Professional Documents

Culture Documents

Mechanical Specification

Mechanical Specification

Uploaded by

johnkarl.benting0 ratings0% found this document useful (0 votes)

6 views2 pagesThis document provides the mechanical specifications for the proposed Motech automotive service and repair shop located in Pasig City, Philippines. It outlines the technical specifications for the electrical works, including compliance with codes and permitting. It also specifies the scope of work for the air conditioning system, compressor, air distribution, and car lifter equipment. This includes supplying, installing, testing and commissioning the systems, as well as providing operating guides and maintenance requirements.

Original Description:

MECHANICAL SPECIFICATION

Original Title

MECHANICAL SPECIFICATION

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document provides the mechanical specifications for the proposed Motech automotive service and repair shop located in Pasig City, Philippines. It outlines the technical specifications for the electrical works, including compliance with codes and permitting. It also specifies the scope of work for the air conditioning system, compressor, air distribution, and car lifter equipment. This includes supplying, installing, testing and commissioning the systems, as well as providing operating guides and maintenance requirements.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

6 views2 pagesMechanical Specification

Mechanical Specification

Uploaded by

johnkarl.bentingThis document provides the mechanical specifications for the proposed Motech automotive service and repair shop located in Pasig City, Philippines. It outlines the technical specifications for the electrical works, including compliance with codes and permitting. It also specifies the scope of work for the air conditioning system, compressor, air distribution, and car lifter equipment. This includes supplying, installing, testing and commissioning the systems, as well as providing operating guides and maintenance requirements.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 2

MECHANICAL SPECIFICATION

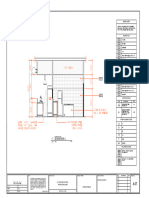

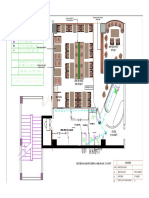

PROJECT : PROPOSED “MOTECH” AUTOMOTIVE SERVICE

& REPAIR SHOP

LOCATION : BERNAL ST. C RAYMUNDO AVE. ROSARIO PASIG CITY

OWNER : MR. CHESTER KIM GO

TECHNICAL SPECIFICATION

1. ALL ELECTRICAL WORKS SHALL BE IN ACCORDANCE WITH THE

PROVISIONS OF THE LATEST EDITION OF THE PHILIPPINE ELECTRICAL

CODE. THE LAWS

AND ORDINANCES OF THE LOCAL CODE. ENFORCING. AUTHORITIES AND

THE EQUIPMENTS OF THE LOCAL POWER AND TELEPHONE UTILITY

COMPANIES.

2. THE CONTRACTOR SHALL SECURE ALL PERMITS AND PAY ALL FEES

EQUIPPED FOR THE WORK AND SHALL FURNISH THE OWNER THROUGH

THE ENGINEERS. FINAL CERTIFICATES OF ELECTRICAL INSPECTION AND

APPROVAL FROM PROPER GOVERNMENT AUTHORITIES FOR COMPLETION

OF WORK.

3. ALL MATERIALS TO BE USED SHALL BE NEW AND INSTALLED IN

APPLICATION FOR WHICH THEY ARE INTENDED.

4. ALL CONDUIT PIPES SHALL BE (PVC) EXCEPT AS

NOTED ON THE PLANS AND SPECIFICATIONS REFER TO SPECIFICATION FOR

INSTALLATION REQUIREMENT.

5. MINIMUM SIZE OF CONDUIT SHALL BE 15 MM DIAMETER.

6. ALL CONDUIT SHALL BE CONCEALED UNLESS SPECIFICALLY SHOWN OF

NOTED OTHERWISE EXPOSED CONDUIT RUNS SHALL BE INSTALLED

PARALLEL TO OR PERPENDICULAR WITH THE BUILDING LINE AND

SUPPORTED BY CONDUIT CLAMPS EVERY 1.50 METERS.

7. PULL BOXES SHALL BE PROVIDED BY THE CONTRACTOR WHENEVER

NECESSARY TO FACILITATE WIRE PULLING EVEN IF THESEARE NOT

INDICATED ON THE PLANS.

8. ALL LIGHTING AND CONVENIENCE OUTLET CIRCUITS SHALL BE 3 WIRE 3.5

SQ MM TW UNLESS OTHERWISE NOTED MINIMUM SIZE OF WIRE SHALL BE

2.0 SQ. MM TW.

9. ALL DUPLEX RECEPTACLE OUTLET SHALL BE GROUNDING TYPE WITH

PARALLEL SHALL FOR 220 V.

SCOPE OF WORKS

AIR CON SYSTEM

1. SUPPLY AND INSTALLATION OF AIR CON SYSTEM.

2. POWER SUPPLY AND CONTROLS

3. NOISE AND VIBRATION

4. TESTING AND COMMISIONING

5. OPERATION AND MAINTENANCE

COMPRESSOR AIR DISTRUBUTION AND CAR LIFTER EQUIPEMENTS

1. SUPPLY MATERIALS CAR LIFTER EQUIPEMENTS AND INSTALLATION SYSTEM

2. PLEASE ALWAYS SAFETY FIRST SURE THAT YOU MAINTAIN SAFETY FIRST AT ALL TIME

FOR INSTALLATION 2 POST CAR LIFTER AND 4 POSY CAR LIFTER.

3. FOLLOW THIS CHART FOR NOW TO YOU IDEA OF HOW TO PLACE COLUMNS ON THE

FLOOR

4. MAKE SURE TO USE CORRECT SIZE DRILL-BIT AS PER CONCRETE BOLT REQUIREMENTS

5. TAP ACHOR BOLT INTO HOLE WITH A HAMMER UNTIL THE WASHER REST AGAINST THE

BASE PLATE.

6. TIGHTEN NUT 3-5 TURNS. DO NOT USE IMPACT WRENCH!

7. INSTALLING CABLES LINES AND HOSES

8. INSTALLING THE LIFT ARMS

9. COMPRESSOR INSTALLING

10. PIPE DISTRIBUTION AIRLINE TO SUPPLY CAR LIFT EQUIPEMENT

11. POWER SUPPLY CAR LIFT

12. GENERATE TO TESTING 2 POST AND 4 POST CAR LIFT EQUIPEMENT

13. OPERATTING GUIDE AND MAINTENANCE

14. OTHER SAFETY TO USE 2 POST AND 4 POST CAR LIFT EQUIPEMENT

MR. CHESTER KIM GO

Owner

Engineer.

You might also like

- General Mechanical NotesDocument1 pageGeneral Mechanical NotesDayan AlmeroNo ratings yet

- General Notes HvacDocument7 pagesGeneral Notes Hvacmilindskulkarni2005@yahoo.co.inNo ratings yet

- Hausmann - 1440 - Series ManualDocument10 pagesHausmann - 1440 - Series ManualAlexandra JanicNo ratings yet

- General Plumbing NotesDocument2 pagesGeneral Plumbing NotesJomarie Alcano100% (4)

- CEM PT HandbookDocument44 pagesCEM PT Handbook翹翹九九100% (2)

- Method Statement For FO Cable PullingDocument3 pagesMethod Statement For FO Cable Pullingnice hossainNo ratings yet

- Manual de Usuario Ups 10-20kva Ul - InglesDocument59 pagesManual de Usuario Ups 10-20kva Ul - Ingleswiiliam buitragpNo ratings yet

- Replacement Parts Medica Pro B/S/R/RE/LPS: ConsumablesDocument7 pagesReplacement Parts Medica Pro B/S/R/RE/LPS: ConsumablesMauro tenjoNo ratings yet

- General NotesDocument7 pagesGeneral NotesAzzirrenNo ratings yet

- Plumbing NotesDocument1 pagePlumbing Notessergio.anacletoNo ratings yet

- General NotesDocument4 pagesGeneral NotesAarth CadavosNo ratings yet

- Specifications: I. General ProvisionsDocument4 pagesSpecifications: I. General Provisionsemem CatzNo ratings yet

- 1301 Pme PDFDocument11 pages1301 Pme PDFCassie GraceNo ratings yet

- Electronics General NotesDocument1 pageElectronics General NotesCzari Muñoz100% (1)

- Potable Water System - General NotesDocument1 pagePotable Water System - General NotessathishNo ratings yet

- Electrical General NotesDocument5 pagesElectrical General NotesjustineNo ratings yet

- NotesDocument4 pagesNotes姜逸飞(jeffery)No ratings yet

- Busway Material Submittal: Prepared By: Eng NadeemDocument1 pageBusway Material Submittal: Prepared By: Eng NadeemnadimuddinNo ratings yet

- Bid Set: Sheet List TableDocument8 pagesBid Set: Sheet List Tableadolf07No ratings yet

- 7.5.2 13 LGA Sprinkler StandardsDocument16 pages7.5.2 13 LGA Sprinkler StandardsWinarkoNo ratings yet

- General Notes FinalsDocument1 pageGeneral Notes FinalsAubrey Rose Dela Peña - Magluyan100% (1)

- General NotesDocument4 pagesGeneral Noteszamree BMNo ratings yet

- General Notes and SpecificationsDocument1 pageGeneral Notes and SpecificationsSheena Mae FloresNo ratings yet

- SECTION - 16465 Bus-Way & Power FeedersDocument7 pagesSECTION - 16465 Bus-Way & Power FeedersWaleed Abd El-HamiedNo ratings yet

- MECHANICALDocument2 pagesMECHANICALDonita AcuinNo ratings yet

- General Notes Earthwork Notes Services: TenderDocument1 pageGeneral Notes Earthwork Notes Services: TenderAnonymous qEPNPwANo ratings yet

- Rehabilitation of Batching Plant With SignDocument3 pagesRehabilitation of Batching Plant With SignRafael ObusanNo ratings yet

- Kitchen HoodDocument18 pagesKitchen HooddrahcirNo ratings yet

- 1 12 C189 - DrawingsDocument28 pages1 12 C189 - DrawingsRamesh Ananthanarayanan100% (2)

- Retrofitting Recommendations and SpecificationsDocument3 pagesRetrofitting Recommendations and SpecificationsJoseph Cloyd LamberteNo ratings yet

- Procedure For Instrument Cabling Works: Cable Installation ActivitiesDocument7 pagesProcedure For Instrument Cabling Works: Cable Installation ActivitiesRUBANNo ratings yet

- Btech SpecificationDocument5 pagesBtech SpecificationCaryll ChuaNo ratings yet

- Particular Specifications For The Supply, Erection, Commissioning and Maintenance of Street Lighting Installations at Wafra Agricultural Farm RoadsDocument21 pagesParticular Specifications For The Supply, Erection, Commissioning and Maintenance of Street Lighting Installations at Wafra Agricultural Farm RoadstafseerahmedNo ratings yet

- Method Statement - Upvc Piping - Rev 01Document10 pagesMethod Statement - Upvc Piping - Rev 01Tamil Da RasckalzNo ratings yet

- Tañamor-Plate6 Eu1Document1 pageTañamor-Plate6 Eu1Hector TañamorNo ratings yet

- Method Statement of Heavy Schedule Piping FabricationDocument6 pagesMethod Statement of Heavy Schedule Piping FabricationMohamedNo ratings yet

- Highway PlanDocument11 pagesHighway PlanShine AtanosoNo ratings yet

- ELECTRICALDocument12 pagesELECTRICALKurt Darryl SabelloNo ratings yet

- Manual M100T Series 50 60Document18 pagesManual M100T Series 50 60Samir KhanNo ratings yet

- Manual Bomba SumergibleDocument18 pagesManual Bomba SumergibleDavic LimachiNo ratings yet

- General Plumbing NotesDocument1 pageGeneral Plumbing NotesDayan AlmeroNo ratings yet

- Ductile Iron Piping Shall Be in Accordance With American Water Works AssociationDocument2 pagesDuctile Iron Piping Shall Be in Accordance With American Water Works AssociationKasuni LiyanageNo ratings yet

- Nichols PLANSDocument23 pagesNichols PLANSnikthomas24100% (1)

- General NotesDocument1 pageGeneral NotesKarenNikz GuillermoNo ratings yet

- Method Statement For ChillersDocument8 pagesMethod Statement For ChillersFark Off100% (1)

- Daewoo Dtq-14n2fc 20n2fc 20j2fc 20n3fc Chassis Cn-115iDocument43 pagesDaewoo Dtq-14n2fc 20n2fc 20j2fc 20n3fc Chassis Cn-115iFernandoSanchezNo ratings yet

- Secure Walls and Partitions Acoustic Treatment For Piping PenetratingDocument1 pageSecure Walls and Partitions Acoustic Treatment For Piping PenetratingAR-Jay ARNo ratings yet

- 11kv Metering CubicleDocument18 pages11kv Metering CubiclePrashant Nankar100% (1)

- eTRICAL wORK SPECIFICATIONDocument7 pageseTRICAL wORK SPECIFICATIONBaren RoyNo ratings yet

- La's (9kv 5ka Line Type) (Ot-155)Document12 pagesLa's (9kv 5ka Line Type) (Ot-155)Yaswanth ReddyNo ratings yet

- Irspec Flash Butt WeldingDocument24 pagesIrspec Flash Butt WeldingKrischaEverNo ratings yet

- Cable Laying MethodlogyDocument9 pagesCable Laying MethodlogyVaibhav JainNo ratings yet

- General NotesDocument1 pageGeneral NotesAlvin ConcepcionNo ratings yet

- Estacio-General Notes and SpecificationsDocument2 pagesEstacio-General Notes and SpecificationsSimon Rei EstacioNo ratings yet

- Gas Yard RequirementsDocument3 pagesGas Yard Requirementssvrs81No ratings yet

- p103-Stts-gec-Asi-ms-ele-004 - Method Statement For Cable Laying On Cable TrayDocument6 pagesp103-Stts-gec-Asi-ms-ele-004 - Method Statement For Cable Laying On Cable TrayAnandu AshokanNo ratings yet

- Trafo Installed IndoorDocument20 pagesTrafo Installed IndoorAtoelAcoNo ratings yet

- Electrical Spec.'S Wiring Devices & Methods of Installation 16130-1Document9 pagesElectrical Spec.'S Wiring Devices & Methods of Installation 16130-1Waleed Abd El-HamiedNo ratings yet

- SECTION - 16465 Bus-Way & Power FeedersDocument7 pagesSECTION - 16465 Bus-Way & Power FeedersWaleed Abd El-HamiedNo ratings yet

- Bid PlansDocument1 pageBid PlansGuillermo SierraNo ratings yet

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Specification Nueva Savory As of Sept 07 2015Document1 pageSpecification Nueva Savory As of Sept 07 2015johnkarl.bentingNo ratings yet

- A7Document1 pageA7johnkarl.bentingNo ratings yet

- With Roof Trellis Proposed 2Nd Floor Extension: Luis P. ArcenoDocument1 pageWith Roof Trellis Proposed 2Nd Floor Extension: Luis P. Arcenojohnkarl.bentingNo ratings yet

- Roof Trellis Framing: Existing StructureDocument1 pageRoof Trellis Framing: Existing Structurejohnkarl.bentingNo ratings yet

- 20X30 Size Digital 3 CopiesDocument1 page20X30 Size Digital 3 Copiesjohnkarl.bentingNo ratings yet

- Schedule of Metal Deck SlabsDocument1 pageSchedule of Metal Deck Slabsjohnkarl.bentingNo ratings yet

- ME04Document1 pageME04johnkarl.bentingNo ratings yet

- AR005Document1 pageAR005johnkarl.bentingNo ratings yet

- EE01Document1 pageEE01johnkarl.bentingNo ratings yet

- Proposed Kitchen UnitDocument1 pageProposed Kitchen Unitjohnkarl.bentingNo ratings yet

- Proposed Two-Storey Building: Strutt-1Document1 pageProposed Two-Storey Building: Strutt-1johnkarl.bentingNo ratings yet

- SERVICES FOR OCCUPANCY For Fitout Mamak RestaurantDocument1 pageSERVICES FOR OCCUPANCY For Fitout Mamak Restaurantjohnkarl.bentingNo ratings yet

- AR002Document1 pageAR002johnkarl.bentingNo ratings yet

- ME002Document1 pageME002johnkarl.bentingNo ratings yet

- AR001Document1 pageAR001johnkarl.bentingNo ratings yet

- Harmony Control Relays - RM35TF30Document7 pagesHarmony Control Relays - RM35TF30معين عزامNo ratings yet

- Table of ContentDocument5 pagesTable of Contentahmeed asNo ratings yet

- COP 1240 Drifter Parts For Atlas Copco: No Crawler Drill Drfter Part Number Part Name Q'ty RemarksDocument6 pagesCOP 1240 Drifter Parts For Atlas Copco: No Crawler Drill Drfter Part Number Part Name Q'ty RemarksDaniel Ricardo Páez AlvarezNo ratings yet

- Legend: All Points Are at 250Mm & 150 MM Ht. Fromffl. Otherwise Indicated On PlanDocument3 pagesLegend: All Points Are at 250Mm & 150 MM Ht. Fromffl. Otherwise Indicated On PlanNit56122No ratings yet

- Tsuji Equipments Running Hours Pulley (Sheave) 2021Document4 pagesTsuji Equipments Running Hours Pulley (Sheave) 2021Abdul BasitNo ratings yet

- E001 Electrical Symbols and SchedulesDocument1 pageE001 Electrical Symbols and Schedulesmrb88No ratings yet

- Juan Rafael Ruiz Lopez: Air Conditioning ProposalDocument13 pagesJuan Rafael Ruiz Lopez: Air Conditioning ProposalJuan Rafael Ruiz LopezNo ratings yet

- Connector: Product SpecificationsDocument2 pagesConnector: Product Specificationspo truongNo ratings yet

- Timelines For Placing CE Marked IVDs On The Great Britain MarketDocument2 pagesTimelines For Placing CE Marked IVDs On The Great Britain MarketLorenaNo ratings yet

- IM MultiV Ducted IDUDocument83 pagesIM MultiV Ducted IDUashoreNo ratings yet

- Everyday Electronics 1972-02Document60 pagesEveryday Electronics 1972-02Toni TursićNo ratings yet

- Vinten HS-102P AutoCam ManualDocument100 pagesVinten HS-102P AutoCam ManualFloydChuangNo ratings yet

- CENTURY Troubleshooting For Old AutopilotsDocument7 pagesCENTURY Troubleshooting For Old AutopilotsBrunoNo ratings yet

- Parts Catalog - Polaroid Land Camera Models 100, 101, 102, 103, 104, 125, 135, 210, 215, 220, 225, 230, 240, & 250 - June 1970Document28 pagesParts Catalog - Polaroid Land Camera Models 100, 101, 102, 103, 104, 125, 135, 210, 215, 220, 225, 230, 240, & 250 - June 1970Elizabeth Perry MuderickNo ratings yet

- Saudi Aramco Inspection ChecklistDocument12 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- Wiring Harness Installation Instructions: For InstallersDocument12 pagesWiring Harness Installation Instructions: For Installersnirut_niceguyNo ratings yet

- FLS, Eng RequirementsDocument9 pagesFLS, Eng RequirementsDeepak DasNo ratings yet

- Air Conditioners With Displacement Air Delivery: TechnicalcatalogueDocument48 pagesAir Conditioners With Displacement Air Delivery: TechnicalcatalogueMarouane OubaidiNo ratings yet

- Dust Collector Circuit: Service Training Manual CM 760/780Document8 pagesDust Collector Circuit: Service Training Manual CM 760/780victor laraNo ratings yet

- M000133 User Manual HMKG ID 1925Document16 pagesM000133 User Manual HMKG ID 1925Suelen MarquesNo ratings yet

- HUKM Maintenance and Operation CostDocument5 pagesHUKM Maintenance and Operation CostmohdkamalhaziqNo ratings yet

- Ficha Tecnica - Red Jacket 3-4 HP Submersible Turbine Pump 60HzDocument4 pagesFicha Tecnica - Red Jacket 3-4 HP Submersible Turbine Pump 60HzSasha RunaNo ratings yet

- 2.1-4 Patch PanelDocument14 pages2.1-4 Patch PanelMaykel Uryeta MamitzNo ratings yet

- RAB Peralatan 12m×126m, 2 Lantai.Document4 pagesRAB Peralatan 12m×126m, 2 Lantai.Kang PurbakesahNo ratings yet

- International & Domestic ATS RoutesDocument1 pageInternational & Domestic ATS RoutesGazi JayedNo ratings yet

- Modelos Side Sonar ScanDocument1 pageModelos Side Sonar ScanMarlon TorresNo ratings yet