2015 V3Document15 pagesMatter and Energy 2015 V3shehabNo ratings yet

- CR810-08-20 - 25 - 30 P&ID Rev.1Document1 pageCR810-08-20 - 25 - 30 P&ID Rev.1Anibal Aldava CrispinNo ratings yet

- Understanding Power MOSFET Data Sheet ParametersDocument28 pagesUnderstanding Power MOSFET Data Sheet Parametersgui9871No ratings yet

- TRG6 C2Document12 pagesTRG6 C2april lightNo ratings yet

- Obulb MC User ManualDocument1 pageObulb MC User ManualJames BurgessNo ratings yet

- EXERCISE 1 - SolDocument19 pagesEXERCISE 1 - SolmaeNo ratings yet

- Modeling of Mechanical (Lumped Parameter) Elements: Handout # 1Document17 pagesModeling of Mechanical (Lumped Parameter) Elements: Handout # 1Oliver KrausNo ratings yet

- TMH 5 Eng 2Document28 pagesTMH 5 Eng 2alireza1941No ratings yet

- Co2 StickerDocument2 pagesCo2 StickerMichael RajNo ratings yet

- End Suction 1600seriesDocument8 pagesEnd Suction 1600seriesjanter edward marpaungNo ratings yet

- MDR Backlog Ldia090 - 4gDocument1 pageMDR Backlog Ldia090 - 4gJakoba FetindrainibeNo ratings yet

- Steam Traps - TypesDocument3 pagesSteam Traps - Typesrenji_danny100% (1)

- 15 AVC INX enDocument4 pages15 AVC INX enARah AtilehNo ratings yet

- Structure Analysis of Cast Iron For Dry Clutch of Amphibious VehicleDocument4 pagesStructure Analysis of Cast Iron For Dry Clutch of Amphibious VehicleseventhsensegroupNo ratings yet

- 11-Stem: Science, Technology, Engineering, Mathematics - Reyneth B. OcampoDocument5 pages11-Stem: Science, Technology, Engineering, Mathematics - Reyneth B. OcamporeynethNo ratings yet

- Air and AtmosphereDocument4 pagesAir and AtmosphereNadeem Haider HammadNo ratings yet

- Hardware Manual ACS800-31 Drives (5.5 To 110 KW) ACS800-U31 Drives (7.5 To 125 HP)Document139 pagesHardware Manual ACS800-31 Drives (5.5 To 110 KW) ACS800-U31 Drives (7.5 To 125 HP)ROSEMARIO PORFIRIONo ratings yet