Professional Documents

Culture Documents

Sealbond 218 P Pressure Injection Epoxy

Sealbond 218 P Pressure Injection Epoxy

Uploaded by

pauwee.arroOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sealbond 218 P Pressure Injection Epoxy

Sealbond 218 P Pressure Injection Epoxy

Uploaded by

pauwee.arroCopyright:

Available Formats

product data Structural Concrete Repairs

SEALBOND 218-P

STRUCTURAL PRESSURE INJECTION EPOXY

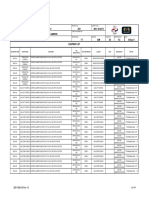

Product Description Technical / Performance Data

SEALBOND PRESSURE INJECTION EPOXY Shrinkage Negligible

(218P) is a two component adhesive system

Compressive Strength 74.1 MPa

composed of 100% solids Epoxy that contains Japan Testing Center for

(JIS A 6024)

polyamide curing agent ensuring a tough and Construction Materials

durable bond resistant to chemicals and corrosion. Compressive Strength Min 8,000 -11,000 at 7 days

This unique low viscosity adhesive is primarily ASTM C109-95/ D695 Max 11,000 -12,000 at 7 days

designed for the all around remedy of structural

Tensile Strength

concrete defects and flaws particularly the repair of (ASTM D638)

7,000-8,000 psi at 7 days

cracks by pressure injection. Aside from sealing

Flexural Strength

cracks and crevices and filling voids, it can also be 6,000 – 9,000 psi at 7 days

(ASTM D790-92)

combined with fine aggregates or silica sand to Bond Strength

result in an Epoxy Mortar for high strength grouting. 3,000 – 5,000 psi at 7 days

(ASTM C882-99)

Hardness

80 Shore D

Application Areas (ASTM D2240)

Viscosity 1670 cps

Structurally re-bond cracked or delaminated Resistance to most organic

concrete, and masonry Resistance to Chemicals solvents, mild acids and

Filling voids in honeycombed or poorly alkalis

consolidated concrete Solid by Volume 100%

Re-sealing of bug holes and pot holes

Patching uneven surfaces Procedure & Guidelines

Sealbond 218-P is tested under Japan Testing

Center for Construction Materials: SURFACE PREPARATION

Compressive Strength performed according to

JIS A 6024 (Epoxy Adhesive for repairing and GENERAL

reinforcement in buildings). All surfaces must be thoroughly cleaned to remove dirt,

grease, mill scale, loose rust, chalk, and any other

contaminants that can reduce adhesion.

Processing Data

MIXING

Mix Ratio Mix 2 Parts by volume of Resin Base (Part A) to 1 Part

2 Part A: 1 Part B by Volume Hardener (Part B) for 3-4 minutes. Any

(by volume)

4 hours changes from the recommended proportion will affect its

Tack Time at 25 ºC

quality. Scrape the bottoms, sides and corners of the

24 hours, 72 hours before container to ensure complete and full blending. Prepare

Full Cured at 25 ºC

applying pressure only enough quantities that can be used within the pot-

Pot Life at 25 ºC 1-2 hours (Admixtures) life period. Do not delay application.

Shelf Life 1 year at room temperature

…………..………………………...…………………………………………… Structural Concrete Repairs

JULY 2021| Rev. 3

This technical data contained herein is true and accurate to the best of our knowledge on the date of publication and is subject to change without prior notice. User must contact Sealbond Chemical Industries Inc. to

verify correctness before specifying or ordering. We assume no responsibility for coverage, performance or injuries resulting from use. Liability, if any, is limited replacement of products. Sealbond Hi-Perfomance is

registered trademark of Sealbond Chemical Industries Inc.

www.sealbondchemicals.com

product data Structural Concrete Repairs

SEAL BOND 218-P

APPLICATION Storage / Packaging

PRESSURE INJECTION

Blow compressed air along the crack lines to SEALBOND 218-P is available in gallon kit.

completely clean, dry and remove dirt and other

loose contaminating materials. Provide temporary This product must be stored dry, protected from sun

seal on crack surface except entry and exit ports. and rain.

Inject Sealbond 218-P starting at the lowest entry

port up to the proceeding ports until the voids are Product Limitations

completely filled. Product can withstand heavy load but cannot withstand

excessive abrasion.

EPOXY GROUTING V-CUT SYSTEM

V-cut all cracks for repair. Blow compressed air along Additional Information - Disclaimer

the crack lines to completely clean, dry and remove

dirt and other loose contaminating materials. Apply The information and in particular, recommendations relating to the application and

end-use of Sealbond products, are given in good faith based on Sealbond’s best

by brush pure Sealbond Epoxy 218-P to serve as knowledge and specialty on construction chemical formulations. Products are

primer then apply Sealbond Epoxy 218-P mixed with properly stored and handled in accordance with Sealbond’s endorsements. Hence,

subject to the care and method of application, deviations (from published values) in

silica sand or patching compound on v-cut surface. performance may occur. In practice, to different materials used, as well as varying

working conditions and environments beyond our control Sealbond Chemical

Industries Inc. strictly recommend carrying out intensive trials to test the suitability

Epoxy Grouting On Concrete Honeycomb: of the product with regards to the required processes and applications. Therefore,

Chip off loose concrete. Remove dust, dirt and other any liability for such recommendations or any oral/verbal advice is expressly

excluded unless we have acted wilfully or by gross negligence. Sealbond

loose contaminating materials. Install formworks on Chemicals Industries Inc. is not liable for installation or faulty installation. It is

honeycomb providing for a small opening on the always the responsibility of the installer/applicator/purchaser to guarantee and

certify the installation of materials.

upper portion. Pour Sealbond Epoxy 218-P mixed

All orders are accepted subject to our current terms of sale and delivery. Users

with silica sand. Remove formworks upon curing of must always refer to the most recent issue of the Product Data Sheet for the

epoxy grout. product awareness, copies of which will be supplied on request and is free of

charge.

CLEANING-UP

Pressure Injection tools and other equipment maybe

cleaned with Sealbond Epoxy Reducer while the

mixture has not yet hardened. Wash off hands with

detergent and warm water.

Health & Safety

Avoid contact with eyes and skin and avoid breathing

its vapor. This product may cause severe skin

irritation after prolonged or repeated exposure. Keep

containers tightly closed and store in a cool dry place.

Product is for Professional use only.

A-2 Araneta St. Cor. Gen. Natividad St.

Bgy. Ibayo,Tipas Taguig City, Philippines

PH: (632) 881-8813 ● (632) 883-1477 ● (632) 845-0205

● (632) 843-4498 ● (632) 845-0137 DOWNLOAD

www.sealbondchemicals.com SCII MOBILE APP

…………..………………………...…………………………………………… Structural Concrete Repairs

JULY 2021| Rev. 3

This technical data contained herein is true and accurate to the best of our knowledge on the date of publication and is subject to change without prior notice. User must contact Sealbond Chemical Industries Inc. to

verify correctness before specifying or ordering. We assume no responsibility for coverage, performance or injuries resulting from use. Liability, if any, is limited replacement of products. Sealbond Hi-Perfomance is

registered trademark of Sealbond Chemical Industries Inc.

www.sealbondchemicals.com

You might also like

- The Design and Performance of The Retaining Walls at Newton StationDocument8 pagesThe Design and Performance of The Retaining Walls at Newton StationfreezefreezeNo ratings yet

- Carboline Carboguard 890 PDSDocument2 pagesCarboline Carboguard 890 PDSSamNo ratings yet

- Sealbond 218-P: Structural Pressure Injection EpoxyDocument2 pagesSealbond 218-P: Structural Pressure Injection EpoxyMarvin BaquialNo ratings yet

- Carboguard 501 PDS 12-03 PDFDocument2 pagesCarboguard 501 PDS 12-03 PDFImran AhmadNo ratings yet

- TDS Conbextra EP10 India6Document3 pagesTDS Conbextra EP10 India6jasonNo ratings yet

- Lapox B-47 - AH-713: Technical Data Sheet - Polymers BusinessDocument4 pagesLapox B-47 - AH-713: Technical Data Sheet - Polymers Businesssriatul2006No ratings yet

- Phenoline 187 Primer and FinishDocument2 pagesPhenoline 187 Primer and Finish이선엽No ratings yet

- T-R-FX763CTGDocument3 pagesT-R-FX763CTGTiago GassmanNo ratings yet

- Dokumen - Tips - High Performance Waterborne Epoxy Formulation For 2019 03 06 19 Table 1 Epoxy ModifiedDocument3 pagesDokumen - Tips - High Performance Waterborne Epoxy Formulation For 2019 03 06 19 Table 1 Epoxy ModifiedLong An ĐỗNo ratings yet

- Anti Crak Brochure ScreenDocument7 pagesAnti Crak Brochure ScreenPablo Quinteros PizarroNo ratings yet

- Carbothane 134 HG Polyurethane Coating MSDSDocument13 pagesCarbothane 134 HG Polyurethane Coating MSDSjgzlzNo ratings yet

- Fosroc Renderoc HB: Technical Data SheetDocument4 pagesFosroc Renderoc HB: Technical Data SheetRJNo ratings yet

- Master EMACO 425 TDSDocument3 pagesMaster EMACO 425 TDSabrar4012No ratings yet

- Sealbond EPC-100 - TDS & MSDSDocument7 pagesSealbond EPC-100 - TDS & MSDSmaridelljabonilloNo ratings yet

- CemFIL AntiCrak HP 6736 Product Sheet WW 10-2014 Rev8 en FinalDocument2 pagesCemFIL AntiCrak HP 6736 Product Sheet WW 10-2014 Rev8 en FinalvliegenkristofNo ratings yet

- IndustrialDocument16 pagesIndustrialVaittianathan MahavapillaiNo ratings yet

- Sikalastic®-560 GCC Co-Elastic TechnologyDocument1 pageSikalastic®-560 GCC Co-Elastic Technologybassem muhannaNo ratings yet

- MasterEmaco 2525 ASEAN V1.4 0713Document2 pagesMasterEmaco 2525 ASEAN V1.4 0713Muhammad Fadhil ImansyahNo ratings yet

- MasterEase 3822 v1Document3 pagesMasterEase 3822 v1dachepalli963No ratings yet

- T-R-FX763Document3 pagesT-R-FX763Tiago GassmanNo ratings yet

- E 1605 SikaCor 255 277Document5 pagesE 1605 SikaCor 255 277manoj_sitecNo ratings yet

- Mci - 2241/mci - 2242 Watertight Coat: Typical Applications and FeaturesDocument2 pagesMci - 2241/mci - 2242 Watertight Coat: Typical Applications and FeaturesAdrian EspinosaNo ratings yet

- F13 - Carboguard 893-Zn PDS 10-09Document2 pagesF13 - Carboguard 893-Zn PDS 10-09naveenbaskaran1989No ratings yet

- TDS Renderoc RG IndiaDocument3 pagesTDS Renderoc RG IndiaBijaya RaulaNo ratings yet

- Chem Poxy Grout E999 Tds Am22319Document2 pagesChem Poxy Grout E999 Tds Am22319Navid HashemiNo ratings yet

- Pro Mastic Ste 87Document4 pagesPro Mastic Ste 87ahmedyahea181No ratings yet

- Phenoline 187 Finish PDSDocument2 pagesPhenoline 187 Finish PDSalejandroNo ratings yet

- Water-Based Resins For Coatings: Portfolio SheetDocument1 pageWater-Based Resins For Coatings: Portfolio SheetCu Caicon100% (1)

- Propiedades de Fisicas de La Resina para AerogeneradoresDocument2 pagesPropiedades de Fisicas de La Resina para Aerogeneradoresluis beltran gomez laricoNo ratings yet

- 18 Vetogrout EG340 - 180321Document2 pages18 Vetogrout EG340 - 180321Maha MuflehNo ratings yet

- Repcon SDocument2 pagesRepcon SRamu SekarNo ratings yet

- TDS Renderoc RG IndiaDocument3 pagesTDS Renderoc RG IndiaPrad RNo ratings yet

- Renderoc RGDocument3 pagesRenderoc RGR.ThangarajNo ratings yet

- 3M Scotchkote Epoxy Primer GP220 - Rev2Document2 pages3M Scotchkote Epoxy Primer GP220 - Rev2satya ranjanNo ratings yet

- Resicrete 2118 - TDSDocument2 pagesResicrete 2118 - TDSPhạm Thanh PhươngNo ratings yet

- Flowcrete Asia Isocrete K Screed May2020 TdsDocument2 pagesFlowcrete Asia Isocrete K Screed May2020 TdsJiawen WeiNo ratings yet

- TDS Renderoc RG India PDFDocument3 pagesTDS Renderoc RG India PDFrajiv_quantumNo ratings yet

- TDS Conbextra EP160 Saudi ArabiaDocument4 pagesTDS Conbextra EP160 Saudi ArabiajasonNo ratings yet

- Cempol SBR: Bonding AdmixtureDocument2 pagesCempol SBR: Bonding AdmixtureJagdishNo ratings yet

- Sealbond ETL 100 Epoxy Tank LiningDocument2 pagesSealbond ETL 100 Epoxy Tank LiningRzeus Adigue100% (1)

- Epoject 304I: General DescriptionDocument2 pagesEpoject 304I: General Descriptionnoblas melNo ratings yet

- Sealbond 385 UE Epoxy UnderwaterDocument2 pagesSealbond 385 UE Epoxy UnderwaterRonalyn Lago R.C.ENo ratings yet

- MasterEase 3702 v4Document2 pagesMasterEase 3702 v4dachepalli963No ratings yet

- X-Roc Epoxybond: Epoxy Resin Bonding AgentDocument2 pagesX-Roc Epoxybond: Epoxy Resin Bonding AgentAmr RagabNo ratings yet

- TDS Renderoc RGM IndiaDocument4 pagesTDS Renderoc RGM IndiaKishore Nayak kNo ratings yet

- Carbomastic 801 PDFDocument2 pagesCarbomastic 801 PDFkayNo ratings yet

- Resutile Topcoat SD System Guide SWDocument4 pagesResutile Topcoat SD System Guide SWServandoNo ratings yet

- DC 995Document3 pagesDC 995Andrea Nicola TurcatoNo ratings yet

- TDS 2800000925 en - USDocument2 pagesTDS 2800000925 en - USIsrael HernandezNo ratings yet

- Belzona 1821: Product Specification SheetDocument2 pagesBelzona 1821: Product Specification SheetAlex BravoNo ratings yet

- TDS Conbextra EP10LV IndiaDocument2 pagesTDS Conbextra EP10LV Indiaraahul_nNo ratings yet

- Carboguard Low Haps Epoxy: Selection & Specification Data Substrates & Surface PreparationDocument2 pagesCarboguard Low Haps Epoxy: Selection & Specification Data Substrates & Surface PreparationImran AhmadNo ratings yet

- Fosroc Conbextra HS: Constructive SolutionsDocument4 pagesFosroc Conbextra HS: Constructive SolutionsCatherine Fatima Mae LeynoNo ratings yet

- Flowcrete Asia Mondéco Crystal May2020 TdsDocument2 pagesFlowcrete Asia Mondéco Crystal May2020 TdsQuoc AnNo ratings yet

- SubseaLV DatasheetDocument1 pageSubseaLV DatasheetPablo TorresNo ratings yet

- Full Submittal ER351 - EP691 - EL499 - UC371 - 240317 - 134220Document230 pagesFull Submittal ER351 - EP691 - EL499 - UC371 - 240317 - 134220manpower.ccorecoNo ratings yet

- OrganizedDocument45 pagesOrganizedpooja patelNo ratings yet

- Arkifloor SLE 2MDocument2 pagesArkifloor SLE 2MChristinaNo ratings yet

- Water Protect Technical Leaflet - 07 12 2020Document2 pagesWater Protect Technical Leaflet - 07 12 2020TahmidtuhinNo ratings yet

- Glass Fibre Grid v1Document13 pagesGlass Fibre Grid v1Anirudh SabooNo ratings yet

- Self Healing Behavior of High Strength Strain Hardening - 2023 - Construction ADocument10 pagesSelf Healing Behavior of High Strength Strain Hardening - 2023 - Construction AGabriela DraghiciNo ratings yet

- Assement of Underwater Concrete Technologies USACEDocument91 pagesAssement of Underwater Concrete Technologies USACEcesaraleNo ratings yet

- Appendix 02 - List of Deliverables PDFDocument32 pagesAppendix 02 - List of Deliverables PDFshareyhouNo ratings yet

- Drill String SlidesDocument93 pagesDrill String SlidesAyush RawatNo ratings yet

- Method Statement Mae Moh TunnelDocument22 pagesMethod Statement Mae Moh Tunneltgme_siammac100% (13)

- BSRM Design & ConstructionDocument2 pagesBSRM Design & ConstructionjamilNo ratings yet

- Installation Instructions LAUFENDocument7 pagesInstallation Instructions LAUFENLapsikNo ratings yet

- DIY TeardropDocument12 pagesDIY TeardropAnonymous MyUcfo100% (1)

- PistonPumpFailure Analysis PDFDocument9 pagesPistonPumpFailure Analysis PDFanandsubbiahNo ratings yet

- M007-Ccc-Str-Mes-00005 Rev1.0Document58 pagesM007-Ccc-Str-Mes-00005 Rev1.0Mikku KattaNo ratings yet

- McGuire Enterprises Launches Curb Ramp™ - An Eco-Friendly Driveway Ramp For Lowered CarsDocument2 pagesMcGuire Enterprises Launches Curb Ramp™ - An Eco-Friendly Driveway Ramp For Lowered CarsPR.comNo ratings yet

- Skye Luxuria 20 Final BrochureDocument21 pagesSkye Luxuria 20 Final BrochureShree MaharajNo ratings yet

- Nonlinear Finite Element Analysis of Reinforced Concrete Beams Strengthened With Externally Bonded Steel Plate Using ANSYSDocument10 pagesNonlinear Finite Element Analysis of Reinforced Concrete Beams Strengthened With Externally Bonded Steel Plate Using ANSYSbroodyNo ratings yet

- Closure To CPT-Based Probabilistic Soil Charct. Cetin 2009Document8 pagesClosure To CPT-Based Probabilistic Soil Charct. Cetin 2009ManuelNo ratings yet

- Ecpmi Ecpmms: 2019: Ethiopian Construction Project Management Manuals SeriesDocument56 pagesEcpmi Ecpmms: 2019: Ethiopian Construction Project Management Manuals SeriesKalkidanNo ratings yet

- 2051-K09-010 Data Sheet - Control Damper Rev 1.0Document14 pages2051-K09-010 Data Sheet - Control Damper Rev 1.0Amro Metwally El HendawyNo ratings yet

- Flash Report Ppli Is 10 Aug 2023Document15 pagesFlash Report Ppli Is 10 Aug 2023Hardy AchdiatNo ratings yet

- Hat PurlinDocument3 pagesHat PurlinAniket DubeNo ratings yet

- Cover Page Ce 412lDocument4 pagesCover Page Ce 412lCatherine Shaina O. PasionNo ratings yet

- Danilo O. Dela Rosa: Job ObjectiveDocument3 pagesDanilo O. Dela Rosa: Job ObjectiveMo NassifNo ratings yet

- M60es44 P449y Man 001Document23 pagesM60es44 P449y Man 001Riski Kurniawan100% (1)

- CS-50 - 50 Ton Capacity Cement Silo - ConstmachDocument5 pagesCS-50 - 50 Ton Capacity Cement Silo - Constmachtemu ShashNo ratings yet

- AASHTO Standard Specifications For Highway Bridges 17th - TOCDocument84 pagesAASHTO Standard Specifications For Highway Bridges 17th - TOCGeorge Christodoulidis71% (7)

- Construction of The Plastic Concrete Cut-Off Wall at Hinze DamDocument9 pagesConstruction of The Plastic Concrete Cut-Off Wall at Hinze Damjuan muneraNo ratings yet

- Duplex Piston Pump Mud PumpDocument2 pagesDuplex Piston Pump Mud PumpDeddy Irawan0% (1)

- Calculation - Cainta 2 Storey Building - RetrofittingDocument58 pagesCalculation - Cainta 2 Storey Building - Retrofittingregino abuzoNo ratings yet

- QS Book PDFDocument191 pagesQS Book PDFBrilliant Temp100% (2)

- Report Group 2Document40 pagesReport Group 2Ignatius SamrajNo ratings yet

- StepocDocument6 pagesStepocRobert WhiteNo ratings yet