Professional Documents

Culture Documents

Installation JSA

Installation JSA

Uploaded by

rahulOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Installation JSA

Installation JSA

Uploaded by

rahulCopyright:

Available Formats

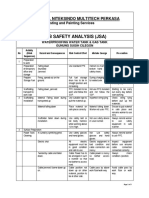

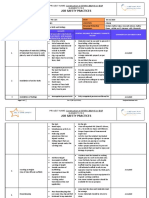

JOB SAFETY ANALYSIS

JSA No : Description: Date :

PTW No : ESP EQUIPMENTS ASSEMBLY Location :

ASSIGNED

JOB STEP POTENTIAL HAZARDS ACTION TO REDUCE POTENTIAL HAZARDS

PERSON

Serious injury causes by incorrect planning, “TAKE TWO” minutes before starting work to

rushing and lack of communication. asses the workplace and possible hazards

Conduct tool box talk and review

1 JSA. Prepare for the job; inspect the

Congested area / tripping and falling Watch your steps

area, tools and equipment

Ensure that all lifting equipment is in good

Bad condition of lifting equipments

condition

Body Injury due to bad position, Use good lifting posture

2 Lifting hand tooling to rig floor Pinch points Identify all pinch hazard on rig floor

Good communication with floor men

Dropped object, slip trip fall

Used hand rails on rig stairs

Fingers and legs injury Keep hands away from rig tongs

Unsure load is balanced before lifting

3 Moving ESP equipment to the catwalk. Having equipment damage

Only one guy to guide crane operator

equipment falling down Use proper lifting belt and tight properly

Only one man to give signal to driller and winch

Bad signal to driller or winch operator

operator

4 Lifting ESP equipment to the rig floor Pick up slowly and use tagline for back tension.

Equipment hit the V Door

Good communication.

Equipment slip out of tail-sling Use proper lifting belt and tigh properly

Injury from falling Equipment Clamp securely tightened to equipment

Clean oil/ fluid from equipment and floor to

5 Equipment assembly Injury from slipping on oil/ fluid on to floor.

prevent slips

Equipment falling in to the well. Use tested certified clamps / chains

Be aware of live electrical and disconnect after

Fire due to electrical sparks

use.

6 Electrical Test of down-hole tool. Flash back CRC – cleaning liquid to eyes Wearing safety goggles / face shield

Make sure cords and plugs are in good

Electrical Shock

condition

Disconnect / Swich Off power before working

Spooler maintenance

on equipment

7 General Dehydration Drink water, keep hydrated

Site to be left in a clean and tidy condition

Poor Housekeeping

during and after completion of work

Everyone has the right to STOP or not start a task that he / she considers unsafe. Any questions STOP and ask your supervisor.

Minimum PPE and Safety Equipment required for all Job Steps

HARD HAT Safety Shoes Safety Goggles / Face Shield

Coverall Leather Gloves / Cotton Gloves

Work Site Supervisor / WET: Sign: ___________________________ Date: __________________

(Lead FS Tech / Commissioning Engr / Shop Tech.

You might also like

- Risk Assessment Air Conditioning Sample PDFDocument7 pagesRisk Assessment Air Conditioning Sample PDFFaisal Raza100% (1)

- Skid Steer (Generic) : Job Safety AnalysisDocument2 pagesSkid Steer (Generic) : Job Safety AnalysisNanthan GanesNo ratings yet

- JHA - Unloading of Sheet PileDocument3 pagesJHA - Unloading of Sheet PileJensen Sunga100% (1)

- JSA Epoxy Coating Machine ShopDocument10 pagesJSA Epoxy Coating Machine ShopMarhendra100% (1)

- Fabrication Work Risk AssessmentDocument11 pagesFabrication Work Risk Assessmentstansilous100% (1)

- JSA Installation of Equipment For Electrical and InstrumentDocument3 pagesJSA Installation of Equipment For Electrical and InstrumentHong Hai Pham80% (5)

- 012 - Risk Ass. - CG 4760 - Earthing Sysytem Installation - S - Rev. 1Document6 pages012 - Risk Ass. - CG 4760 - Earthing Sysytem Installation - S - Rev. 1nsadnan100% (11)

- JSA DrillingDocument4 pagesJSA DrillingAmalNo ratings yet

- JHA - Lifting ACUs With 60 Ton CraneDocument2 pagesJHA - Lifting ACUs With 60 Ton Cranescottie MailauNo ratings yet

- Job Hazard Analysis For Enikkom DredgeDocument2 pagesJob Hazard Analysis For Enikkom DredgeOgunwa EmmanuelNo ratings yet

- Safety: JOB AnalysisDocument4 pagesSafety: JOB AnalysisAjay kumar100% (1)

- 012 Risk Ass CG 4760 Earthing Sysytem Installation S Rev 1Document5 pages012 Risk Ass CG 4760 Earthing Sysytem Installation S Rev 1Em Niax50% (2)

- Kaztec Fabrication Yard, Snake Island: Job Safety Analysis (JSA)Document3 pagesKaztec Fabrication Yard, Snake Island: Job Safety Analysis (JSA)Ogunwa EmmanuelNo ratings yet

- Job Safety Analysis Sheet: Operation Concrete Batching PlantDocument2 pagesJob Safety Analysis Sheet: Operation Concrete Batching Plantzabiulla88% (8)

- JSA Painting Aut Tranformer Unit 3 OutageDocument7 pagesJSA Painting Aut Tranformer Unit 3 OutageMarhendraNo ratings yet

- JSA SK Erection DismantlingDocument1 pageJSA SK Erection DismantlingSamuel Hugos80% (5)

- Job Safety Analysis: (Risk Assessment)Document9 pagesJob Safety Analysis: (Risk Assessment)MarhendraNo ratings yet

- Jsa For Chemical Ware HouseDocument4 pagesJsa For Chemical Ware Housesalauddin0mohammedNo ratings yet

- Job Safety Analysis (Jsa) : DQE International Iraq BranchDocument4 pagesJob Safety Analysis (Jsa) : DQE International Iraq Branchhassan100% (1)

- Centrifuge JSADocument2 pagesCentrifuge JSAandriNo ratings yet

- JSA Additional Lamp Paiton 3Document10 pagesJSA Additional Lamp Paiton 3MarhendraNo ratings yet

- Hot Work Gift Gift / Near Gis SEPCOO III Early Comb: Job Hazard Analysis (Jha) WorksheetDocument4 pagesHot Work Gift Gift / Near Gis SEPCOO III Early Comb: Job Hazard Analysis (Jha) Worksheet王志伟No ratings yet

- Work Method Statement For Coring Works A PDFDocument3 pagesWork Method Statement For Coring Works A PDFmichelleNo ratings yet

- Job Safety Analysis (Jsa) : Pt. Niteksindo Multitech PerkasaDocument3 pagesJob Safety Analysis (Jsa) : Pt. Niteksindo Multitech PerkasalukiNo ratings yet

- Tower Crane Dismantling JSA HSE ProfessionalsDocument2 pagesTower Crane Dismantling JSA HSE ProfessionalsnabeelNo ratings yet

- JSA of CentrifugeDocument8 pagesJSA of CentrifugeGajanan NalegaonkarNo ratings yet

- SWP - Lifting ContainersDocument2 pagesSWP - Lifting Containersmapulengmofokeng01No ratings yet

- Builder Hoist Erection JSA HSE ProfessionalsDocument2 pagesBuilder Hoist Erection JSA HSE ProfessionalsMAM ENERGINDONo ratings yet

- Drain Line Work JSADocument2 pagesDrain Line Work JSAm.rehanhseNo ratings yet

- Job Safety Analysis - Cone ErectionDocument6 pagesJob Safety Analysis - Cone ErectionEslam lotfy- Eslam elsadatNo ratings yet

- Job Hazard Analysis (Jha) Worksheet SPOC-433-CPF-JSA-ELEC-001Document2 pagesJob Hazard Analysis (Jha) Worksheet SPOC-433-CPF-JSA-ELEC-001asteway gonfaNo ratings yet

- Drain Line Work JSA HSE ProfessionalsDocument2 pagesDrain Line Work JSA HSE ProfessionalsSamadov 13No ratings yet

- Job Safety AnalysisDocument6 pagesJob Safety AnalysisNishar BalkavadeNo ratings yet

- Project: Job Title:Suspended Rope Platform S.No Activities Hazard Risk Control MeasuresDocument3 pagesProject: Job Title:Suspended Rope Platform S.No Activities Hazard Risk Control Measureskhaja asifuddin100% (1)

- Kaztec Fabrication Yard, Snake Island: Job Safety Analysis (JSA)Document3 pagesKaztec Fabrication Yard, Snake Island: Job Safety Analysis (JSA)Ogunwa EmmanuelNo ratings yet

- Ra - Floor Box Ins - QCSD - Rev 0Document7 pagesRa - Floor Box Ins - QCSD - Rev 0irfan vpNo ratings yet

- Job Safety Analysis (Jsa) FormDocument4 pagesJob Safety Analysis (Jsa) FormNaukhez A. KashifNo ratings yet

- JSA 48-Man Basket Lifting and MovingDocument3 pagesJSA 48-Man Basket Lifting and MovinggolusinghdataNo ratings yet

- Job Hazard Analysis (JHA) Worksheet: Jerp # 3, Aromatics Unit CompanyDocument9 pagesJob Hazard Analysis (JHA) Worksheet: Jerp # 3, Aromatics Unit CompanyTeodoro Esquillo100% (1)

- JSA-SCF (Offshore)Document2 pagesJSA-SCF (Offshore)sreekanth.gNo ratings yet

- Job Safety Analysis - Cone ErectionDocument7 pagesJob Safety Analysis - Cone ErectionMohammed MinhajNo ratings yet

- JHA HondaDocument2 pagesJHA HondaJaycee QuinNo ratings yet

- KKD-SAMUR-HSEJHA-004 JHA LIFTING Revised UPDATE 30.7.2013Document5 pagesKKD-SAMUR-HSEJHA-004 JHA LIFTING Revised UPDATE 30.7.2013Fadzli MaddyNo ratings yet

- Risk Assessment Example - BP CompanyDocument2 pagesRisk Assessment Example - BP CompanyMahmoud SaidNo ratings yet

- Job Safety Analysis (Jsa) : Country / Location: MZLN-09 Date Description of Job or Work Activity: Rig: Jsa #Document2 pagesJob Safety Analysis (Jsa) : Country / Location: MZLN-09 Date Description of Job or Work Activity: Rig: Jsa #madjid bobNo ratings yet

- Hirarc Unioil ProjectDocument3 pagesHirarc Unioil ProjectJason CuisonNo ratings yet

- 5.19.3 Job Safety Practices Installation of Anchor Bolts and RailingsDocument3 pages5.19.3 Job Safety Practices Installation of Anchor Bolts and RailingsBarkat UllahNo ratings yet

- Job Safety Analysis Work Sheet: Date Prepared D / M / YDocument4 pagesJob Safety Analysis Work Sheet: Date Prepared D / M / Ykkalvi0% (1)

- ISLA JHA Blank FormDocument1 pageISLA JHA Blank Formaasafety06No ratings yet

- Job Safety Analysis - Cement SiloDocument9 pagesJob Safety Analysis - Cement SiloMohammed Minhaj100% (1)

- JSA For Internals Installation - 2230-31Document8 pagesJSA For Internals Installation - 2230-31Khalid IrfanNo ratings yet

- JHA Align Towers & Torque All NutsDocument5 pagesJHA Align Towers & Torque All NutsGord BullNo ratings yet

- TA-Work at Heights - Cleaning of The Indoor Facilty at NACDocument7 pagesTA-Work at Heights - Cleaning of The Indoor Facilty at NACShannon MooreNo ratings yet

- Risk Assessment Lift New Sil Installation WorkDocument4 pagesRisk Assessment Lift New Sil Installation Workkristina panjaitanNo ratings yet

- Erection of Fabricated Staircase JSA HSE ProfessionalsDocument2 pagesErection of Fabricated Staircase JSA HSE ProfessionalsSamadov 13No ratings yet

- VIBRATOR - C52JSA-200 - N90 Changing Vibrator Axle - 25-12-12Document4 pagesVIBRATOR - C52JSA-200 - N90 Changing Vibrator Axle - 25-12-12hechame TamerhouletNo ratings yet

- JSA 12-Rev.02 - Pipe or Spool Erection by Using of Chain Blocks or Rope PulleyDocument3 pagesJSA 12-Rev.02 - Pipe or Spool Erection by Using of Chain Blocks or Rope PulleygolusinghdataNo ratings yet

- Assembly of Steel StructuresDocument2 pagesAssembly of Steel StructuresDelta akathehuskyNo ratings yet

- 5.19.3 Job Safety Practices Installation of Cable TrayDocument3 pages5.19.3 Job Safety Practices Installation of Cable TrayBarkat UllahNo ratings yet

- R INDIA-1Document1 pageR INDIA-1rahulNo ratings yet

- Transformer - Principle of OperationsDocument84 pagesTransformer - Principle of OperationsrahulNo ratings yet

- Motor and Drives Ebook 2023Document54 pagesMotor and Drives Ebook 2023rahulNo ratings yet

- 11 ESP in Gassy WellsDocument36 pages11 ESP in Gassy WellsrahulNo ratings yet

- MQ 024 00034Document2 pagesMQ 024 00034rahulNo ratings yet

- H17ec Apr P2022-2023Document4 pagesH17ec Apr P2022-2023rahulNo ratings yet

- Well StimulationDocument64 pagesWell StimulationrahulNo ratings yet

- CNOOC Tender DrillingServices 11 Wells 2024Document5 pagesCNOOC Tender DrillingServices 11 Wells 2024rahulNo ratings yet

- 2023 Forcetec Esp Product Group Middle EastDocument39 pages2023 Forcetec Esp Product Group Middle EastrahulNo ratings yet

- Ready To Use 101 Powerful Excel VBA Code Just Copy - Paste - Run (For Functional Users) (Anil Nahar) (Z-Library)Document152 pagesReady To Use 101 Powerful Excel VBA Code Just Copy - Paste - Run (For Functional Users) (Anil Nahar) (Z-Library)rahulNo ratings yet

- BP - ESP Troubleshooting GuidelinesDocument55 pagesBP - ESP Troubleshooting GuidelinesrahulNo ratings yet

- 08jan24 Anbunathan - 240126 - 204010Document2 pages08jan24 Anbunathan - 240126 - 204010rahulNo ratings yet

- 00 - Advanced ESP-Course OutlineDocument5 pages00 - Advanced ESP-Course OutlinerahulNo ratings yet

- Friday, Mar 31, 2023 New Delhi 19 C: Explore SearchDocument37 pagesFriday, Mar 31, 2023 New Delhi 19 C: Explore SearchrahulNo ratings yet

- Astr 2Document1 pageAstr 2rahulNo ratings yet

- Mumbai Kochi: Jqemfj CompleteDocument5 pagesMumbai Kochi: Jqemfj CompleterahulNo ratings yet

- PDO TrialDocument1 pagePDO TrialrahulNo ratings yet

- Friday, Mar 31, 2023 New Delhi 19 C: Explore SearchDocument28 pagesFriday, Mar 31, 2023 New Delhi 19 C: Explore SearchrahulNo ratings yet

- UntitledDocument1 pageUntitledrahulNo ratings yet

- As 4Document1 pageAs 4rahulNo ratings yet

- Annexure C - FCNB - Prem - Customer Consent LetterDocument2 pagesAnnexure C - FCNB - Prem - Customer Consent LetterrahulNo ratings yet

- Astro 3Document2 pagesAstro 3rahulNo ratings yet

- Travel CertificateDocument2 pagesTravel CertificaterahulNo ratings yet

- Travel ReservationDocument1 pageTravel ReservationrahulNo ratings yet

- Covishield Vaccination CertificateDocument1 pageCovishield Vaccination CertificaterahulNo ratings yet

- Informal LettersDocument1 pageInformal LettersrahulNo ratings yet

- Travel ReservationDocument1 pageTravel ReservationrahulNo ratings yet

- International Covid-19 Jagratha Page 1Document2 pagesInternational Covid-19 Jagratha Page 1rahulNo ratings yet

- Short/Regular Visit Registration Short/Regular Visit RegistrationDocument3 pagesShort/Regular Visit Registration Short/Regular Visit RegistrationrahulNo ratings yet

- International Covid-19 Jagratha Page 1Document2 pagesInternational Covid-19 Jagratha Page 1rahulNo ratings yet

- Foqus BrochureDocument24 pagesFoqus Brochureirina_gheorghe_2No ratings yet

- 65-HACCP Certification Scheme June 2012Document64 pages65-HACCP Certification Scheme June 2012Osman AitaNo ratings yet

- Hazard Identification, Risk Assessment and Risk ControlDocument4 pagesHazard Identification, Risk Assessment and Risk ControlNarayanasami Kannan0% (1)

- Project Engineer AdsDocument2 pagesProject Engineer Adsayiep1202No ratings yet

- Capture Hood User Checks and LogbookDocument4 pagesCapture Hood User Checks and Logbookmaruthi prasad KNo ratings yet

- Risk Management Prtactices of Sport CoachesDocument34 pagesRisk Management Prtactices of Sport CoachesJasmin Goot RayosNo ratings yet

- Hazard Identification of ConstructionDocument29 pagesHazard Identification of ConstructionPintu Jaiswal100% (1)

- Introduction To Industrial Security ConceptsDocument34 pagesIntroduction To Industrial Security ConceptsTricia Mae TalplacidoNo ratings yet

- At The Helm 10 PDFDocument16 pagesAt The Helm 10 PDFmfazioliNo ratings yet

- State Mining Corporation: Career OpportunitiesDocument38 pagesState Mining Corporation: Career OpportunitiesRashid BumarwaNo ratings yet

- TLE - Hazard Control and PreventionDocument9 pagesTLE - Hazard Control and Preventionmarci.alimb16No ratings yet

- Fire Safety in BuildingDocument8 pagesFire Safety in BuildingDr. Yahya Mohamad YatimNo ratings yet

- Risk Assessment For Maintenance - Ricky Smith - LceDocument4 pagesRisk Assessment For Maintenance - Ricky Smith - LceFernando AlvarezNo ratings yet

- Company ProfileDocument8 pagesCompany ProfileVictor BoatengNo ratings yet

- DNV Rules For Classification of Ships and International ConventionsDocument97 pagesDNV Rules For Classification of Ships and International ConventionsResandi SasmitaNo ratings yet

- Associate Analytics M1 Faculty GuideDocument126 pagesAssociate Analytics M1 Faculty Guidebejjanki.kumaraswamyNo ratings yet

- User Manual XG-PM Eng V2.0Document470 pagesUser Manual XG-PM Eng V2.0pham linhNo ratings yet

- Mooring - Do It Safely (2013) PDFDocument88 pagesMooring - Do It Safely (2013) PDFtyuNo ratings yet

- Monthly HSSE Inspection ChecklistDocument5 pagesMonthly HSSE Inspection ChecklistEric TNo ratings yet

- Fire Risk AssessmentDocument57 pagesFire Risk AssessmentIlvi Lian SuriNo ratings yet

- Aramco Pre-Spud ChecklistDocument3 pagesAramco Pre-Spud ChecklistCISHAC FPNo ratings yet

- LT-LT-: Satellite TracerDocument70 pagesLT-LT-: Satellite TracerMarly SalasNo ratings yet

- Fire and Earthquake SymposiumDocument2 pagesFire and Earthquake Symposiumirinakayla27No ratings yet

- Risk Assessment For Accommodation With Examples Jan 2015Document7 pagesRisk Assessment For Accommodation With Examples Jan 2015Melwin DsouzaNo ratings yet

- Risk Assessment Pc4dp-A (Draft)Document11 pagesRisk Assessment Pc4dp-A (Draft)HSE PULAI ANo ratings yet

- A Operator's Manual Beam Creel BC - ADocument23 pagesA Operator's Manual Beam Creel BC - AvikiNo ratings yet

- Machine Guarding LP PDFDocument4 pagesMachine Guarding LP PDFrexivyNo ratings yet

- Tolley's Handbook of Disaster and Emergency ManagementDocument723 pagesTolley's Handbook of Disaster and Emergency Managementasdqwe3371100% (2)

- MSDS Waterplug SdsDocument6 pagesMSDS Waterplug Sdsmovie clipNo ratings yet