Professional Documents

Culture Documents

Method Statement For ELS

Method Statement For ELS

Uploaded by

ymkawai224Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Method Statement For ELS

Method Statement For ELS

Uploaded by

ymkawai224Copyright:

Available Formats

Method statement for RBL1220 CHK Project, ELS

EXCAVATION AND LATERAL SUPPORT WORKS FOR THE CABLE LANDING

STATION DEVELOPMENT AT RBL 1220, CHUNG HOM KOK, HONG KONG

Method Statement for Pipe Pile

CONTENTS

1. Introduction

2. Construction Works

2.1 Preparation Works

2.2 Working Procedures

2.2.1 Welling

2.3 Submission and Record

3. Plant & Materials

4. Health and Safety

3.1 Manpower

3.2 Equipment

3.3 Safe Lifting Procedure

5. Environment Protection

Appendices

Appendix A - ELS Layout Plan

Appendix B - Inspection and Testing Plan (ITP)

Appendix C - Template of Boring Record Form

Appendix D - Plant Catalogue

Method Statement for Pipe Pile

1 INTRODUCTION

This method statement describes the details and sequence for the ELS works.

2 CONSTRUCTION WORKS

2.1 Preparation Works

i) Before commencement of ELS works, monitoring check points shall be installed

around the site.

ii) Site Safety Induction should be carried out before commencement of work.

iii) Setting out of pipe pile locution shall be marked on site for inspection before

commencement.

2.2 Working Procedures

Welding

Step 1: Setting out for wailing level and strut locution shall refer to ELS layout plan

attached in Appendix A.

Step 2: Check that survey points have been installed and are regularly monitored and the

results kept on site. Check those positions of pipe pile, or other supports does not

conflict with services or adjoining foundations.

Step 3: Excavate to the first layer wailing (e.g. mPD 43.93). Excavate downwards by an

additional 300mm-500mm to provide enough working space for the welder.

Method Statement for Pipe Pile

Step 4: Prior welding operation, contractor shall ensure cleanness at welding joint. All

improper materials (e.g. slag, dirt, irregularities, oil etc.) shall be removed from

joints prior to welding.

Step 5: Weld the 203*203*86UC in the appropriate position to pipe pile. as a platform to

support the I-beam, then weld the I-beam to pipe pile wall. Once wailing is

completed. weld strut to kicker.

Step 6: Conduct welding inspection afterwards, and ensure sufficient support is achieved

upon receiving the report before proceeding to excavate to the second layer

wailing (e.g. mPD +41.93).

Step 7: Carry out excavation to the lines, level, dimensions and slope specified.

Step 8: When excavating, start digging until the first temporary wailing level is reached,

the welding process of that wailing should be completed first, and then inspected.

Only after completion can excavation proceed to the second wailing level to

ensure that the excavation process is carried out without affecting public facilities.

Step 10: Excavate in such a manner that suitable material is kept separate and store in

temporary spoil heaps, where required for use in the works without contamination

by unsuitable material or deterioration. Where in the opinion of the

AP/RSE/RGE, suitable material has become contaminated by unsuitable material

or allowed to deteriorate, this material shall be removed from site and replaced

with suitable imported material at the contractor’s expense.

2.3 Submission and Record

i) Inspection form should be submitted by Contractor before works commencement.

Method Statement for Pipe Pile

ii) Laboratory testing report.

Method Statement for Pipe Pile

3 PLANT & MATERIALS

Item Description Quantity

1 Crawler Crane 1 nos.

2 Excavator 3 nos.

3 Sedimentation Tank 1 no.

4 Wastewater Treatment Plant 1 nos.

5 Electric Generator 2 nos.

4 HEALTH AND SAFETY

4.1 Manpower

i) All Personnel will complete the Construction Industry Safety Training Certificate

(Green Card).

ii) All workers will undergo a safety induction course before the commencement of works

on site.

iii) Pre-work briefing will be provided before commencement of work.

iv) The appropriate PPE shall be worn.

v) All workers working at height are to be equipped with full-body type safety harness

with suitable lanyards and secure anchorage for the attachment of safety harnesses.

4.2 Equipment

i) The emergency contact list will be displayed near the gate.

ii) The protection barrier will be provided during the works.

iii) An effective ventilation system shall be provided to keep the air quality in the working

area at an acceptable level.

Method Statement for Pipe Pile

iv) All lifting gear including lifting clamp should be tested and thoroughly examinated by

RPE.

v) All machine, equipment and lifting gear shall be checked by site safety team.

vi) The design of lifting eye should be certified by Independent Checking Engineer.

vii) Spare lifting gears shall be provided to prevent inappropriate equipment were used.

4.3 Safe Lifting Procedures

i) Rigger or Signalman should be fenced off the lifting area and make sure no one stay

inside the lifting zone prior to lifting commence.

ii) The Plant operator should verify the instruction on lifting operation before taking

action.

iii) Lifting Clamp or Lifting Eye should be used to lifting circular hollow and steel

reinforcement.

iv) The Rigger or Signalman should keep well communication with the plant operator by

using walkie-talkie and signal.

v) During lifting, in order to prevent the swing of the object, a 3-4m long tagline shall be

attached to the lifting object and controlled by Rigger or Signalman.

vi) Prior to lifting operation, the balance conditions shall be checked at about 0.5m above

ground.

vii) Rigger or Signalman must stop the work if any abnormal operation is observed.

Material storage zone should be set up and fenced off. During lifting operation, only

Rigger or Signalman stays inside the storage zone to help processing lifting.

viii) A color coding system shall be adopted on all lifting gears such as wire ropes and

slings, etc. The color system is Blue (Jan – Mar), Yellow (Apr – Jun), Green (Jul –

Sep) and Orange (Oct – Dec).

Method Statement for Pipe Pile

5 ENVIRONMENTAL PROTECTION

i) Sump pit will be set up at suitable location to collect the fluid and pump to settlement

tanks prior to discharging to the drainage system during pile installation.

ii) All cement bags and grout bags will be placed in the disposal bin on site.

iii) Emission generated by mechanical plant shall be monitored and controlled.

Method Statement for Pipe Pile

Appendix A

Piling Layout Plan

Method Statement for Pipe Pile

Method Statement for Pipe Pile

Appendix B

Inspection and Testing Plan (ITP)

Method Statement for Pipe Pile

Project: EXCAVATION AND LATERAL SUPPORT WORKS FOR THE CABLE LANDING STATION

DEVELOPMENT AT RBL 1220, CHUNG HOM KOK, HONG KONG

Inspection and Test Plan for Pipe pile

Activit Activity Inspection Test Requirements Control Documents Inspection / Verifying

y No. Verification Documents /

Test or Frequency Code / Spec. / Acceptance Criteria Contractor Enginee Demonstrated

Inspection Drawings etc. r Evidence

Performed

Approval Refer to ELS layout

1 Welding Test Visual Randomly C H Inspection Form

Drawings plan

Survey Check Approval Refer to ELS layout

2 Final Excavation Level Randomly C H Inspection Form

& Visual Drawings plan

C - Control Point

W - Witness

H - Hold Point

Method Statement for Pipe Pile

Appendix G

Plant Catalogue

(As listed or equivalent)

Method Statement for Pipe Pile

You might also like

- Method Statement Excavation Works: Page 1 of 13Document13 pagesMethod Statement Excavation Works: Page 1 of 13J. Kumar Infraprojects Ltd67% (3)

- Method Statement Water Supply Line Tie in Point Re-RoutingDocument17 pagesMethod Statement Water Supply Line Tie in Point Re-RoutingShyju Melepurath83% (6)

- Method Statement DuctingDocument29 pagesMethod Statement DuctingAnish Kumar100% (8)

- Electrical Feeder Method StatementDocument3 pagesElectrical Feeder Method StatementAngelo Castro100% (1)

- Ledge Wall ConstructionDocument3 pagesLedge Wall ConstructionGabriel Gabe100% (1)

- Field Study 2 Learning Episode 7Document6 pagesField Study 2 Learning Episode 7Mc Dave Mendoza Mangurali II100% (6)

- Method Statement For Electrical Surface Conduit InstallationDocument14 pagesMethod Statement For Electrical Surface Conduit Installationshareyhou100% (1)

- Mechanical CompletionDocument5 pagesMechanical CompletionAshish100% (2)

- 16-UI MapsDocument76 pages16-UI MapsLakshmiNarayana PuttamchettyNo ratings yet

- Method Statement For ExcavationDocument13 pagesMethod Statement For Excavationymkawai224No ratings yet

- Excavation Earthwork and FillingDocument4 pagesExcavation Earthwork and FillingTAHER AMMARNo ratings yet

- Excavation, Earthwork and Filling Method StatementDocument4 pagesExcavation, Earthwork and Filling Method StatementSharafaz ShamsudeenNo ratings yet

- Methode of StatementDocument10 pagesMethode of StatementmaninderpreetNo ratings yet

- Pre-Commissioning Checklist For New Assets Water Sites: Page 1 of 5Document5 pagesPre-Commissioning Checklist For New Assets Water Sites: Page 1 of 5u nizami0% (1)

- Method Earth WorkDocument5 pagesMethod Earth Workibrahim hegazyNo ratings yet

- PierDocument15 pagesPierGANGARAJU N BNo ratings yet

- Procedure For Fabrication and Erection of HP Piping Extract From Tata Cons - LTDDocument12 pagesProcedure For Fabrication and Erection of HP Piping Extract From Tata Cons - LTDSushanta NaikNo ratings yet

- Method Statement - Water Reticulation WorkDocument7 pagesMethod Statement - Water Reticulation WorkRashidi RahmanNo ratings yet

- MS ExcavationDocument12 pagesMS ExcavationJaafar LagayanNo ratings yet

- Tank Method Statement - r0Document11 pagesTank Method Statement - r0AravindanNo ratings yet

- Method Statement For Chipping of False Floor OpeningDocument7 pagesMethod Statement For Chipping of False Floor Openingnsadnan0% (1)

- ExcavationDocument5 pagesExcavationHamza GoudjilNo ratings yet

- Method StatementDocument9 pagesMethod Statementtmopeli3130No ratings yet

- Boxt Field Quality PlanDocument86 pagesBoxt Field Quality PlanHariom GuptaNo ratings yet

- Slide Presentation of Cfa Installation (Benisede) Final 04-04-16-1Document33 pagesSlide Presentation of Cfa Installation (Benisede) Final 04-04-16-1oaklamNo ratings yet

- Guidelines For Fabrication of Steel Girder Procedure in WordDocument17 pagesGuidelines For Fabrication of Steel Girder Procedure in WordManas Rawat100% (1)

- Guidelines For Fabrication of Steel GirderDocument17 pagesGuidelines For Fabrication of Steel Girderradhakrishnang100% (3)

- Electrical Feeder System Method StatementDocument7 pagesElectrical Feeder System Method StatementAngelo Castro100% (1)

- Method Statement For Backfilling and Compaction ProcedureDocument22 pagesMethod Statement For Backfilling and Compaction ProcedureAlbertyNo ratings yet

- Method Statements of Road WorksDocument38 pagesMethod Statements of Road WorksivanlewizNo ratings yet

- 01 - Method Statement For Excavation Work222Document9 pages01 - Method Statement For Excavation Work222Ahmed Samir SalimNo ratings yet

- MS Earthing of Bonding Lighting ArrestorsDocument25 pagesMS Earthing of Bonding Lighting ArrestorsJaafar LagayanNo ratings yet

- Method of Statement For Installation of Fire Protection SystemsDocument6 pagesMethod of Statement For Installation of Fire Protection SystemsSuriya KumarNo ratings yet

- Method Statement For BACKFILLING WORKSDocument12 pagesMethod Statement For BACKFILLING WORKSYash Sharma50% (2)

- Guidelines For Fabrication of Steel Girders For Field EngineersDocument55 pagesGuidelines For Fabrication of Steel Girders For Field EngineersradhakrishnangNo ratings yet

- 2 - Underground Sewers and PipingDocument7 pages2 - Underground Sewers and PipingYusufNo ratings yet

- MS009 Water Treatment PlantDocument11 pagesMS009 Water Treatment PlantMhando Ignas100% (1)

- Section 555 Directional Bore 555-1 DescriptionDocument7 pagesSection 555 Directional Bore 555-1 Descriptiongplese0No ratings yet

- MOS For Geo Technical Investigation Report-Apr 15 2024Document21 pagesMOS For Geo Technical Investigation Report-Apr 15 2024Habib ur rahmanNo ratings yet

- Rev Description Prepared by Approved by Date Method Statement For Cold Water Services PJSBDocument5 pagesRev Description Prepared by Approved by Date Method Statement For Cold Water Services PJSBToyEn MEgatNo ratings yet

- Bs 110 (R) With A&c Guidelines For Fabrication of Steel Girder Procedure March 16Document57 pagesBs 110 (R) With A&c Guidelines For Fabrication of Steel Girder Procedure March 16Vvs RayuduNo ratings yet

- MS Boiler & CalorifierDocument14 pagesMS Boiler & CalorifierSanto ENo ratings yet

- WMS Excavation & BACKFILLINGDocument28 pagesWMS Excavation & BACKFILLINGRepl microsoft, PuneNo ratings yet

- Method StatementDocument4 pagesMethod StatementshyankaranNo ratings yet

- Section 02300 Earthworks R2Document21 pagesSection 02300 Earthworks R2MØhãmmed ØwięsNo ratings yet

- Method Statement - Drain PipingDocument17 pagesMethod Statement - Drain PipingAnish KumarNo ratings yet

- Excavation Earthwork and FillingDocument5 pagesExcavation Earthwork and FillingZaleha AzlanNo ratings yet

- Erection of Sag RodsDocument2 pagesErection of Sag RodsKaran PrabhakarNo ratings yet

- Pipeline Maintenance Section: IndexDocument55 pagesPipeline Maintenance Section: Indextenneti CHALAPATHY RAONo ratings yet

- 1.0 Method Statement Above Ground - Drainage SystemDocument19 pages1.0 Method Statement Above Ground - Drainage Systemمقاول تكييف كهرباء وصحيNo ratings yet

- SOP-0016 - Standard Operating (Work) Procedure - ToWER ERECTIONDocument24 pagesSOP-0016 - Standard Operating (Work) Procedure - ToWER ERECTIONAvidip DeyNo ratings yet

- Method Statement-Intake Leak TestDocument5 pagesMethod Statement-Intake Leak Testharun yucelNo ratings yet

- Method Statement For Room Control UnitDocument14 pagesMethod Statement For Room Control UnitshareyhouNo ratings yet

- Client: F C I PMC: Lotus Harvestec PVT LTD CONTRACTOR: KCC Infra PVT LTDDocument14 pagesClient: F C I PMC: Lotus Harvestec PVT LTD CONTRACTOR: KCC Infra PVT LTDNaiyer AzamNo ratings yet

- Lifting Plane Rein .CageDocument37 pagesLifting Plane Rein .Cagehossam saadNo ratings yet

- Method Statement For Installation of Electric PVC Conduits and AccessoriesDocument6 pagesMethod Statement For Installation of Electric PVC Conduits and AccessoriessamsungloverNo ratings yet

- Report of The Inspection Carried Out On Construction of byDocument4 pagesReport of The Inspection Carried Out On Construction of byaloysius akpanNo ratings yet

- Qcs 2010 Part 10 Pipeline Cleaning and Inspection SurveyDocument18 pagesQcs 2010 Part 10 Pipeline Cleaning and Inspection SurveyRotsapNayrbNo ratings yet

- Method Statement For Piping Fabrication & Erection Work Procedure - BlankDocument9 pagesMethod Statement For Piping Fabrication & Erection Work Procedure - BlankNaning Kusuma100% (1)

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)

- Soil Investigation and Foundation DesignFrom EverandSoil Investigation and Foundation DesignRating: 4.5 out of 5 stars4.5/5 (9)

- Milling Guide Mastercam x5Document151 pagesMilling Guide Mastercam x5ELECTROM08100% (1)

- The Hitchhiker's Guide To Operating SystemsDocument16 pagesThe Hitchhiker's Guide To Operating SystemsBùi Thị Như QuỳnhNo ratings yet

- SCADA Data Gateway Fact SheetDocument3 pagesSCADA Data Gateway Fact SheetFrank RudolphNo ratings yet

- Wildcatx MANUALDocument187 pagesWildcatx MANUALAlex CachuNo ratings yet

- Make To Order Strategy: Published by Team of SAP Consultants at SAPTOPJOBSDocument23 pagesMake To Order Strategy: Published by Team of SAP Consultants at SAPTOPJOBSrtmathew12100% (3)

- All GuestsDocument14 pagesAll Guestsbinksahu2No ratings yet

- Books For Aerospace EngineersDocument3 pagesBooks For Aerospace EngineerssivasaipranavjNo ratings yet

- DSC-W710 W730 Guide EN 2Document202 pagesDSC-W710 W730 Guide EN 2FahriHidayatNo ratings yet

- Browser Automation PDFDocument1 pageBrowser Automation PDFAries LhiNo ratings yet

- Smartrac - Iolineug - r5Document66 pagesSmartrac - Iolineug - r5Darwin Elvis Giron HurtadoNo ratings yet

- List of Instruments and Pressure GaugesDocument1 pageList of Instruments and Pressure Gaugesram dhukeNo ratings yet

- Learn Java - Inheritance and Polymorphism Cheatsheet - CodecademyDocument4 pagesLearn Java - Inheritance and Polymorphism Cheatsheet - CodecademyIliasAhmed0% (1)

- 4610 Suremark Printer: User'S GuideDocument51 pages4610 Suremark Printer: User'S GuideRONEY NOGUEIRANo ratings yet

- I CubeDocument27 pagesI CubeapkinehaNo ratings yet

- SG 246351Document390 pagesSG 246351siva_krishna_42No ratings yet

- Driver Assistance DeviceDocument17 pagesDriver Assistance DeviceGaurav SinghNo ratings yet

- RAP Protocol Route Access ProtocolDocument1 pageRAP Protocol Route Access ProtocolRough MetalNo ratings yet

- M12-2 Installation GuideDocument146 pagesM12-2 Installation GuideAdrian Gabriel GhiţăNo ratings yet

- Acknowledgment: UNIVERSITY For Providing Us A Chance To Complete This ProjectDocument26 pagesAcknowledgment: UNIVERSITY For Providing Us A Chance To Complete This Projectpattanaik ashutoshNo ratings yet

- SystemC and Codesign Additional LecturesDocument58 pagesSystemC and Codesign Additional Lectureskarim94No ratings yet

- ProfimDocument5 pagesProfimFernando ValenciaNo ratings yet

- LAB AssignmentDocument4 pagesLAB AssignmentAlwani IzzatiNo ratings yet

- SL Nx-OsDocument676 pagesSL Nx-Osa_salesmanNo ratings yet

- NEX US: Jobo, John Matthew B. Gestsoc - Y16Document4 pagesNEX US: Jobo, John Matthew B. Gestsoc - Y16John Matthew JoboNo ratings yet

- Eurotech Mh190e35p Technical DescriptionsDocument29 pagesEurotech Mh190e35p Technical Descriptionsjadan tupuaNo ratings yet

- LH T7652SBDocument67 pagesLH T7652SBSerp1972No ratings yet

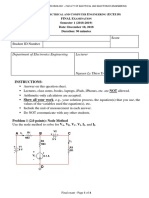

- 181 ECE110 Final ExamDocument4 pages181 ECE110 Final ExamPham Lê HuyNo ratings yet

- Ac/Dc Distribution Panel: Detail A Detail B Detail CDocument4 pagesAc/Dc Distribution Panel: Detail A Detail B Detail CEdwin PinzonNo ratings yet