Professional Documents

Culture Documents

Hawke CableGland 153 UNIV Industrial Jan-2022

Hawke CableGland 153 UNIV Industrial Jan-2022

Uploaded by

RamzzzCopyright:

Available Formats

You might also like

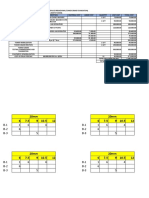

- Solve The Following by The Parallel Method of Resource Allocation. The Resource Limits Are As Follows 5M and 2H.Document8 pagesSolve The Following by The Parallel Method of Resource Allocation. The Resource Limits Are As Follows 5M and 2H.Arya AnujNo ratings yet

- Hawke CableGland 153 UNIV Industrial V2Document1 pageHawke CableGland 153 UNIV Industrial V2Saqib JavedNo ratings yet

- 501/453/UNIV: Cable Gland Selection TableDocument2 pages501/453/UNIV: Cable Gland Selection TableIng ZenerNo ratings yet

- 501/453 UNIVERSAL: Cable Gland Selection TableDocument2 pages501/453 UNIVERSAL: Cable Gland Selection TableManikandan ShriNo ratings yet

- 501/453/UNIV: Cable Gland Selection TableDocument1 page501/453/UNIV: Cable Gland Selection TableAkmalNo ratings yet

- Hawke CableGland 501 453 RAC Compression V6Document2 pagesHawke CableGland 501 453 RAC Compression V6Ing ZenerNo ratings yet

- 501/453 UNIVERSAL Hazardous Area Cable GlandDocument1 page501/453 UNIVERSAL Hazardous Area Cable Glandhashmin karuvathilNo ratings yet

- 501-453 Universal Cable GalndsDocument1 page501-453 Universal Cable Galndsmeribout adelNo ratings yet

- 153/RAC/L: Cable Gland Selection TableDocument2 pages153/RAC/L: Cable Gland Selection TableManikandan ShriNo ratings yet

- Type 501-453-Universal PDFDocument1 pageType 501-453-Universal PDFwe202No ratings yet

- 501,453 Classified GlandDocument1 page501,453 Classified GlandMuhammad RamzanNo ratings yet

- 501/453/universal Cable Gland Type: Flameproof and Increased SafetyDocument1 page501/453/universal Cable Gland Type: Flameproof and Increased SafetymahdimaziniNo ratings yet

- HAWKE GLAND-type OnlyDocument1 pageHAWKE GLAND-type OnlyJaaffer AliNo ratings yet

- 150 RacDocument1 page150 RacM Umar ChatthaNo ratings yet

- 501 453 Universal ColdFlowDocument2 pages501 453 Universal ColdFlowRavi VarmaNo ratings yet

- Hawke CableGland 121 Industrial June2019Document1 pageHawke CableGland 121 Industrial June2019Jalal AlbadriNo ratings yet

- Hke - 501 453 Univ (Upd260318)Document1 pageHke - 501 453 Univ (Upd260318)pneuma110No ratings yet

- North American Cable Glands/ConnectorsDocument1 pageNorth American Cable Glands/ConnectorsrhomadonaNo ratings yet

- 701 Cable Gland Type: Industrial General PurposeDocument1 page701 Cable Gland Type: Industrial General Purposewe202No ratings yet

- Hawke 501 - 423 DatasheetDocument2 pagesHawke 501 - 423 DatasheetjaybnovemNo ratings yet

- 501 453 UnivDocument1 page501 453 UnivVishnu LalNo ratings yet

- Unarmored Hawke Gland Datasheet 501-421Document1 pageUnarmored Hawke Gland Datasheet 501-421Sudeep SNo ratings yet

- 753 Cable Gland Type: Explosion ProofDocument1 page753 Cable Gland Type: Explosion Proofwe202No ratings yet

- HKE 114 Industrial Cable-Gland DatasheetDocument1 pageHKE 114 Industrial Cable-Gland DatasheetSai KamalaNo ratings yet

- Hawke - CableGland - 501 - 421 - Compression - Jan 2022Document2 pagesHawke - CableGland - 501 - 421 - Compression - Jan 2022Mohammad Nabil AbdullahNo ratings yet

- Hawke CableGland 501 421Document2 pagesHawke CableGland 501 421rajdavid9655No ratings yet

- HKE Cable Glands CatalogueDocument17 pagesHKE Cable Glands Cataloguesogetsu kazamaNo ratings yet

- 501/423 Cable Gland Type: Flameproof and Increased SafetyDocument1 page501/423 Cable Gland Type: Flameproof and Increased Safetymadhan rajNo ratings yet

- Hawke Gland CatalogDocument1 pageHawke Gland CatalogIon NitaNo ratings yet

- Hawke GlandsDocument1 pageHawke GlandsIon NitaNo ratings yet

- Vicflex Sprinkler Fittings Series Ah2-300 and Ah2-Cc-300 Braided Flexible Hose AssembliesDocument21 pagesVicflex Sprinkler Fittings Series Ah2-300 and Ah2-Cc-300 Braided Flexible Hose AssembliesEliel AbadNo ratings yet

- Cable Gland Types E1W, E2W, E1X, E2X, E1U & E2UDocument2 pagesCable Gland Types E1W, E2W, E1X, E2X, E1U & E2UWidhi ImranovichNo ratings yet

- ICG/653/UNIV: Cable Gland Selection TableDocument2 pagesICG/653/UNIV: Cable Gland Selection Table萧家一族No ratings yet

- CATALOG 153 GLAND HAWKE - O-0.5in NPTDocument1 pageCATALOG 153 GLAND HAWKE - O-0.5in NPTgalfandraNo ratings yet

- Manual - Pro-series-fish-manual-G3 - B10414 Iss1Document72 pagesManual - Pro-series-fish-manual-G3 - B10414 Iss1gregorioNo ratings yet

- Cable Gland 501 Hazardous Type 501 - 421Document1 pageCable Gland 501 Hazardous Type 501 - 421rhomadonaNo ratings yet

- Manual Lewmar V700Document20 pagesManual Lewmar V700Eduardo Dantas LobãoNo ratings yet

- Vicflex Sprinkler Fittings Series Ah2-300 and Ah2-Cc-300 Braided Flexible Hose AssembliesDocument20 pagesVicflex Sprinkler Fittings Series Ah2-300 and Ah2-Cc-300 Braided Flexible Hose AssembliesbalaasenthilNo ratings yet

- True Union ValveDocument3 pagesTrue Union Valverenne_mujicaNo ratings yet

- Ducab Cables-Pages-5Document1 pageDucab Cables-Pages-5Bilal JavaidNo ratings yet

- Single Core Insulated and SheathedDocument1 pageSingle Core Insulated and SheathedImthiyasNo ratings yet

- Single Core Insulated and Sheathed PDFDocument1 pageSingle Core Insulated and Sheathed PDFalamNo ratings yet

- 121 Cable Gland Type: Industrial General PurposeDocument1 page121 Cable Gland Type: Industrial General Purposewe202No ratings yet

- Victaulic Flexible Hose Connecting To Regular Reliable SprinklerDocument27 pagesVictaulic Flexible Hose Connecting To Regular Reliable SprinklerOwais AhmedNo ratings yet

- N2XCY 1 X (1.5-800) MM 0.6/1 KVDocument5 pagesN2XCY 1 X (1.5-800) MM 0.6/1 KVCombox BlackNo ratings yet

- Ball Valve, Stainless Steel: ConstructionDocument19 pagesBall Valve, Stainless Steel: ConstructionSanjay MaheshNo ratings yet

- HAWKE Cable - Gland - Accessories - CatalogueDocument10 pagesHAWKE Cable - Gland - Accessories - Cataloguelam266No ratings yet

- Instrumentation Cable BSDocument42 pagesInstrumentation Cable BSShivaniNo ratings yet

- Multicore Insulated and Sheathed-Flat Cable PDFDocument1 pageMulticore Insulated and Sheathed-Flat Cable PDFAyantha SampathNo ratings yet

- Hawke 501Document1 pageHawke 501Nurdin MubarokNo ratings yet

- GlandDocument2 pagesGlandhtc one x9No ratings yet

- SS2KGPDocument3 pagesSS2KGPSamdan NamhaisurenNo ratings yet

- Aberdare Cable Selection ChartDocument18 pagesAberdare Cable Selection ChartEdwin Cob Guri100% (1)

- North American Cable Glands/ConnectorsDocument1 pageNorth American Cable Glands/ConnectorsOel NaubNo ratings yet

- Closed Swage Sockets National Swage ButtonsDocument1 pageClosed Swage Sockets National Swage ButtonshoiNo ratings yet

- Wire & Cable 202312261659586681900588413Document24 pagesWire & Cable 202312261659586681900588413Amir IqbalNo ratings yet

- HKE - 711-713 - Cable-Gland - Datasheet (Cable Interlock)Document1 pageHKE - 711-713 - Cable-Gland - Datasheet (Cable Interlock)Ing ZenerNo ratings yet

- Millimetre Wave Antennas for Gigabit Wireless Communications: A Practical Guide to Design and Analysis in a System ContextFrom EverandMillimetre Wave Antennas for Gigabit Wireless Communications: A Practical Guide to Design and Analysis in a System ContextNo ratings yet

- Mechanics of Optimal Structural Design: Minimum Weight StructuresFrom EverandMechanics of Optimal Structural Design: Minimum Weight StructuresNo ratings yet

- Material Science at BorobudurDocument5 pagesMaterial Science at BorobudurUday DokrasNo ratings yet

- De Montfort Mark 9 Incinerator - Construction PDFDocument9 pagesDe Montfort Mark 9 Incinerator - Construction PDFRomário CaribéNo ratings yet

- Assignment-6question and Solution Civil EngineeringDocument10 pagesAssignment-6question and Solution Civil EngineeringMohit NaraNo ratings yet

- Beam Cut ListDocument12 pagesBeam Cut ListCyrilleNo ratings yet

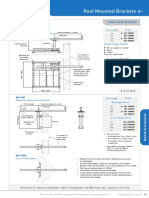

- SB1-RM and SB1-PM Datasheet v4.2Document1 pageSB1-RM and SB1-PM Datasheet v4.2Anonymous XYAPaxjbYNo ratings yet

- Test On BricksDocument3 pagesTest On BricksMukesh KumarNo ratings yet

- 1 - Redi Rock General Installation GuideDocument25 pages1 - Redi Rock General Installation GuideED WARMONDNo ratings yet

- CB 514 - Lec001 - V01Document14 pagesCB 514 - Lec001 - V01b.i.mousaNo ratings yet

- HU High Voltage UndergroundDocument197 pagesHU High Voltage UndergroundARUN TOMARNo ratings yet

- D.L. Cervantes: Construction CorporationDocument1 pageD.L. Cervantes: Construction CorporationSebastian AbordoNo ratings yet

- Product Brochure - FraminiDocument2 pagesProduct Brochure - FraminiJinxian XuNo ratings yet

- Module 1 & 2Document198 pagesModule 1 & 2john fordNo ratings yet

- Chimney Bid DocumentDocument222 pagesChimney Bid Documentoundhakar100% (1)

- Brevini Evolution Winches Series CTF048000 20Document112 pagesBrevini Evolution Winches Series CTF048000 20Denis RembrantNo ratings yet

- MPWT - Defect WorkDocument118 pagesMPWT - Defect WorkVorn Ra VuthNo ratings yet

- Tower Crane Operator's Handbook LRDocument32 pagesTower Crane Operator's Handbook LRPeter Verhoef100% (1)

- Secondary Suites: Building Permit Application GuideDocument8 pagesSecondary Suites: Building Permit Application Guideevren bozmasiNo ratings yet

- Tle05 - Module 1Document292 pagesTle05 - Module 1Lifmark Villacorte TalamayanNo ratings yet

- 3 Storey PlanDocument8 pages3 Storey Planrainergoogol01No ratings yet

- RW SFB 22 - 2Document1 pageRW SFB 22 - 2Yong TonghannNo ratings yet

- Aluminium Door & PartitionDocument1 pageAluminium Door & PartitionAshutosh Singh100% (4)

- Assignment 2.3: Republic of The Philippines (Formerly Naval State University)Document4 pagesAssignment 2.3: Republic of The Philippines (Formerly Naval State University)jesica quijanoNo ratings yet

- Instruction:: CENG85A: Principles OF Steel DesignDocument8 pagesInstruction:: CENG85A: Principles OF Steel DesignDEUS PHILIP DURANNo ratings yet

- SWMS Ingress Gate 2Document10 pagesSWMS Ingress Gate 2Sam LimNo ratings yet

- BS 1370 1979Document13 pagesBS 1370 1979thushtikaNo ratings yet

- Johnnie Coats USADocument2 pagesJohnnie Coats USAPhong AnhNo ratings yet

- Diagrid SystemDocument20 pagesDiagrid SystemHansika MadipadigeNo ratings yet

- Why Theoretical Concrete Quantity Is More Than Actual Poured Qty If There Is Mass Concrete or by Mechanical Concrete - Civil4MDocument4 pagesWhy Theoretical Concrete Quantity Is More Than Actual Poured Qty If There Is Mass Concrete or by Mechanical Concrete - Civil4MPritha DasNo ratings yet

- Sandwich Type Bus DuctDocument2 pagesSandwich Type Bus DuctPankaj KumarNo ratings yet

Hawke CableGland 153 UNIV Industrial Jan-2022

Hawke CableGland 153 UNIV Industrial Jan-2022

Uploaded by

RamzzzOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hawke CableGland 153 UNIV Industrial Jan-2022

Hawke CableGland 153 UNIV Industrial Jan-2022

Uploaded by

RamzzzCopyright:

Available Formats

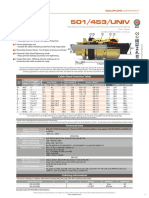

CABLE GLAND INDUSTRIAL SERIES

153/UNIV

MADE IN Industrial gland for indoor or outdoor use

BRITAIN

1 2 3 4 5

’C’

1 Inspectable Deluge Seal

- Offering IP66, IP67, IP68 & IP69 Ingress Protection

2 Passive diaphragm seal

- Suitable for cables exhibiting ‘Cold Flow.’ Fully inspectable

Ø’A’ Ø’B’

3 Reversible Armour Clamp - For all types of armour and braid

4 Patented Cable Gland Tightening Guide

- Helps prevent damage caused by over tightening

5 Unique Rear Seal - Offering ultimate sealing over an

extremely wide cable acceptance range

15 mm ‘G’ Approx

Metric Entry

The industrial 153/Universal Cable Gland is robust and for use with single wire armour ‘W’, wire braid ‘X’, steel tape armour ‘Z’,

elastomer and plastic insulated cables. For particular use with cables that exhibit ‘Cold Flow’ characteristics.

Cable Gland Selection Table

Entry Thread Size ‘A’ Cable Acceptance Details Hexagon Dimensions

Size

Inner Sheath Outer Sheath ‘B’ Armour/Braid ‘C’ ‘G’ Across

Ref. Metric NPT* Across Flats Corners

Min Max Min Max Orientation 1 Orientation 2

Os M202 ½” 3.5 8.1 5.5 12 0.8/1.25 0.0/0.8 58.4 24 26.5

O M202 ½” 6.5 11.4 9.5 16 0.8/1.25 0.0/0.8 58.4 24 26.5

A M20 ¾” or ½” 8.4 14.3 12.5 20.5 0.8/1.25 0.0/0.8 59.6 30 32.5

B M25 1” or ¾” 11.1 19.7 16.9 26 1.25/1.6 0.0/0.7 66.4 36 39.5

C M32 1¼” or 1” 17.6 26.5 22 33 1.6/2.0 0.0/0.7 71.2 46 50.5

C2 M40 1½” or 1¼” 23.1 32.5 28 41 1.6/2.0 0.0/0.7 75.2 55 60.6

D M50 2” or 1½” 28.9 44.4/42.31 36 52.6 1.8/2.5 0.0/1.0 98 65 70.8

E M63 2½” or 2” 39.9 56.3/54.31 46 65.3 1.8/2.5 0.0/1.0 94.4 80 88.0

F M75 3” or 2½” 50.5 68.2/65.31 57 78 1.8/2.5 0.0/1.0 102 95 104.0

G M80 3½” 67 73 75 89.5 2.0/3.5 0.0/1.0 90.6 106.4 115.0

H M90 3½” 67 77.6 75 89.5 2.0/3.5 0.0/1.0 90.6 115 130.0

J M100 4” 75 91.6 88 104.5 2.5/4.0 0.0/1.0 90.6 127 142.0

All dimensions in millimetres (except * where dimensions are in inches). Os - F size metric entry threads are 1.5mm pitch as standard, 15mm length of thread. For G size glands and

above, a 2mm pitch is supplied as standard, 20mm length of thread (1.5mm pitch with 15mm length of thread can be supplied) please specify when ordering.

G size and above are available in the 153/RAC design style.

1 Smaller value is applicable when selecting reduced NPT entry option.

2 Sizes Os and O are available with an M16 thread size. For O size with M16 thread, the maximum cable outer sheath diameter is 10.9mm.

Technical Data

Material Options Manufactured in Brass, Nickel Plated Brass or 316L Stainless Steel

Construction & Test Standards IEC/EN 62444 (Anchorage Type D)

Ingress Protection IP66, IP67, IP69 to IEC/EN 60529 and NEMA 4X

Enclosure Protection IK10 to IEC 62262

Deluge Protection DTS01

Operating Temperature -60°C to +80°C

Alternative Reversible Armour Clamping Ring Size Selection

Size Ref Orientation 1 Orientation 2

B 0.9 - 1.25 0.5 - 0.9

C 1.2 - 1.6 0.6 - 1.2

C2 1.2 - 1.6 0.6 - 1.2

D 1.45 - 1.8 1.0 - 1.45

E 1.45 - 1.8 1.0 - 1.45

F 1.45 - 1.8 1.0 - 1.45

Ordering Information

Format for ordering is as follows: Alternative Clamping Ring (AR), add suffix AR to ordering information

Cable Gland Type Size Thread Material (Optional)

153/UNIV C M32 Brass AR

153/UNIV C 1¼" NPT NP Brass AR

HKE-DS-153-V3 January 2022

Example Code: 153/UNIV C M32 Stainless

UK / Europe / Africa / North America T: +44 (0)141 810 9644 E: hhsales1@hubbell.com

Asia / Middle East / South America T: +44 (0)141 810 9666 E: hhsales2@hubbell.com

CABLE GLAND INDUSTRIAL SERIES

Cable Gland Tightening Guide

Whilst Hawke International goes to great lengths to ensure products are designed to be as simple to install,

inspect and maintain as is possible, differing levels of competency, training and understanding can lead to

glands being incorrectly installed. With hazardous area products, any poor installation issues can not only lead

to expensive equipment failure, but also potential explosion risks and associated risk to life.

To help address issues with the overtightening of cable glands and the resultant damage to cables and seals,

Hawke International has developed the patented INBUILT TIGHTENING GUIDE.

Without the need for fiddly measuring systems, the guide provides a permanent visual indication of the gland

tightness through installation, inspection and maintenance.

How it works

The gland is permanently marked with various lines/numbers indicating the correct tightening level related

to the cable diameter. Following the relevant cable gland Installation Instructions, the back seal should be

tightened until a seal is formed on the cable outer sheath and then tightened one further turn.

Step 1 Step 2 Step 3

1

Follow cable gland installation instructions

until final stage – tightening of rear seal

2

Tighten backnut until a seal is formed onto

the cable, then tighten one further turn

3

The backnut should be level with the marking guide

corresponding to its diameter – this can be visually

inspected and adjusted as necessary

Note: The cable gland installation instructions have a printed cable OD measure for if the cable OD is not known

Product design and specifications are subject to change without notice. Please check the Hawke website for latest specifications.

www.ehawke.com

You might also like

- Solve The Following by The Parallel Method of Resource Allocation. The Resource Limits Are As Follows 5M and 2H.Document8 pagesSolve The Following by The Parallel Method of Resource Allocation. The Resource Limits Are As Follows 5M and 2H.Arya AnujNo ratings yet

- Hawke CableGland 153 UNIV Industrial V2Document1 pageHawke CableGland 153 UNIV Industrial V2Saqib JavedNo ratings yet

- 501/453/UNIV: Cable Gland Selection TableDocument2 pages501/453/UNIV: Cable Gland Selection TableIng ZenerNo ratings yet

- 501/453 UNIVERSAL: Cable Gland Selection TableDocument2 pages501/453 UNIVERSAL: Cable Gland Selection TableManikandan ShriNo ratings yet

- 501/453/UNIV: Cable Gland Selection TableDocument1 page501/453/UNIV: Cable Gland Selection TableAkmalNo ratings yet

- Hawke CableGland 501 453 RAC Compression V6Document2 pagesHawke CableGland 501 453 RAC Compression V6Ing ZenerNo ratings yet

- 501/453 UNIVERSAL Hazardous Area Cable GlandDocument1 page501/453 UNIVERSAL Hazardous Area Cable Glandhashmin karuvathilNo ratings yet

- 501-453 Universal Cable GalndsDocument1 page501-453 Universal Cable Galndsmeribout adelNo ratings yet

- 153/RAC/L: Cable Gland Selection TableDocument2 pages153/RAC/L: Cable Gland Selection TableManikandan ShriNo ratings yet

- Type 501-453-Universal PDFDocument1 pageType 501-453-Universal PDFwe202No ratings yet

- 501,453 Classified GlandDocument1 page501,453 Classified GlandMuhammad RamzanNo ratings yet

- 501/453/universal Cable Gland Type: Flameproof and Increased SafetyDocument1 page501/453/universal Cable Gland Type: Flameproof and Increased SafetymahdimaziniNo ratings yet

- HAWKE GLAND-type OnlyDocument1 pageHAWKE GLAND-type OnlyJaaffer AliNo ratings yet

- 150 RacDocument1 page150 RacM Umar ChatthaNo ratings yet

- 501 453 Universal ColdFlowDocument2 pages501 453 Universal ColdFlowRavi VarmaNo ratings yet

- Hawke CableGland 121 Industrial June2019Document1 pageHawke CableGland 121 Industrial June2019Jalal AlbadriNo ratings yet

- Hke - 501 453 Univ (Upd260318)Document1 pageHke - 501 453 Univ (Upd260318)pneuma110No ratings yet

- North American Cable Glands/ConnectorsDocument1 pageNorth American Cable Glands/ConnectorsrhomadonaNo ratings yet

- 701 Cable Gland Type: Industrial General PurposeDocument1 page701 Cable Gland Type: Industrial General Purposewe202No ratings yet

- Hawke 501 - 423 DatasheetDocument2 pagesHawke 501 - 423 DatasheetjaybnovemNo ratings yet

- 501 453 UnivDocument1 page501 453 UnivVishnu LalNo ratings yet

- Unarmored Hawke Gland Datasheet 501-421Document1 pageUnarmored Hawke Gland Datasheet 501-421Sudeep SNo ratings yet

- 753 Cable Gland Type: Explosion ProofDocument1 page753 Cable Gland Type: Explosion Proofwe202No ratings yet

- HKE 114 Industrial Cable-Gland DatasheetDocument1 pageHKE 114 Industrial Cable-Gland DatasheetSai KamalaNo ratings yet

- Hawke - CableGland - 501 - 421 - Compression - Jan 2022Document2 pagesHawke - CableGland - 501 - 421 - Compression - Jan 2022Mohammad Nabil AbdullahNo ratings yet

- Hawke CableGland 501 421Document2 pagesHawke CableGland 501 421rajdavid9655No ratings yet

- HKE Cable Glands CatalogueDocument17 pagesHKE Cable Glands Cataloguesogetsu kazamaNo ratings yet

- 501/423 Cable Gland Type: Flameproof and Increased SafetyDocument1 page501/423 Cable Gland Type: Flameproof and Increased Safetymadhan rajNo ratings yet

- Hawke Gland CatalogDocument1 pageHawke Gland CatalogIon NitaNo ratings yet

- Hawke GlandsDocument1 pageHawke GlandsIon NitaNo ratings yet

- Vicflex Sprinkler Fittings Series Ah2-300 and Ah2-Cc-300 Braided Flexible Hose AssembliesDocument21 pagesVicflex Sprinkler Fittings Series Ah2-300 and Ah2-Cc-300 Braided Flexible Hose AssembliesEliel AbadNo ratings yet

- Cable Gland Types E1W, E2W, E1X, E2X, E1U & E2UDocument2 pagesCable Gland Types E1W, E2W, E1X, E2X, E1U & E2UWidhi ImranovichNo ratings yet

- ICG/653/UNIV: Cable Gland Selection TableDocument2 pagesICG/653/UNIV: Cable Gland Selection Table萧家一族No ratings yet

- CATALOG 153 GLAND HAWKE - O-0.5in NPTDocument1 pageCATALOG 153 GLAND HAWKE - O-0.5in NPTgalfandraNo ratings yet

- Manual - Pro-series-fish-manual-G3 - B10414 Iss1Document72 pagesManual - Pro-series-fish-manual-G3 - B10414 Iss1gregorioNo ratings yet

- Cable Gland 501 Hazardous Type 501 - 421Document1 pageCable Gland 501 Hazardous Type 501 - 421rhomadonaNo ratings yet

- Manual Lewmar V700Document20 pagesManual Lewmar V700Eduardo Dantas LobãoNo ratings yet

- Vicflex Sprinkler Fittings Series Ah2-300 and Ah2-Cc-300 Braided Flexible Hose AssembliesDocument20 pagesVicflex Sprinkler Fittings Series Ah2-300 and Ah2-Cc-300 Braided Flexible Hose AssembliesbalaasenthilNo ratings yet

- True Union ValveDocument3 pagesTrue Union Valverenne_mujicaNo ratings yet

- Ducab Cables-Pages-5Document1 pageDucab Cables-Pages-5Bilal JavaidNo ratings yet

- Single Core Insulated and SheathedDocument1 pageSingle Core Insulated and SheathedImthiyasNo ratings yet

- Single Core Insulated and Sheathed PDFDocument1 pageSingle Core Insulated and Sheathed PDFalamNo ratings yet

- 121 Cable Gland Type: Industrial General PurposeDocument1 page121 Cable Gland Type: Industrial General Purposewe202No ratings yet

- Victaulic Flexible Hose Connecting To Regular Reliable SprinklerDocument27 pagesVictaulic Flexible Hose Connecting To Regular Reliable SprinklerOwais AhmedNo ratings yet

- N2XCY 1 X (1.5-800) MM 0.6/1 KVDocument5 pagesN2XCY 1 X (1.5-800) MM 0.6/1 KVCombox BlackNo ratings yet

- Ball Valve, Stainless Steel: ConstructionDocument19 pagesBall Valve, Stainless Steel: ConstructionSanjay MaheshNo ratings yet

- HAWKE Cable - Gland - Accessories - CatalogueDocument10 pagesHAWKE Cable - Gland - Accessories - Cataloguelam266No ratings yet

- Instrumentation Cable BSDocument42 pagesInstrumentation Cable BSShivaniNo ratings yet

- Multicore Insulated and Sheathed-Flat Cable PDFDocument1 pageMulticore Insulated and Sheathed-Flat Cable PDFAyantha SampathNo ratings yet

- Hawke 501Document1 pageHawke 501Nurdin MubarokNo ratings yet

- GlandDocument2 pagesGlandhtc one x9No ratings yet

- SS2KGPDocument3 pagesSS2KGPSamdan NamhaisurenNo ratings yet

- Aberdare Cable Selection ChartDocument18 pagesAberdare Cable Selection ChartEdwin Cob Guri100% (1)

- North American Cable Glands/ConnectorsDocument1 pageNorth American Cable Glands/ConnectorsOel NaubNo ratings yet

- Closed Swage Sockets National Swage ButtonsDocument1 pageClosed Swage Sockets National Swage ButtonshoiNo ratings yet

- Wire & Cable 202312261659586681900588413Document24 pagesWire & Cable 202312261659586681900588413Amir IqbalNo ratings yet

- HKE - 711-713 - Cable-Gland - Datasheet (Cable Interlock)Document1 pageHKE - 711-713 - Cable-Gland - Datasheet (Cable Interlock)Ing ZenerNo ratings yet

- Millimetre Wave Antennas for Gigabit Wireless Communications: A Practical Guide to Design and Analysis in a System ContextFrom EverandMillimetre Wave Antennas for Gigabit Wireless Communications: A Practical Guide to Design and Analysis in a System ContextNo ratings yet

- Mechanics of Optimal Structural Design: Minimum Weight StructuresFrom EverandMechanics of Optimal Structural Design: Minimum Weight StructuresNo ratings yet

- Material Science at BorobudurDocument5 pagesMaterial Science at BorobudurUday DokrasNo ratings yet

- De Montfort Mark 9 Incinerator - Construction PDFDocument9 pagesDe Montfort Mark 9 Incinerator - Construction PDFRomário CaribéNo ratings yet

- Assignment-6question and Solution Civil EngineeringDocument10 pagesAssignment-6question and Solution Civil EngineeringMohit NaraNo ratings yet

- Beam Cut ListDocument12 pagesBeam Cut ListCyrilleNo ratings yet

- SB1-RM and SB1-PM Datasheet v4.2Document1 pageSB1-RM and SB1-PM Datasheet v4.2Anonymous XYAPaxjbYNo ratings yet

- Test On BricksDocument3 pagesTest On BricksMukesh KumarNo ratings yet

- 1 - Redi Rock General Installation GuideDocument25 pages1 - Redi Rock General Installation GuideED WARMONDNo ratings yet

- CB 514 - Lec001 - V01Document14 pagesCB 514 - Lec001 - V01b.i.mousaNo ratings yet

- HU High Voltage UndergroundDocument197 pagesHU High Voltage UndergroundARUN TOMARNo ratings yet

- D.L. Cervantes: Construction CorporationDocument1 pageD.L. Cervantes: Construction CorporationSebastian AbordoNo ratings yet

- Product Brochure - FraminiDocument2 pagesProduct Brochure - FraminiJinxian XuNo ratings yet

- Module 1 & 2Document198 pagesModule 1 & 2john fordNo ratings yet

- Chimney Bid DocumentDocument222 pagesChimney Bid Documentoundhakar100% (1)

- Brevini Evolution Winches Series CTF048000 20Document112 pagesBrevini Evolution Winches Series CTF048000 20Denis RembrantNo ratings yet

- MPWT - Defect WorkDocument118 pagesMPWT - Defect WorkVorn Ra VuthNo ratings yet

- Tower Crane Operator's Handbook LRDocument32 pagesTower Crane Operator's Handbook LRPeter Verhoef100% (1)

- Secondary Suites: Building Permit Application GuideDocument8 pagesSecondary Suites: Building Permit Application Guideevren bozmasiNo ratings yet

- Tle05 - Module 1Document292 pagesTle05 - Module 1Lifmark Villacorte TalamayanNo ratings yet

- 3 Storey PlanDocument8 pages3 Storey Planrainergoogol01No ratings yet

- RW SFB 22 - 2Document1 pageRW SFB 22 - 2Yong TonghannNo ratings yet

- Aluminium Door & PartitionDocument1 pageAluminium Door & PartitionAshutosh Singh100% (4)

- Assignment 2.3: Republic of The Philippines (Formerly Naval State University)Document4 pagesAssignment 2.3: Republic of The Philippines (Formerly Naval State University)jesica quijanoNo ratings yet

- Instruction:: CENG85A: Principles OF Steel DesignDocument8 pagesInstruction:: CENG85A: Principles OF Steel DesignDEUS PHILIP DURANNo ratings yet

- SWMS Ingress Gate 2Document10 pagesSWMS Ingress Gate 2Sam LimNo ratings yet

- BS 1370 1979Document13 pagesBS 1370 1979thushtikaNo ratings yet

- Johnnie Coats USADocument2 pagesJohnnie Coats USAPhong AnhNo ratings yet

- Diagrid SystemDocument20 pagesDiagrid SystemHansika MadipadigeNo ratings yet

- Why Theoretical Concrete Quantity Is More Than Actual Poured Qty If There Is Mass Concrete or by Mechanical Concrete - Civil4MDocument4 pagesWhy Theoretical Concrete Quantity Is More Than Actual Poured Qty If There Is Mass Concrete or by Mechanical Concrete - Civil4MPritha DasNo ratings yet

- Sandwich Type Bus DuctDocument2 pagesSandwich Type Bus DuctPankaj KumarNo ratings yet