Professional Documents

Culture Documents

EurlSrm Observation CS2 Hydrolysis Version3 240119

EurlSrm Observation CS2 Hydrolysis Version3 240119

Uploaded by

Andres RestrepoOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

EurlSrm Observation CS2 Hydrolysis Version3 240119

EurlSrm Observation CS2 Hydrolysis Version3 240119

Uploaded by

Andres RestrepoCopyright:

Available Formats

EURL-SRM - Analytical Observations Report

Concerning the following…

o Compound(s): Dithiocarbamates, such as maneb, mancozeb, metiram, propineb, thiram and ziram

o Commodities: Plant origin (except of high oil-content) and milk

o Extraction Method(s): Reductive cleavage with HCl/SnCl2 followed by partitioning of CS2 into isooctane

o Instrumental analysis: GC-MS/MS (or -ECD)

Analysis of residues of dithiocarbamate fungicides

in low-oil content food of plant origin

involving cleavage into carbon disulfide, partitioning into isooctane

and measurement by GC-MS/MS or GC-ECD

Version 3 (last update: December 2023)

1. Introduction and background information

This document describes an adjusted procedure for the analysis of dithiocarbamate residues in fruits, vegeta-

bles and cereals via the common moiety (carbon disulfide = CS2) approach1 involving cleavage with HCl/SnCl2,

partitioning of CS2 into isooctane, and measurement by GC-techniques.

The procedure described in the previous version (V2) had to be adjusted for several reasons including the

following:

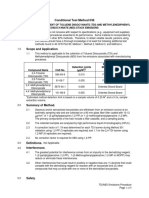

i) it provided satisfactory recovery rates for thiram, but rather insufficient recovery rates2 for certain

polymeric dithiocarbamates (such as metiram and propineb), see Figure 1;

ii) the consumption of chemicals was considered too high; and

iii) it didn’t include the use of GC-MS/MS for measurement.

1 Asrequired by Reg. (EC) No. 396/2005.

2 Outside of the 80-120% range required by the AQC-document for not requiring correction of results for bias (https://www.eurl-

pesticides.eu/userfiles/file/EurlALL/SANTE_11312_2021.pdf)

EU Reference Laboratory for Pesticides Requiring Single Residue Methods Page 1- 2 -

CVUA Stuttgart, Schaflandstr. 3/2, 70736 Fellbach, Germany

EURL@cvuas.bwl.de

The new procedure described below entails the following:

a) an extended hydrolysis time, from previously 2 h to 3 h;

b) a slightly higher reaction temperature, from previously 80 °C to 85 °C;

c) a reduced sample weight, from previously 25-50 g to 5-10 g (taking into account that subsampling

variability portion sizes in the range of 5 to 10 g still ensure satisfactory portion-to-portion variability

when homogenates are used);

d) an increased reagent-to-sample ratio, from previously 3:1 (150 mL HCl/SnCl2 reagent for 50 g sample)

to 7.5:1 (75 mL reagent for 10 g sample), but still a 2-fold reduction of reagent amount per sample;

e) the use of smaller reaction vessels (100 mL) compared to the previous 250 mL vessels (allowing faster

energy/temperature transfer to the reaction mixture within the bottles, thus allowing faster heating

and cooling, but also reducing the space required); and

f) The use of a GC-MS/MS instrument (with GC-ECD being maintained as an alternative)

Figure 1: Recovery of five dithiocarbamate fungicides spiked on comminuted tomato using the reductive cleavage condi-

tions of the previous version of the document (50 g sample weight, 150 hydrolytic agent of 0.1 M /SnCl2 in 4 M HCl, cleav-

age conducted at 80 °C for 2 h) (each n = 5).

EU Reference Laboratory for Pesticides Requiring Single Residue Methods Page 2

2. Analyte properties

Physicochemical properties and additional information on carbon disulfide are given in Table 1.

Table 1: Chemical Properties of carbon disulfide

Carbon disulfide (CAS: 75-15-0), Synonyms: Carbon disulphide, methanedithione

Parameter Value/Notes

Molecular Mass 76.13 g/mol

Formula CS2

Boiling point 42.2 °C (at 997-998 hPa)

pKa No ionizable atoms present

LogP Chemicalize.com (computed): 1.95

Water solubility Up to 2.9 g/L

Stability Chemically stable but take measures to minimize evaporation losses!

Residue definition 1) Carbon disulfite (refers to the use of CS2 as a fumigant)

(EU) 2) Dithiocarbamates (dithiocarbamates expressed as CS2, including maneb, mancozeb, metiram, propineb, thiram and ziram)

Approved in … The use of CS2 as such (as a fumigant) is currently not approved within the EU;

The following dithiocarbamate fungicides, having CS2 as common moiety, are approved within the EU:

Metiram: AT, BE, BG, CY, CZ, DE, EL, ES, FR, HR, HU, IT, LU, NL, PL, PT, RO, SI, SK (MS shall withdraw PPP authorizations contain-

ing metiram by 28 May 2024. Grace period shall expire by 28 Nov. 2024).

Ziram (AT, BE, CY, CZ, EL, FR, HR, HU, IT, MT, PL, PT, RO, SI, SK (expires 15 Mar. 2025)

Note that numerous dithiocarbamate fungicides (of all three types, i.e.: ethylene-bis, propylene-bis and dimethyl) are still ap-

proved in many third countries

Toxicity Flam Liq. 2; Acute Tox. 4; Skin Irrit. 2; Eye Irrit. 2; Repr. 2; STOT RE 1

Other sources Dithiocarbamates are also widely used in other areas, e.g. as vulcanisation accelators in the rubber industry. Therefore, con-

taminations with CS2-precursors in the lab, due to the use of rubber-containing vessels or contaminated solvents, may be pos-

sible.

Natural precursor compounds, contained in certain crop types (e.g. brassica and allium crops), are known to generate CS2 dur-

ing the stated cleavage. Natural CS2 formation has also been reported in shiitake mushrooms. The EURLs have prepared a col-

lection of data concerning the CS2 background levels in various crops3.

3. Chemicals and Consumables

Where water is indicated, de-ionized water is to be used.

3.1 Isooctane (e.g. Merck, EMSURE® ACS, Reag. Ph Eur, art. no.: 1.04727.2500)

3.2 Toluene (e.g. Merck, EMSURE® ACS, ISO, Reag. Ph Eur, art. no.: 1.08325.1000)

3.3 Hydrochloric acid, fuming (36.5% = 12 N) (e.g. by Thermo Scientific, art. no.: 33257)

3.4 Tin(II)-chloride (e.g. Merck, anhydrous for synthesis, art. no.: 8.18150.0100)

3.5 Carbon disulfide (CS2), density 1266 mg/mL at 25°C, (e.g. Merck, EMSURE® ACS,Reag. Ph Eur, art. no.:

1022141000)

3.6 Acetonitrile (e.g. Merck, suitable for HPLC, gradient grade, ≥99.9%; art.-No. 34851).

3 https://www.eurl-pesticides.eu/userfiles/file/EurlSRM/2022_Poster-EPRW_Carbon-disulphide_PM-06.pdf

EU Reference Laboratory for Pesticides Requiring Single Residue Methods Page 3

3.7 Thiram (e.g. Dr. Ehrenstorfer, art. no.: C17570000)

3.8 Chloroform, density: 1.49 g/cm³ at 25°C (e.g. Sigma Aldrich, art. no.: C2432);

3.9 Internal standard stock solution: e.g. 10.0 mg/mL in isooctane:

14.8 mL of isooctane (see 3.1) are filled into a 20 ml screw-cap glass tube and 100 µL (= 149 mg) of chloro-

form (see 3.7) is added. Close the vessel immediately and shake well. Keep the solution in a fridge or freezer

for long-term storage.

Note 1: If a 20 mL volumetric flask is used, add 134 µL of formic acid to 19 mL isooctane and fill up to

volume with isooctane. Shake well. Transfer the solution into a well sealable (e.g. screw cap) vessel for

long-term storage.

Note 2: Pneumatic pipettes may get contaminated with chloroform fumes and will need to be aerated

well before further pipetting to prevent cross-contamination. Air or nitrogen stream will accelerate aer-

ation. Check the behavior of your pipette to assess the contamination potential and adjust the aeration

procedure.

Note 3: Pipette contamination is avoided by weighing the chloroform. For a 10 mg/mL stock solution add

10 mL of isooctane into a screw cap bottle, close the bottle with the cap and tare the balance. Open the

vial, add 5 drops of chloroform using a Pasteur pipette, corresponding to roughly 80-100 µL (roughly 120-

150 mg), close the vial immediately and weigh again. Depending on the weight of chloroform added,

calculate the volume of the remaining isooctane that needs to be added as follows: remailing volume of

isooctane to be added [in mL] = 0.1*X -10 (where X = mg of chloroform weighed into the bottle)4.

3.10 Internal standard working solutions:

Internal standard working solution 1 (IS-WS1): 100 μg/mL in isooctane: Transfer 19.80 mL of isooctane

(see 3.1) is pipetted into a 20 ml screw-cap glass tube and 200 µL of internal standard stock solution (at

1 mg/mL, see 3.9) is added. Close immediately and shake well.

Internal standard working solution 2 (IS-WS2): 10 μg/mL in isooctane: Transfer 18.00 mL of isooctane

(see 3.1) is pipetted into a 20 ml screw-cap glass tube and 2.00 mL of internal standard working solution

1 (100 µg/mL) is added and shaken well.

3.11 CS2 stock solution at 10.0 mg/mL in isooctane:

12.55 mL of isooctane (see 3.1) is filled into a 20 ml screw-cap glass tube; and 100 µL (=126.5 mg5) of CS2

(see 3.5) is added. Close the vessel immediately and shake well.

4 This formula is simplified (volume and purity of chloroform disregarded) and as the absolute concentration of the IS is of secondary importance

5 Assuming 99,9% purity

EU Reference Laboratory for Pesticides Requiring Single Residue Methods Page 4

Note 1: Since CS2 is volatile, it has the potential of cross-contamination. When handling with pure CS2,

highly concentrated working standards and CS2–contaminated waste, make sure that low-concentrated

standards and sample extracts are not contaminated with CS2 fumes.

Note 2: Pneumatic pipettes may be used for preparing CS2 stock and working solutions, but the pipettes

used for pure CS2 or highly concentrated working standards should not be immediately reused for pipetting

low-concentrated calibration solutions, internal standard solutions or sample extracts, as there is a high

risk of cross contamination potentially leading to false positives and/or to artificially raised calibration

curves. Let contaminated pipettes to aerate well before reusing them. Flushing pipettes with a stream of

air will speed-up aeration. Conduct cross-contamination experiments to establish a suitable aeration pro-

tocol for your lab.

Note 3: Pipette contamination can be avoided by weighing the CS2. For a 10 mg/mL stock solution add

10 mL of isooctane into a screw cap bottle, close the bottle with the cap and tare the balance. Open the

vial, add 5-8 drops of CS2 using a Pasteur pipette, corresponding to roughly 100-150 µL (roughly 110-180

mg)6, close the vial immediately and weigh again. Depending on the weight of CS2 added, calculate the

volume of the remaining isooctane that needs to be added as follows: remailing volume of isooctane to

be added [in mL] = 0.1*X * CS2 purity ̶ (10+X/1266) (where X = mg of CS2 weighed into the bottle).

Note 4: For long-term storage of stock solutions, use well sealable screw cap containers7, making sure

that the headspace volume remains small8. To avoid tempering the stock solution to room temperature

for preparing further working solutions from it, see notes under 3.12.

3.12 CS2 working solutions

Working solution 1 (WS1) at 100 μg/mL in isooctane: Transfer 19.8 mL of isooctane (see 3.1) into a 20

ml screw-cap glass tube and add 200 µL of CS2 stock solution at 10 mg/mL (see 3.11). Close the bottle

and shake well.

Working solution 2 (WS2) at 10 µg/mL in isooctane: Transfer 18.0 mL of isooctane (see 3.1) into a 20 ml

screw-cap glass tube and add 2.0 mL of WS1 at 100 mg/mL (see 3.11). Close the bottle and shake well.

Working solution 3 (WS3) at 1 µg/mL in isooctane: Transfer 18.0 mL of isooctane (see 3.1) into a 20 mL

screw cap bottle, add 2.0 mL of WS2 solution at 10 µg/mL, close bottle and shake well.

Working solution 4 (WS4) at 0.1 μg/mL in isooctane: Transfer 18.0 mL of isooctane (see 3.1) into a 20 mL

screw cap bottle, add 2.0 mL of WS3 solution at 1 µg/mL, close bottle and shake well.

6 Check the approximate weight in a pre-experiment to make sure that the weight will range between 100 and 200 mg

7 Avoid using volumetric flasks, but rather vials with screw caps and good quality seal.

8 If parts of a stock solution or of a highly concentrated working solutions need to be discarded, take measures to minimize cross contamination of

sample, sample extracts and solvents.

EU Reference Laboratory for Pesticides Requiring Single Residue Methods Page 5

Note 1: You may proceed with the preparation of working standards either using the freshly prepared

stock solution or after cooling it down before use. Cooling the stock solution to refrigerator temperature

before use will reduce CS2 fumes. In this case, any dilutions for the preparation of working solutions will

need to be done with isooctane of the same temperature (i.e. refrigerator cold).

Note 2: For long-term storage of working solutions, store them into well sealable screw cap containers,

making sure that the headspace volume is small9. Store these solutions in a refrigerator or a freezer. If

stored in a freezer temperate to refrigerator temperature before reuse, again using isooctane of the

same temperature for any dilutions. This way you avoid the need to temperate the solution(s) to room

temperature, thus reducing evaporation and cross-contamination in the lab.

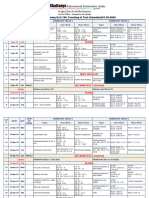

3.13 CS2 calibration standards:

Prepare calibration standards at e.g. 1.0; 0.5; 0.2; 0.05, 0.02, 0.01 μg/mL CS2 in isooctane following the

pipetting scheme in Table 2.

Table 2: Pipetting scheme for exemplary CS2 calibration solutions.

Calibration solution

1.0 µg/mL 0.5 µg/mL 0.2 µg/mL 0.05 µg/mL 0.02 µg/mL 0.01 µg/mL

CS2

Volume of internal stand-

ard working solution 100 µl 100 µl 100 µl 100 µl 100 µl 100 µl

10 µg/mL (see 0)

Volume of

800 µl 850 µl 700 µl 850 µl 700 µl 800 µl

isooctane (see 3.1)

Volume of CS2 working so- 100 µl of WS2 50 µl of WS2 200 µl of WS2 50 µl of WS3 200 µl of WS3 100 µl of WS4

lutions (see 3.12) 10 µg/mL sol. 10 µg/mL sol. 10 µg/mL sol. 1 µg/mL sol. 1 µg/mL sol. 0.1 µg/mL

Total volume 1000 µl 1000 µl 1000 µl 1000 µl 1000 µl 1000 µl

Note 3: It is recommended to prepare many series of calibration solutions in one go and to store them

in the freezer until use. Calibration solutions are prepared directly in well sealable GC-vials. If stored in

the freezer, calibration solutions filled into GC-vials, may be used for at least 3 months.

9If parts of a stock solution or of a highly concentrated working solutions need to be discarded, take measures to minimize cross contamination of

sample, sample extracts and solvents.

EU Reference Laboratory for Pesticides Requiring Single Residue Methods Page 6

3.14 Stock solution thiram: 1 mg/mL in toluene:

A stock solution of thiram in toluene (3.2) at a concentration of 1,00 mg/mL is prepared. Volume of solvent

(mL) = weight of thiram (mg) x purity. Note: 1,00 mg of thiram theoretically generates 0.6333 mg CS2

3.15 Working solution thiram: 0.100 mg/mL in isooctane:

In a 20 mL screw cap vessel, mix 1.00 mL of thiram stock solution (see 3.10) with 9.00 mL of isooctane

and shake well.

3.16 Hydrolysis reagent:

Weigh 75 g of tin(II) chloride into a 2 L volumetric flask add 666 mL HCl conc. (see 3.3) and fill up to

volume with with water. Shake well to dissolve the salt.

3.17 Xanthan gum (e.g. Sigma Aldrich, art.-No. G1253).

3.18 Water/acetonitrile (95/5, v/v) mixture:

Add 5 mL of acetonitrile (3.6) into a 100 mL glass volumetric flask and fill up to the mark with deionized

water.

3.19 Mixture of water/acetonitrile/xanthan gum (95/5/0.2 V/V/W)10:

Weigh a portion of 0.2 g of xanthan gum (3.17) into e.g. a 500 mL glass beaker and add 100 mL of the

water/acetonitrile (95/5, v/v) mixture (3.18). Mix well e.g. by using an immersion blender. Any formed

air bubbles may be removed by ultra-sonication. This solution can be stored for several weeks in a fridge

and pipetted by standard automatic pipettes (4.7).

3.20 Stock and working suspensions for other dithiocarbamate active substances

Stock suspensions for the dithiocarbamate active substances (other than thiram) are following the pro-

cedure presented by Zipper et al. 10. For this, a certain amount of the analytical standard is mixed with

an appropriate volume of the prepared water/acetonitrile/xanthan gum (95/5/0.2 V/V/W) mixture

(3.19) to achieve the desired concentration. The purity of the respective standard substance is taken

into account. Working suspensions are prepared by diluting stock suspensions using the same water/ac-

etonitrile/xanthan gum mixture (3.19). Stock and working suspensions are stable for only a short time

and should be preferably used within 60 min following preparation.

10 According to the procedure presented by Zipper et al. of the EURL-SRM: https://www.eurl-pesticides.eu/userfiles/file/EurlFV/Joint2021/Wachtler-Zipper.pdf

EU Reference Laboratory for Pesticides Requiring Single Residue Methods Page 7

4. Apparatus and Glassware

4.1 20 ml screw-cap glass tube (e.g. Klaus Ziemer GmbH, art.-No. 1.300160 and 2.301273)

4.2 Cleavage vessels: 100 mL Duran® glass bottles with a screw cap suitable for high-temperature applications

(glass fiber-containing PBT with PTFE-coated silicone septum), obtained from DWK Life Sciences (pur-

chased via Carl Roth GmbH + Co. KG, Product-No. KCN6.1).

4.3 High speed mill (e.g. Stephan UM 5 universal CUT or Thermomix TM5 or equivalent)

4.4 Shaking water bath with thermostat (e.g. GFL, type 1083)

4.5 Vials amenable to GC autosampler with plastic septum, free of CS2-emitting components

4.6 Solvent dispensers (10 - 50 mL)

4.7 Pipettes: Automatic pipettes (50 - 1000 μL and 5 -100 μL), pipette tips (100 μL and 1000 μL)

4.8 Ultra-sonicator

5. Sample Preparation

A homogenized sample portion of 10.0 g, or 2.0 g in case of dried herbs and spices, is weighed into a cleavage

vessel (see 4.2) and 10 mL of isooctane (see3.1) are added. Then, 75 mL of hydrolysis reagent (0.1 M tin (II)-

chloride in 4 M hydrochloric acid, see 3.15) and 100 µL of internal standard working solution 100 µg/mL (see

3.10) are added and the vessel is immediately closed with a screw-cap with septum. The vessels are put into a

shaking-water bath for 3 hours at 85°C. Within 2-5 minutes after placing the bottles into the water bath, tighten

the screw cap further. After 10-20 min shake the vials giving emphasis on samples that show signs of coagula-

tion. Thereafter shake the samples every approx. 60 min, making sure to wash down any sample parts that

could have possibly stuck to the cap. After the 3 hours have passed, cool down the bottles to preferably <10°C

(but at least to < 20°C), by placing them into a cooling water bath11. Once the cooling process after extraction

is completed, shake the container before opening and withdrawing the aliquot of isooctane. This is to ensure

that CS2 that may have enriched in the headspace is absorbed into the isooctane. The isooctane aliquots may

be transferred directly into GC-vials. Make sure that the aliquot occupies almost the entire volume of the stor-

age container to reduce the volume of the headspace. In the case of GC-vials, transfer e.g. 1.5 mL of the isooc-

tane-phase into a well sealable GC vial12. The isooctane extract is directly subjected to GC-MS/MS measure-

ment. If the vials are not measured within 1-2 days, store them in a freezer13.

11 The cool-down can be accelerated by adding ice cubes into the water bath. Placing the precooled bottles into a freezer for 15 min or a refrigerator

for 30 min will also accelerate the process.

12 Consider filling up one or more GC-vials with the same extract, as a backup, e.g. in case the CS level of the sample falls out of the calibration range

2

or in case problems in measurement come up, requiring re-injection.

13 The use of a coolable autosampler is preferred.

EU Reference Laboratory for Pesticides Requiring Single Residue Methods Page 8

6. Measurement

Exemplary GC-MS/MS and –ECD conditions are given in Table 3 and Table 4.

Table 3: Instrumentation and method details for GC-MS/MS analysis (Injector: Gerstel MPS, GC: Agilent 8890; MS/MS:

7010B GC/TQ)

Instrument parameters Conditions

Injection volume 1 µL

Injection temperature 200 °C (constant)

Split 1:10

Pre-column HP-VOC Agilent (approx.. 1 m, 0.20 mm ID, 1.12 µm film thickness)

Column HP-VOC Agilent (30 m, 0.20 mm ID, 1.12 µm film thickness)

Carrier gas and gas flow Helium, 1.0 mL/min (constant flow)

Rate (°C/min) Temperature (°C) Hold Time [min]

Oven temperature program - 35 2

50 150 0

120 260 10

Transfer Line temperature 250 °C

Ion Source Temperature 250 °C

Ion source mode and voltage EI positive, 70 eV

Mass transitions and their MS-parameters

Compound

Q 1 (m/z) Q 3 (m/z) Collision Energy (V)

76 44 40

76 76 5

Acquired mass transitions (m/z) Carbon disulfide (CS2)

78 46 40

78 78 5

85 49 40

Chloroform (Internal Standard)

85 47 40

Table 4: Instrumentation and method details for GC-ECD analysis (Injector: Gerstel MPS, GC-ECD: Thermo Scientific Trace

1310)

Instrument parameters Conditions

Injection volume 2 µL

Injection temperature 200 °C (constant)

Split 1:10

Pre-column HP-VOC Agilent (approx.. 1 m, 0.20 mm ID, 1.12 µm film thickness)

Column HP-VOC Agilent (30 m, 0.20 mm ID, 1.12 µm film thickness)

Carrier gas and gas flow Helium, 1.0 mL/min (constant flow)

Rate (°C/min) Temperature (°C) Hold Time [min]

Oven temperature program - 45 2

12 95 0

125 260 8

EU Reference Laboratory for Pesticides Requiring Single Residue Methods Page 9

7. Quality Control and Critical Steps:

It is advisable to run a recovery check with each series of samples. The respective dithiocarbamate working

solution (thiram) or working suspension (polymeric dithiocarbamates) should be spiked onto the, preferably

still frozen, analytical portion before the addition of isooctane and hydrolysis agent.

In principle, the initial temperature of the blank homogenate to be spiked as well as the waiting time between

spiking and the start of the reaction should reflect the routine procedure. But it is considered beneficial to

cryogenically mill fresh produce and to keep the homogenates frozen till the start of the above-described pro-

cedure. Extensive exposure of the dithiocarbamate compound with defrosted matrix may result in the for-

mation of degradation products that may not be transformable to CS2 during the procedure, and consequently

to reduced recovery rates.

Ideally, the average recovery rate following conversion to CS2 and partitioning of the later to isooctane should

be between 80 and 120 % with the RSD being ≤20% (see Document Nº SANTE/11312/2021).

Significantly overestimated mean recoveries may be an indication of a too low CS2 concentration in the cali-

bration standards (e.g. due to evaporation losses). Poor recovery rates may have various reasons, including

the following: low purity of the dithiocarbamate compound spiked, too large particle sizes of the dithiocarba-

mate compound spiked, evaporation losses of CS2 due to leaking reaction bottles or careless handling after the

reaction (normally the internal standard should partly correct such losses), too weak reaction conditions (tem-

perature, time, reagent), too complex matrix. A critical step in the procedure is the cooling down of the reac-

tion bottles prior to opening them. Adding the internal standard (chloroform) to the reaction bottle after the

addition isooctane is also essential, as it reduces evaporation losses.

Make sure that the rims of the cleavage vessels as well as the seals of the caps are intact. Leaks may lead to

evaporation losses during the reaction process.

Conversion factors for the calculation of spiked dithiocarbamate compounds to CS2—concentration are shown

in Table 5.

Table 5: Conversion factor for seven dithiocarbamate active substances for the calculation of the spiked concentration into

the corresponding CS2-concentration.

0.1 mg CS2/kg sample cor-

Molecular Molecular

No. of CS2-moieties Resulting con- responds to the following

DTC-Compound weight weight of CS2

per molecule14 version factor levels of DTC-compound

(g/mol) (g/mol)

in the sample

Thiram 240.44 2 0.633 0.158

Ziram 305.83 2 0.498 0.201

Metiram 1088.7 8 0.559 0.179

Maneb 265.31 2 76.139 0.574 0.174

Mancozeb 541.07 4 0.563 0.178

Propineb 289.79 2 0.525 0.190

Zineb 275.76 2 0.552 0.181

14 Di- or oligomers are used for the calculation. In the polymer the situation may be slightly different.

EU Reference Laboratory for Pesticides Requiring Single Residue Methods Page 10

8. Validation data:

Validation experiments for several dithiocarbamate active substances were conducted using matrices repre-

senting high water-content, high acid-content and dry plant commodities15 as well as milk. The analytes were

spiked in quintuplicate to the respective weighed portions of the sample homogenates with freshly prepared

working suspensions according the previously described in chapter 3.2010.

The conducted validations at 0.02 mg/kg CS2 were successful for at least three mass traces of all matrix-active

substance-combinations according the criteria stated in Document Nº SANTE/11312/2021 V2, see Table 6.

Table 6: Recoveries (Rec.), relative standard deviations (RSD) for the validation of several dithiocarbamate active sub-

stances in banana, wheat flour, milk, potato and tomato at 0.02 mg/kg CS2, each n = 5.

Banana Wheat Flour Milk Potato Tomato

Pesticide (10 g) (10 g) (10 g) (10 g) (10 g)

CS2 mass traces16

spiked Avg. Rec. RSD Avg. Rec. RSD Avg. Rec. Avg. Rec. RSD Avg. Rec. RSD

RSD (%)

(%) (%) (%) (%) (%) (%) (%) (%) (%)

MRM 1 (76/76) 85 3.4 88 3.2 100 2.8 80 2.8 90 3.0

MRM 2 (76/44) 79 4.9 86 3.2 98 1.2 76 4.5 90 1.5

Metiram

MRM 3 (78/78) 93 9.2 83 11.0 103 6.1 102 7.2 100 10.1

MRM 4 (78/46) 76 2.4 99 18.3 113 7.2 74 5.6 92 10.0

MRM 1 (76/76) 96 9.3 100 7.4 99 4.1

MRM 2 (76/44) 98 8.6 101 7.8 98 4.9

Propineb

MRM 3 (78/78) 93 8.2 102 6.7 111 7.3

MRM 4 (78/46) 102 15.0 104 10.3 92 8.7

MRM 1 (76/76) 108 3.7 103 4.1

MRM 2 (76/44) 111 3.6 101 4.3

Thiram

MRM 3 (78/78) 128 5.4 105 14.1

MRM 4 (78/46) 108 3.5 103 10.7

MRM 1 (76/76) 89 3.4 111 3.4 107 4.8

MRM 2 (76/44) 79 13.4 105 8.2 97 15.0

Zineb

MRM 3 (78/78) 90 21.3 120 14.2 119 5.0

MRM 4 (78/46) 88 4.1 109 4.1 107 5.8

MRM 1 (76/76) 94 8.6 97 14.0 104 6.8

MRM 2 (76/44) 95 11.0 129 41.6 107 10.7

Ziram

MRM 3 (78/78) 99 15.9 90 19.3 101 6.7

MRM 4 (78/46) 93 8.6 97 14.1 103 8.5

9. Miscelanneous hints

- When analyzing plant material with sulphur-containing components (e.g. brassica crops, allium crops, pa-

paya) high sample blank values have to be taken into account. Blank values are higher if homogenized

samples are left standing at room temperature. A Compilation of background levels can be found online

on the EURL-SRM website.3

- Vulcanized latex gloves can contain traces of carbon disulphide and, should therefore not be used.

15 According of the grouping of commodities in Document Nº SANTE/11312/2021 V2;

16 In the order of signal intensity

EU Reference Laboratory for Pesticides Requiring Single Residue Methods Page 11

10. Document History

Document

Action When Changes / Actions

Version

- Various changes regarding the cleavage conditions replacing

sections 5.2, 6.1.1 and 6.1.2 of V2;

- Implementation of GC-MS/MS conditions amending section

Publication of V3 Dec. 2023 6.5 of V2; V3

- Introducing validation data of several dithiocarbamate ac-

tive substances using the optimized cleavage conditions

- General updates throughout the document

In 2016 and in

Optimisation of method

2022-2023

- Addition of exemplary chromatograms

Publication of V2 Dec. 2009 - Improvement of sample preparation part V2

- removal of text errors

Publication of V1 March 2009 V1

Drafting the document 2008-2009 V1

Elaboration of method 2008

EU Reference Laboratory for Pesticides Requiring Single Residue Methods Page 12

You might also like

- Cod Procedure For HACH DR 2800Document8 pagesCod Procedure For HACH DR 2800Berliana Cahya NingtiasNo ratings yet

- Organotin CompoundDocument10 pagesOrganotin CompoundAtsar Leswara NinditaNo ratings yet

- Method - Total SiO2 ContentDocument5 pagesMethod - Total SiO2 ContentyaarangeNo ratings yet

- CTM 036 TDI EmisionesDocument8 pagesCTM 036 TDI EmisionesNicolas ZeballosNo ratings yet

- Dithiocarbamate-Group-GC MethodsDocument5 pagesDithiocarbamate-Group-GC MethodsAnonymous w7gZFE8No ratings yet

- AI63770 E1013S EnvironmentalAnalysisCompendium V3Document233 pagesAI63770 E1013S EnvironmentalAnalysisCompendium V3mikicacicaNo ratings yet

- The Hong Kong Polytechnic UniversityDocument18 pagesThe Hong Kong Polytechnic UniversityJasmine TsoNo ratings yet

- EPA Method 8015DDocument5 pagesEPA Method 8015DBrenda AcuñaNo ratings yet

- Formulas: Table 1 MW: Table 1 Cas: Table 1 Rtecs: Table 1: Ketones Ii 2553Document4 pagesFormulas: Table 1 MW: Table 1 Cas: Table 1 Rtecs: Table 1: Ketones Ii 2553Nicolas ZeballosNo ratings yet

- Exp 1 Chemical Oxygen DemandDocument4 pagesExp 1 Chemical Oxygen Demandkh!mNo ratings yet

- Supercritical Extraction and Separation of Antioxidants From Residues of The Wine IndustryDocument5 pagesSupercritical Extraction and Separation of Antioxidants From Residues of The Wine IndustryJeni NicolaeNo ratings yet

- ISO Common Name Chemical Name Empirical Formula RMM M.P. V.P. SolubilityDocument6 pagesISO Common Name Chemical Name Empirical Formula RMM M.P. V.P. Solubilityjessica montielNo ratings yet

- ETP UpgradationDocument7 pagesETP UpgradationYogesh DhekaleNo ratings yet

- Industrial Design of Multifunctional Supercritical Extraction Plant For Agro-Food Raw MaterialsDocument6 pagesIndustrial Design of Multifunctional Supercritical Extraction Plant For Agro-Food Raw MaterialsSiraj AL sharifNo ratings yet

- Analysis of Dithiocarbamate Pesticides by GC MsDocument5 pagesAnalysis of Dithiocarbamate Pesticides by GC MsGuy EntractNo ratings yet

- Methyl AcetateDocument3 pagesMethyl AcetatetranhungNo ratings yet

- Plastificanti Come DOPDocument5 pagesPlastificanti Come DOPMarco CorrengiaNo ratings yet

- Scaling-Up Effects On Supercritical CO Extraction Kinetics of Pelletized TomatoDocument6 pagesScaling-Up Effects On Supercritical CO Extraction Kinetics of Pelletized Tomatoanand singhNo ratings yet

- Analysis of Chromic Oxide v3Document4 pagesAnalysis of Chromic Oxide v3Diu NgoNo ratings yet

- Bio Protocol233Document6 pagesBio Protocol233yusufNo ratings yet

- CH CHO MW: 44.05 CAS: 75-07-0 RTECS: AB1925000: Acetaldehyde by GC 2538Document4 pagesCH CHO MW: 44.05 CAS: 75-07-0 RTECS: AB1925000: Acetaldehyde by GC 2538Haryo SaputroNo ratings yet

- Bromine Containing Fumigants Determined As Total Inorganic BromideDocument5 pagesBromine Containing Fumigants Determined As Total Inorganic BromidemcosicNo ratings yet

- Gravimetric Method For The Determination of Diclofenac in Pharmaceutical PreparationsDocument4 pagesGravimetric Method For The Determination of Diclofenac in Pharmaceutical PreparationsJuanNo ratings yet

- Journal of Environmental Chemical Engineering: Carla Albertina Demarchi, Mayara Campos, Clo Vis Antonio RodriguesDocument9 pagesJournal of Environmental Chemical Engineering: Carla Albertina Demarchi, Mayara Campos, Clo Vis Antonio RodriguesdiyanaNo ratings yet

- 9.2.27 AOAC Official Method 988.11 Mercury (Methyl) in Fish and ShellfishDocument2 pages9.2.27 AOAC Official Method 988.11 Mercury (Methyl) in Fish and ShellfishLêXuânThắngNo ratings yet

- 6009Document5 pages6009Oktasari Dyah AnggrainiNo ratings yet

- GBT 2912 - 2009 - Formaldehyde - Tessili1Document10 pagesGBT 2912 - 2009 - Formaldehyde - Tessili1kenses100% (1)

- ETP ReportDocument13 pagesETP ReportMUHAMMED SHAMEEMNo ratings yet

- Institute of Geophysics and Geology, Laboratory of Geochemistry "GEOLAB" Academiei Str. 3, Of. 133, Chisinau, MD2028, MoldovaDocument10 pagesInstitute of Geophysics and Geology, Laboratory of Geochemistry "GEOLAB" Academiei Str. 3, Of. 133, Chisinau, MD2028, MoldovaAditya Febrian MasriNo ratings yet

- 2008 Bioprocess Biosys Eng A. Mosquera 31-6-535-540Document6 pages2008 Bioprocess Biosys Eng A. Mosquera 31-6-535-540monica2061No ratings yet

- D 1166 - 84 R95 Rdexnjytodrsotvfmq - PDFDocument4 pagesD 1166 - 84 R95 Rdexnjytodrsotvfmq - PDFRufo CascoNo ratings yet

- Anaerobic Processes (Chapter 10) : AdvantagesDocument13 pagesAnaerobic Processes (Chapter 10) : AdvantagesΔημητρηςΣαρακυρουNo ratings yet

- Manual Experiment SMA TestDocument9 pagesManual Experiment SMA TestJair Ferreira JúniorNo ratings yet

- Niosh 1403Document5 pagesNiosh 1403MICROLABORATORIO S.A de C.VNo ratings yet

- Liquid Phase Glycerol Hydrogenolysis Using Commercial and Laboratory Prepared Cu-Cr CatalystDocument4 pagesLiquid Phase Glycerol Hydrogenolysis Using Commercial and Laboratory Prepared Cu-Cr CatalystEdidiong AsuquoNo ratings yet

- (+) - (7as) - 7a-METHYL-2,3,7,7a-TETRAHYDRO-1 H-INDENE-1,5 - (6H-DIONEDocument7 pages(+) - (7as) - 7a-METHYL-2,3,7,7a-TETRAHYDRO-1 H-INDENE-1,5 - (6H-DIONEAlex CumbaNo ratings yet

- Iso 11262 2011Document5 pagesIso 11262 2011CRISTINA TAMASNo ratings yet

- EPA Method TO 2Document32 pagesEPA Method TO 2Ebru Ersoz TenekeciNo ratings yet

- Manual Biodiesel MgoDocument6 pagesManual Biodiesel Mgoaurelio quispeNo ratings yet

- BioProtoc 8 10 2844Document8 pagesBioProtoc 8 10 2844Lucas WillianNo ratings yet

- Analysis of TalcDocument5 pagesAnalysis of Talcalexander_suarez_19No ratings yet

- Automated Determination of The Hydroxyl Number (HN) According To ASTM E 1899-08 and DIN 53240-2Document13 pagesAutomated Determination of The Hydroxyl Number (HN) According To ASTM E 1899-08 and DIN 53240-2DIENLUU150489100% (1)

- CMT 565 CodDocument11 pagesCMT 565 CodAiNo ratings yet

- ( ) - (1S, 4R) - Camphanoyl ChlorideDocument5 pages( ) - (1S, 4R) - Camphanoyl ChlorideAlex CumbaNo ratings yet

- 1,1,1,2-TETRACHLORO-2,2-DIFLUOROETHANE and 1016 (2) 1,1,2,2-TETRACHLORO-1,2-DIFLUOROETHANEDocument4 pages1,1,1,2-TETRACHLORO-2,2-DIFLUOROETHANE and 1016 (2) 1,1,2,2-TETRACHLORO-1,2-DIFLUOROETHANEPatricia RoaNo ratings yet

- En 15662Document12 pagesEn 15662Ina Bulat RotariNo ratings yet

- Niosh 2555Document5 pagesNiosh 2555KayceePortsNo ratings yet

- PDF 170897 93786Document9 pagesPDF 170897 93786ali abdulrahman al-ezziNo ratings yet

- Hidroxipropilmetil Celulosa SIN 464Document7 pagesHidroxipropilmetil Celulosa SIN 464Andrea Sanchez AbarcaNo ratings yet

- Addition of The Additive in The DefoamerDocument6 pagesAddition of The Additive in The DefoamerSilvio TakayamaNo ratings yet

- D3860 Determination of Adsorptive Capacity of Activated Carbon by Aqueous Phase Isotherm TechniqueDocument4 pagesD3860 Determination of Adsorptive Capacity of Activated Carbon by Aqueous Phase Isotherm TechniqueLaura Torres ArtunduagaNo ratings yet

- Appendix A To Part 136 Methods For Organic Chemical Analysis of Municipal and Industrial Wastewater Method 604-PhenolsDocument22 pagesAppendix A To Part 136 Methods For Organic Chemical Analysis of Municipal and Industrial Wastewater Method 604-PhenolsEliana MercedesNo ratings yet

- Mass Spectrometry for the Analysis of Pesticide Residues and their MetabolitesFrom EverandMass Spectrometry for the Analysis of Pesticide Residues and their MetabolitesNo ratings yet

- Bio-Based SolventsFrom EverandBio-Based SolventsFrançois JérômeNo ratings yet

- Sustainable synthesis of ciclopentene derivatives through multicomponent reactions in continuous flow regimeFrom EverandSustainable synthesis of ciclopentene derivatives through multicomponent reactions in continuous flow regimeNo ratings yet

- Clean Ironmaking and Steelmaking Processes: Efficient Technologies for Greenhouse Emissions AbatementFrom EverandClean Ironmaking and Steelmaking Processes: Efficient Technologies for Greenhouse Emissions AbatementNo ratings yet

- Environmental Scenario in Indian Mining Industry - an OverviewFrom EverandEnvironmental Scenario in Indian Mining Industry - an OverviewNo ratings yet

- HL PAPER 3 MockDocument37 pagesHL PAPER 3 MockIda Bagus Alit ManuabaNo ratings yet

- EXP CHEM F5 - ACT 1d - Displacement of HalogenDocument3 pagesEXP CHEM F5 - ACT 1d - Displacement of HalogenRoszamzuliani SharipuddinNo ratings yet

- Flowserve Pump Engineering ManualDocument85 pagesFlowserve Pump Engineering ManualCustodio SantosNo ratings yet

- 1st Year Chemistry Shortcuts For Nmdcat or Other Competitive TestDocument24 pages1st Year Chemistry Shortcuts For Nmdcat or Other Competitive Testralmalik210No ratings yet

- Class 12 Chemistry Chapter 1 Worksheet CbseDocument2 pagesClass 12 Chemistry Chapter 1 Worksheet Cbselakshsinghchauhan26No ratings yet

- Coshh, Risk Assessment and Chemical SafetyDocument8 pagesCoshh, Risk Assessment and Chemical SafetyMD AZHER ULLAH BAIGNo ratings yet

- Name and FormulaDocument3 pagesName and FormulaErina Rizki NugrahaniNo ratings yet

- Experiment 5Document12 pagesExperiment 5g googleNo ratings yet

- Che. 2024-25 - Incoming Sr.C-120 - Teaching & Test Schedule@01-03-2024Document7 pagesChe. 2024-25 - Incoming Sr.C-120 - Teaching & Test Schedule@01-03-2024bdsouza899No ratings yet

- Acid Base and Salt QuestionsDocument3 pagesAcid Base and Salt QuestionsBikash DasNo ratings yet

- CSEC Chemistry January 2017 P2Document17 pagesCSEC Chemistry January 2017 P2Michaela HarrilalNo ratings yet

- Full Download Book Advances in Synthesis Gas Methods Technologies and Applications Volume 4 Syngas Process Modelling and Apparatus Simulation PDFDocument41 pagesFull Download Book Advances in Synthesis Gas Methods Technologies and Applications Volume 4 Syngas Process Modelling and Apparatus Simulation PDFchristopher.vale567100% (29)

- 9845 Gelatine PowderDocument2 pages9845 Gelatine PowderAbdalkaher AhmedNo ratings yet

- 1 s2.0 S1749772817300854 MainDocument9 pages1 s2.0 S1749772817300854 Mainsally.marshNo ratings yet

- General Chemistry Module 1Document32 pagesGeneral Chemistry Module 1Christine Joy GalantoNo ratings yet

- Chemistry Structure and Properties 1St Edition Tro Test Bank Full Chapter PDFDocument23 pagesChemistry Structure and Properties 1St Edition Tro Test Bank Full Chapter PDFjulianna.washington847100% (18)

- Lower Secondary Science 7 End-Of-Year TestDocument9 pagesLower Secondary Science 7 End-Of-Year TestsamaarsalemNo ratings yet

- SD ArticleDocument44 pagesSD ArticleSimon ChovauNo ratings yet

- Chemistry Module Iii Inorganic Chemistry For Iit Jee Main and Advanced Vineet Agarwal Mcgraw Hill Education Vineet Agarwal Full Chapter PDF ScribdDocument68 pagesChemistry Module Iii Inorganic Chemistry For Iit Jee Main and Advanced Vineet Agarwal Mcgraw Hill Education Vineet Agarwal Full Chapter PDF Scribdeula.gibbs793100% (5)

- MSDS New BERKO GUARD 421Document5 pagesMSDS New BERKO GUARD 421haiderparrai00No ratings yet

- Teks Promosi Produk Dalam Bahasa InggrisDocument2 pagesTeks Promosi Produk Dalam Bahasa Inggrisdesikhairunnisa59No ratings yet

- Innes 1957Document2 pagesInnes 1957Magesh kumarNo ratings yet

- 10 HHW With Art - MergedDocument17 pages10 HHW With Art - Mergedyharshvardhan2570% (1)

- Clearix Rex Liq en (Flayer)Document4 pagesClearix Rex Liq en (Flayer)Tayfun AltınoğluNo ratings yet

- Coordination Chemistry Reviews: Christopher J. Kingsbury, Mathias O. SengeDocument23 pagesCoordination Chemistry Reviews: Christopher J. Kingsbury, Mathias O. Sengecmaery1102No ratings yet

- Textbook CRC Handbook of Chemistry and Physics 95Th Edition William M Haynes Ebook All Chapter PDFDocument53 pagesTextbook CRC Handbook of Chemistry and Physics 95Th Edition William M Haynes Ebook All Chapter PDFtodd.malone938100% (17)

- DPPH, TPC, TFC, If 8Document6 pagesDPPH, TPC, TFC, If 8Afaq AhmadNo ratings yet

- AOAC 999.07B AflatoxinDocument4 pagesAOAC 999.07B AflatoxinKATHERINE LISBETH BERNAL CANALESNo ratings yet

- AltraWash Blue SDSDocument5 pagesAltraWash Blue SDSkarirojas678No ratings yet

- Test Per Topic QP (Reaction Rates 2021) - 240505 - 112129Document8 pagesTest Per Topic QP (Reaction Rates 2021) - 240505 - 112129kesiyanemNo ratings yet