Professional Documents

Culture Documents

Xt39 Spec Sheet

Xt39 Spec Sheet

Uploaded by

jdcomptonOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Xt39 Spec Sheet

Xt39 Spec Sheet

Uploaded by

jdcomptonCopyright:

Available Formats

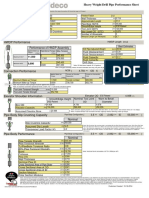

Drill Pipe Performance Characteristics Workstrings International 2011 Version 1.

Pipe Size and Weight: Pipe Grade: Range: Tool Joint:

4.000" 14.00ppf 0.330" wall IU S-135 2 4.875" X 2.688" XT39

Pipe Body

OD (in) Wall Thickness (in) Nominal ID (in) Calculated Plain End Weight (lbs/ft) 513,600 41,900 33,500 19,491 20,141 485,800 39,600 31,700 21,161 18,604 458,100 37,300 29,800 20,048 17,042 403,500 32,800 26,200 17,820 13,836

New (Nominal) 4.000 0.330 3.340 12.935 95% RBW 3.967 0.314 3.340 12.233 Cross Sectional Area of Pipe Body (in2) Cross Sectional Area of OD (in2) 2 Cross Sectional Area of ID (in ) Section Modulus (in3) 3 Polar Section Modulus (in ) 90% RBW 3.934 0.297 3.340 11.537 Premium 3.868 0.264 3.340 10.162

New (Nominal) 3.805 12.566 8.762 3.229 6.458

API Premium 2.989 11.751 8.762 2.523 5.046

Tensile Strength (lbs) Torsional Strength (ft-lbs) 80% Torsional Strength (ft-lbs) Burst Pressure (psi) Collapse Pressure (psi)

Notes: Pipe Properties are calculated based on uniform OD and wall thickness New = 100% RBW. Premium = 80% RBW Burst Pressure for New based on 87.5% RBW per API

Tool Joint 120,000 psi Material Yield Strength XT39 OD (in) ID (in) 4.875 2.688

Drill Pipe Assembly with Grant Prideco XT39 eXtreme Torque Connection New

(New guaranteed 95% RBW Pipe with IPC)

Pin Tong Length (in) Box Tong Length (in) Fluid Displacement (gal/ft) Fluid Capacity (gal/ft) Fluid Capacity (bls/ft) Drift Size (in) Max Upset OD (in)

12.0 15.0

Adjusted Weight (lbs/ft) Approximate Length (ft)

16.15 32.0

(without IPC)

Torsional Strength (ft-lbs) Max Recommended Make-up Torque (ft-lbs) Min Recommended Make-up Torque (ft-lbs) 35,300 21,200 17,700

0.25 0.43 0.010 2.563 4.188

Fluid Capacity (gal/ft) Fluid Capacity (bls/ft)

0.43 0.010

Tensile Strength at Max Recommended MUT (lbs) Tool Joint/Drill Pipe Torsional Ratio (New Pipe) Tool joint/Drill Pipe Torsional Ratio (Premium Pipe) Balance OD (in) Minimum OD for Premium (in) 553,300 0.84 1.08 4.926 4.652

Notes: The Drill Pipe Assembly adjusted weight, capacity and displacement calculations account for the adjusted ID in the manufacture of 95% RBW guaranteed pipe with 0.009" internal plastic coating. These values may vary with actual values due to pipe body mill tolerances, internal plastic coating tolerances, and other factors. New pipe guaranteed to 95% RBW will have a smaller ID (3.285'') than new pipe guaranteed to 87.5% RBW

Box OD (in) Elevator Capacity (lbs)

Smooth Edge Height 5.062 631,200

Nominal TJ OD 4.875 470,100

Worn to min TJ OD for API Premium 4.652 286,300

Assumed Elevator Bore (in)

4.281

Notes: Elevator capacity is weaker than pipe tensile Elevator capacity based on assumed Elevator Bore, no wear factor, and contact stress of 110,100 psi A raised elevator OD increases elevator capacity without affecting make-up torque

The technical information contained herein, including the product performance sheet and other attached documents, has been extracted from information available from the manufacturer and is for reference only and not a recommendation. The user is fully responsible for the accuracy and suitability of use of the technical information. Workstrings International cannot assume responsibility for the results obtained through the use of this material. No expressed or implied warranty is intended. Drill pipe assembly properties are calculated based on uniform OD and wall thickness. No safety factor is applied. The information provided for various inspection classes and for various wear conditions (remaining body wall) is for information only and does not represent or imply acceptable operation limits. It is the responsibility of the customer and the end user to determine the appropriate performance ratings, acceptable use of the product, maintain safe operational practices, and to apply a prudent safety factor suitable for the application. For API connections that have different pin and box IDs, tool joint ID refers to the pin ID. Per Chapter B, Section 4 VII of the IADC drilling manual, it is recommended that drilling torque should not exceed 80% of MUT. JCT 03-21-2011

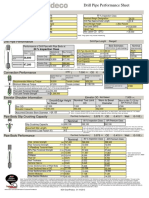

Torque Tension Graph

Connection: XT39 (4.875 (in) OD X 2.688 (in) ID) SMYS = 120,000 (psi) Pipe Body: 80% Inspection Class, 4.000 (in) OD, 0.330 (in) wall thickness, S 135 Pipe Grade (safety factor = 1.0)

Pipe Body in Combined Loading

Pipe Body Yield at 80% Inspection Class

700,000

600,000

Connection Performance (based on MUT)

Tool Joint Yield Tool Joint Shoulder Separation TJ Operational Limit (Rec MUT) TJ Operational Limit (Min MUT)

500,000

400,000

Tens sion (lbs)

300,000

200,000

100,000

Torque (ft lbs)

Connection Wear for XT39 (4.875 (in) OD X 2.688 (in) ID)

Material SMYS (specified minimum yield strength) = 120,000 (psi)

40,000

35,000

30,000

Connection

Torsional Strength Recommended MUT Minimum MUT

25,000

T Torque (ft lbs)

20,000

15,000

Pipe Body

80% of Premium Pipe Body Torsional Strength

Pipe Body: 4.000 (in) OD, 0.330 (in) wall thickness, S 135 Pipe Grade

10,000

5,000

Tool Joint OD (in)

You might also like

- Tubulares Hydril WThread (WT) PDFDocument28 pagesTubulares Hydril WThread (WT) PDFAnonymous VUH1VkS2j100% (2)

- Turbotorque™: Lightning Fast Torque On DemandDocument16 pagesTurbotorque™: Lightning Fast Torque On DemandDileep KumarNo ratings yet

- HWDPDocument15 pagesHWDPjinyuan74No ratings yet

- Anderson and Burge The Handbook of Optics FabricationDocument36 pagesAnderson and Burge The Handbook of Optics Fabricationkndprasad01No ratings yet

- Compatible Tubing Ts6Document28 pagesCompatible Tubing Ts6Defi Jodi Permana0% (1)

- Drill Pipe Float Valves CatalogueDocument14 pagesDrill Pipe Float Valves Cataloguecorsini999100% (1)

- ConnectionsDocument82 pagesConnectionsseabrake83% (12)

- Optimal Spacing For Casing Centralizer PDFDocument10 pagesOptimal Spacing For Casing Centralizer PDFimampranadipaNo ratings yet

- Quick Union Chart PDFDocument1 pageQuick Union Chart PDFMuhammad ShahrukhNo ratings yet

- Toro Tool Joint Identifier PDFDocument9 pagesToro Tool Joint Identifier PDFkrishnsgk100% (1)

- Vam Field Procedure - VFP Vam Eis v3.1Document28 pagesVam Field Procedure - VFP Vam Eis v3.1Bepdj67% (3)

- BOP 2006 E-CatalogDocument32 pagesBOP 2006 E-Catalogwoodiehed903950% (2)

- Manual Book XQ29-1.8B Sucker Rod Power Tong PDFDocument31 pagesManual Book XQ29-1.8B Sucker Rod Power Tong PDFadi Julianto100% (1)

- ASME B31.3: Code For Process PipingDocument53 pagesASME B31.3: Code For Process Pipingdipesh6030100% (2)

- EWAD-TZ D-EIMAC00904-14 IOM Installation Manuals EnglishDocument229 pagesEWAD-TZ D-EIMAC00904-14 IOM Installation Manuals EnglishAmir ShamshiriNo ratings yet

- Tablas Tuberia XTDocument35 pagesTablas Tuberia XTArcadio Bahena100% (1)

- DrillPipe, 80%, 5.875 OD, 0.500 Wall, IEU, S-135.. XT57 (7.000 X 4.250)Document3 pagesDrillPipe, 80%, 5.875 OD, 0.500 Wall, IEU, S-135.. XT57 (7.000 X 4.250)Garcia C L AlbertoNo ratings yet

- Drill Pipe Performance SheetDocument3 pagesDrill Pipe Performance Sheetjinyuan74No ratings yet

- Rotary and Handling Tools Catalog PDFDocument190 pagesRotary and Handling Tools Catalog PDFjinyuan74100% (3)

- Quick Union Identification ChartDocument1 pageQuick Union Identification ChartRefisal BonnetNo ratings yet

- Visual SL APEXDocument3 pagesVisual SL APEXOscar Gomez Gonzalez100% (1)

- Rotary Shouldered Connections BMCPDocument37 pagesRotary Shouldered Connections BMCPOGIS MKNo ratings yet

- GrantPrideco Drill Pipe Data TablesDocument25 pagesGrantPrideco Drill Pipe Data TableschoaybNo ratings yet

- XTM XTMF DPR Presentation.Document21 pagesXTM XTMF DPR Presentation.frmarzoNo ratings yet

- CG - Eng .223 Drill Pipe Care and HandlingDocument12 pagesCG - Eng .223 Drill Pipe Care and Handlingjinyuan74No ratings yet

- Drill Pipe Performance DataDocument35 pagesDrill Pipe Performance DatasnatajNo ratings yet

- Sara Sae - Manual TongDocument5 pagesSara Sae - Manual Tonganon_374733272No ratings yet

- Rotary SlipsDocument118 pagesRotary SlipsMEREUEULEU100% (6)

- Type SDS SDML SDXL Rotary Slip Cut SheetDocument2 pagesType SDS SDML SDXL Rotary Slip Cut SheetJose Barrero100% (1)

- Grant Prideco Rotary Shoulder HandbookDocument112 pagesGrant Prideco Rotary Shoulder Handbookrlk2806No ratings yet

- 16-25k Hydraulic Power Tong WatherfordDocument6 pages16-25k Hydraulic Power Tong WatherfordJose Mauricio SandovalNo ratings yet

- Hydril 533Document4 pagesHydril 533Fernando OlaveoNo ratings yet

- Woodco: Hub and Clamp Reference ChartDocument11 pagesWoodco: Hub and Clamp Reference Chartkrishnsgk100% (3)

- Drilling Assembly HandbookDocument99 pagesDrilling Assembly HandbookRodrigo Sena100% (7)

- Wellhead Equipment CatalogDocument29 pagesWellhead Equipment CatalogDewy PambayunNo ratings yet

- Drilling&Connection PDFDocument199 pagesDrilling&Connection PDFRazvan RaduNo ratings yet

- Hydril 563Document4 pagesHydril 563Cw LeeNo ratings yet

- 575 Venturi Jet Basket Mini Tech Brief Ver 3 PDFDocument8 pages575 Venturi Jet Basket Mini Tech Brief Ver 3 PDFJhonathan MirandaNo ratings yet

- MKT 001 Rev 02 Rotary Shoulder Handbook RS PDFDocument116 pagesMKT 001 Rev 02 Rotary Shoulder Handbook RS PDFKarla Hernandez0% (1)

- Drill Pipe ConnectionDocument20 pagesDrill Pipe ConnectionAlex Boz75% (4)

- Tool Joint Data Assembly Data: Drill Pipe Data TablesDocument5 pagesTool Joint Data Assembly Data: Drill Pipe Data TablesSefa AslanhanNo ratings yet

- Nov Mission Drilling SolutionsDocument24 pagesNov Mission Drilling SolutionsahnafNo ratings yet

- Fundamentals of Drilling Engineering: MCQs and Workout Examples for Beginners and EngineersFrom EverandFundamentals of Drilling Engineering: MCQs and Workout Examples for Beginners and EngineersNo ratings yet

- 4.000in 0.330wall IU CYX105-120 XT39 (4.875 X 2.688 TJ) 12P 15BDocument3 pages4.000in 0.330wall IU CYX105-120 XT39 (4.875 X 2.688 TJ) 12P 15BjohangomezruizNo ratings yet

- Trispiral XT39Document1 pageTrispiral XT39Cerón Niño SantiagoNo ratings yet

- LandingString, 80%, 5.875 OD, 0.750 Wall, IEU, S-135.. XT57 (7.250 X 3.500)Document3 pagesLandingString, 80%, 5.875 OD, 0.750 Wall, IEU, S-135.. XT57 (7.250 X 3.500)Garcia C L AlbertoNo ratings yet

- DrillPipe, 80%, 5.000 OD, 0.362 Wall, IEU, X-95.. XT50 (6.625 X 3.938)Document3 pagesDrillPipe, 80%, 5.000 OD, 0.362 Wall, IEU, X-95.. XT50 (6.625 X 3.938)Johann ZabaletaNo ratings yet

- Landing String 6.625 .938 v150 FH Slip Proof 95rbw PDFDocument4 pagesLanding String 6.625 .938 v150 FH Slip Proof 95rbw PDFMarcelo VeronezNo ratings yet

- DrillPipe, 80%, 5.875 OD, 0.750 Wall, IEU, G-105.. XT57 (7.250 X 3.500)Document3 pagesDrillPipe, 80%, 5.875 OD, 0.750 Wall, IEU, G-105.. XT57 (7.250 X 3.500)Garcia C L AlbertoNo ratings yet

- HeavyWeight 3.5 25.58lbs NC-38Document3 pagesHeavyWeight 3.5 25.58lbs NC-38Инженер Луис А. ГарсиаNo ratings yet

- Performance Sheet Drill Pipe: Pipe Body: Tubular AssemblyDocument2 pagesPerformance Sheet Drill Pipe: Pipe Body: Tubular AssemblyGarcia C L AlbertoNo ratings yet

- 2.500 X 1.375 DC With MW20 SlickDocument1 page2.500 X 1.375 DC With MW20 SlickHadi Bapir SlemanNo ratings yet

- Drill Pipe Performance Sheet 5.875 XT57 G105Document3 pagesDrill Pipe Performance Sheet 5.875 XT57 G105Garcia C L AlbertoNo ratings yet

- DrillPipe, 80%, 5.500 OD, 0.415 Wall, IEU, G-105.. XT57 (7.000 X 4.000)Document3 pagesDrillPipe, 80%, 5.500 OD, 0.415 Wall, IEU, G-105.. XT57 (7.000 X 4.000)Johann ZabaletaNo ratings yet

- DrillPipe, 80%, 5.000 OD, 0.500 Wall, IEU, S-135.. XT50 (6.625 X 3.750Document3 pagesDrillPipe, 80%, 5.000 OD, 0.500 Wall, IEU, S-135.. XT50 (6.625 X 3.750Инженер Луис А. ГарсиаNo ratings yet

- DrillPipe, 80%, 4.000 OD, 0.330 Wall, IU, G-105.. XT39 (4.875 X 2.563)Document3 pagesDrillPipe, 80%, 4.000 OD, 0.330 Wall, IU, G-105.. XT39 (4.875 X 2.563)Johann ZabaletaNo ratings yet

- DrillPipe, 80%, 3.500 OD, 0.449 Wall, EU, G-105.. XT39 (4.938 X 2.563) PDFDocument3 pagesDrillPipe, 80%, 3.500 OD, 0.449 Wall, EU, G-105.. XT39 (4.938 X 2.563) PDFGarcia C L Alberto100% (1)

- Performance Sheet Drill Pipe: Pipe Body: Tubular AssemblyDocument2 pagesPerformance Sheet Drill Pipe: Pipe Body: Tubular AssemblyGarcia C L AlbertoNo ratings yet

- 5 7/8" 23.4 PPF S135 Pipe SpecsDocument2 pages5 7/8" 23.4 PPF S135 Pipe SpecsTiffany DacinoNo ratings yet

- Drill Pipe Configuration: 95 % Inspection ClassDocument3 pagesDrill Pipe Configuration: 95 % Inspection ClassSaurav SenguptaNo ratings yet

- Drill Pipe Performance SheetDocument3 pagesDrill Pipe Performance SheetGarcia C L AlbertoNo ratings yet

- Performance Sheet Drill Pipe: Pipe Body: Tubular AssemblyDocument2 pagesPerformance Sheet Drill Pipe: Pipe Body: Tubular AssemblyGarcia C L AlbertoNo ratings yet

- 07 Piping BOQDocument54 pages07 Piping BOQHRK65No ratings yet

- Lead-Free Piezoelectrics Current Status and PerspeDocument22 pagesLead-Free Piezoelectrics Current Status and PerspeHamdi FakhFakhNo ratings yet

- AS LAB Man IDocument84 pagesAS LAB Man IVadivel AeroNo ratings yet

- Accepted Manuscript: Materials LettersDocument11 pagesAccepted Manuscript: Materials LettersKUMAR RAJASEKARNo ratings yet

- EhemDocument9 pagesEhemAaron RoyNo ratings yet

- Establishment of Deformation and Subsidence Monitoring Baseline in The Coastal Environment - A Case Study of University of LagosDocument15 pagesEstablishment of Deformation and Subsidence Monitoring Baseline in The Coastal Environment - A Case Study of University of LagosabdulNo ratings yet

- Piping S1Document44 pagesPiping S1Rajkumar ANo ratings yet

- Sintech Pumps For Sugar Processing PlantDocument18 pagesSintech Pumps For Sugar Processing Plantsahildhingra100% (3)

- Catalog OGV PrihodaDocument32 pagesCatalog OGV PrihodaQuốc Huy HoàngNo ratings yet

- Methods of Tube Expansion in Tube To TubDocument19 pagesMethods of Tube Expansion in Tube To Tubkurcek100% (1)

- Nptel: Forming - Web CourseDocument2 pagesNptel: Forming - Web CourseKasia MazurNo ratings yet

- Pipeline Specification and ConstructionDocument12 pagesPipeline Specification and ConstructionShanza AsifNo ratings yet

- 33mva TransformerDocument6 pages33mva TransformerJoule BarkNo ratings yet

- Torque Flow PumpsDocument2 pagesTorque Flow PumpssahildhingraNo ratings yet

- Rock & Fluid LabDocument22 pagesRock & Fluid LabsifatNo ratings yet

- Manuel Operation Dir DG Operation Manual 1409065937Document2 pagesManuel Operation Dir DG Operation Manual 1409065937Satima NezeNo ratings yet

- PMP GG OilDocument19 pagesPMP GG OilmasdikaNo ratings yet

- Chapter-5 Results and DiscussionDocument17 pagesChapter-5 Results and DiscussionSunil ChaudharyNo ratings yet

- 3 Secondary Recovery (1) .PPT Ok OkDocument36 pages3 Secondary Recovery (1) .PPT Ok OkEslam Atif AzkolNo ratings yet

- 10march - Grade 6 - Test PDFDocument27 pages10march - Grade 6 - Test PDFEron Roi Centina-gacutanNo ratings yet

- ENGMEC3 LQ1 ReviewerDocument21 pagesENGMEC3 LQ1 ReviewerMikko Arvin ChuaNo ratings yet

- Chemical Engineering Syllabus For GateDocument2 pagesChemical Engineering Syllabus For Gatechintz BhatNo ratings yet

- Development of High Torque Gear Using Powder MetallurgyDocument13 pagesDevelopment of High Torque Gear Using Powder MetallurgyArunKumarNo ratings yet

- Local Buckling Tests On Cold-Formed Steel Beams by Yu 2003Document11 pagesLocal Buckling Tests On Cold-Formed Steel Beams by Yu 2003fahmi aballiNo ratings yet

- Adama RainfallDocument5 pagesAdama RainfallkNo ratings yet

- Mig Manual RX 250 & RX 400Document18 pagesMig Manual RX 250 & RX 400Madhavesh KulkarniNo ratings yet

- Preliminary Pins HearDocument3 pagesPreliminary Pins HearBara NuansaNo ratings yet