Professional Documents

Culture Documents

MachineryFaultsDiagnosis Poster Redesign en

MachineryFaultsDiagnosis Poster Redesign en

Uploaded by

lucascpizzettiOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MachineryFaultsDiagnosis Poster Redesign en

MachineryFaultsDiagnosis Poster Redesign en

Uploaded by

lucascpizzettiCopyright:

Available Formats

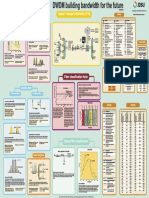

MACHINERY FAULT DIAGNOSIS

Unbalance Misalignment Structural Looseness Belt Drive Resonance Journal Bearings Electrical Motors

Unbalance is the condition when the geometric centerline of a rotation axis doesn’t coincide with the mass

centerline.

Misalignment is the condition when the geometric centerline of two coupled shafts are not co-linear along

the rotation axis of both shafts at operating condition. A 1X and 2X vibration signal predominant in the axial

Rotating looseness occur by an excessive clearance between rotor and bearing. PM PM

Belt transmission a common

Resonance is a condition caused when forcing frequency coincides with (or is close to) the natural frequency

of the machine’s structure. The result will be a high vibration.

Journal bearings provide a very low friction surface to support and guide a rotor through a cylinder that

surrounds the shaft and is filled with a lubricant preventing metal to metal contact. ELECTROMAGNETIC FORCES VIBRATIONS

direction is generally the indicator of a misalignment between two coupled shafts. drive system in industry

consisting of: Twice line frequency vibration: 2 · fL

MP • Driver Pulley 0,3-0,5X 1X Bar meshing frequency: fbar = fn · nbar

MP • Driven Pulley s [micron] Synchronous frequency: fsyn = 2 · fL / p

v [Inch/s] 1X PM PM

Funbalance = m d ω2

ANGULAR MISALIGNMENT • Poor mounting

• Poor base

• Belt 1st form of natural flexure 2nd form of natural flexure 3rd form of natural flexure Slip Frequency: fslip = fsyn – fn

Pole pass frequency: fp = p · fslip

The dynamic relationship is:

• Poor base support Ø1 ω1 = Ø2 ω2

• Warped base

MP MP Belt frequency: 3,1416 ω1 Ø1

l = belt length ƒB = fL: line frequency

I

nbar: number of rotor bars

p: number of poles

v [Inch/s] 1X 2X 3X Shaft 1st, 2nd and 3rd critical

speeds cause a resonance state • Stator eccentricity

Axial 1X when operation is near these no harmonic • Loose stator windings

f [cpm] v [Inch/s] critical speeds. relationship • Eccentric rotor

Structural looseness may produce a 1X signal

in the radial direction predominant in the Radial BELT DRIVE FAULTS 1st nat 2nd nat 3rd nat

flexure flexure flexure f [cpm]

• Rotor problems

• Loose connections

horizontal reading.

High vibration damping due to the oil film: Oil whirl: • Loose Rotor Bars

Measurements should be made on the bolts, Belt Worn Eccentric Pulleys

A pure unbalance will generate a signal at the rotation speed 1X vibration signal predominant at the radial • High frequencies signals may not be • Oil-film stability problems • Loose Rotor

feet and bases in order to see a change in the

direction. transmitted • May cause 0,3-0,5X component

amplitude and phase. A decrease in amplitude fN

a [g] Resonance Step-up • Displacement sensor and continuous in the spectrum

f [cpm] and 180° phase difference will confirm this • Resonance can be confused with other common

monitoring recommended

problem. problems in machinery.

Inch/s

1X, 2X, 3XfB • Resonance requires some additional tests to be

diagnosed. Clearance problems (rotating mechanical looseness)

STATOR ECCENTRICITY

STATIC UNBALANCE f [cpm]

f [cpm] • Loose iron

The geometric center doesn’t coincide with Phase jump at 180° • Shorted stator laminations

the rotating center of the pulley. • Soft foot

f [cpm]

Grad

The belt frequency fB and first two (or High 1X of the eccentric pulley visible in the spectrum,

Blades & Vanes even three) harmonics are visible in the

spectrum.

predominant in the radial direction.

Easy to confuse with unbalance, but: PM PM

Rolling Element Bearings PM PM

2 fB generally dominates the spectrum. • Measurement phase in vertical an horizontal directions f [cpm]

may be 0° or 180°. v [Inch/s] 1X v [Inch/s] 1X

• The vibration may be higher in the direction of the

belts. 1.O. v1 = 1.18 Inch/s WEAR

Pulley Misalignment ϕ1 = 60... 80° a [g] 1X 2X

The static unbalance is seen when the machine is not in a [g] fBPF Lifetime exceeded. Bearing overload Incorrect assembly. Manufacturing error Insufficient lubrication. • 1X and 2X signals

1X of driver or driven pulley visible and Belt Resonance

operation, the rotor will turn so the unbalance mass is at the • fL without sidebands

Radial predominant in the axial reading. If the belt natural frequency coincides with • Radial predominant

Static unbalance is caused by an unbalance lowest position. The static unbalance produces a vibration 2fL

Angular misalignment is seen when the shaft centerlines coincide at one point along the projected axis of PM either the driver or driven 1X, this frequency v1 = 118.1 Inch/s • High resolution should be used when analyzing two

mass out of the gravity centerline. signal at 1X, radial predominant and on phase signals in both a [g]

both shafts. The spectrum shows high axial vibration at 1X plus some 2X and 3X with 180° phase difference may be visible in the spectrum. ϕ1 = 240° poles machines

shaft extremes.

across the coupling in the axial direction. These signals may be also visible in the radial direction at a lower PM

amplitude and in phase.

f [cpm] f [cpm]

Amplitude at rotation frequency fn by residual Strong increase in amplitude of the rotation Wear

unbalance on rigid rotor. frequency fn at the point of resonance,

MOMENT UNBALANCE step-up dependent on the excitation f [cpm]

(unbalanced condition) and damping.

PARALLEL MISALIGNMENT f [cpm]

A blade or vane generate a signal frequency Example: Twisted Offset Angular

called blade pass frequency fBPF = s fn 3 struts in the intake; x = 3

9 blades; s = 9 RUN UP OR COAST DOWN TEST Износ

Identify and trend fBPF, an increase and harmonics x · fBPF = fn · s · x

Wear

ECCENTRIC ROTOR

may be a symptom of a problem like blade-diffuser

v [Inch/s] 1X 2X 3X Performed when the machine is turned on or

or volute air gap differences.

turned off.

Radial • Rotor offset

Series of spectra at different vibration signals • Misalignment

Rotating Looseness

The vibration spectrum has a higher ‘noise’ level and bearing characteristic frequencies can be

tracking may reveal a resonance. identified. Increased level of shock pulses. • Poor base

The use of tachometer is optional and the

data collector must support this kind of test.

Moment unbalance may be statically balanced. When rotating RACE DAMAGE PM PM

dynamic unbalance produces a vibration signal at 1X, radial Rotating looseness occur by an excessive clearance between rotor and bearing.

Moment unbalance is caused by two predominant and in opposite phase signals in both shaft f [cpm]

identical unbalance masses located at 180° extremes.

in the transverse area of the shaft.

Vibration Limits - ISO 10816-3

1 – Outer race damage

2 – Inner race damage

RESONANCE DIAGNOSING TESTS 3 – Rolling element damage

0-P [g]

Mechanical vibration – Evaluation of machine vibration by measurements on non-rotating parts. 4 – Cage damage

a [g] fp 1X 2X Tslippage

DYNAMIC UNBALANCE Rolling element bearing Journal bearing

Bump Test

aENV [g] Radial s [micron] Radial Radial

2fL

Outer race damage

Rotation Rotation 1BPFO 2 .. 3 .. 4BPFO

a [g]

frequency 1X frequency 1X

Excitation – force pulse Response – component vibration

and harmonics harmonics and

subharmonics v[Inch/s]

s[Inch] α angle of contact t [ms]

D pitch diameter f [cpm]

d rolling element diameter

Z number of rolling elements Outer race damage

Parallel misalignment is produced when the centerlines are parallel but offset. The spectrum shows high Decaying function frequency BPFO as well as • fp, 1X, 2X and 2fL signals • Modulation of the vibration time

n shaft RPM f [cpm] • 1X and 2fL with sidebands at fP signal with the slip frequency fslip

radial vibration at 2X and a lower 1X with 180° phase difference across the coupling in the radial direction. harmonics clearly visible

These signals may be also visible in the axial direction in a lower amplitude and 180° phase difference across f [cpm] f [cpm] • Radial predominant • Tslip ≈ 2–5 s

the coupling in the axial direction. Shock component, Frequency response, vertical Frequency response, Inner race damage • High resolution needed

In practice, dynamic unbalance is the most common form of natural vibration, vertical horizontal a [g]

Ball Pass Frequency, Outer Race fSidebands at intervals of 1X

unbalance found. When rotating the dynamic unbalance N

Dynamic unbalance is static and moment produces a vibration signal at 1X, radial predominant and the 2nd mod.

1st mod. n · Z (1 – d cos α)

unbalance at the same time. phase will depend on the mass distribution along the axis. ALIGNMENT TOLERANCE TABLE BPFO =

60 · 2 D

1BPFI 2 .. 3 .. 4BPFI

Permissable overall vibra�on values v in mm/s (RMS) - according to ISO 20816-8

Natural frequency, vertical Natural frequency, horizontal

Ball Pass Frequency, Inner Race Inner race damage frequency ROTOR PROBLEMS

* Small bore BPFI as well as numerous f [cpm]

Frame Cylinder (lateral) Cylinder (rod) n · Z (1 + d cos α)

Component Founda�on Design type Design type connec�ons; BPFI = sidebands at intervals of 1X.

(top) horiz. vert. horiz. vert. piping; dampers 60 · 2 D

40

DOCUMENTATION OF BALANCING

28.5

Vibra�on 30

19.5

24.0 24.0

19.5

Ball Spin Frequency Rolling element damage

velocity 20

12.0 16.0 16.0 19.0 Sidebands in 1. Rotor thermal bow

d

2 · BSF = n · D (1 – [ cos α]2) a [g]

13.0 13.0 12.7

10 10.7 10.7 intervals of FTF

8.0 8. 7 8.7 60 · d D 1X

v in mm/s 5 4.5

(RMS) 5.3 a [g]

3 Fundamental Train Frequency

3.0 Radial

Fluid

2

2.0 FTF = n (1 – d cos α) • Unbalanced rotor bar current

1

© Copyrigh t 2 018 PRÜFTECHNIK A G

60 · 2 D • Unbalance rotor conditions

Before

DIN ISO 13373-3:2015 Large Bearings Small bearings Rolling elements rollover

• Observable after some operation time

After frequency BSF with harmonics

as well as sidebands in intervals f [cpm]

of FTF.

a��[m/s2] Example of rollover frequencies

Valid for reciproca�ong compressors on rigid founda�ons in the speed range 120 - 1800 RPM. Ball bearing SKF 6211; n = 2998 RPM

There are two basic moving fluid problems PM PM Frequency range for movable omponents: 2 - 1000 Hzl for sta�onary components: 10 - 200 Hz. Cage damage

diagnosed with vibration analysis: a [g] FTF and 2nd, 3rd, 4th

* Note: Refer to the descrip�on of the DIN ISO 10816-8 before using the table.

• Turbulence harmonics

• Cavitation f [cpm]

Dimensions Rollover frequencies

D = 3.05 Inch BPFO = n / 60 · 4,0781 = 12240 cpm

d = 0.56 Inch BPFI = n / 60 · 5,922 = 17640 cpm 2. Broken or cracked rotor bars

Cage rotation frequency

Frequency spectra before/after balancing, and balancing diagram. Z = 10 2 BSF = n / 60 · 5,239 = 15840 cpm

α = 0° FTF = n / 60 · 0,4079 = 1200 cpm FTF and harmonics visible

f [cpm]

1X 2X 3X 4X

Assessment of vibra�ons in piping systems according a [g]

Frequency range for

WHERE IS TO BE MEASURED? a [g] 1X

Turbulence a [g]

1X fBPF Cavitation to VDI 3842 RMS and 0P acceleration

Radial • 1X and harmonics with sidebands at fP

• High resolution spectrum needed

200 measurements is LUBRICATION PROBLEMS • Possible beating signal

The measurement locations with the highest 1X vibration level are dependent on the rotor structure and the 10Hz - 10kHz

Random

location of the unbalance. 100

Major fluctuation in level of

The suggested alignment tolerances shown above are general values based upon experience and should not mm/s a���[m/s2] shock pulses and damage Subsequent small Large temperature

be exceeded. They are to be used only if existing in-house standards or the manufacturer of the machine or Random RMS temperature increase increase after lubrication

frequencies

coupling prescribe no other values. Bearing in good Bearing condition is to Bad bearing

condition be concidered condition

f [cpm]

10

Vibra�on velocity

f [cpm] f [cpm]

3. Loose rotor bar

1X 2X fbar 2fbar

Shaft Bending 1

1 10 Frequency

© Copyright 2 0 18 PRÜFTECHNI K A G

100 Hz 300 • Race damage • Insufficient lubricant • Maintenance error

a [g]

• Defective sealing • Underrating • Defective grease regulator • fbar and 2fbar with 2fL sidebands

Danger Correc�on Marginal Design

Fan Categories and Vibra�on Limits Pumps Pumps

• Contaminated lubricant used • Grease nipple blocked Radial • 2fbar can be higher

• 1X and 2X can appear

according to ISO 14694

A shaft bending is produced either by an axial asymmetry

of the shaft or by external forces on the shaft producing

BEARING RINGS DEFORMED

the deformation. 12,5 12,5 12,5 12,5

A bent shaft causes axial opposed forces on the bearings 11,8 11,8 11,8 11,8

11,2 11,2 11,2 • Incorrect installation Bearing forces on floating bearing

identified in the vibration spectrum as 1X in the axial

• Wrong bearing storage • Incorrect installation

vibration. 2X and radial readings can also be visible.

• Shaft manufacturing error • Wrong housing calculation f [cpm]

• Bearing housing overtorqued • Manufacturing error in bearing housing

9,0 9,0 9,0 9,0

Permissable evalua�on velocity in mm/s - according to VDI 3834

4. Loose connections

7,1 7,1 7,1 7,1 7,1 7,1 7,1 7,1 7,1 7,1 Frequency range 10 H z - 1000 Hz 10 Hz - 1000 Hz 10 H z - 1000 Hz ≤ 0.1 Hz - 1 0 H z

Severe

1X 2X 6,3 6,3 6,3 6,3 100 vibration

n

100

v [Inch/s] Bearing 1X 2X 2fL

50

60

a [g]

Axial temperature

30

20

4,5 4,5 4,5 4,5 4,5 4,5 4,5 4,5 4,5 4,5 V in mm/s 10.0

increases Radial • 2fL excessive signal with sidebands at 1/3 fL

10

n Fixed bearing

WO

5

5.6

6.0 • Electrical phase problem

RMS in mm/s 3.2

Shock

2,8 2,8 2,8

3

2

3.5

Air gap • Correction must be done immediately

2.0 pulse

©PRÜFTECHNIK AG 1

rigid flex. rigid flex. rigid flex. rigid flex. rigid flex. rigid flex. rigid flex. Damage Floating bearing

Main bearing Gearbox Generator Nacelle/Tower frequencies

P ≤ 300 kW P ≤ 15 kW P > 15 kW P ≤ 37 kW P > 37 kW P ≤ 75 kW P > 75 kW envelope Cocked bearing

Industrial, Component Incorrect installation

Power Generator Transportation, Marine Petrochemical Transit,Tunnel

Dirt Axial 1X, 2X & 3X

f [cpm] MBR GBX GEN NAT

Very good condi�on Good condi�on Limited condi�on/alarm Cri�cal condi�on/shutdown f [cpm]

Fluke Deutschland GmbH 85737 Ismaning, Germany See our worldwide contacts at: © Fluke Deutschland GmbH

LIT 01.601.en

Tel.: +49 89 99616-0 www.pruftechnik.com

You might also like

- DWDM PosterDocument1 pageDWDM Posterapi-3806249100% (1)

- Kasha Guitar PlanDocument1 pageKasha Guitar PlanAndrey BalalinNo ratings yet

- Indian Gear Standard Is.8830.2007Document65 pagesIndian Gear Standard Is.8830.2007Manoj Singh100% (2)

- p1 PDFDocument12 pagesp1 PDFDhirendra Kumar PandeyNo ratings yet

- CE 382 Reinforced Concrete Fundamentals: Beams Are Subjected To Flexure, Shear and Axial LoadDocument8 pagesCE 382 Reinforced Concrete Fundamentals: Beams Are Subjected To Flexure, Shear and Axial LoadElif UlusoyNo ratings yet

- 200-01 Basement Foundation ReinforcementDocument1 page200-01 Basement Foundation ReinforcementrendaninNo ratings yet

- Lecture 3: Approximate Analysis: ECE 5984: Power Distribution System AnalysisDocument17 pagesLecture 3: Approximate Analysis: ECE 5984: Power Distribution System Analysisante mitarNo ratings yet

- MagmediaDocument9 pagesMagmedia조성철No ratings yet

- Installation Instructions: FORM 1164BDocument2 pagesInstallation Instructions: FORM 1164BPoothares WongchindaNo ratings yet

- Bound State Paper ArXivDocument16 pagesBound State Paper ArXivmipiacemrgoldsteinNo ratings yet

- 4124 Ai Du 21710i002s01 Is01 - CheckprintDocument1 page4124 Ai Du 21710i002s01 Is01 - Checkprinttitir bagchiNo ratings yet

- Machinery Fault DiagnosisDocument1 pageMachinery Fault DiagnosisVLD DiagnosticsNo ratings yet

- MachineryFaultsDiagnosis PUTRANATADocument1 pageMachineryFaultsDiagnosis PUTRANATAdaniel_silabanNo ratings yet

- Seismic Inversion Mind MapDocument1 pageSeismic Inversion Mind MapAdel ShakerNo ratings yet

- DWDM Impairments Optical Transport Networks (OTN) : Linear EffectsDocument1 pageDWDM Impairments Optical Transport Networks (OTN) : Linear Effectskapil dev pandeyNo ratings yet

- Shimano Resetting Disc Brake PistonsDocument1 pageShimano Resetting Disc Brake PistonsJose Luis GutierrezNo ratings yet

- Strength of Adhesive Joints - Lectures 18+19Document11 pagesStrength of Adhesive Joints - Lectures 18+19Roger FeltmanNo ratings yet

- AGU 2002 PosterDocument1 pageAGU 2002 PosterBrian ShiroNo ratings yet

- Presentation 2Document30 pagesPresentation 2Muhammad Kashif SaeedNo ratings yet

- Cahir Issue A1 LDocument1 pageCahir Issue A1 LOluwaseyi JohnNo ratings yet

- Marine MOPO 2022 REV 0 - 1 MAY 2022Document2 pagesMarine MOPO 2022 REV 0 - 1 MAY 2022assidikkerjaNo ratings yet

- 4011-DRA-ABE-057-370-0011 - LTSA Warehouses GTG and Solar System - DRAFT FM200 PDFDocument2 pages4011-DRA-ABE-057-370-0011 - LTSA Warehouses GTG and Solar System - DRAFT FM200 PDFAnonymous J2B1utLYnNo ratings yet

- Alilean, Special & General Relativity: Física Del Cosmos: Lecture IDocument24 pagesAlilean, Special & General Relativity: Física Del Cosmos: Lecture IGuillermo Martínez RamónNo ratings yet

- Mc616ste 20Document2 pagesMc616ste 20ahmed ktebahNo ratings yet

- MagnetoDocument20 pagesMagneto조성철No ratings yet

- 00 Basement Foundation LayoutDocument1 page00 Basement Foundation LayoutrendaninNo ratings yet

- Reverse CurveDocument4 pagesReverse CurveVICTORIA OMEGA JARAMILLANo ratings yet

- Massve Fermion-Pk ApriDocument17 pagesMassve Fermion-Pk ApriKhanin LaylasNo ratings yet

- Electrical Specifications: Get AnDocument1 pageElectrical Specifications: Get Anflor johnNo ratings yet

- Section 8 Designing The Input Supply: Figure 8-1. Rectification SchemesDocument6 pagesSection 8 Designing The Input Supply: Figure 8-1. Rectification Schemescmvb123No ratings yet

- MOPO 2019 Updated Rev. 10 PDFDocument1 pageMOPO 2019 Updated Rev. 10 PDFdede SinbadNo ratings yet

- Senior Assisted Living Facility Base Line, Highland, Ca: Site PlanDocument5 pagesSenior Assisted Living Facility Base Line, Highland, Ca: Site PlanCarlo G VianaNo ratings yet

- 4 - RESC - Teo - 2122Document49 pages4 - RESC - Teo - 2122paulo.jcr.oliveiraNo ratings yet

- Transformer Testing Diagnostics ToolDocument1 pageTransformer Testing Diagnostics ToolOsi MalickNo ratings yet

- Attachment 1 (RFI 271 Rev 00)Document1 pageAttachment 1 (RFI 271 Rev 00)Ramume188No ratings yet

- Appendix 5 MOPO ToucanDocument2 pagesAppendix 5 MOPO ToucanOndo Akwe SergeNo ratings yet

- 1.3 Extragalactic EmpiricismDocument4 pages1.3 Extragalactic EmpiricismSHAM painNo ratings yet

- Slides 10Document33 pagesSlides 10aaroncete14No ratings yet

- EMINENCE Tone - GuideDocument1 pageEMINENCE Tone - Guideghjghjghj456No ratings yet

- VINUKONDA LC 263 Closure - V9 - APPROVE - P81 PDFDocument1 pageVINUKONDA LC 263 Closure - V9 - APPROVE - P81 PDFsadiqNo ratings yet

- Lecture 9Document5 pagesLecture 9SACHIN VISHWAKARMANo ratings yet

- Classic3plan PDFDocument1 pageClassic3plan PDFarantxa16No ratings yet

- Map Cycling VancouverDocument2 pagesMap Cycling VancouverdonnayNo ratings yet

- 3063 PDFDocument1 page3063 PDFAnonymous SPKUOsUbSNo ratings yet

- Industrisl Security Building Office Finishing ScheduleDocument1 pageIndustrisl Security Building Office Finishing ScheduleBrando BandidoNo ratings yet

- RF and EMC Formulas and Charts: Conversions for 50Ω Environment Antenna Equations www.arworld.usDocument1 pageRF and EMC Formulas and Charts: Conversions for 50Ω Environment Antenna Equations www.arworld.usamirNo ratings yet

- Applicable Overhead Sign Supports, Wind Velocity & Ice Zones ForDocument1 pageApplicable Overhead Sign Supports, Wind Velocity & Ice Zones ForAnonymous ZO1piE3VNo ratings yet

- TransmitDocument18 pagesTransmit조성철No ratings yet

- SCHP53RD01 PDFDocument1 pageSCHP53RD01 PDFsnamprogNo ratings yet

- Wlan Ez1100 DownloadDocument1 pageWlan Ez1100 Downloadc85320d9ddb90c13f4a215f1f0a87b531ab33310No ratings yet

- Cavity WallDocument1 pageCavity WallAkriti GhildiyalNo ratings yet

- ECU de 4 ConectoresDocument1 pageECU de 4 ConectoresHarold Rodriguez CastilloNo ratings yet

- Pin ConnectionDocument10 pagesPin ConnectionngocnnNo ratings yet

- Japan Metro Routemap - MajorrailsubDocument1 pageJapan Metro Routemap - MajorrailsubgandhiNo ratings yet

- Kop-Flex - KS (Membranas HP)Document3 pagesKop-Flex - KS (Membranas HP)marcelo castilloNo ratings yet

- Member Schedule Legend: Safe AustraliaDocument1 pageMember Schedule Legend: Safe Australiarao_vinay8296No ratings yet

- Aco Drain OverviewDocument2 pagesAco Drain Overviews11174444No ratings yet

- Solids & Semiconductors (Theory)Document25 pagesSolids & Semiconductors (Theory)Avi KedarrNo ratings yet

- Seepage Forces and Liquefaction of A Sandy Soil"Document4 pagesSeepage Forces and Liquefaction of A Sandy Soil"Harold MantillaNo ratings yet

- Adjustment Item ListDocument1 pageAdjustment Item ListMaigandi AdoNo ratings yet

- The Effect of Discontinuity Frequency On Ground Vibrations ProducedDocument9 pagesThe Effect of Discontinuity Frequency On Ground Vibrations ProducedF AguirreNo ratings yet

- A Robotic Cane For Balance Maintenance AssistanceDocument12 pagesA Robotic Cane For Balance Maintenance AssistancesouravNo ratings yet

- Csvtu 8th Sem Syllabus For Mechanical EngineeringDocument34 pagesCsvtu 8th Sem Syllabus For Mechanical Engineeringveer_s0% (1)

- ST-101 Data SheetDocument2 pagesST-101 Data Sheetlibrero2014salNo ratings yet

- Choir AcousticsDocument17 pagesChoir Acousticssuoiviet100% (1)

- Structural-Vibration Analysis Design and Troubleshooting PDFDocument2 pagesStructural-Vibration Analysis Design and Troubleshooting PDFDEVI S KURUPNo ratings yet

- Regulatory Guide 1.92 2012Document24 pagesRegulatory Guide 1.92 2012mateoNo ratings yet

- Pressure SensorsDocument20 pagesPressure Sensorshitesh bhoiNo ratings yet

- ENVR-S335 - U7 Basic Principles of Noise ConceptsDocument98 pagesENVR-S335 - U7 Basic Principles of Noise ConceptsPeter LeeNo ratings yet

- Data Processing For Data Acquisition Systems: Analysis of Vibrations in StructuresDocument3 pagesData Processing For Data Acquisition Systems: Analysis of Vibrations in StructuresmathsantosNo ratings yet

- 3-Single Degree Free VibrationDocument124 pages3-Single Degree Free VibrationsolomonrajarNo ratings yet

- Effect of Blast Vibration On Slope Stability: November 1999Document23 pagesEffect of Blast Vibration On Slope Stability: November 1999Lodro BamasugandiNo ratings yet

- Index/ Instructor's Evaluation of Experiment ReportsDocument22 pagesIndex/ Instructor's Evaluation of Experiment Reportssirajudeen INo ratings yet

- Genta 1988Document8 pagesGenta 1988Phuor TyNo ratings yet

- Reliability Improvement-Integrally Geared Air CompressorsDocument20 pagesReliability Improvement-Integrally Geared Air CompressorsAbdulrahman AlkhowaiterNo ratings yet

- Mayer-2016-Fatigue & Fracture of Engineering Materials & StructuresDocument27 pagesMayer-2016-Fatigue & Fracture of Engineering Materials & StructuresmohamadNo ratings yet

- Frequency Detection in Vortex Flowmeter For Low Reynolds Number Using Piezoelectric Sensor and Installation EffectsDocument9 pagesFrequency Detection in Vortex Flowmeter For Low Reynolds Number Using Piezoelectric Sensor and Installation EffectsBurak YalımNo ratings yet

- Backus - Vibrations of The Reed and The Air Column in The Clarinet - JASA1961Document5 pagesBackus - Vibrations of The Reed and The Air Column in The Clarinet - JASA1961colinot.tomNo ratings yet

- Tampoane Elastice PaulstraDocument150 pagesTampoane Elastice PaulstraStoianovici CristianNo ratings yet

- Chapter 18 - Vibration and Noise Analysis and AttenuationDocument9 pagesChapter 18 - Vibration and Noise Analysis and AttenuationŞükrü ÇarkçiNo ratings yet

- Logarithmic Decrement: Consider Eq.8A For Underdamped SystemDocument6 pagesLogarithmic Decrement: Consider Eq.8A For Underdamped SystemVjh GNo ratings yet

- Slug Flow Analysis Using Dynamic Spectrum Method in Caesar IIDocument7 pagesSlug Flow Analysis Using Dynamic Spectrum Method in Caesar IIJ A S JAS100% (1)

- Vibscanner ManualDocument76 pagesVibscanner Manualhzq1e100% (1)

- Generator Set RoomsDocument7 pagesGenerator Set RoomsAnonymous TvOpvXNo ratings yet

- ICAF2015 FatigueDamageSpectrum NCode-Plaskitt WebposterDocument1 pageICAF2015 FatigueDamageSpectrum NCode-Plaskitt WebpostercarlidrdNo ratings yet

- Cep VibrationDocument4 pagesCep VibrationMuhammad HaziqNo ratings yet

- Theoretical Modeling and Optimal Matching On The Damping (MAIN)Document25 pagesTheoretical Modeling and Optimal Matching On The Damping (MAIN)Rithin mathewNo ratings yet

- VIBRONET Signalmaster Standard - 1Document21 pagesVIBRONET Signalmaster Standard - 1DeepakNo ratings yet