Professional Documents

Culture Documents

7 Marla House With Basement Design

7 Marla House With Basement Design

Uploaded by

Ali RazaCopyright:

Available Formats

You might also like

- Foundation Works Method Statement PDFDocument10 pagesFoundation Works Method Statement PDFKaranja0% (1)

- Specifications FOR Single Storey Residential Building: Prepared byDocument9 pagesSpecifications FOR Single Storey Residential Building: Prepared byruel buntog100% (1)

- Method Statement FOR Artificial Rock WorkDocument9 pagesMethod Statement FOR Artificial Rock Workbhupsjangir100% (2)

- Mbma-Guide For Inspecting Metal Building Systems PreviewsDocument10 pagesMbma-Guide For Inspecting Metal Building Systems Previewsjackcan501No ratings yet

- Casa Mila & Sagrada FamiliaDocument34 pagesCasa Mila & Sagrada FamiliaLeo ShashankNo ratings yet

- General NotesDocument1 pageGeneral NotesEngr Arslan RazaNo ratings yet

- Southspring Heights Brgy, San Miguel Sto - Tomas BatangasDocument10 pagesSouthspring Heights Brgy, San Miguel Sto - Tomas Batangasleona lopezNo ratings yet

- Arch 530 - BT4 Technical SpecificationsDocument13 pagesArch 530 - BT4 Technical SpecificationsAlyanna PanganibanNo ratings yet

- Specifications (San Carlos Heights)Document10 pagesSpecifications (San Carlos Heights)Bryan Soriano PascualNo ratings yet

- Short Construction-SpecificationsDocument8 pagesShort Construction-SpecificationsRany YambaoNo ratings yet

- Technical SpecificationsDocument8 pagesTechnical SpecificationsAngel AbrajanoNo ratings yet

- Structural Specifications - OakridgeDocument13 pagesStructural Specifications - OakridgeJuliet Lobrino RozosNo ratings yet

- Culvert Drawing BinderDocument5 pagesCulvert Drawing BinderAhmed Nader KhurshidNo ratings yet

- Guideline Notes For RCC WorkDocument10 pagesGuideline Notes For RCC Workvikas WaghmareNo ratings yet

- Division 01 General Requirements: Kaypian, San Jose Del Monte BulacanDocument7 pagesDivision 01 General Requirements: Kaypian, San Jose Del Monte BulacanKristine MalabayNo ratings yet

- 2.Superstructure final_TRUSS 50MDocument14 pages2.Superstructure final_TRUSS 50MSudarshan SapkotaNo ratings yet

- Excavation and Backfill For Structures PDFDocument6 pagesExcavation and Backfill For Structures PDFjitendra kumar dhawanNo ratings yet

- Excavation and Backfill For StructuresDocument6 pagesExcavation and Backfill For StructuresMonali VarpeNo ratings yet

- Long SpecificationDocument33 pagesLong SpecificationRenvil PedernalNo ratings yet

- Buildings Department Practice Note For Authorized Persons, Registered Structural Engineers and Registered Geotechnical Engineers APP-68Document7 pagesBuildings Department Practice Note For Authorized Persons, Registered Structural Engineers and Registered Geotechnical Engineers APP-68030093No ratings yet

- Secant PilingDocument15 pagesSecant Pilingwalid abou kachfe100% (1)

- Coldbox Foundation Procedures Rev 2Document2 pagesColdbox Foundation Procedures Rev 2Rose ManipolNo ratings yet

- UG-IV-1-Concrete WorkDocument8 pagesUG-IV-1-Concrete WorkshreejeshNo ratings yet

- Civil Works-MethodologyDocument11 pagesCivil Works-MethodologyMarvilou Gomez100% (1)

- RD Conc PavingDocument10 pagesRD Conc PavingAurelius GoraNo ratings yet

- Section 6: Foundation: 6.1 GeneralDocument13 pagesSection 6: Foundation: 6.1 GeneralwaliNo ratings yet

- Earthquake PaperDocument2 pagesEarthquake PaperSurendra TamrakarNo ratings yet

- 10.CivilSpecification 151to252Document102 pages10.CivilSpecification 151to252gaurangagola1991No ratings yet

- 900 - Rigid PavementsDocument22 pages900 - Rigid Pavementsruwan.smb1No ratings yet

- 19 - Bearings (Section-2000)Document40 pages19 - Bearings (Section-2000)Ankit MaindoliaNo ratings yet

- Mech ElecSpec AppdMakeCapex2013 PDFDocument133 pagesMech ElecSpec AppdMakeCapex2013 PDFyash shahNo ratings yet

- HB 12350Document21 pagesHB 12350Pawan Kumar PrajapatNo ratings yet

- SPECIFICATIONDocument25 pagesSPECIFICATIONkingcedsNo ratings yet

- Structural Specifications Items General: City Building and Architecture OfficeDocument11 pagesStructural Specifications Items General: City Building and Architecture OfficeEd AnchetaNo ratings yet

- m01 Construction ProceduresDocument2 pagesm01 Construction ProceduresRose ManipolNo ratings yet

- Technical Specifications: Proposed Two Storey Residential BuildingDocument10 pagesTechnical Specifications: Proposed Two Storey Residential BuildingAeron AcioNo ratings yet

- Part B 1000 Bedded HostelDocument128 pagesPart B 1000 Bedded Hosteldhirajagarwal1989No ratings yet

- 02 - Part A - Earth WorkDocument32 pages02 - Part A - Earth Workkartick adhikaryNo ratings yet

- Specification For Precast Concrete WorksDocument39 pagesSpecification For Precast Concrete Worksm.nurhishamm100% (2)

- Grade Beam Procedures Rev 3Document2 pagesGrade Beam Procedures Rev 3Rose ManipolNo ratings yet

- Technical Specifications:: Conversion of Concrete Sidewalk To RampDocument2 pagesTechnical Specifications:: Conversion of Concrete Sidewalk To RampAnton_Young_1962100% (1)

- Foundation CriteriaDocument2 pagesFoundation CriteriaAbdullah Al MamunNo ratings yet

- General SpecificationsDocument9 pagesGeneral SpecificationsTyron CustodioNo ratings yet

- 02 - Part A - Earth WorkDocument41 pages02 - Part A - Earth Worksanthosh kumar t mNo ratings yet

- 20 - Open Foundations (Section-2100)Document6 pages20 - Open Foundations (Section-2100)Ankit MaindoliaNo ratings yet

- Work Method Statement FOR Reinforced Concrete WorksDocument5 pagesWork Method Statement FOR Reinforced Concrete WorksLynn Mail100% (1)

- 7 TechnicalSpecifications 3Document121 pages7 TechnicalSpecifications 3Ramkumar KumaresanNo ratings yet

- MS OF Raft & Water ProofingDocument4 pagesMS OF Raft & Water ProofingnipunNo ratings yet

- Section6 - Bill of QuantitiesDocument7 pagesSection6 - Bill of QuantitiesEngr. HayathNo ratings yet

- Shiela S. Portillo Ang Specification 09112021Document9 pagesShiela S. Portillo Ang Specification 09112021JR De LeonNo ratings yet

- PD 0158 SM 01Document1 pagePD 0158 SM 01FAIZAN AHMEDNo ratings yet

- Technical Specifications for 2 storey BldgDocument11 pagesTechnical Specifications for 2 storey BldgNestor Cantilang MalinaoNo ratings yet

- Concepcion SpecificationsDocument7 pagesConcepcion SpecificationsMark Daniel RodajeNo ratings yet

- Standard Specification For General Construction Proposed Two-Storey Residential House Mrs. Maria Rechel B.EricksonDocument5 pagesStandard Specification For General Construction Proposed Two-Storey Residential House Mrs. Maria Rechel B.EricksonRocky SioresNo ratings yet

- Technical Specifications (Civil, Structural Works)Document26 pagesTechnical Specifications (Civil, Structural Works)Neil DinerosNo ratings yet

- Technical Specifications I. Demolition WorksDocument14 pagesTechnical Specifications I. Demolition WorksKiel CorpuzNo ratings yet

- Micropile SpecificationDocument9 pagesMicropile SpecificationchongptNo ratings yet

- Department of Public Works and HighwaysDocument10 pagesDepartment of Public Works and HighwaysAnthony TangNo ratings yet

- Technical Specifications:: Construction of Concrete Pavement For Parking AreaDocument2 pagesTechnical Specifications:: Construction of Concrete Pavement For Parking AreaAnton_Young_1962No ratings yet

- Spec Mechanical WorksDocument41 pagesSpec Mechanical Worksbhawani consultantNo ratings yet

- Construction of DecksDocument12 pagesConstruction of DecksAung Naing Latt AungNo ratings yet

- Reinforced Concrete Grade Beams, Piles & Caissons: A Practical Guide for Hillside ConstructionFrom EverandReinforced Concrete Grade Beams, Piles & Caissons: A Practical Guide for Hillside ConstructionNo ratings yet

- Cor A Vent Product GuideDocument103 pagesCor A Vent Product GuideB D PorterNo ratings yet

- Arslanhane MosqueDocument7 pagesArslanhane MosqueAysegul AkınNo ratings yet

- 2011 Trevi TowersDocument32 pages2011 Trevi TowersCMChuaNo ratings yet

- Fire Safety Checklist On Building Plans FinalDocument2 pagesFire Safety Checklist On Building Plans FinalFerdinand M. Turbanos100% (1)

- Kest 5th Septic Tank & Soak Away MT 1Document166 pagesKest 5th Septic Tank & Soak Away MT 1EphremHailuNo ratings yet

- Install Wooden Door JambDocument14 pagesInstall Wooden Door JambJeanelle SamsonNo ratings yet

- Catalogo Self Spanning EngDocument10 pagesCatalogo Self Spanning EngatiNo ratings yet

- Renaissance ArchitectureDocument26 pagesRenaissance ArchitectureMiroslav Šilić100% (1)

- Section Elevation: Shard PlaceDocument1 pageSection Elevation: Shard PlacefereetNo ratings yet

- Rate Analysis CalculationDocument6 pagesRate Analysis CalculationSanjay Babu RaghubanshiNo ratings yet

- Yung Ho Spring I&IIDocument21 pagesYung Ho Spring I&IIKelvin XuNo ratings yet

- NCSCM Building BOQ Structural Vol 4aDocument126 pagesNCSCM Building BOQ Structural Vol 4akkodgeNo ratings yet

- General Authority of Civil Aviation Building: Construction ConstructionDocument3 pagesGeneral Authority of Civil Aviation Building: Construction ConstructionAnonymous a3K3WgNo ratings yet

- Office Interiors Office Space: The Open Plan System FurnitureDocument19 pagesOffice Interiors Office Space: The Open Plan System Furniturekumara nathanNo ratings yet

- Technical Drafting 9 - Draft Roof PlansDocument16 pagesTechnical Drafting 9 - Draft Roof PlansMary-Angel AlastreNo ratings yet

- 67 - M. Dimovska-Colovic - The Clock Towers in MacedoniaDocument5 pages67 - M. Dimovska-Colovic - The Clock Towers in MacedoniaZoran PavlovNo ratings yet

- Floating Cottages Master Bedroom Guest Room Loft Living Area Total Bed CapacityDocument4 pagesFloating Cottages Master Bedroom Guest Room Loft Living Area Total Bed CapacityIvaan ValenzuelaNo ratings yet

- 17 PDFDocument1 page17 PDFMMNo ratings yet

- Nordlund HandoutDocument12 pagesNordlund HandoutmybestloveNo ratings yet

- RAB Retaining Wall - REVDocument167 pagesRAB Retaining Wall - REVOkti AfriadelaNo ratings yet

- Neo VernacularDocument2 pagesNeo VernacularBerliana Para'pakNo ratings yet

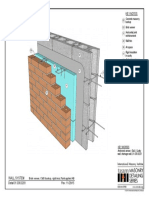

- Key Notes: Wall SystemDocument1 pageKey Notes: Wall SystemMyo Min ThuNo ratings yet

- Cost Effective Alternate SystemsDocument18 pagesCost Effective Alternate SystemshiteshiNo ratings yet

- Bill of QuantitiesDocument5 pagesBill of QuantitiesUlquiorra Garcia0% (1)

- Niagara Falls Construction Project ASLI-terkunciDocument12 pagesNiagara Falls Construction Project ASLI-terkunciTopan ArdiansyahNo ratings yet

- GBC Mod I-IIIDocument218 pagesGBC Mod I-IIIBrian KoechNo ratings yet

- Hoa Module 4 P1Document94 pagesHoa Module 4 P1cyril delfin100% (2)

- Cantilever Retaining Walls 2019Document8 pagesCantilever Retaining Walls 2019yassir dafallaNo ratings yet

7 Marla House With Basement Design

7 Marla House With Basement Design

Uploaded by

Ali RazaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

7 Marla House With Basement Design

7 Marla House With Basement Design

Uploaded by

Ali RazaCopyright:

Available Formats

1. Design is in accordance with ACI —318 Code, 1995 Specifications.

2. All work shall be carried out in accordance with the job specifications.

16. During construction, safety and stability of the structure and all temporary works

3. All Reinforced concrete except column is 3000 psi cube strength at 28 Days

shall be given prime importance. Utmost care and precaution shall be

(Min. mix is 1 :2:4).

Exercised by the contractor during the work against any mishap or accident.

All Reinforced concrete in column ns is 3750 psi cube strength at 28 Days

(Min. mix is 1 : 1.5:3). 17. Bars in beams shall be joggled in vertical plane for laps and shallbe

4. Design of specified concrete mix shaII be submitted by the Contractor a n d staggered.

shall be got approved form the Engineer well before concreting of relevant 18. All Laps ore 50 times bar diameter.

structures along with result of test cylinders tested as per ASTM C 39. 19. Bars in column shall be joggled for laps with starter bars.

Test specimens shall be made and cured in accordance with ASTM C 31.

20. Position of bars in beams shall be adjusted keeping in view the position of

For steel use Grade 60 (Deformed) Rein forceme nt with Fy = 60,000 psi

vertical bars of the columns.

Yiel d strength and Fu = 9 0,000 psi Ultimate strength. Further steel specifications

are a s per ASTM A—6 15 specif ications. 21. Stirrups shall be placed in such a way that their hooks shall be staggered

Cement from different sources sha II not be mixed for the structure. and located in compression face.

7. Coarse Sand f rom approved quarries should be used. Approved quarries a re 22. Concrete test cylinder shall be cured with the same method and under same

chenab and lawrencepur only. conditions as those for the concrete work they represent.

8. Well graded crushed stone from approved quarries shall be used as coarse aggregate.The 23. No concrete shall be poured until its form work and reinforcement has

proportion in which crush should be used in concrete mix will be 50% been inspected and approved by the Engineer.

1/2” Down and 50% 1/2” Pure. 24. Sequence of removal of form work shall be as approved by the Engineer.

9. Potable water shall be used for concrete and shall be free of organic and 25. Existing underground services if any, required to be left in position, shall

other impurities. be carefully protected during excavation.

26. Excavation adjacent to existing structures and/or under—ground services

All drawings should be read in conjunction with the relevant architectural and servicedrawings.

And please confirm all the dimensions and levels from Architectural drawingsbefore shall be made by hand.

execution. 27. Adequate shoring and support to the sides of all excavation sh all be

Unless otherwise shown on the plans, Concrete cover provided for supplied and erected where required to safe guard workmen or protect

reinforcement shall be as follows;

any adjacent structures.

1 ) Footing s o n 1 :4:8

28. Foundations have been designed for bearing capacity of 0.98T/ft*2 at

a) Bottom 2” Footing base level. In case of any adverse variety of soil or

b) Sides 2” bearing capacity found during construction, it shall be immediately

2) Slabs 3/4”

brought to thenotice of Engineer in cha rge for further instructions.

5) Beams & Colum ns 1:2:4

29. While back filling of excavation for footings compaction shall be done

12. All layout, configuration, dimensions and levels shall be verified before proceeding

in layers. Material provided for back filling should not be cohesive and ifcohesive

with the work. If N.S level is not some in the construction area then take the

material provided then also provide proper drainage facility.

lowest level as reference level.

13. All reinforcing bars shall be held firmly in place before and during the 30. All conduits and pipes to be laid in concrete shall be located above ma in

pouring of concrete by means of adequate number of wires and supports reinforcement of slabs and beams and with the approval of the Eng ineer.

31. Excavation including dewatering, bracing of excavation to safeguard the

to prevent dislocation during the course of construction.

adjoining property and life and dewatering pits in case of rain is contractor’s CLIENT:

14. Construction joint not shown on the drawing shall be properly planned to

responsibility. USMAN SB

make and must be located as to least impair the strength of structure andalso TITLE:

GENERAL NOTES &

SPECIFICATION

need prior approval of the Engineer. I n general they shall be located SCALE: DRAWING NO.

near the middIe of the s pan of sIabs and bea ms. DATE:

N.T.S.

Joints sha II be perpendicular to main reinforcement. All reinforcing steel 5-00

shall be continued properly across the joints.

15. Use #3@12” bars for binding all top steel in slabs.

ENGR ALI RAZA, 03046726750

ENGR ALI RAZA, 03046726750

You might also like

- Foundation Works Method Statement PDFDocument10 pagesFoundation Works Method Statement PDFKaranja0% (1)

- Specifications FOR Single Storey Residential Building: Prepared byDocument9 pagesSpecifications FOR Single Storey Residential Building: Prepared byruel buntog100% (1)

- Method Statement FOR Artificial Rock WorkDocument9 pagesMethod Statement FOR Artificial Rock Workbhupsjangir100% (2)

- Mbma-Guide For Inspecting Metal Building Systems PreviewsDocument10 pagesMbma-Guide For Inspecting Metal Building Systems Previewsjackcan501No ratings yet

- Casa Mila & Sagrada FamiliaDocument34 pagesCasa Mila & Sagrada FamiliaLeo ShashankNo ratings yet

- General NotesDocument1 pageGeneral NotesEngr Arslan RazaNo ratings yet

- Southspring Heights Brgy, San Miguel Sto - Tomas BatangasDocument10 pagesSouthspring Heights Brgy, San Miguel Sto - Tomas Batangasleona lopezNo ratings yet

- Arch 530 - BT4 Technical SpecificationsDocument13 pagesArch 530 - BT4 Technical SpecificationsAlyanna PanganibanNo ratings yet

- Specifications (San Carlos Heights)Document10 pagesSpecifications (San Carlos Heights)Bryan Soriano PascualNo ratings yet

- Short Construction-SpecificationsDocument8 pagesShort Construction-SpecificationsRany YambaoNo ratings yet

- Technical SpecificationsDocument8 pagesTechnical SpecificationsAngel AbrajanoNo ratings yet

- Structural Specifications - OakridgeDocument13 pagesStructural Specifications - OakridgeJuliet Lobrino RozosNo ratings yet

- Culvert Drawing BinderDocument5 pagesCulvert Drawing BinderAhmed Nader KhurshidNo ratings yet

- Guideline Notes For RCC WorkDocument10 pagesGuideline Notes For RCC Workvikas WaghmareNo ratings yet

- Division 01 General Requirements: Kaypian, San Jose Del Monte BulacanDocument7 pagesDivision 01 General Requirements: Kaypian, San Jose Del Monte BulacanKristine MalabayNo ratings yet

- 2.Superstructure final_TRUSS 50MDocument14 pages2.Superstructure final_TRUSS 50MSudarshan SapkotaNo ratings yet

- Excavation and Backfill For Structures PDFDocument6 pagesExcavation and Backfill For Structures PDFjitendra kumar dhawanNo ratings yet

- Excavation and Backfill For StructuresDocument6 pagesExcavation and Backfill For StructuresMonali VarpeNo ratings yet

- Long SpecificationDocument33 pagesLong SpecificationRenvil PedernalNo ratings yet

- Buildings Department Practice Note For Authorized Persons, Registered Structural Engineers and Registered Geotechnical Engineers APP-68Document7 pagesBuildings Department Practice Note For Authorized Persons, Registered Structural Engineers and Registered Geotechnical Engineers APP-68030093No ratings yet

- Secant PilingDocument15 pagesSecant Pilingwalid abou kachfe100% (1)

- Coldbox Foundation Procedures Rev 2Document2 pagesColdbox Foundation Procedures Rev 2Rose ManipolNo ratings yet

- UG-IV-1-Concrete WorkDocument8 pagesUG-IV-1-Concrete WorkshreejeshNo ratings yet

- Civil Works-MethodologyDocument11 pagesCivil Works-MethodologyMarvilou Gomez100% (1)

- RD Conc PavingDocument10 pagesRD Conc PavingAurelius GoraNo ratings yet

- Section 6: Foundation: 6.1 GeneralDocument13 pagesSection 6: Foundation: 6.1 GeneralwaliNo ratings yet

- Earthquake PaperDocument2 pagesEarthquake PaperSurendra TamrakarNo ratings yet

- 10.CivilSpecification 151to252Document102 pages10.CivilSpecification 151to252gaurangagola1991No ratings yet

- 900 - Rigid PavementsDocument22 pages900 - Rigid Pavementsruwan.smb1No ratings yet

- 19 - Bearings (Section-2000)Document40 pages19 - Bearings (Section-2000)Ankit MaindoliaNo ratings yet

- Mech ElecSpec AppdMakeCapex2013 PDFDocument133 pagesMech ElecSpec AppdMakeCapex2013 PDFyash shahNo ratings yet

- HB 12350Document21 pagesHB 12350Pawan Kumar PrajapatNo ratings yet

- SPECIFICATIONDocument25 pagesSPECIFICATIONkingcedsNo ratings yet

- Structural Specifications Items General: City Building and Architecture OfficeDocument11 pagesStructural Specifications Items General: City Building and Architecture OfficeEd AnchetaNo ratings yet

- m01 Construction ProceduresDocument2 pagesm01 Construction ProceduresRose ManipolNo ratings yet

- Technical Specifications: Proposed Two Storey Residential BuildingDocument10 pagesTechnical Specifications: Proposed Two Storey Residential BuildingAeron AcioNo ratings yet

- Part B 1000 Bedded HostelDocument128 pagesPart B 1000 Bedded Hosteldhirajagarwal1989No ratings yet

- 02 - Part A - Earth WorkDocument32 pages02 - Part A - Earth Workkartick adhikaryNo ratings yet

- Specification For Precast Concrete WorksDocument39 pagesSpecification For Precast Concrete Worksm.nurhishamm100% (2)

- Grade Beam Procedures Rev 3Document2 pagesGrade Beam Procedures Rev 3Rose ManipolNo ratings yet

- Technical Specifications:: Conversion of Concrete Sidewalk To RampDocument2 pagesTechnical Specifications:: Conversion of Concrete Sidewalk To RampAnton_Young_1962100% (1)

- Foundation CriteriaDocument2 pagesFoundation CriteriaAbdullah Al MamunNo ratings yet

- General SpecificationsDocument9 pagesGeneral SpecificationsTyron CustodioNo ratings yet

- 02 - Part A - Earth WorkDocument41 pages02 - Part A - Earth Worksanthosh kumar t mNo ratings yet

- 20 - Open Foundations (Section-2100)Document6 pages20 - Open Foundations (Section-2100)Ankit MaindoliaNo ratings yet

- Work Method Statement FOR Reinforced Concrete WorksDocument5 pagesWork Method Statement FOR Reinforced Concrete WorksLynn Mail100% (1)

- 7 TechnicalSpecifications 3Document121 pages7 TechnicalSpecifications 3Ramkumar KumaresanNo ratings yet

- MS OF Raft & Water ProofingDocument4 pagesMS OF Raft & Water ProofingnipunNo ratings yet

- Section6 - Bill of QuantitiesDocument7 pagesSection6 - Bill of QuantitiesEngr. HayathNo ratings yet

- Shiela S. Portillo Ang Specification 09112021Document9 pagesShiela S. Portillo Ang Specification 09112021JR De LeonNo ratings yet

- PD 0158 SM 01Document1 pagePD 0158 SM 01FAIZAN AHMEDNo ratings yet

- Technical Specifications for 2 storey BldgDocument11 pagesTechnical Specifications for 2 storey BldgNestor Cantilang MalinaoNo ratings yet

- Concepcion SpecificationsDocument7 pagesConcepcion SpecificationsMark Daniel RodajeNo ratings yet

- Standard Specification For General Construction Proposed Two-Storey Residential House Mrs. Maria Rechel B.EricksonDocument5 pagesStandard Specification For General Construction Proposed Two-Storey Residential House Mrs. Maria Rechel B.EricksonRocky SioresNo ratings yet

- Technical Specifications (Civil, Structural Works)Document26 pagesTechnical Specifications (Civil, Structural Works)Neil DinerosNo ratings yet

- Technical Specifications I. Demolition WorksDocument14 pagesTechnical Specifications I. Demolition WorksKiel CorpuzNo ratings yet

- Micropile SpecificationDocument9 pagesMicropile SpecificationchongptNo ratings yet

- Department of Public Works and HighwaysDocument10 pagesDepartment of Public Works and HighwaysAnthony TangNo ratings yet

- Technical Specifications:: Construction of Concrete Pavement For Parking AreaDocument2 pagesTechnical Specifications:: Construction of Concrete Pavement For Parking AreaAnton_Young_1962No ratings yet

- Spec Mechanical WorksDocument41 pagesSpec Mechanical Worksbhawani consultantNo ratings yet

- Construction of DecksDocument12 pagesConstruction of DecksAung Naing Latt AungNo ratings yet

- Reinforced Concrete Grade Beams, Piles & Caissons: A Practical Guide for Hillside ConstructionFrom EverandReinforced Concrete Grade Beams, Piles & Caissons: A Practical Guide for Hillside ConstructionNo ratings yet

- Cor A Vent Product GuideDocument103 pagesCor A Vent Product GuideB D PorterNo ratings yet

- Arslanhane MosqueDocument7 pagesArslanhane MosqueAysegul AkınNo ratings yet

- 2011 Trevi TowersDocument32 pages2011 Trevi TowersCMChuaNo ratings yet

- Fire Safety Checklist On Building Plans FinalDocument2 pagesFire Safety Checklist On Building Plans FinalFerdinand M. Turbanos100% (1)

- Kest 5th Septic Tank & Soak Away MT 1Document166 pagesKest 5th Septic Tank & Soak Away MT 1EphremHailuNo ratings yet

- Install Wooden Door JambDocument14 pagesInstall Wooden Door JambJeanelle SamsonNo ratings yet

- Catalogo Self Spanning EngDocument10 pagesCatalogo Self Spanning EngatiNo ratings yet

- Renaissance ArchitectureDocument26 pagesRenaissance ArchitectureMiroslav Šilić100% (1)

- Section Elevation: Shard PlaceDocument1 pageSection Elevation: Shard PlacefereetNo ratings yet

- Rate Analysis CalculationDocument6 pagesRate Analysis CalculationSanjay Babu RaghubanshiNo ratings yet

- Yung Ho Spring I&IIDocument21 pagesYung Ho Spring I&IIKelvin XuNo ratings yet

- NCSCM Building BOQ Structural Vol 4aDocument126 pagesNCSCM Building BOQ Structural Vol 4akkodgeNo ratings yet

- General Authority of Civil Aviation Building: Construction ConstructionDocument3 pagesGeneral Authority of Civil Aviation Building: Construction ConstructionAnonymous a3K3WgNo ratings yet

- Office Interiors Office Space: The Open Plan System FurnitureDocument19 pagesOffice Interiors Office Space: The Open Plan System Furniturekumara nathanNo ratings yet

- Technical Drafting 9 - Draft Roof PlansDocument16 pagesTechnical Drafting 9 - Draft Roof PlansMary-Angel AlastreNo ratings yet

- 67 - M. Dimovska-Colovic - The Clock Towers in MacedoniaDocument5 pages67 - M. Dimovska-Colovic - The Clock Towers in MacedoniaZoran PavlovNo ratings yet

- Floating Cottages Master Bedroom Guest Room Loft Living Area Total Bed CapacityDocument4 pagesFloating Cottages Master Bedroom Guest Room Loft Living Area Total Bed CapacityIvaan ValenzuelaNo ratings yet

- 17 PDFDocument1 page17 PDFMMNo ratings yet

- Nordlund HandoutDocument12 pagesNordlund HandoutmybestloveNo ratings yet

- RAB Retaining Wall - REVDocument167 pagesRAB Retaining Wall - REVOkti AfriadelaNo ratings yet

- Neo VernacularDocument2 pagesNeo VernacularBerliana Para'pakNo ratings yet

- Key Notes: Wall SystemDocument1 pageKey Notes: Wall SystemMyo Min ThuNo ratings yet

- Cost Effective Alternate SystemsDocument18 pagesCost Effective Alternate SystemshiteshiNo ratings yet

- Bill of QuantitiesDocument5 pagesBill of QuantitiesUlquiorra Garcia0% (1)

- Niagara Falls Construction Project ASLI-terkunciDocument12 pagesNiagara Falls Construction Project ASLI-terkunciTopan ArdiansyahNo ratings yet

- GBC Mod I-IIIDocument218 pagesGBC Mod I-IIIBrian KoechNo ratings yet

- Hoa Module 4 P1Document94 pagesHoa Module 4 P1cyril delfin100% (2)

- Cantilever Retaining Walls 2019Document8 pagesCantilever Retaining Walls 2019yassir dafallaNo ratings yet