Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

3 viewsM.khizer 4155 Assignment 2 S&P

M.khizer 4155 Assignment 2 S&P

Uploaded by

Fahad HussainThe document discusses how supplier selection and performance measurement can contribute to effective supply chain risk management. It outlines that choosing reliable suppliers through a thorough selection process and continuously monitoring their performance allows organizations to mitigate risks. Supplier selection helps identify high-risk partnerships and diversify sources to avoid disruptions. Performance measurement enables early detection of potential problems and drives continuous improvement. Together, selection and measurement create a comprehensive approach to manage risks and ensure a resilient supply chain.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You might also like

- Assignment 2 Q ND Q ApproachesDocument7 pagesAssignment 2 Q ND Q ApproachesshuantinasheNo ratings yet

- Supply Chain ManagementDocument11 pagesSupply Chain Managementprohacker4714No ratings yet

- Unit 6Document23 pagesUnit 6ABHISHEK JBNo ratings yet

- Supplier Relationship ManagementDocument3 pagesSupplier Relationship ManagementJawad RasheedNo ratings yet

- Supplier Relationship Management An IntroductionDocument10 pagesSupplier Relationship Management An Introductionapp nanaNo ratings yet

- S&VM Practice Questions Piyush - GautamDocument8 pagesS&VM Practice Questions Piyush - GautamPIYUSH GAUTAMNo ratings yet

- Computational ThinkingDocument10 pagesComputational ThinkingHà Vi ĐinhNo ratings yet

- Supplier Evaluation The First Step in Effective SoDocument4 pagesSupplier Evaluation The First Step in Effective SoShatender kumar Kumar100% (1)

- Muneeswaran - Project 2Document6 pagesMuneeswaran - Project 2Roopesh BabuNo ratings yet

- Cbme Finals ReviewerDocument39 pagesCbme Finals ReviewerRev Richmon De ChavezNo ratings yet

- 7.supply Chain Risk ManagementDocument3 pages7.supply Chain Risk ManagementREON RODRIGUESNo ratings yet

- SIPNDocument32 pagesSIPNShriyog MhatreNo ratings yet

- Advantages of Supply ChainDocument4 pagesAdvantages of Supply ChainRachel R. AbogatalNo ratings yet

- Supply Chain SummaryDocument5 pagesSupply Chain Summary2021304217No ratings yet

- Assignment 3 - Supply Chain ManagementDocument2 pagesAssignment 3 - Supply Chain ManagementRITHIK KUMARAN KNo ratings yet

- Ahmed Mohamed Abdelkhalek - 2U - Sunday 6 PMDocument7 pagesAhmed Mohamed Abdelkhalek - 2U - Sunday 6 PMahmed abdelkhalikNo ratings yet

- Supply Chain Integration and ManagementDocument2 pagesSupply Chain Integration and ManagementOpindra Kumar SinghNo ratings yet

- Supplier Information and Performance DossierDocument10 pagesSupplier Information and Performance DossierZycusIncNo ratings yet

- Supply Chain OptimizationDocument15 pagesSupply Chain OptimizationArihoruhanga VincentNo ratings yet

- Measuring Supplier Performance GRP 7 FinalDocument8 pagesMeasuring Supplier Performance GRP 7 FinalAbigaelNo ratings yet

- Supply Chain Risk and Mitigation in Service Sector by Bisma SamirDocument2 pagesSupply Chain Risk and Mitigation in Service Sector by Bisma SamirMohsin IqbalNo ratings yet

- Vendor Management ProgramDocument2 pagesVendor Management ProgramJW9425No ratings yet

- Week 2 MemoDocument1 pageWeek 2 MemoKaushal reddyNo ratings yet

- Unit - 1Document9 pagesUnit - 1Harshit KumarNo ratings yet

- Supplier Management - Benefits, Process, & Best PracticesDocument14 pagesSupplier Management - Benefits, Process, & Best PracticesgodkabetaNo ratings yet

- Empirical workDocument4 pagesEmpirical workHossam IZMAOUENENo ratings yet

- A Vendor Risk Management Audit Checklist - RiskXchangeDocument2 pagesA Vendor Risk Management Audit Checklist - RiskXchangeSaNo ratings yet

- Procurement Due Diligence-2Document12 pagesProcurement Due Diligence-2Klementius SilalahiNo ratings yet

- Supply Chain ManagementDocument3 pagesSupply Chain ManagementSubham KumarNo ratings yet

- Notes For SCRDocument3 pagesNotes For SCRlitee1983No ratings yet

- Ba 208Document8 pagesBa 208rahmat wibowoNo ratings yet

- Unit 08 Supplier RelationsDocument35 pagesUnit 08 Supplier RelationsPratham GoelNo ratings yet

- MODULE-II Sourcing ManagementDocument14 pagesMODULE-II Sourcing ManagementumeshNo ratings yet

- Supply Chain ManagementDocument23 pagesSupply Chain ManagementSri Sarveentaran100% (1)

- Module 6 OMTQMDocument7 pagesModule 6 OMTQMAlisonNo ratings yet

- 22mba0050 PASS ASSIGNMENT 1Document5 pages22mba0050 PASS ASSIGNMENT 1Nishant RanaNo ratings yet

- SRMDocument3 pagesSRMgs randhawaNo ratings yet

- SRMDocument3 pagesSRMgs randhawaNo ratings yet

- Best Sourcing Strategies With SuppliersDocument2 pagesBest Sourcing Strategies With Supplierskvk301712No ratings yet

- Strategic GRP AssgnmtDocument10 pagesStrategic GRP AssgnmtYaikob MaskalaNo ratings yet

- Ensuring Vendor ContinuityDocument7 pagesEnsuring Vendor ContinuitySamNo ratings yet

- Engineering ManagementDocument19 pagesEngineering Managementveil davidNo ratings yet

- Supplier PartnershipDocument11 pagesSupplier PartnershipLuoise KimNo ratings yet

- ASSIGMENT DeadlineDocument11 pagesASSIGMENT DeadlineCaamir Dek HaybeNo ratings yet

- SupplDocument1 pageSupplajaysoftdevNo ratings yet

- Reducing Risk Through Quality What The C-Suite Needs To KnowDocument7 pagesReducing Risk Through Quality What The C-Suite Needs To KnowJulie julNo ratings yet

- Vendor Management: Definition and UsesDocument3 pagesVendor Management: Definition and UsessnowFlakes A0% (1)

- Governance Risk Management and Compliance FrameworkDocument4 pagesGovernance Risk Management and Compliance FrameworkAmandaNo ratings yet

- Benchmarking Supply ChainDocument8 pagesBenchmarking Supply ChainsanoNo ratings yet

- Outsourcing More Critical FunctionsDocument24 pagesOutsourcing More Critical FunctionsApoloTrevinoNo ratings yet

- Week 12 SELECT or PINPOINT POTENTIAL SUPPLIERS OF RAW MATERIALS AND OTHER INPUTS NECESSARY FOR THE PRODUCTION OF THE PRODUCT OR SERVICEDocument3 pagesWeek 12 SELECT or PINPOINT POTENTIAL SUPPLIERS OF RAW MATERIALS AND OTHER INPUTS NECESSARY FOR THE PRODUCTION OF THE PRODUCT OR SERVICEMARY GLORY IGNACIO100% (1)

- Chapter No 1 Supply ChainDocument3 pagesChapter No 1 Supply ChainSimra SalmanNo ratings yet

- SC MR Supplier de Volo PmentDocument3 pagesSC MR Supplier de Volo PmentJelena JovićNo ratings yet

- Quality Risk Planning Part-BDocument2 pagesQuality Risk Planning Part-BGowrisanthosh PalikaNo ratings yet

- Chapter 5 Supplier Relation Ship MGTDocument10 pagesChapter 5 Supplier Relation Ship MGTselamawitmul2013No ratings yet

- TQM ReviewerDocument54 pagesTQM ReviewerMaryan SabelNo ratings yet

- Welspun India Corporate GovernanaceDocument2 pagesWelspun India Corporate GovernanaceRNo ratings yet

- The Accredited Supply Chain ProfessionalFrom EverandThe Accredited Supply Chain ProfessionalRating: 5 out of 5 stars5/5 (1)

- Mastering Financial Risk Management : Strategies for SuccessFrom EverandMastering Financial Risk Management : Strategies for SuccessNo ratings yet

- Chapter 4 Contract AdministrationDocument49 pagesChapter 4 Contract AdministrationFahad HussainNo ratings yet

- Inam. Mam AqsaDocument4 pagesInam. Mam AqsaFahad HussainNo ratings yet

- Chapters-Internship ReportDocument48 pagesChapters-Internship ReportFahad HussainNo ratings yet

- Ethics AssignmentDocument2 pagesEthics AssignmentFahad HussainNo ratings yet

- Final Presentation Supply Chain - Group-3Document4 pagesFinal Presentation Supply Chain - Group-3Fahad HussainNo ratings yet

- Brn.... AssignmentDocument7 pagesBrn.... AssignmentFahad HussainNo ratings yet

- Final Presentation - Group No. 3 - Supply ChainDocument10 pagesFinal Presentation - Group No. 3 - Supply ChainFahad HussainNo ratings yet

- Developing Pricing Strategies & ProgramsDocument43 pagesDeveloping Pricing Strategies & ProgramsFahad HussainNo ratings yet

- Setting Product StrategyDocument29 pagesSetting Product StrategyFahad HussainNo ratings yet

- HRM Final Project DoneDocument18 pagesHRM Final Project DoneFahad HussainNo ratings yet

- Assignment #1 Name: Fahad Hussain Class: Bba-4-A Roll No: LCM 4139 Subject: Human Resource Management Submitted To: Mam Erum BatoolDocument25 pagesAssignment #1 Name: Fahad Hussain Class: Bba-4-A Roll No: LCM 4139 Subject: Human Resource Management Submitted To: Mam Erum BatoolFahad HussainNo ratings yet

- FINAL PROJECT Marketing ManagementDocument11 pagesFINAL PROJECT Marketing ManagementFahad HussainNo ratings yet

- Final Project BCDocument5 pagesFinal Project BCFahad HussainNo ratings yet

- Factors Effecting Factors Effecting Brand Preferences: A Comparative Study of Mcdonald'S and KFCDocument16 pagesFactors Effecting Factors Effecting Brand Preferences: A Comparative Study of Mcdonald'S and KFCFahad HussainNo ratings yet

- Abraham Viji: Career ObjectiveDocument3 pagesAbraham Viji: Career ObjectiveabinNo ratings yet

- "Comparative Study of Indian Credit Rating Agencies" by Sameer SawantDocument43 pages"Comparative Study of Indian Credit Rating Agencies" by Sameer SawantSawant SameerNo ratings yet

- Digital Transformation Project in Telkomsel by Pt. Mitra Integrasi InformatikaDocument11 pagesDigital Transformation Project in Telkomsel by Pt. Mitra Integrasi Informatikamazhar100% (1)

- Learning Activity Sheet Abm 12 Fundamentals of Abm 2 (Q2-Wk1-2) Bank Reconciliation IDocument14 pagesLearning Activity Sheet Abm 12 Fundamentals of Abm 2 (Q2-Wk1-2) Bank Reconciliation IKimverlee Anne GarciaNo ratings yet

- CRM System in VodafoneDocument18 pagesCRM System in VodafonePrashant LokhandeNo ratings yet

- Asli Masala (Chilli Powder) : By: Amit Naik (11201) Vishal Deore (11213) Nilesh Hiremath (11218) Sagar Zaparde (11255)Document16 pagesAsli Masala (Chilli Powder) : By: Amit Naik (11201) Vishal Deore (11213) Nilesh Hiremath (11218) Sagar Zaparde (11255)Nilesh HiremathNo ratings yet

- Frederick Winslow Taylor One Hundred Years of Managerial InsightDocument9 pagesFrederick Winslow Taylor One Hundred Years of Managerial InsightGian CarloNo ratings yet

- Internship Program-Anurag RaiDocument5 pagesInternship Program-Anurag RaiUtkarsh SrivastavaNo ratings yet

- Riba Outline Plan of WorkDocument3 pagesRiba Outline Plan of Workmarston22No ratings yet

- D-Exam-Syllabus - LEVEL DDocument4 pagesD-Exam-Syllabus - LEVEL DINGCESA PANAMANo ratings yet

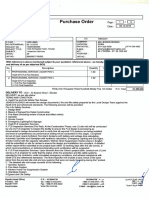

- Purchase Order: DeliveryDocument3 pagesPurchase Order: DeliverySiddiq KhanNo ratings yet

- Pmbok Guide Part 1Document86 pagesPmbok Guide Part 1neil_scribd2012No ratings yet

- Corp Gov - TybmsDocument46 pagesCorp Gov - TybmsNurdayantiNo ratings yet

- MBE BA 9263 PPT Unit IIIDocument16 pagesMBE BA 9263 PPT Unit IIIstandalonembaNo ratings yet

- The Business Model Canvas: Key Partners Key Activities Value Proposition Customer Relationships Customer SegmentsDocument3 pagesThe Business Model Canvas: Key Partners Key Activities Value Proposition Customer Relationships Customer SegmentsTri Septia Rahmawati KaharNo ratings yet

- InfoQ NoProjects EmagDocument30 pagesInfoQ NoProjects EmagVictor SantiagoNo ratings yet

- The Difference Between Auditors and Forensic AccountantsDocument1 pageThe Difference Between Auditors and Forensic AccountantsMohammed MickelNo ratings yet

- Applied Economics m6Document60 pagesApplied Economics m6Maricar GuanNo ratings yet

- Golden State Home Health Inc Is A Large California Based For ProfitDocument3 pagesGolden State Home Health Inc Is A Large California Based For ProfitDoreen0% (1)

- Interlink Interchange Reimbursement Fees April2012Document3 pagesInterlink Interchange Reimbursement Fees April2012rosekjarNo ratings yet

- JIGAR S DESAI MES ResumeDocument2 pagesJIGAR S DESAI MES ResumeJigar Desai100% (1)

- Data Architecture Project Presentation - Modern StatspptxDocument21 pagesData Architecture Project Presentation - Modern StatspptxPatricio Ernesto RepettoNo ratings yet

- Adv MediaDocument44 pagesAdv MediaFRANCIS JOSEPHNo ratings yet

- Cema Release 0Document2 pagesCema Release 0rajayu20002724No ratings yet

- New Microsoft Office Power Point Presentation On NestleDocument86 pagesNew Microsoft Office Power Point Presentation On NestlesameenNo ratings yet

- La OpalaDocument28 pagesLa OpalaYash PoddarNo ratings yet

- The Only Source of Knowledge Is Experience - Albert EinsteinDocument35 pagesThe Only Source of Knowledge Is Experience - Albert EinsteinAanchal VardhaniNo ratings yet

- Business Marketing Management-WDDocument81 pagesBusiness Marketing Management-WDMaruko ChanNo ratings yet

- LabourDocument86 pagesLabourchaithraNo ratings yet

M.khizer 4155 Assignment 2 S&P

M.khizer 4155 Assignment 2 S&P

Uploaded by

Fahad Hussain0 ratings0% found this document useful (0 votes)

3 views4 pagesThe document discusses how supplier selection and performance measurement can contribute to effective supply chain risk management. It outlines that choosing reliable suppliers through a thorough selection process and continuously monitoring their performance allows organizations to mitigate risks. Supplier selection helps identify high-risk partnerships and diversify sources to avoid disruptions. Performance measurement enables early detection of potential problems and drives continuous improvement. Together, selection and measurement create a comprehensive approach to manage risks and ensure a resilient supply chain.

Original Description:

Original Title

M.khizer-4155-assignment-2-S&P

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document discusses how supplier selection and performance measurement can contribute to effective supply chain risk management. It outlines that choosing reliable suppliers through a thorough selection process and continuously monitoring their performance allows organizations to mitigate risks. Supplier selection helps identify high-risk partnerships and diversify sources to avoid disruptions. Performance measurement enables early detection of potential problems and drives continuous improvement. Together, selection and measurement create a comprehensive approach to manage risks and ensure a resilient supply chain.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

3 views4 pagesM.khizer 4155 Assignment 2 S&P

M.khizer 4155 Assignment 2 S&P

Uploaded by

Fahad HussainThe document discusses how supplier selection and performance measurement can contribute to effective supply chain risk management. It outlines that choosing reliable suppliers through a thorough selection process and continuously monitoring their performance allows organizations to mitigate risks. Supplier selection helps identify high-risk partnerships and diversify sources to avoid disruptions. Performance measurement enables early detection of potential problems and drives continuous improvement. Together, selection and measurement create a comprehensive approach to manage risks and ensure a resilient supply chain.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 4

Department of Management Sciences, Lahore.

ASSIGNMENT NO: 2

Programme: BBA-8-Evening

Subject: Sourcing & Procurement

Submitted by: Muhammad Khizer (LCM-4155)

Submitted to: Ma’am Aqsa

Submission date: 7-03-2024

Question:

How supplier selection and performance measurement can

contribute to effective supply chain risk management?

Answer:

The success of any organization heavily relies on the efficiency and

resilience of its supply chain. However, the globalized and

interconnected nature of modern supply chains exposes them to

various risks, such as disruptions, quality issues, and financial

instability. To navigate these challenges and ensure a smooth flow of

goods and services,

Effective supply chain risk management (SCRM) is crucial. This

involves proactively identifying, assessing, and mitigating potential

disruptions throughout the supply chain.

Supplier selection and performance measurement play a vital role

in establishing a robust SCRM framework. They act as the foundation

for building strong relationships with reliable suppliers, ultimately

contributing to a more resilient and efficient supply chain.

1. Supplier Selection: Mitigating Risks at the Onset

Choosing the right suppliers is the first step towards mitigating risks

in the supply chain. A thorough and well-defined selection process

helps organizations identify and partner with suppliers who are not

only cost-effective but also possess the capabilities to meet their

specific needs while minimizing potential risks. Here's how supplier

selection contributes to SCRM:

Risk Identification: By evaluating potential suppliers based on

various criteria, such as financial stability, quality control practices,

geographical location, and compliance with regulations, organizations

can identify red flags and avoid high-risk partnerships.

Diversification: Selecting multiple suppliers for critical materials or

components can mitigate the risk of single-source vulnerability. This

ensures that disruptions from one supplier can be compensated for by

others.

Contractual Agreements: Establishing clear contracts with suppliers

can define performance expectations, quality standards, risk-sharing

mechanisms, and contingency plans in case of disruptions.

2. Performance Measurement: Proactive Risk Detection and

Mitigation

Monitoring and measuring supplier performance allows

organizations to continuously assess the effectiveness of their

partnerships and identify potential risks early on. This enables

proactive mitigation strategies to be implemented before disruptions

occur. Here's how performance measurement contributes to SCRM:

Early Warning Signs: By monitoring key performance indicators

(KPIs) such as on-time delivery, quality control metrics, and financial

stability, organizations can identify early signs of potential problems

with a supplier. This allows them to intervene and address issues

before they escalate into major disruptions.

Continuous Improvement: Regularly evaluating and comparing

supplier performance against established benchmarks helps identify

areas for improvement. This can involve collaborating with suppliers

to address deficiencies in quality, efficiency, or risk management

practices, ultimately strengthening the overall supply chain resilience.

Benchmarking: Comparing the performance of different suppliers

allows organizations to identify best practices and encourage

continuous improvement across the supplier base.

Effective supplier selection and performance measurement are

not isolated processes. They work together to create a

comprehensive SCRM approach. By carefully selecting reliable

suppliers and continuously monitoring their performance,

organizations can build a robust and resilient supply chain,

minimizing the impact of disruptions and ensuring the smooth flow of

goods and services.

Additional Considerations:

Technology: Utilizing technology such as supplier relationship

management (SRM) software can streamline the supplier selection

and performance measurement processes, allowing for real-time data

analysis and informed decision-making.

Collaboration: Building strong relationships and fostering open

communication with suppliers is crucial for effective SCRM. This

allows for early identification and collaborative resolution of potential

issues.

Continuous Monitoring: The global business landscape is constantly

evolving, and new risks can emerge. Therefore, organizations must

continuously monitor their supply chain and adapt their SCRM

strategies accordingly.

By acknowledging the vital role that supplier selection and

performance measurement play in SCRM, organizations can

proactively manage risks, foster strong supplier relationships, and

build a more resilient and efficient supply chain.

You might also like

- Assignment 2 Q ND Q ApproachesDocument7 pagesAssignment 2 Q ND Q ApproachesshuantinasheNo ratings yet

- Supply Chain ManagementDocument11 pagesSupply Chain Managementprohacker4714No ratings yet

- Unit 6Document23 pagesUnit 6ABHISHEK JBNo ratings yet

- Supplier Relationship ManagementDocument3 pagesSupplier Relationship ManagementJawad RasheedNo ratings yet

- Supplier Relationship Management An IntroductionDocument10 pagesSupplier Relationship Management An Introductionapp nanaNo ratings yet

- S&VM Practice Questions Piyush - GautamDocument8 pagesS&VM Practice Questions Piyush - GautamPIYUSH GAUTAMNo ratings yet

- Computational ThinkingDocument10 pagesComputational ThinkingHà Vi ĐinhNo ratings yet

- Supplier Evaluation The First Step in Effective SoDocument4 pagesSupplier Evaluation The First Step in Effective SoShatender kumar Kumar100% (1)

- Muneeswaran - Project 2Document6 pagesMuneeswaran - Project 2Roopesh BabuNo ratings yet

- Cbme Finals ReviewerDocument39 pagesCbme Finals ReviewerRev Richmon De ChavezNo ratings yet

- 7.supply Chain Risk ManagementDocument3 pages7.supply Chain Risk ManagementREON RODRIGUESNo ratings yet

- SIPNDocument32 pagesSIPNShriyog MhatreNo ratings yet

- Advantages of Supply ChainDocument4 pagesAdvantages of Supply ChainRachel R. AbogatalNo ratings yet

- Supply Chain SummaryDocument5 pagesSupply Chain Summary2021304217No ratings yet

- Assignment 3 - Supply Chain ManagementDocument2 pagesAssignment 3 - Supply Chain ManagementRITHIK KUMARAN KNo ratings yet

- Ahmed Mohamed Abdelkhalek - 2U - Sunday 6 PMDocument7 pagesAhmed Mohamed Abdelkhalek - 2U - Sunday 6 PMahmed abdelkhalikNo ratings yet

- Supply Chain Integration and ManagementDocument2 pagesSupply Chain Integration and ManagementOpindra Kumar SinghNo ratings yet

- Supplier Information and Performance DossierDocument10 pagesSupplier Information and Performance DossierZycusIncNo ratings yet

- Supply Chain OptimizationDocument15 pagesSupply Chain OptimizationArihoruhanga VincentNo ratings yet

- Measuring Supplier Performance GRP 7 FinalDocument8 pagesMeasuring Supplier Performance GRP 7 FinalAbigaelNo ratings yet

- Supply Chain Risk and Mitigation in Service Sector by Bisma SamirDocument2 pagesSupply Chain Risk and Mitigation in Service Sector by Bisma SamirMohsin IqbalNo ratings yet

- Vendor Management ProgramDocument2 pagesVendor Management ProgramJW9425No ratings yet

- Week 2 MemoDocument1 pageWeek 2 MemoKaushal reddyNo ratings yet

- Unit - 1Document9 pagesUnit - 1Harshit KumarNo ratings yet

- Supplier Management - Benefits, Process, & Best PracticesDocument14 pagesSupplier Management - Benefits, Process, & Best PracticesgodkabetaNo ratings yet

- Empirical workDocument4 pagesEmpirical workHossam IZMAOUENENo ratings yet

- A Vendor Risk Management Audit Checklist - RiskXchangeDocument2 pagesA Vendor Risk Management Audit Checklist - RiskXchangeSaNo ratings yet

- Procurement Due Diligence-2Document12 pagesProcurement Due Diligence-2Klementius SilalahiNo ratings yet

- Supply Chain ManagementDocument3 pagesSupply Chain ManagementSubham KumarNo ratings yet

- Notes For SCRDocument3 pagesNotes For SCRlitee1983No ratings yet

- Ba 208Document8 pagesBa 208rahmat wibowoNo ratings yet

- Unit 08 Supplier RelationsDocument35 pagesUnit 08 Supplier RelationsPratham GoelNo ratings yet

- MODULE-II Sourcing ManagementDocument14 pagesMODULE-II Sourcing ManagementumeshNo ratings yet

- Supply Chain ManagementDocument23 pagesSupply Chain ManagementSri Sarveentaran100% (1)

- Module 6 OMTQMDocument7 pagesModule 6 OMTQMAlisonNo ratings yet

- 22mba0050 PASS ASSIGNMENT 1Document5 pages22mba0050 PASS ASSIGNMENT 1Nishant RanaNo ratings yet

- SRMDocument3 pagesSRMgs randhawaNo ratings yet

- SRMDocument3 pagesSRMgs randhawaNo ratings yet

- Best Sourcing Strategies With SuppliersDocument2 pagesBest Sourcing Strategies With Supplierskvk301712No ratings yet

- Strategic GRP AssgnmtDocument10 pagesStrategic GRP AssgnmtYaikob MaskalaNo ratings yet

- Ensuring Vendor ContinuityDocument7 pagesEnsuring Vendor ContinuitySamNo ratings yet

- Engineering ManagementDocument19 pagesEngineering Managementveil davidNo ratings yet

- Supplier PartnershipDocument11 pagesSupplier PartnershipLuoise KimNo ratings yet

- ASSIGMENT DeadlineDocument11 pagesASSIGMENT DeadlineCaamir Dek HaybeNo ratings yet

- SupplDocument1 pageSupplajaysoftdevNo ratings yet

- Reducing Risk Through Quality What The C-Suite Needs To KnowDocument7 pagesReducing Risk Through Quality What The C-Suite Needs To KnowJulie julNo ratings yet

- Vendor Management: Definition and UsesDocument3 pagesVendor Management: Definition and UsessnowFlakes A0% (1)

- Governance Risk Management and Compliance FrameworkDocument4 pagesGovernance Risk Management and Compliance FrameworkAmandaNo ratings yet

- Benchmarking Supply ChainDocument8 pagesBenchmarking Supply ChainsanoNo ratings yet

- Outsourcing More Critical FunctionsDocument24 pagesOutsourcing More Critical FunctionsApoloTrevinoNo ratings yet

- Week 12 SELECT or PINPOINT POTENTIAL SUPPLIERS OF RAW MATERIALS AND OTHER INPUTS NECESSARY FOR THE PRODUCTION OF THE PRODUCT OR SERVICEDocument3 pagesWeek 12 SELECT or PINPOINT POTENTIAL SUPPLIERS OF RAW MATERIALS AND OTHER INPUTS NECESSARY FOR THE PRODUCTION OF THE PRODUCT OR SERVICEMARY GLORY IGNACIO100% (1)

- Chapter No 1 Supply ChainDocument3 pagesChapter No 1 Supply ChainSimra SalmanNo ratings yet

- SC MR Supplier de Volo PmentDocument3 pagesSC MR Supplier de Volo PmentJelena JovićNo ratings yet

- Quality Risk Planning Part-BDocument2 pagesQuality Risk Planning Part-BGowrisanthosh PalikaNo ratings yet

- Chapter 5 Supplier Relation Ship MGTDocument10 pagesChapter 5 Supplier Relation Ship MGTselamawitmul2013No ratings yet

- TQM ReviewerDocument54 pagesTQM ReviewerMaryan SabelNo ratings yet

- Welspun India Corporate GovernanaceDocument2 pagesWelspun India Corporate GovernanaceRNo ratings yet

- The Accredited Supply Chain ProfessionalFrom EverandThe Accredited Supply Chain ProfessionalRating: 5 out of 5 stars5/5 (1)

- Mastering Financial Risk Management : Strategies for SuccessFrom EverandMastering Financial Risk Management : Strategies for SuccessNo ratings yet

- Chapter 4 Contract AdministrationDocument49 pagesChapter 4 Contract AdministrationFahad HussainNo ratings yet

- Inam. Mam AqsaDocument4 pagesInam. Mam AqsaFahad HussainNo ratings yet

- Chapters-Internship ReportDocument48 pagesChapters-Internship ReportFahad HussainNo ratings yet

- Ethics AssignmentDocument2 pagesEthics AssignmentFahad HussainNo ratings yet

- Final Presentation Supply Chain - Group-3Document4 pagesFinal Presentation Supply Chain - Group-3Fahad HussainNo ratings yet

- Brn.... AssignmentDocument7 pagesBrn.... AssignmentFahad HussainNo ratings yet

- Final Presentation - Group No. 3 - Supply ChainDocument10 pagesFinal Presentation - Group No. 3 - Supply ChainFahad HussainNo ratings yet

- Developing Pricing Strategies & ProgramsDocument43 pagesDeveloping Pricing Strategies & ProgramsFahad HussainNo ratings yet

- Setting Product StrategyDocument29 pagesSetting Product StrategyFahad HussainNo ratings yet

- HRM Final Project DoneDocument18 pagesHRM Final Project DoneFahad HussainNo ratings yet

- Assignment #1 Name: Fahad Hussain Class: Bba-4-A Roll No: LCM 4139 Subject: Human Resource Management Submitted To: Mam Erum BatoolDocument25 pagesAssignment #1 Name: Fahad Hussain Class: Bba-4-A Roll No: LCM 4139 Subject: Human Resource Management Submitted To: Mam Erum BatoolFahad HussainNo ratings yet

- FINAL PROJECT Marketing ManagementDocument11 pagesFINAL PROJECT Marketing ManagementFahad HussainNo ratings yet

- Final Project BCDocument5 pagesFinal Project BCFahad HussainNo ratings yet

- Factors Effecting Factors Effecting Brand Preferences: A Comparative Study of Mcdonald'S and KFCDocument16 pagesFactors Effecting Factors Effecting Brand Preferences: A Comparative Study of Mcdonald'S and KFCFahad HussainNo ratings yet

- Abraham Viji: Career ObjectiveDocument3 pagesAbraham Viji: Career ObjectiveabinNo ratings yet

- "Comparative Study of Indian Credit Rating Agencies" by Sameer SawantDocument43 pages"Comparative Study of Indian Credit Rating Agencies" by Sameer SawantSawant SameerNo ratings yet

- Digital Transformation Project in Telkomsel by Pt. Mitra Integrasi InformatikaDocument11 pagesDigital Transformation Project in Telkomsel by Pt. Mitra Integrasi Informatikamazhar100% (1)

- Learning Activity Sheet Abm 12 Fundamentals of Abm 2 (Q2-Wk1-2) Bank Reconciliation IDocument14 pagesLearning Activity Sheet Abm 12 Fundamentals of Abm 2 (Q2-Wk1-2) Bank Reconciliation IKimverlee Anne GarciaNo ratings yet

- CRM System in VodafoneDocument18 pagesCRM System in VodafonePrashant LokhandeNo ratings yet

- Asli Masala (Chilli Powder) : By: Amit Naik (11201) Vishal Deore (11213) Nilesh Hiremath (11218) Sagar Zaparde (11255)Document16 pagesAsli Masala (Chilli Powder) : By: Amit Naik (11201) Vishal Deore (11213) Nilesh Hiremath (11218) Sagar Zaparde (11255)Nilesh HiremathNo ratings yet

- Frederick Winslow Taylor One Hundred Years of Managerial InsightDocument9 pagesFrederick Winslow Taylor One Hundred Years of Managerial InsightGian CarloNo ratings yet

- Internship Program-Anurag RaiDocument5 pagesInternship Program-Anurag RaiUtkarsh SrivastavaNo ratings yet

- Riba Outline Plan of WorkDocument3 pagesRiba Outline Plan of Workmarston22No ratings yet

- D-Exam-Syllabus - LEVEL DDocument4 pagesD-Exam-Syllabus - LEVEL DINGCESA PANAMANo ratings yet

- Purchase Order: DeliveryDocument3 pagesPurchase Order: DeliverySiddiq KhanNo ratings yet

- Pmbok Guide Part 1Document86 pagesPmbok Guide Part 1neil_scribd2012No ratings yet

- Corp Gov - TybmsDocument46 pagesCorp Gov - TybmsNurdayantiNo ratings yet

- MBE BA 9263 PPT Unit IIIDocument16 pagesMBE BA 9263 PPT Unit IIIstandalonembaNo ratings yet

- The Business Model Canvas: Key Partners Key Activities Value Proposition Customer Relationships Customer SegmentsDocument3 pagesThe Business Model Canvas: Key Partners Key Activities Value Proposition Customer Relationships Customer SegmentsTri Septia Rahmawati KaharNo ratings yet

- InfoQ NoProjects EmagDocument30 pagesInfoQ NoProjects EmagVictor SantiagoNo ratings yet

- The Difference Between Auditors and Forensic AccountantsDocument1 pageThe Difference Between Auditors and Forensic AccountantsMohammed MickelNo ratings yet

- Applied Economics m6Document60 pagesApplied Economics m6Maricar GuanNo ratings yet

- Golden State Home Health Inc Is A Large California Based For ProfitDocument3 pagesGolden State Home Health Inc Is A Large California Based For ProfitDoreen0% (1)

- Interlink Interchange Reimbursement Fees April2012Document3 pagesInterlink Interchange Reimbursement Fees April2012rosekjarNo ratings yet

- JIGAR S DESAI MES ResumeDocument2 pagesJIGAR S DESAI MES ResumeJigar Desai100% (1)

- Data Architecture Project Presentation - Modern StatspptxDocument21 pagesData Architecture Project Presentation - Modern StatspptxPatricio Ernesto RepettoNo ratings yet

- Adv MediaDocument44 pagesAdv MediaFRANCIS JOSEPHNo ratings yet

- Cema Release 0Document2 pagesCema Release 0rajayu20002724No ratings yet

- New Microsoft Office Power Point Presentation On NestleDocument86 pagesNew Microsoft Office Power Point Presentation On NestlesameenNo ratings yet

- La OpalaDocument28 pagesLa OpalaYash PoddarNo ratings yet

- The Only Source of Knowledge Is Experience - Albert EinsteinDocument35 pagesThe Only Source of Knowledge Is Experience - Albert EinsteinAanchal VardhaniNo ratings yet

- Business Marketing Management-WDDocument81 pagesBusiness Marketing Management-WDMaruko ChanNo ratings yet

- LabourDocument86 pagesLabourchaithraNo ratings yet