Professional Documents

Culture Documents

The Benefits of Ultrasonic Testing in Determining Corrosion Rate and Service Life

The Benefits of Ultrasonic Testing in Determining Corrosion Rate and Service Life

Uploaded by

sooraj.cknambiar0 ratings0% found this document useful (0 votes)

4 views2 pagesUltrasonic testing (UT) can accurately measure pipe wall thickness and determine corrosion rates, pitting, and remaining service life. Compared to older methods like corrosion coupons, UT provides a more comprehensive assessment by accounting for factors like galvanic activity and under deposit corrosion. While low corrosion rates may seem minor, the buildup of iron oxide deposits over time can significantly reduce heat transfer and flow. UT is a cost-effective way to monitor aging piping systems and better inform long-term maintenance planning compared to unexpected failures.

Original Description:

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentUltrasonic testing (UT) can accurately measure pipe wall thickness and determine corrosion rates, pitting, and remaining service life. Compared to older methods like corrosion coupons, UT provides a more comprehensive assessment by accounting for factors like galvanic activity and under deposit corrosion. While low corrosion rates may seem minor, the buildup of iron oxide deposits over time can significantly reduce heat transfer and flow. UT is a cost-effective way to monitor aging piping systems and better inform long-term maintenance planning compared to unexpected failures.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

4 views2 pagesThe Benefits of Ultrasonic Testing in Determining Corrosion Rate and Service Life

The Benefits of Ultrasonic Testing in Determining Corrosion Rate and Service Life

Uploaded by

sooraj.cknambiarUltrasonic testing (UT) can accurately measure pipe wall thickness and determine corrosion rates, pitting, and remaining service life. Compared to older methods like corrosion coupons, UT provides a more comprehensive assessment by accounting for factors like galvanic activity and under deposit corrosion. While low corrosion rates may seem minor, the buildup of iron oxide deposits over time can significantly reduce heat transfer and flow. UT is a cost-effective way to monitor aging piping systems and better inform long-term maintenance planning compared to unexpected failures.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 2

The Benefits of Ultrasonic Testing in

Determining Pipe Corrosion Rate,

Pitting, and Remaining Service Life

Compared to steel pipe installed in the coupons can significantly under report

1950's, where a 1-2 mil per year (MPY) actual wall losses by a factor of 10 or greater

corrosion rate could be reliably assumed, - this often to the surprise of building owners

most open water cooling or process water and operators years later, and after

systems average 3-5 MPY or greater today. substantial piping damage has occurred.

Ultrasonic testing, or UT as it is Low pressure open water cooling tower While the threat of a piping leak is an

commonly called, is the procedure of systems, once exclusively constructed using obvious concern, a high corrosion condition

introducing a high frequency sound wave schedule 80 or extra strong pipe until the can produce even more serious secondary

into one exterior side of a material, and early 1970's, are now installed with schedule effects which can often exist for years

reflecting the sound wave from its interior 40 and even ultra thin schedule 10 as a without being detected.

surface to produce a precise measurement means to cut material and installation costs.

True Meaning Of MPY

of wall thickness. The round trip duration of Less Effective Controls

travel, divided by the known sound velocity A low to moderate corrosion rate of 3

Chemical treatment programs are far MPY at a 12 in. condenser water pipe for

through that particular material, provides a

less effective in all but the most strictly example, while seemingly minor, actually

wall thickness measurement equally

maintained and highly monitored piping translates to a physical loss of 39 lbs. of

accurate to a micrometer reading.

systems, yet still fail to equal the corrosion steel per every 100 linear feet. At 10 MPY,

Ultrasound is a well proven and control of decades ago. At the same time approximately 128 lbs. of metal is lost.

respected diagnostic tool routinely employed that micro biological agents are being

for weld and flaw detection in critical Multiplied by the number of years in

recognized as a significant factor in many

applications such as aviation, aerospace, service, and overall length, and the true

high corrosion rate scenarios, stricter

military, and nuclear power. Yet, while magnitude of system corrosion takes on

environmental regulations have not only cut

improvements in instrumentation have much greater significance than when

the effectiveness of many chemical biocides, reported as simply 1, 2, or 5 mils per year.

moved this technology into other areas such but have reduced their active half life as well.

as manufacturing and quality control, its Various weight losses for different pipe

Regular monitoring for corrosion and

benefits to plant engineers and property sizes and corrosion rates can be found at

remaining system life is often lacking for all

owners as a diagnostic and predictive tool the table below.

but the largest or most critical building or

are still widely unknown and underutilized.

Many Advantages

As a nondestructive method, UT offers

obvious advantages over cutting out pipe for

metallurgical inspection. It is non-intrusive,

accurate, reliable, safe to both building and

inspection personnel, provides immediate

results, requires no system shutdown, and is

extremely cost effective. Depending upon

the measurement technique, degree of

testing, and data analysis method used,

ultrasound can produce a general asses-

sment of building piping condition, provide

direction for capital projects, or focus in on a

specific area of concern.

Such advance information is becoming

more valuable to plant engineers as the

former "run to failure" mode of operation

moves toward one where all possible

vulnerabilities of an HVAC or process But while even a 5 MPY loss of metal

operation are known and monitored, and process operations. Even when employed,

most testing methods provide little can be tolerated by some piping systems for

where long term planning has replaced

information relative to the true corrosion an extended period of time before resulting

unexpected failures and emergency repairs. in a leak, it is the deposits created, and their

activity existing within the piping system.

Establishing the condition of an aged eventual deposition, that will inevitably

piping system becomes especially important Corrosion Coupon Limitations produce even more serious long term

due to its critical function in any HVAC Corrosion coupons, the most commonly secondary problems.

building environment, and due to the wide used and widely accepted method of Steel, when corroded back into iron

variety of problems which can potentially corrosion monitoring, exclude most of the oxide, produces a significantly greater

develop. environmental forces normally acting against volume of less dense material. This, in turn,

Greater Corrosion Problems any steel recirculating system. Typically ultimately creates a substantial loss of heat

housed in an isolated loop separate of the transfer efficiency, constricted flow, and

Though not often recognized by building

main piping system, corrosion coupons under deposit wall loss.

owners and operators, the corrosion threat

to most piping systems has increased never suffer the negative consequences of

galvanic activity, biofilm attachment, flow Internal Deposits Created

significantly over the past 20 years. This is Given a 5 MPY corrosion rate at 12 in.

rate, erosion, and most importantly - under

due to less effective chemical corrosion

deposit attack. pipe, approximately 2.6 cubic feet of iron

inhibitors, more corrosion susceptible steels,

Under Reporting Corrosion oxide deposits are created per every 100

less tolerant engineering practices - and yet, linear feet. Over a decade, and throughout

always greater operating demands. Although providing a relative indication a large building property, enormous

of chemical inhibitor effectiveness, corrosion

volumes of foreign debris will normally even at the top and bottom of the same corrosion rate estimates are generally

accumulate unless filtered out. section of pipe. accurate, and will fall within a certain range

An estimate of deposits created for Combined, such unknowns make it of values depending upon piping service.

different pipe sizes and corrosion rates can unlikely that a clear, thorough, and accurate A theoretical minimum acceptable wall

be found at the table below. understanding of current pipe condition thickness calculation, or estimate of the

exists. lowest point the pipe should be allowed to

safely operate, can also be made based

upon material strength, system pressure,

pipe diameter, thread loss, temperature, and

corrosion factor.

This allows a further prediction of the

remaining service life of the pipe according

to the time it will take to deteriorate from its

current wall thickness, at the current

corrosion rate, to its minimum acceptable

value. From this point, a retirement date or

remaining service estimate can be offered.

With sufficient pipe locations tested,

individual results can be grouped according

to various criteria, and graphed to show any

similarity or differences within the same

piping service.

Such advanced analysis helps to

identify possible data errors, but most

Open vs. Closed Systems importantly will highlight any corrosion

Whether a piping system is open or Very often, a determination of piping trends within the piping system. Data

closed becomes far more significant where integrity is made based upon assumption, analysis and trending may show, for

such internal deposits are concerned. visual observation, prior opinion, and example, a higher corrosion rate at the

Closed system deposits often remain hidden unreliable data - especially that suggested smaller, low flow areas, or greater losses at

for decades, whereas a condenser water or by corrosion coupon results and/or the water the return side piping.

process cooling problem will reveal itself treatment contractor.

Multiple Benefits

much sooner at the cooling tower pans, Hard Data Required

Overall, ultrasonic pipe testing offers

strainers, condenser tubes or heat In order to provide the greatest degree tremendous benefits. For many building

exchanger plates. of reliability, any evaluation method must operators, ultrasound will very often provide

An open cooling tower typically blows address the various sizes of pipe installed, the first suggestion of a corrosion problem or

down 10% or some percentage of its the furthermost areas of the system, top and concern, and provide the advance notice

recirculation rate in order to prevent tube bottom areas, horizontal and vertical runs, required to address it effectively. Many

scaling - thereby also providing the removal and both threaded and welded pipe. years of 1 MPY corrosion coupon results

of some particulates from the system. A reliable piping evaluation, therefore, may, in reality, prove to be substantially

Supplemental filtration may also be in use. must address sufficient sections of pipe at its higher.

Closed piping systems, by definition, most vulnerable areas, offer accuracy and Ultrasonic pipe testing can provide

contain and concentrate their foreign ease of use, cost effectiveness, as well as solid, irrefutable evidence of a suspected

deposits - with the heat exchanger coils, present a minimum of interference with corrosion problem, or document that a piping

horizontal lines, and lowest points of the system operations. Accommodating such system has fulfilled its useful service life and

system often providing ideal settlement needs and more, ultrasonic testing becomes is in need of replacement. At the high cost

areas. Except where a problem has already the overwhelmingly preferred choice. associated with any capitol piping replace-

been identified, filtration is rarely provided Taking multiple wall thickness readings ment, an ultrasound report will provide the

for closed systems. at any pipe section not only identifies its hard documentation necessary to move the

For most building operations, responsi- current status, but more importantly, project forward.

bility for the current piping condition may provides a virtual image and profile of its Similarly, ultrasound can save money

span across multiple property owners and interior wall surface. The more uniform the by confirming that suspected bad pipe is still

an even greater number of HVAC plant result, the more likely that a mild and general suitable for decades of additional use, or

operators. corrosion condition exists. limit repairs to specific areas.

Most likely, various water treatment A wildly varying thickness profile, in UT Provides The Answers

contractors, utilizing different programs, contrast, will indicate not only a pitting

Where no problems exist, ultrasound

have been employed with varying degrees of condition, but the high probability that even

will provide greater security, and most

success. Corrosion monitoring may be lower thickness values exist beyond those

importantly, establish a solid baseline from

inaccurate when employed, intermittent, or identified. Typically, a highest to lowest

which future and even more accurate and

much more likely - nonexistent. variation in wall thickness of 0.100 in. or

reliable estimates of corrosion rate and

Common Problem Areas more strongly suggests, by itself, a severe

remaining pipe life can be made.

corrosion and pitting condition. It also raises

Some areas of pipe such as dead ends,

greater concern for those most vulnerable

by-pass lines, basement areas, low flow

areas of the system.

sections, threaded joints, lead and lag

equipment, or those periodically drained, are Statistical Predictions

virtually guaranteed to exhibit significantly With the original pipe wall thickness and

higher and more damaging corrosion and time in service known, calculations can be

pitting activity. made regarding the approximate speed, as CorrView International, LLC

indicated in mils per year, that the pipe has P.O. Box 8513, Landing, NJ 07850

In addition, wide differences in corro-

reached its current thickness level. Tel: (973) 770-7764

sion rates are commonly found where Bill Duncan, CVI

dissimilar metals meet, at horizontal vs. Even though the pipe is not likely to www.CorrView.com

vertical pipe, at supply vs. return lines, and have corroded evenly over time, such Info@CorrView.com

You might also like

- Asset Preservation - Mothballing and Lay-Up PDFDocument7 pagesAsset Preservation - Mothballing and Lay-Up PDFJOÃO CARLOS SILVANo ratings yet

- A Strategy For Preventing Corrosion Under Insulation On Pipeline in The Petrochemical IndustryDocument6 pagesA Strategy For Preventing Corrosion Under Insulation On Pipeline in The Petrochemical Industry이영준No ratings yet

- Chapter 13 - Student Solutions Manual Applied Statistics and Probability ForDocument22 pagesChapter 13 - Student Solutions Manual Applied Statistics and Probability ForKingba Olayemi50% (2)

- CorrView Corrosion Technical Bulletin C-01Document5 pagesCorrView Corrosion Technical Bulletin C-01sooraj.cknambiarNo ratings yet

- Corrosion Can Casuse LivesDocument2 pagesCorrosion Can Casuse Livesvirous08No ratings yet

- Sensors 22 07562 v2Document29 pagesSensors 22 07562 v2sautoudosu001No ratings yet

- 01131129.pdf CorrosionDocument2 pages01131129.pdf Corrosionade2012No ratings yet

- Corrosion Control Linings and Coatings NWP BrochureDocument5 pagesCorrosion Control Linings and Coatings NWP BrochureAndrew ChenNo ratings yet

- Are Your Corrosion Control Practices Rusty?: Sponsored byDocument16 pagesAre Your Corrosion Control Practices Rusty?: Sponsored byJuan BustamanteNo ratings yet

- Corrosion CouponsDocument2 pagesCorrosion CouponsAsNo ratings yet

- WoodruffNov05 LinkedDocument6 pagesWoodruffNov05 LinkedMatteo CarusoNo ratings yet

- Eaton HVAC Application PDFDocument4 pagesEaton HVAC Application PDFsanjay ukalkarNo ratings yet

- Repair PipelineDocument10 pagesRepair Pipelinesolrac4371No ratings yet

- Pipeline Coating Specifiation and RehabilitationDocument78 pagesPipeline Coating Specifiation and RehabilitationArabian Industries India Pvt LtdNo ratings yet

- Lifetime Assessment of NH - Plants: Approach For Lifetime ExtensionDocument12 pagesLifetime Assessment of NH - Plants: Approach For Lifetime Extensionvaratharajan g rNo ratings yet

- Enhanced Steam Reformer Tube Inspection and Remaining Life Assessment ApproachDocument4 pagesEnhanced Steam Reformer Tube Inspection and Remaining Life Assessment ApproachRabah BrikaNo ratings yet

- Spe 128336 PDFDocument10 pagesSpe 128336 PDFDaniel DamboNo ratings yet

- Residual Lifetime Assessment of Pe Pipelines: White PaperDocument4 pagesResidual Lifetime Assessment of Pe Pipelines: White PaperNurhadi SiswantoroNo ratings yet

- Composite Clamp Design, TestingDocument15 pagesComposite Clamp Design, TestingDaniel Inemugha100% (1)

- Pipeline: Contamination ControlDocument8 pagesPipeline: Contamination ControlMarcelo García FacalNo ratings yet

- 1 PCRDocument78 pages1 PCRTressa SoNo ratings yet

- Silicone Housings For High Voltage ApplicationsDocument13 pagesSilicone Housings For High Voltage ApplicationsBardok MendozaNo ratings yet

- External Corrosion of Pipelines PDFDocument9 pagesExternal Corrosion of Pipelines PDFRangga AfyanNo ratings yet

- Spe 125060 MS P PDFDocument13 pagesSpe 125060 MS P PDFDamir986No ratings yet

- Spe 100476Document6 pagesSpe 100476HSEQ AZUL ENERGYNo ratings yet

- Selection and Deployment of Non-Destructive Testing For Through-Life Integrity Assurance of Composite-Repaired PipeDocument14 pagesSelection and Deployment of Non-Destructive Testing For Through-Life Integrity Assurance of Composite-Repaired PipeDavid RodriguesNo ratings yet

- Corrosion Protection Underground PipelinesDocument34 pagesCorrosion Protection Underground PipelinesLuis Bohr Ruda Valencia100% (2)

- Corrosion Monitoring Techniques (R-815)Document8 pagesCorrosion Monitoring Techniques (R-815)Ernesto LeonNo ratings yet

- Offshore Facilities: Technology FocusDocument8 pagesOffshore Facilities: Technology FocusAdhi Putra PamungkasNo ratings yet

- Corrosion Sensors For Structural Health MonitoringDocument32 pagesCorrosion Sensors For Structural Health MonitoringFelipe TobiasNo ratings yet

- Good Practice Guide No. 121: Corrosion Control For Buried PipelinesDocument22 pagesGood Practice Guide No. 121: Corrosion Control For Buried PipelinesMochamad Irvan MaulanaNo ratings yet

- 3ek7 e PDFDocument8 pages3ek7 e PDFHoracio BerniNo ratings yet

- Performance of Reinforced Thermosetting Resin Pipe Systems in Desalination Applications: A Long-Term Solution To Corrosion - The Arabian Gulf ExampleDocument6 pagesPerformance of Reinforced Thermosetting Resin Pipe Systems in Desalination Applications: A Long-Term Solution To Corrosion - The Arabian Gulf ExamplejatecconsultNo ratings yet

- What Is Corrosion Under InsulationDocument7 pagesWhat Is Corrosion Under Insulationanggara_nurrachman123No ratings yet

- Corrosion Protection: Arcelormittal Europe - Long Products Sections and Merchant BarsDocument48 pagesCorrosion Protection: Arcelormittal Europe - Long Products Sections and Merchant BarstecnidibujosNo ratings yet

- Corrosion Monitoring & Corrosion Coupons - Global Water TechnologyDocument7 pagesCorrosion Monitoring & Corrosion Coupons - Global Water TechnologyMohsin ModiNo ratings yet

- Pipelines Cathodic Protection Design Methodologies For Impressed Current and Sacrificial Anode SystemsDocument8 pagesPipelines Cathodic Protection Design Methodologies For Impressed Current and Sacrificial Anode SystemsGcNo ratings yet

- Il or in JournalDocument8 pagesIl or in JournalMasood KhanNo ratings yet

- Sinha 2006Document4 pagesSinha 2006Emharion DinNo ratings yet

- Emi TestDocument5 pagesEmi TestTL Corrosión Inspección e IntegridadNo ratings yet

- A Review of Field Corrosion Control and Monitoring Techniques of The Upstream Oil and Gas PipelinesDocument8 pagesA Review of Field Corrosion Control and Monitoring Techniques of The Upstream Oil and Gas PipelinesGaviotik JarochaNo ratings yet

- Protective EngDocument8 pagesProtective Engkarim hassanNo ratings yet

- Real 3 Corrision PipeDocument8 pagesReal 3 Corrision PipeNazriNo ratings yet

- Brochure LargeDiameterPipeDocument16 pagesBrochure LargeDiameterPipeeissa16No ratings yet

- Corrosion in Water Systems (AutoRecovered)Document9 pagesCorrosion in Water Systems (AutoRecovered)GILBERT AGBEVENo ratings yet

- Peng 2020Document15 pagesPeng 2020whilpontesNo ratings yet

- Galvanic Protection For Reinforced Concrete Structures: Case Studies and Performance AssessmentDocument10 pagesGalvanic Protection For Reinforced Concrete Structures: Case Studies and Performance AssessmentSteve LukatherNo ratings yet

- (2001) Impressed Current Retrofits On Offshore PlatformsDocument15 pages(2001) Impressed Current Retrofits On Offshore PlatformsGinka WidiantoNo ratings yet

- Application of Automated Corrosion Sensors For Monitoring The Rate of Corrosion During Accelerated Corrosion TestsDocument9 pagesApplication of Automated Corrosion Sensors For Monitoring The Rate of Corrosion During Accelerated Corrosion Testsmajor danielNo ratings yet

- 025 Ivk1 2017 SM MHM Emk CF MabDocument8 pages025 Ivk1 2017 SM MHM Emk CF MabOmar BouledrouaNo ratings yet

- 001CorrosionArticleAntiCorrosionTechWEIQ PDFDocument3 pages001CorrosionArticleAntiCorrosionTechWEIQ PDFJACK100% (1)

- Civil EngineeringDocument14 pagesCivil EngineeringCE18D003 MAYAKUNTLA PRASANNA KUMARNo ratings yet

- Services in Multi-Storey BuildingsDocument21 pagesServices in Multi-Storey BuildingsSodik KarimovNo ratings yet

- 100% Polyurethane - IndiaDocument9 pages100% Polyurethane - Indiaeric paglinawanNo ratings yet

- State of The Art Transformer Bushing MonitoringDocument9 pagesState of The Art Transformer Bushing MonitoringParveen KumarNo ratings yet

- PVC Hepworth Tech HandbookDocument43 pagesPVC Hepworth Tech HandbookskodgeNo ratings yet

- SoniTech Whitepaper - Fire Sprinkler Preventive MaintenanceDocument9 pagesSoniTech Whitepaper - Fire Sprinkler Preventive MaintenanceTim FrederickNo ratings yet

- 21 Types of Pipe Corrosion & Failure PDFDocument10 pages21 Types of Pipe Corrosion & Failure PDFianhar100% (1)

- Conference Corrosion Technical ProgramDocument11 pagesConference Corrosion Technical ProgrammariaNo ratings yet

- Case Study - Knockout DrumDocument2 pagesCase Study - Knockout DrumAshfaq AnwerNo ratings yet

- TAL040Document12 pagesTAL0403efooNo ratings yet

- 5 Pressure MeasurementDocument28 pages5 Pressure MeasurementMorshedul IslamNo ratings yet

- The Application of Quantum Mechanics: SpectrosDocument7 pagesThe Application of Quantum Mechanics: SpectrosRa saNo ratings yet

- Matrices and Determinant (Students Study Material & Assignment)Document31 pagesMatrices and Determinant (Students Study Material & Assignment)DAVID ABDULSHUAIB AYEDUNNo ratings yet

- To Study Nature and Size of ImageDocument11 pagesTo Study Nature and Size of ImageUnknown???No ratings yet

- Tabel Baja Profil WF PDFDocument15 pagesTabel Baja Profil WF PDFNielson SaefatuNo ratings yet

- Bentone 27 Rheological Additive: For Lubricating Grease ManufactureDocument2 pagesBentone 27 Rheological Additive: For Lubricating Grease ManufactureKrishna YeoleNo ratings yet

- 4.mechanical (Qa)Document22 pages4.mechanical (Qa)Osama AzaiemNo ratings yet

- Magnetic Particle Testing (Basics)Document23 pagesMagnetic Particle Testing (Basics)DILEEP KUMARNo ratings yet

- Terminologies of WeldsDocument19 pagesTerminologies of WeldsAli AsgharNo ratings yet

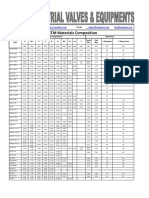

- ASTM Materials Composition: EmailDocument1 pageASTM Materials Composition: EmailLakshmi NarayananNo ratings yet

- Pipe SizingDocument29 pagesPipe SizingLexus Zander RambaudNo ratings yet

- MVN Student Entrance Test Syllabus Class Xi-2024 2025Document4 pagesMVN Student Entrance Test Syllabus Class Xi-2024 2025purple11102007No ratings yet

- English For SSC Exam: By-Aman TrivediDocument64 pagesEnglish For SSC Exam: By-Aman TrivediKundan kumarNo ratings yet

- Drill Monitoring For Rock Mass Grouting: Case Study at The Stockholm BypassDocument12 pagesDrill Monitoring For Rock Mass Grouting: Case Study at The Stockholm BypassPato IrfanNo ratings yet

- Applied Robotics 09Document22 pagesApplied Robotics 09noorulain66.csNo ratings yet

- Water Rocket PhysicsDocument8 pagesWater Rocket PhysicsFrancisco100% (1)

- CE 421 Open Channel Flow Part-1 (2322)Document37 pagesCE 421 Open Channel Flow Part-1 (2322)Afrahim Chowdhury Fashol 201-47-393No ratings yet

- Surveying NotesDocument7 pagesSurveying NotesTrina SambasNo ratings yet

- Soal B InggrisDocument6 pagesSoal B Inggrishari fajarNo ratings yet

- Dosimetric Evaluation of Newly Developed Well-Type Ionization Chamber For Use inDocument11 pagesDosimetric Evaluation of Newly Developed Well-Type Ionization Chamber For Use inman gobinda chowdhuryNo ratings yet

- Chapter 4: Integrals: by Assoc - Prof. Mai Duc ThanhDocument23 pagesChapter 4: Integrals: by Assoc - Prof. Mai Duc ThanhTriet TruongNo ratings yet

- Modelling of The Mechanical Interaction Between Anchored Wire Meshes and Granular SoilsDocument17 pagesModelling of The Mechanical Interaction Between Anchored Wire Meshes and Granular SoilsRodrigo MorgadoNo ratings yet

- Test - 01 - AIATS - JEE (M) - 2024 - FS - GR - 01 & 02 - (Code-A) - 18-09-2022 - Sol.Document13 pagesTest - 01 - AIATS - JEE (M) - 2024 - FS - GR - 01 & 02 - (Code-A) - 18-09-2022 - Sol.Akshay KumarNo ratings yet

- Shell Energy Balances and Temperature Distribution in Solids and Laminar FlowsDocument17 pagesShell Energy Balances and Temperature Distribution in Solids and Laminar FlowsImran UnarNo ratings yet

- Physics 2121 Lab Manual 11 0eDocument121 pagesPhysics 2121 Lab Manual 11 0e???????? ??????No ratings yet

- Effect of Pulse Change in Input Concentration To The Concentration of Solute in Continuous Stirred Tank ReactorDocument13 pagesEffect of Pulse Change in Input Concentration To The Concentration of Solute in Continuous Stirred Tank ReactorMegat DanishNo ratings yet

- FB HelixMark Katalog EN 3 DSDocument7 pagesFB HelixMark Katalog EN 3 DSPuteri StevaniNo ratings yet

- HVDC Transmission Line DesignDocument55 pagesHVDC Transmission Line DesignJamal khanNo ratings yet