Professional Documents

Culture Documents

Appendix B

Appendix B

Uploaded by

Delta akathehuskyOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Appendix B

Appendix B

Uploaded by

Delta akathehuskyCopyright:

Available Formats

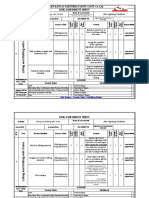

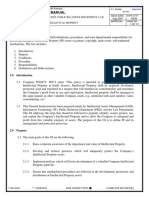

Appendix B - Concrete Mix Design Data Sheet

(9COM 6000000453: RMC – SAEP-85)

TO BE COMPLETED BY PURCHASER AND APPROVED BY BP & CTU/ID PER 09-SAMSS-097, 2018 -6.6.2

READY MIX CONCRETE MIX DESIGN WITH WAIVER SPECIAL CONCRETE

STRUCTURAL NON-STRUCTURAL

PLANT NAME: MIX DESIGN ID NO:

LOCATION: TYPE OF CEMENT: I (GRAY) V (GRAY)

DATE: I (GRAY + FLY ASH +ISF)

CRM No: I (GRAY + Micro silica)

EXPOSURE TYPE (10-02145, SAES-Q-001-18, TABLES 1B & 2): S1 (Old Exposure II &V)

MIX DESIGN REQUIREMENTS DESIGN TRIAL BATCH WEIGHTS / CUBIC METER

IN READY MIXED CONCRETE CRITERIA RESULTS MATERIALS QUANTITY REMARKS

Uniformity Tests – Mixer %, ASTM C94M-A1.1 Cement (kg)

Uniformity Tests – Truck %, ASTM C94M-A1.1 Micro silica (kg)

Comp. Strength @ 56 days, psi ¾" Aggregate (kg)

Comp. Strength @ 28 days, psi ⅜" Aggregate (kg)

Cementitious material (kg) Sand (kg)

W/C Ratio (Max.) Free Water (kg)

Slump (mm) Ice Flakes (kg)

ASSIC on Hardened Concrete (%) Admixture - F/G (ml.)

WSCIC on Hardened Concrete (%)

ASSIC on

ASSIC on Hardened

Hardened Concrete

Concrete (%)

(%) Admixture - A/B (ml.)

Coarse Aggregate

Fine Aggregate

REQUIRED ATTACHMENTS

A) Mineral Aggregates and Raw Material Latest Test Reports by a Saudi Aramco Approved TPCTL.

Limits Limits (B) Tests on concrete mixing water

Mandatory Tests ¾" ⅜" (%) Sand (%) (C) Cementitious material mill certificate

Clay Lumps & Friable Particles 5.0 3.0 (D) Admixtures MTD Sheet

Materials Finer than #200 Sieve 1.0 3.0 (E) Appendices A, C & 7, 28 days CST

Chert, Coal & Lignite 5.0/0.5 3.0/1 (F) Central Mixers Uniformity Tests

Magnesium Sulfates Soundness 25 25 (G) Document batch printout

Raw 1 & 2 Combined 6.0 6.0 (H) Truck Mixers Uniformity Tests

Los Angeles Abrasion 50 - (I) Tests on WSCIC/ ASSIC on Concrete

Absorption 2.5 -

Elongation/Flakiness 14.1/17 -

Unit Supervisor

Batch Plant - Manager Batch Plants & Civil Testing Unit

Approval of this mix design is valid as long as the raw materials are not modified (source, type, quantity). The validity of the approval remains only as long as the required

quality testing reports of all the raw materials are updated as required by Saudi Aramco appropriate standards and submitted to ID/ITSD/BP & CTU. This quality record is

valid for 3 years SPECIFIED ABOVE as required by ASTM C1077 unless revoked by Inspection Department.

Saudi Aramco: Company General Use

You might also like

- A Problem Solving Approach To Mathematics For Elementary School Teachers 13Th Edition Full ChapterDocument42 pagesA Problem Solving Approach To Mathematics For Elementary School Teachers 13Th Edition Full Chapterchristopher.hess142100% (23)

- General Instruction Manual: ContentDocument13 pagesGeneral Instruction Manual: ContentDelta akathehuskyNo ratings yet

- Scaffolders Training MatrixDocument2 pagesScaffolders Training MatrixDelta akathehuskyNo ratings yet

- Astm F1941 PDFDocument11 pagesAstm F1941 PDFKamal BhandariNo ratings yet

- DBM Mix DesignDocument22 pagesDBM Mix DesignImran Khan50% (10)

- General Instruction Manual: Saudi Arabian Oil Company (Saudi Aramco) 710.014 Issuing Org. 3/01/2009 NEW Subject 1 OF 9Document9 pagesGeneral Instruction Manual: Saudi Arabian Oil Company (Saudi Aramco) 710.014 Issuing Org. 3/01/2009 NEW Subject 1 OF 9Delta akathehuskyNo ratings yet

- Aec3414 Philosophy FinalDocument5 pagesAec3414 Philosophy Finalapi-532996380No ratings yet

- VOLVO EC360C HR EC360CHR EXCAVATOR Service Repair Manual PDFDocument19 pagesVOLVO EC360C HR EC360CHR EXCAVATOR Service Repair Manual PDFfjjsjekdmme0% (1)

- Material Submittal For Al Sarh Trading & Cont. (C20 &C25 Screed) PDFDocument117 pagesMaterial Submittal For Al Sarh Trading & Cont. (C20 &C25 Screed) PDFBikasNo ratings yet

- Lab1 All Experiments Part2Document50 pagesLab1 All Experiments Part2Parth GuptaNo ratings yet

- T S R T.S.R.: (Dd-Mmm-Year)Document2 pagesT S R T.S.R.: (Dd-Mmm-Year)Sami AjNo ratings yet

- Appendix CDocument1 pageAppendix CDelta akathehuskyNo ratings yet

- Concrete - NAJDocument1 pageConcrete - NAJTari IslamNo ratings yet

- Assessment of Potential of Marble Slurry As A Mineral Admixture in ConcreteDocument14 pagesAssessment of Potential of Marble Slurry As A Mineral Admixture in ConcreteEditor IJTSRDNo ratings yet

- Cube Strength-1Document1 pageCube Strength-1Joe ArmandaNo ratings yet

- Test Report: Consulting Engineers Group LTDDocument9 pagesTest Report: Consulting Engineers Group LTDImran Khan100% (1)

- ACI 211.1 Study ExampleDocument20 pagesACI 211.1 Study ExampleSinan İcikNo ratings yet

- 0a Afal Jaf (1) 14i 03Document2 pages0a Afal Jaf (1) 14i 03RenjithNo ratings yet

- Wakaaladda Horumarinta Wadooyinka: Free Zone ProjectDocument7 pagesWakaaladda Horumarinta Wadooyinka: Free Zone ProjectsacsewNo ratings yet

- T S R T.S.R.: (Dd-Mmm-Year)Document2 pagesT S R T.S.R.: (Dd-Mmm-Year)raja qammarNo ratings yet

- SQM - Application - 134391 - Abdulla Abdulaziz Al Sudais Company LTD - Readymix Concrete (Updated 28-11-2021) 2Document8 pagesSQM - Application - 134391 - Abdulla Abdulaziz Al Sudais Company LTD - Readymix Concrete (Updated 28-11-2021) 2Ahmed KingNo ratings yet

- Check List For Green Concrete-PortraitDocument2 pagesCheck List For Green Concrete-PortraitYash SharmaNo ratings yet

- HAIL-BBC-Design Class - C (23.07.2019)Document127 pagesHAIL-BBC-Design Class - C (23.07.2019)mido_20067581No ratings yet

- Mix Design Report - C37-1Document11 pagesMix Design Report - C37-1mohamed nomanNo ratings yet

- Cemented Sand B E C MIX 23-9Document7 pagesCemented Sand B E C MIX 23-9Mohammed Ghareib NasrNo ratings yet

- Calculation of Design Mix: Fine Aggerates Coarse AggregatesDocument6 pagesCalculation of Design Mix: Fine Aggerates Coarse AggregatesVALIENT CANCERANNo ratings yet

- Ijciet: International Journal of Civil Engineering and Technology (Ijciet)Document12 pagesIjciet: International Journal of Civil Engineering and Technology (Ijciet)Eng mohammadNo ratings yet

- Review On The Industrial Waste As A Building Material. Jaya RathoreDocument9 pagesReview On The Industrial Waste As A Building Material. Jaya RathoreJaya RathoreNo ratings yet

- Chapter 3Document24 pagesChapter 3Md Ashiqur RahmanNo ratings yet

- B.07 Acpjmf 12Document4 pagesB.07 Acpjmf 12Kreesthu ReddyNo ratings yet

- Megha Engineering & Infrastructures LTD: List of Register TechnicalDocument31 pagesMegha Engineering & Infrastructures LTD: List of Register TechnicalLaxmikanta swainNo ratings yet

- 1 PBDocument9 pages1 PBhysh89000No ratings yet

- Saic Q 1006Document2 pagesSaic Q 1006Hussain Nasser Al- Nowiesser100% (1)

- SABIC ConcreteDocument14 pagesSABIC ConcreteBasker BaluNo ratings yet

- Mastic-Mix DesignDocument10 pagesMastic-Mix DesignVaasu KotyadaNo ratings yet

- Test Report: M/S Pcil & MBPCL Joint VentureDocument7 pagesTest Report: M/S Pcil & MBPCL Joint VentureImran KhanNo ratings yet

- 09 - TRF (Cube Testing)Document1 page09 - TRF (Cube Testing)Santosh KumarNo ratings yet

- Calculation of Design Mix: Fine Aggerates Coarse AggregatesDocument6 pagesCalculation of Design Mix: Fine Aggerates Coarse AggregatesVALIENT CANCERANNo ratings yet

- Labratory TESTING FORMSDocument71 pagesLabratory TESTING FORMSMesfin Derbew100% (1)

- Concrete Technology (CE205) Concrete Technology Laboratory Report Academic Year (2021-2022)Document18 pagesConcrete Technology (CE205) Concrete Technology Laboratory Report Academic Year (2021-2022)Rahand KawaNo ratings yet

- Clinet Contractor ConsultantDocument4 pagesClinet Contractor ConsultantMesafint lisanuNo ratings yet

- CTSB For Service RoadDocument31 pagesCTSB For Service RoadAkash SarkarNo ratings yet

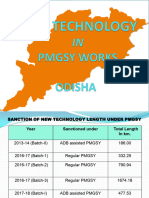

- Odisha - PMGSYDocument31 pagesOdisha - PMGSYmohammad aamirNo ratings yet

- Highway Engineering (2150601) Lab Manual - 07072016 - 052130AMDocument129 pagesHighway Engineering (2150601) Lab Manual - 07072016 - 052130AMShiv77PatilNo ratings yet

- Analysis On Compressive Strength of Concrete Using Different Sources of Fine AggregatesDocument6 pagesAnalysis On Compressive Strength of Concrete Using Different Sources of Fine AggregatesAbhishekNo ratings yet

- Bitumen Extraction Test: ObservationDocument7 pagesBitumen Extraction Test: ObservationQuality JamNo ratings yet

- Durability and Performance Characteristics of Recycled Aggregate ConcreteDocument7 pagesDurability and Performance Characteristics of Recycled Aggregate ConcreteValeria Vanessa Quiñones OdicioNo ratings yet

- M-45 (RCC) U STP - RevDocument8 pagesM-45 (RCC) U STP - Revaashish patidarNo ratings yet

- Saic M 1006Document2 pagesSaic M 1006Hussain Nasser Al- NowiesserNo ratings yet

- Comparison of Isi and Aci Methods For Absolute Volume Concrete Mix DesignDocument9 pagesComparison of Isi and Aci Methods For Absolute Volume Concrete Mix DesignazapNo ratings yet

- Clinet Contractor ConsultantDocument5 pagesClinet Contractor ConsultantMesafint lisanuNo ratings yet

- Pond AshDocument1 pagePond AshRavindra singh TanwarNo ratings yet

- QCR RegisteregisterDocument19 pagesQCR Registeregisterchitranjan4kumar-8No ratings yet

- Indian Institute of Technology BhubaneswarDocument1 pageIndian Institute of Technology BhubaneswarGeraldo Cavamba VinjangoNo ratings yet

- Statistical Quality Control in Portland Cement Concrete PavementsDocument12 pagesStatistical Quality Control in Portland Cement Concrete Pavementssalahromdhani89No ratings yet

- A1 F5 (DS and Us)Document2 pagesA1 F5 (DS and Us)Engr Zin Myo MinNo ratings yet

- Bitumen Extraction Test: ObservationDocument9 pagesBitumen Extraction Test: ObservationQuality JamNo ratings yet

- Initial Survey LATEST 2022 MARDocument6 pagesInitial Survey LATEST 2022 MARDelta akathehuskyNo ratings yet

- Reference Manufacturing Quality Plan: For NTPC Use Review Ed by Approved byDocument4 pagesReference Manufacturing Quality Plan: For NTPC Use Review Ed by Approved byNaresh RajuNo ratings yet

- Assignment Highway Edited IIDocument3 pagesAssignment Highway Edited IIsamueladdissu92No ratings yet

- FlakinessDocument1 pageFlakinessRasikul Hossein SkNo ratings yet

- Ijciet: ©iaemeDocument6 pagesIjciet: ©iaemefndsfsbskbNo ratings yet

- 032 Spec On ConcreteDocument19 pages032 Spec On Concrete伟雄No ratings yet

- Field Density Test by Sand Cone MethodDocument5 pagesField Density Test by Sand Cone MethodChris AdaminovicNo ratings yet

- Cement Mill Test Report3Document3 pagesCement Mill Test Report3MT JasonNo ratings yet

- A Case Study On Performance of Self-Compacting Concrete in Highly Congested Reinforcement of Cast in Situ StructureDocument11 pagesA Case Study On Performance of Self-Compacting Concrete in Highly Congested Reinforcement of Cast in Situ StructureEASHANNo ratings yet

- Durability Design of Concrete Structures: Phenomena, Modeling, and PracticeFrom EverandDurability Design of Concrete Structures: Phenomena, Modeling, and PracticeNo ratings yet

- Concrete Finishing Level2 QualificationsDocument58 pagesConcrete Finishing Level2 QualificationsDelta akathehuskyNo ratings yet

- Concrete Finisher - AssessmentDocument1 pageConcrete Finisher - AssessmentDelta akathehuskyNo ratings yet

- Watercooler SafetyDocument14 pagesWatercooler SafetyDelta akathehuskyNo ratings yet

- Insulation SeminarDocument55 pagesInsulation SeminarDelta akathehuskyNo ratings yet

- Asphalt Paving DWGDocument1 pageAsphalt Paving DWGDelta akathehuskyNo ratings yet

- ASTM C805 (2002) Schmidt Hammer TestDocument3 pagesASTM C805 (2002) Schmidt Hammer TestDelta akathehuskyNo ratings yet

- Cable InformationDocument2 pagesCable InformationDelta akathehuskyNo ratings yet

- Appendix ADocument1 pageAppendix ADelta akathehuskyNo ratings yet

- AconexDocument2 pagesAconexDelta akathehuskyNo ratings yet

- Saep 1152Document19 pagesSaep 1152Delta akathehuskyNo ratings yet

- Home Safety ChecklistDocument2 pagesHome Safety ChecklistDelta akathehuskyNo ratings yet

- Waste ComputationDocument2 pagesWaste ComputationDelta akathehuskyNo ratings yet

- Pre-Interview Evaluation - (Revised 2022) - ExpatDocument3 pagesPre-Interview Evaluation - (Revised 2022) - ExpatDelta akathehuskyNo ratings yet

- Assessment ReportDocument1 pageAssessment ReportDelta akathehuskyNo ratings yet

- Basic of Iso 9001bDocument43 pagesBasic of Iso 9001bDelta akathehuskyNo ratings yet

- Assembly of Steel StructuresDocument2 pagesAssembly of Steel StructuresDelta akathehuskyNo ratings yet

- Travelling of CraneDocument3 pagesTravelling of CraneDelta akathehuskyNo ratings yet

- General Instruction Manual: ScopeDocument10 pagesGeneral Instruction Manual: ScopeDelta akathehuskyNo ratings yet

- KCC Lifting and Shifting With CraneDocument7 pagesKCC Lifting and Shifting With CraneDelta akathehuskyNo ratings yet

- General Instruction Manual: ScopeDocument11 pagesGeneral Instruction Manual: ScopeDelta akathehuskyNo ratings yet

- General Instruction Manual: Saudi Arabian Oil Company (Saudi Aramco)Document9 pagesGeneral Instruction Manual: Saudi Arabian Oil Company (Saudi Aramco)Delta akathehuskyNo ratings yet

- General Instruction Manual: ContentDocument22 pagesGeneral Instruction Manual: ContentDelta akathehuskyNo ratings yet

- Scaffolding Site Instruction Control SheetDocument21 pagesScaffolding Site Instruction Control SheetDelta akathehuskyNo ratings yet

- Gi 0002 - 718 Contractor Site Allotment ProcedureDocument12 pagesGi 0002 - 718 Contractor Site Allotment ProcedureDelta akathehuskyNo ratings yet

- Material Order FormDocument3 pagesMaterial Order FormDelta akathehuskyNo ratings yet

- General Instruction Manual: ContentDocument13 pagesGeneral Instruction Manual: ContentDelta akathehuskyNo ratings yet

- Meisei Scaffolding Materials ForecastDocument4 pagesMeisei Scaffolding Materials ForecastDelta akathehuskyNo ratings yet

- Virtual Trials and Real-World Evidence Data CollectionDocument4 pagesVirtual Trials and Real-World Evidence Data CollectionRoopali AggarwalNo ratings yet

- Piping Design Professional: Kamalakannan ADocument4 pagesPiping Design Professional: Kamalakannan AKamalakannan AyyaduraiNo ratings yet

- Concrete Mix Design Excel SheetDocument12 pagesConcrete Mix Design Excel SheetDhanush SNo ratings yet

- Test Bank For Biology 4th Edition by BrookerDocument37 pagesTest Bank For Biology 4th Edition by BrookerShannon Melancon100% (44)

- Forces and MomentsDocument17 pagesForces and MomentsRan OronceNo ratings yet

- Personal Selling - CH 6 - Adaptive Selling For Relationship BuildingDocument65 pagesPersonal Selling - CH 6 - Adaptive Selling For Relationship Buildingash.khanNo ratings yet

- Conscience: Mr. Jose A. Procalla JR., MsmeDocument17 pagesConscience: Mr. Jose A. Procalla JR., MsmeStella SalvadorNo ratings yet

- Oracle Machine Learning R Release NotesDocument8 pagesOracle Machine Learning R Release NotesHarish NaikNo ratings yet

- Reporte de US Consultants Del Codigo de RedDocument309 pagesReporte de US Consultants Del Codigo de RedLily ParadaNo ratings yet

- Lakshy Management Has Initiated ISO 9001:2008 & ISO 27001:2005 Consultancy and Certification Project For Motion Matters Inc., Kabul Afghanistan.Document2 pagesLakshy Management Has Initiated ISO 9001:2008 & ISO 27001:2005 Consultancy and Certification Project For Motion Matters Inc., Kabul Afghanistan.Kaushal SutariaNo ratings yet

- Transfusion Science Sample QuestionsDocument4 pagesTransfusion Science Sample QuestionsIT Professional TrainingNo ratings yet

- 15 Anxiety Worksheets and Workbooks For Teens, Kids, AdultsDocument23 pages15 Anxiety Worksheets and Workbooks For Teens, Kids, AdultsGilang Faisal AndrianNo ratings yet

- LIC DeductionDocument1 pageLIC Deductionbala govindamNo ratings yet

- Contrast Weighting Glascher Gitelman 2008Document12 pagesContrast Weighting Glascher Gitelman 2008danxalreadyNo ratings yet

- Slope Monitoring Using Total StationDocument13 pagesSlope Monitoring Using Total StationIamEm B. MoNo ratings yet

- Ang Hiyas Campus Journalists Dominates DSPC 2018Document1 pageAng Hiyas Campus Journalists Dominates DSPC 2018Pauline Karen Macaisa-ConcepcionNo ratings yet

- Upload TextilDocument2 pagesUpload TextilManoj MandavkarNo ratings yet

- Module Programming and Reprogramming Service Tips September 2013 Update V4Document1 pageModule Programming and Reprogramming Service Tips September 2013 Update V4Mauri accattoliNo ratings yet

- Cnchiwatec CatalogDocument16 pagesCnchiwatec Catalogriski utomoNo ratings yet

- CIAC - 2 - After Sales ServiceDocument18 pagesCIAC - 2 - After Sales Serviceleonardoacastro9886No ratings yet

- Standard-Based School Improvement Plan HDocument3 pagesStandard-Based School Improvement Plan HLhyn ThonNo ratings yet

- What Is MulticulturalismDocument7 pagesWhat Is MulticulturalismamnahNo ratings yet

- SO2ndEdAUnitTest3Document2 pagesSO2ndEdAUnitTest3coilch11No ratings yet

- BELL B40C - 872071-01 Section 3-Power TrainDocument106 pagesBELL B40C - 872071-01 Section 3-Power TrainALI AKBAR100% (1)

- Report of Large Motor ReliabilityDocument28 pagesReport of Large Motor Reliabilitythawatchai11222512100% (1)

- Statistics: It'S Your TurnDocument7 pagesStatistics: It'S Your TurnMarjie Bay-asenNo ratings yet