Professional Documents

Culture Documents

FT.74700.1 en

FT.74700.1 en

Uploaded by

Marcelo PerettiOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

FT.74700.1 en

FT.74700.1 en

Uploaded by

Marcelo PerettiCopyright:

Available Formats

Overflow Valve 74700

MS

I Application

The overflow valve is a valve used to perform pressure bypasses for safety purposes in order

to protect lines, pumps, accessories, pools, etc.

With a sanitary design and fully manufactured in stainless steel, the 74700 valve is the most

suitable option for protection of facilities in the dairies, food, beverages, pharmaceutical and

fine chemicals industries.

I Operating principle

Under normal operating conditions, the valve remains closed.

The valve is calibrated to a specific pressure by regulating the spring with the pressure

nut.The calibrated pressure is a maximum safety pressure defined to avoid damage of the

plant.

When the pressure in the circuit exceeds the calibrated pressure, the valve opens letting the

flow pass and reducing the pressure of the pipe system.

The valve can incorporate a handle designed to partially open the valve. When the handleis

kept in the open position during the CIP process, the cleaning products can pass through the

valve.

I Design and features

The valve is normally closed.

Easy manual adjustment.

Gaskets according to FDA.177.2600

Standard connections: DIN 11851

Available in diameters: DN25 to DN80

I Materials

Parts in contact with media AISI 316L

Other parts in stainless steel AISI 304L

Gaskets EPDM accrding to FDA FDA.177.2600)

Internal surface finish Ra< 0.8 μm

External surface finish bright polish

Overflow Valve 74700

I Options

Connections: FIL-IDF, BS-RJT, SMS, Clamp, flanges, Macon.

Gaskets available in NBR and FPM.

Several operating ranges (changing the spring).

The assembly of the handle allows to partially open the valve in order to allow the

passage of fluid for CIP cleaning (for use with positive displacement pump bypass).

Safety seal to identify the factory calibration.

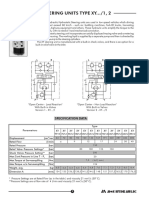

I Technical specifications

Max. temperature 121ºC (EPDM) 250ºF

Max. operating pressure

adjustable spring 0-3bar/0-6bar/0-10bar 0-43,5PSI/0-87PSI/0-145PSI

H

0d1

I

0d1

I

DN d1 H I DN d1 H I

25 26 219 50 1˝ 22,1 219 50

INCHES

40 38 238 60 1½˝ 34,8 238 60

DIN

50 50 252 70 2˝ 47,5 252 70

65 66 284 80 2½˝ 60,2 284 80

80 81 301 90 3˝ 72,9 301 90

FT74700.1.EN-0606

The information contained in this brochure is for guidance only. We reserve the right to modify any material or

feature without notice in advance. For further information, please, consult our web site. www.inoxpa.com

You might also like

- Logbook KoDocument13 pagesLogbook KoMarkmar AnchetaNo ratings yet

- SV1-10 en 01 PDFDocument8 pagesSV1-10 en 01 PDFcomec100% (1)

- Hydraulic Pressure Control Valves - OOVAL - Product CatalogDocument16 pagesHydraulic Pressure Control Valves - OOVAL - Product CatalogIsrael Exporter100% (2)

- Analysing Centrifugal-Pump CircuitsDocument5 pagesAnalysing Centrifugal-Pump CircuitsMarcelo PerettiNo ratings yet

- Analysing Centrifugal-Pump CircuitsDocument5 pagesAnalysing Centrifugal-Pump CircuitsMarcelo PerettiNo ratings yet

- Solved Problems On Mass Transfer PDFDocument12 pagesSolved Problems On Mass Transfer PDFProtim DasNo ratings yet

- FT.7550.1 enDocument2 pagesFT.7550.1 enFelipe DamascenoNo ratings yet

- Sandwich Type Butterfly Valve: I ApplicationDocument2 pagesSandwich Type Butterfly Valve: I ApplicationFery FebryantoNo ratings yet

- 1 1 122 eDocument2 pages1 1 122 edjkruggerNo ratings yet

- Valvula Combinada Bermad C30Document4 pagesValvula Combinada Bermad C30EDUARDO GALICIA RUANONo ratings yet

- TD3020A D00050 1 D00052 1 and D000731Document1 pageTD3020A D00050 1 D00052 1 and D000731Gustavo Adolfo Cepeda SalazarNo ratings yet

- Valves Brochure2019 PDFDocument50 pagesValves Brochure2019 PDFscibduser001No ratings yet

- FT.6400.1 - enDocument2 pagesFT.6400.1 - enHedi Ben MohamedNo ratings yet

- Inoxpa 6400 Ball Vave enDocument2 pagesInoxpa 6400 Ball Vave enRizky edytyaNo ratings yet

- Variable Area TrainingDocument12 pagesVariable Area TrainingRexCrazyMindNo ratings yet

- Etatron GB BP Motor Pump Datasheet 2017Document2 pagesEtatron GB BP Motor Pump Datasheet 2017Mohamed amine BenfarhatNo ratings yet

- Iom - Wav2212 - Vannair - Wxa12005 C - enDocument7 pagesIom - Wav2212 - Vannair - Wxa12005 C - ensuhaib.aljafari.nctcNo ratings yet

- WW C70 Product-Page English 12-2015 1Document5 pagesWW C70 Product-Page English 12-2015 1rafaelcoserNo ratings yet

- Wandfluh SIN35VDocument2 pagesWandfluh SIN35VChairuddin SaidNo ratings yet

- Check Valve Keystone F85Document4 pagesCheck Valve Keystone F85Robi KeiNo ratings yet

- Valves Brochure2015Document48 pagesValves Brochure2015lcandoNo ratings yet

- 2.1 Normpumpe DIN 24255Document8 pages2.1 Normpumpe DIN 24255hgpinheiroNo ratings yet

- SystemSpecification PVC-U Metric 2015 en PDFDocument24 pagesSystemSpecification PVC-U Metric 2015 en PDFpablo mendoza ibarraNo ratings yet

- DPNT CatalogueDocument5 pagesDPNT CatalogueShofchatin MardiyahNo ratings yet

- Pinch ValveDocument2 pagesPinch ValveKali Dass KMNo ratings yet

- Helac Basket Rotator L20 ManualDocument24 pagesHelac Basket Rotator L20 ManualStuart Sainsbury100% (1)

- Varec Tank Gauge TEC012 - 6700Document6 pagesVarec Tank Gauge TEC012 - 6700PraveenNo ratings yet

- Catalog XY.. HKU.. HKUQ.. HKUS..Document34 pagesCatalog XY.. HKU.. HKUQ.. HKUS..KADNo ratings yet

- Shut in Tool: FeaturesDocument2 pagesShut in Tool: FeaturesJuanNo ratings yet

- X PumpsDocument4 pagesX Pumpspankaj chacholiyaNo ratings yet

- Rod/Piston Seal: DesignDocument14 pagesRod/Piston Seal: DesignRPINILLA (EICO S.A.)No ratings yet

- Technical Data Sheet D6..NL: Type OverviewDocument4 pagesTechnical Data Sheet D6..NL: Type OverviewApetrii DoruNo ratings yet

- VM479Document8 pagesVM479Benydictus Ari SetiabudiNo ratings yet

- UntitledDocument131 pagesUntitledCristhian Tarqui DuranNo ratings yet

- 34 Grebenaste Sklopke K-SerijeDocument76 pages34 Grebenaste Sklopke K-SerijeplennyNo ratings yet

- GSR Data Sheet Solenoid Valve Type 23Document4 pagesGSR Data Sheet Solenoid Valve Type 23vishadkapadiaNo ratings yet

- Synconta 700 TDSDocument2 pagesSynconta 700 TDSRenan BarelaNo ratings yet

- Shur Joint Class 300 FittingsDocument7 pagesShur Joint Class 300 FittingsSajid SaleemNo ratings yet

- Ad600 PDFDocument2 pagesAd600 PDFRubén MontalvanNo ratings yet

- Bronze Relief Valve DN10 DN15 DN20Document2 pagesBronze Relief Valve DN10 DN15 DN20billNo ratings yet

- DA PIP-Hygienic-Dry PIV PIS PIVS EN 110418Document9 pagesDA PIP-Hygienic-Dry PIV PIS PIVS EN 110418Fernando RuedaNo ratings yet

- Jis B2001 (1987)Document8 pagesJis B2001 (1987)adprimNo ratings yet

- 3 - Butterfly ValveDocument4 pages3 - Butterfly ValvesureshkanuboyinaNo ratings yet

- CSG Vietwater22 BrochureDocument33 pagesCSG Vietwater22 BrochureTukang InsinyurNo ratings yet

- Ss 03044Document2 pagesSs 03044hyarub9No ratings yet

- Selfact DINDocument20 pagesSelfact DINmrbundle3129No ratings yet

- H - Disc Valves PDFDocument4 pagesH - Disc Valves PDFMIDHUN RAJNo ratings yet

- A Polyhydron Group Company: DescriptionDocument2 pagesA Polyhydron Group Company: DescriptionRenjithSivaNo ratings yet

- Spray Ball Terkait CIPDocument6 pagesSpray Ball Terkait CIPTuti SusilawatiNo ratings yet

- 3.20 On-Off - 27000Document13 pages3.20 On-Off - 27000Cuong TranNo ratings yet

- Series SDocument4 pagesSeries SMario VidićNo ratings yet

- Eng 1 1 10Document9 pagesEng 1 1 10Mohammed SalehNo ratings yet

- EN NM TD 60HzDocument90 pagesEN NM TD 60HzAshraf alZeidyNo ratings yet

- A-Ibis200 Vaporizer-2014.6Document4 pagesA-Ibis200 Vaporizer-2014.6Adi SupriantoNo ratings yet

- Variable Area TrainingDocument12 pagesVariable Area TrainingRexCrazyMindNo ratings yet

- 1.0 EBSRAY EMVI CatalogDocument16 pages1.0 EBSRAY EMVI Catalogckyee88-1No ratings yet

- EsparragosDocument134 pagesEsparragosNelloNo ratings yet

- Chemical Dosing PotsDocument3 pagesChemical Dosing PotsBuddhika100% (1)

- EHYD6 Hydraulic Valves HY14-2502k001Document9 pagesEHYD6 Hydraulic Valves HY14-2502k001Ahmet SaygılıNo ratings yet

- San Ace 92WF32 EDocument2 pagesSan Ace 92WF32 ECuong tran anhNo ratings yet

- Pressostato - Prospect - Hds - EnglishDocument4 pagesPressostato - Prospect - Hds - EnglishRicardo RoquettiNo ratings yet

- SEM-DG Approximation For Elasto-Acoustics: Hélène Barucq, Henri Calandra, Aurélien Citrain, Julien Diaz, Christian GoutDocument53 pagesSEM-DG Approximation For Elasto-Acoustics: Hélène Barucq, Henri Calandra, Aurélien Citrain, Julien Diaz, Christian GoutMarcelo PerettiNo ratings yet

- UntitledDocument15 pagesUntitledMarcelo PerettiNo ratings yet

- Cop Online Assessment Presentation 0Document24 pagesCop Online Assessment Presentation 0Marcelo PerettiNo ratings yet

- DG RdsoDocument14 pagesDG RdsoMarcelo PerettiNo ratings yet

- Arkema MP Chemical Process Industry Market PresentationDocument17 pagesArkema MP Chemical Process Industry Market PresentationMarcelo PerettiNo ratings yet

- Epd 0011Document11 pagesEpd 0011Marcelo PerettiNo ratings yet

- MixerDocument4 pagesMixerMarcelo PerettiNo ratings yet

- Checklist Question Checklist Response Evidence/CommentsDocument3 pagesChecklist Question Checklist Response Evidence/CommentsMarcelo PerettiNo ratings yet

- Quality Control of HDPE, LDPE, and PP: Non-Destructive Determination of Polymers Within One Minute With NIRSDocument5 pagesQuality Control of HDPE, LDPE, and PP: Non-Destructive Determination of Polymers Within One Minute With NIRSMarcelo PerettiNo ratings yet

- Computer Aided Chemical Process Design: The Flowtran SystemDocument11 pagesComputer Aided Chemical Process Design: The Flowtran SystemMarcelo PerettiNo ratings yet

- High Density Polyethylene: TipelinDocument10 pagesHigh Density Polyethylene: TipelinMarcelo PerettiNo ratings yet

- EBARA Reference DataDocument6 pagesEBARA Reference DataMarcelo Peretti100% (1)

- Centrifugal Pumps and System HydraulicsDocument23 pagesCentrifugal Pumps and System HydraulicsMarcelo PerettiNo ratings yet

- Sulzer Centrifugal Pumps - Basic OperationDocument26 pagesSulzer Centrifugal Pumps - Basic OperationMarcelo PerettiNo ratings yet

- AgitatorDocument3 pagesAgitatorMarcelo PerettiNo ratings yet

- Alfa Laval Principles of Cleaning and CipDocument43 pagesAlfa Laval Principles of Cleaning and CipMarcelo PerettiNo ratings yet

- NPSH - SchneiderDocument3 pagesNPSH - SchneiderMarcelo PerettiNo ratings yet

- Kimre Aiche 2008Document12 pagesKimre Aiche 2008Marcelo PerettiNo ratings yet

- Selecting The Right PumpDocument12 pagesSelecting The Right PumpMarcelo PerettiNo ratings yet

- Facts at Your Fingertips - Distillation PDFDocument1 pageFacts at Your Fingertips - Distillation PDFMarcelo PerettiNo ratings yet

- Analyzing Centrifugal-Pump CircuitsDocument12 pagesAnalyzing Centrifugal-Pump CircuitsMarcelo PerettiNo ratings yet

- Sizing, Specifying and Selecting Centrifugal PumpsDocument5 pagesSizing, Specifying and Selecting Centrifugal PumpsMarcelo Peretti100% (1)

- Anti-Surge Valves For Dynamic Compressors - Chemical Engineering November 2012Document5 pagesAnti-Surge Valves For Dynamic Compressors - Chemical Engineering November 2012Leon SanchezNo ratings yet

- Pump Branch DesignDocument7 pagesPump Branch DesignMarcelo PerettiNo ratings yet

- Pump Branch DesignDocument7 pagesPump Branch DesignMarcelo PerettiNo ratings yet

- Vacuum PumpsDocument1 pageVacuum PumpsMarcelo Peretti50% (2)

- Relationship Between Quality of Life and Social SupportDocument9 pagesRelationship Between Quality of Life and Social SupportDragos IvanNo ratings yet

- Soilless Media MatthewDocument13 pagesSoilless Media MatthewmatthewNo ratings yet

- Poem Analysis INVICTUSDocument1 pagePoem Analysis INVICTUSNina PerezNo ratings yet

- Slide Presentation Passive DesignDocument24 pagesSlide Presentation Passive DesignNuratiqah Sharifah100% (1)

- Gad AccomplishementxlsxDocument4 pagesGad AccomplishementxlsxDenielle DelosoNo ratings yet

- Demonstration of Physiological ExperimentsDocument2 pagesDemonstration of Physiological Experimentsalphabetagama713085No ratings yet

- CAIE8 - Physics - PT3 - Revision WorksheetDocument11 pagesCAIE8 - Physics - PT3 - Revision WorksheetadityadabxNo ratings yet

- William M Leahey - Bullying The BulliesDocument8 pagesWilliam M Leahey - Bullying The BullieswilliammleaheyNo ratings yet

- Baypren® 320-1 Safety Data SheetDocument10 pagesBaypren® 320-1 Safety Data SheetXiaofeng MengNo ratings yet

- Sharon W Tiffany - Anthropology and The Study of WomenDocument7 pagesSharon W Tiffany - Anthropology and The Study of WomenvinesimaNo ratings yet

- Franciscan ThePulseNewsletterDocument4 pagesFranciscan ThePulseNewsletterJill McDonoughNo ratings yet

- HEALTH MELCs Grade 3 PDFDocument3 pagesHEALTH MELCs Grade 3 PDFMarcelina Ellar50% (2)

- MCO - Available - KiosksDocument3 pagesMCO - Available - KiosksSobanah ChandranNo ratings yet

- Engineering Solutions: KLM Technology GroupDocument27 pagesEngineering Solutions: KLM Technology Groupramadan rashadNo ratings yet

- عبدالرحمن جمال الدين water injectionDocument15 pagesعبدالرحمن جمال الدين water injectionwaleed El-azabNo ratings yet

- Section-1: Drilling Fluids CriteriaDocument8 pagesSection-1: Drilling Fluids CriteriaMohamed AbozeimaNo ratings yet

- Premature BurialDocument9 pagesPremature Burialaidee bogadoNo ratings yet

- DiverDocument9 pagesDiverAli MinusNo ratings yet

- Polyethylene Glycol vs. Lactulose in Infants and Children With Functional ConstipationDocument5 pagesPolyethylene Glycol vs. Lactulose in Infants and Children With Functional ConstipationGabriela Peláez silvaNo ratings yet

- FSSC Version 6 Requirements (Foodkida)Document6 pagesFSSC Version 6 Requirements (Foodkida)jacky786No ratings yet

- Product Overview: Ethylene Oxide Handling SafetyDocument3 pagesProduct Overview: Ethylene Oxide Handling Safetymanojkp33No ratings yet

- Genetic Counseling Graduate Program at Wayne State UniversityDocument6 pagesGenetic Counseling Graduate Program at Wayne State Universityrazvanp13No ratings yet

- CARPER (Comprehensive Agrarian Reform Program Extension With Reforms) RA 9700Document1 pageCARPER (Comprehensive Agrarian Reform Program Extension With Reforms) RA 9700megawhat115No ratings yet

- Pengaruh Konseling Keluarga Berencana Terhadap Pengambilan Keputusan Alat KontrasepsiDocument5 pagesPengaruh Konseling Keluarga Berencana Terhadap Pengambilan Keputusan Alat KontrasepsiIsabenna AlvieraNo ratings yet

- 1 - States of MatterDocument9 pages1 - States of Mattermostafa barakatNo ratings yet

- Botanical Pesticides and Their Mode of A PDFDocument27 pagesBotanical Pesticides and Their Mode of A PDFRafil HamdillahNo ratings yet

- EpilepsyDocument19 pagesEpilepsyJashwanth KNo ratings yet

- New Employees GuideDocument16 pagesNew Employees GuideDavid RobinsonNo ratings yet