Professional Documents

Culture Documents

Iq-Oq-Pq - Wet Granulator (GH-1)

Iq-Oq-Pq - Wet Granulator (GH-1)

Uploaded by

Carlos OrtizOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Iq-Oq-Pq - Wet Granulator (GH-1)

Iq-Oq-Pq - Wet Granulator (GH-1)

Uploaded by

Carlos OrtizCopyright:

Available Formats

ENCAPSULANDO LTD.

Customer : Effective Date 27/04/2021

Sheet

Revision 00 1 of 13

EQUIPMENT VALIDATION QUALIFICATION

Equipment Wet Granulator – GH-1

VALIDATION

PROTOCOL

OF

WET GRANULATOR

GH-1

Wet Granulator – GH-1

ENCAPSULANDO LTD.

Customer : Effective Date 27/04/2021

Sheet

Revision 00 2 of 13

EQUIPMENT VALIDATION QUALIFICATION

Equipment Wet Granulator – GH-1

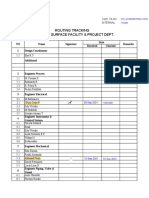

PROTOCOLS APPROVALS FOR USE

Approvals Name Designation Signature Date

Written by

Reviewed by

Client approvals

Production

Representative

Quality

Representative

DOCUMENT CONTROL AFTER APPROVAL

Original This Copy

Original Held By Copy No

Effective Date of

Issued To

Document

Issued By

Wet Granulator – GH-1

ENCAPSULANDO LTD.

Customer : Effective Date 27/04/2021

Sheet

Revision 00 3 of 13

EQUIPMENT VALIDATION QUALIFICATION

Equipment Wet Granulator – GH-1

TABLE OF CONTENTS

WET GRANULATOR – GH-1

Sr No. Content Page No.

1. Design Qualification ---------------------------------------------------------------- 06

2. Installation / Operational Verification -------------------------------------------- 07

3. Material Of Construction ---------------------------------------------------------- 11

4. Final Approval ------------------------------------------------------------------------ 12

5. Inspection cum Warranty Certificate ------------------------------------------ 13

Wet Granulator – GH-1

ENCAPSULANDO LTD.

Customer : Effective Date 27/04/2021

Sheet

Revision 00 4 of 13

EQUIPMENT VALIDATION QUALIFICATION

Equipment Wet Granulator – GH-1

EQUIPMENT NAME

GH-1

Wet Granulator

TYPE

HWGS

MODEL NO.

GH-1

M/C SERIAL NO.

2 1 0 3 0 1 3

2 1 0 3 0 1 4

2 1 0 3 0 1 5

CUSTOMER

Wet Granulator – GH-1

ENCAPSULANDO LTD.

Customer : Effective Date 27/04/2021

Sheet

Revision 00 5 of 13

EQUIPMENT VALIDATION QUALIFICATION

Equipment Wet Granulator – GH-1

Name of Equipment : Wet Granulator – GH-1

Equipments Serial no. : 2103013 , 2103014 , 2103015

Name of Customer :

Purchase Order no. :

The purpose of the document is to Qualify Wet Granulator – GH-1, M/s. ENCAPSULANDO LTD.

This document provides evidence that the Wet Granulator – GH-1 Designed, Manufactured,

Supplied, Installed and Commissioned as per the requirement of the user. This also confirms &

meets all the requirement of Product, Process, Safety, Regulatory Bodies and CGMP obligations.

Functional Area Name Signature Date

Engineering

R&D

Quality Control

Wet Granulator – GH-1

ENCAPSULANDO LTD.

Customer : Effective Date 27/04/2021

Sheet

Revision 00 6 of 13

EQUIPMENT VALIDATION QUALIFICATION

Equipment Wet Granulator – GH-1

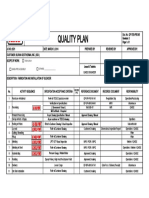

1. DESIGN QUALIFICATION

1.1 Purpose

The purpose of Design Qualification is to ensure that all the critical aspect of Product

Requirement, Process, CGMP and Safety has been considered in designing the

Equipment.

1.2 Design Specification

Sr No. Features

1. Working Capacity 20/25 Kg / Hr.- Max

2. Rotor Oscillation 0-410 / Per minute

3. Oscillation Angle 900 (Degree)

41” x 27” x 17”

4. Dimension

[L x W x H]

1.3 Principle

The unit operates on the oscillating rotor principle, compressing granules a pre-

determined size of sieve. Granules are collected in Tray.

2. INSTALLATION / OPERATIONAL VERIFICATION

Wet Granulator – GH-1

ENCAPSULANDO LTD.

Customer : Effective Date 27/04/2021

Sheet

Revision 00 7 of 13

EQUIPMENT VALIDATION QUALIFICATION

Equipment Wet Granulator – GH-1

2.1 Design Verification For Important Assembly - (Refer Manual)

Part Meet Requirements

Part No. Part Name Remarks

No. Yes / No

1 HM21064 Drive Shaft Yes

5 HM21104 Handle Yes

6 HM21170 Rotor Assembly Yes

8 HM21284 Pressure Spindle Yes

12 HM21463 Wire Mesh Yes

13 HM21254 Shaft Rear Yes

Meets Requirements : Yes/No

Remark :

Verified by : ____________________ Reviewed by : ____________________

2.2 Equipment installation operational check list

Wet Granulator – GH-1

ENCAPSULANDO LTD.

Customer : Effective Date 27/04/2021

Sheet

Revision 00 8 of 13

EQUIPMENT VALIDATION QUALIFICATION

Equipment Wet Granulator – GH-1

Meets

Sr. no. Description Specified Requirements Remarks

Yes/No

Visual Check • No physical Damage.

1.

• All Visible Parts are as per

Manual Assembly Drawing.

2. Rotor • Material Use as specified.

• Mounted with Four Blades.

• Good Finish as per GMP.

Pressure • Material use as per GMP.

3.

Spindle

• Engaged with Rotor (6).

• Fitted with Spindle nut & Handle

wheels are mounted.

4. Sieves with • Sieve size & material used as

Starching specified

Handle • Sieve is hold in slot of pipe (15)

5. Housing • Outside surface paint finish.

Drive/Rear • Inner side are with cover as per

GMP.

Wet Granulator – GH-1

ENCAPSULANDO LTD.

Customer : Effective Date 27/04/2021

Sheet

Revision 00 9 of 13

EQUIPMENT VALIDATION QUALIFICATION

Equipment Wet Granulator – GH-1

Meets

Sr. no. Description Specified Requirements Remarks

Yes/No

6. Cleaning • Loosen Hand Wheel (11).

• Rotate Hand Wheel (10)

clockwise for dislocating & Anti-

clockwise for repositioning after

cleaning.

• Loosen Ratchet pin (9) & pull-out

starching handle (5) for replacing

or cleaning wire mesh.

• Repeat The above Process (5)

7. Performance

• Ensure No Axial Movement of

Rotor.

• Sieve is not Strached too much.

• Mount Unit With Tightly Secured

with Nuts on Main Drive.

• Switch on the Drive and

Gradually Increase the speed

Rpm Max.

Wet Granulator – GH-1

ENCAPSULANDO LTD.

Customer : Effective Date 27/04/2021

Sheet

Revision 00 10 of 13

EQUIPMENT VALIDATION QUALIFICATION

Equipment Wet Granulator – GH-1

• Repeat the process as per (6)

8. Performance

with suitable size of Sieve.

• Keep collecting tray below the

Unit.

• Switch On the Unit.

• Feed moistened powder/Slug to

be granulated with required

speed.

• Clean the unit as per Point (5) at

the end of process.

Remark :

Verified by : ____________________ Reviewed by : ____________________

Wet Granulator – GH-1

ENCAPSULANDO LTD.

Customer : Effective Date 27/04/2021

Sheet

Revision 00 11 of 13

EQUIPMENT VALIDATION QUALIFICATION

Equipment Wet Granulator – GH-1

3. MATERIAL OF CONSTRUCTION / IMPORTANT /

CRITICAL PARTS

Meets

Sr No. Part Name M.O.C. Reference Requirement

Yes/No

1 Rotor S.S.316 As per specification Yes

2 Sieves S.S.316 As per specification Yes

Remark :

Verified by : ____________________ Reviewed by : ____________________

Wet Granulator – GH-1

ENCAPSULANDO LTD.

Customer : Effective Date 27/04/2021

Sheet

Revision 00 12 of 13

EQUIPMENT VALIDATION QUALIFICATION

Equipment Wet Granulator – GH-1

4. FINAL REPORT

Verified by : ____________________ Reviewed by : ____________________

Dated : ____________________ Dated : ____________________

Wet Granulator – GH-1

ENCAPSULANDO LTD.

Customer : Effective Date 27/04/2021

Sheet

Revision 00 13 of 13

EQUIPMENT VALIDATION QUALIFICATION

Equipment Wet Granulator – GH-1

INSPECTION CUM WARRANTY CERTIFICATE

Model : Wet Granulator -GH-1

Serial No. : 2103013 , 2103014 , 2103015

This is to certify that the above said equipment is inspected and tested for its relevant specification

and performance is satisfactory. We give warranty for the above said equipment for Twelve Month

from the date of dispatch to repairs/replace any defective parts because of defective material or

bad workman ship which are manufactured by US. The Electrical and Electronic parts are brought

out parts are excluded. And do not carry any warranty.

The warranty will lapse if its parts are tempered, altered by un authorized persons or not

maintained / followed in use as per our instruction, under no circumstance we under liability for

indirect loss or damage of any nature.

For, ENCAPSULANDO LTD.

(Authorized Signatory)

Wet Granulator – GH-1

You might also like

- POM Case StudyDocument2 pagesPOM Case StudysabahatfatimaNo ratings yet

- Practical Research 2 Week 3Document5 pagesPractical Research 2 Week 3Phoebe Rafunsel Sumbongan Juyad88% (25)

- MEG-PRG-NISSAN-001-100 Rev 001-Automatic Inspection Machine PDFDocument18 pagesMEG-PRG-NISSAN-001-100 Rev 001-Automatic Inspection Machine PDFMerced HernandezNo ratings yet

- Itp and Test Plan Rubber Fender Rev. 0Document5 pagesItp and Test Plan Rubber Fender Rev. 0Danu Sutanto100% (1)

- Form A1 Fertilizer LicenceDocument3 pagesForm A1 Fertilizer Licenceriyas0% (1)

- Instruction Manual - Wet Granulator (GH-1)Document9 pagesInstruction Manual - Wet Granulator (GH-1)Carlos OrtizNo ratings yet

- Method Statement For Pumps FFDocument46 pagesMethod Statement For Pumps FFriyazaliNo ratings yet

- Ilovepdf MergedDocument15 pagesIlovepdf MergedInspection VideosNo ratings yet

- Regulator ValveDocument2 pagesRegulator Valveso borathNo ratings yet

- GPE-16 Refractory Concrete Installation Procedure R. 1pdfDocument12 pagesGPE-16 Refractory Concrete Installation Procedure R. 1pdfmaupatas100% (1)

- Bog CompressorDocument7 pagesBog CompressorsswahyudiNo ratings yet

- QP-QA-05-Control of Non-Conforming ProductDocument2 pagesQP-QA-05-Control of Non-Conforming ProductDebkanta DasNo ratings yet

- QCP 23-196 Rev.1Document4 pagesQCP 23-196 Rev.1ARKA technocorpNo ratings yet

- Expansion Tank (Et) : Rabigh II Project Interconnecting Package (UO1)Document14 pagesExpansion Tank (Et) : Rabigh II Project Interconnecting Package (UO1)dodonggNo ratings yet

- QG-QSP-08 Procedure For Control of Non-Conformance Product.Document5 pagesQG-QSP-08 Procedure For Control of Non-Conformance Product.omprakash yadavNo ratings yet

- MRM - Jan-2015Document8 pagesMRM - Jan-2015RajVardhanNo ratings yet

- Acp Exa Icg Pci Qly Ps 009 Fat Procedure Rev.aDocument15 pagesAcp Exa Icg Pci Qly Ps 009 Fat Procedure Rev.aRicardo NapitupuluNo ratings yet

- Routing Tracking Operation Surface Facility & Project Dept.: 015 - JX-200238-PHG-LI-VD-21 TA-026Document8 pagesRouting Tracking Operation Surface Facility & Project Dept.: 015 - JX-200238-PHG-LI-VD-21 TA-026aurinkokelloNo ratings yet

- Iq RMG001Document30 pagesIq RMG001Dhaval ChaplaNo ratings yet

- Bgl-Pm-Qa-12 Control of Non Conforming OutputsDocument4 pagesBgl-Pm-Qa-12 Control of Non Conforming OutputsMohit SinghNo ratings yet

- SH-Testing and Commissioning of DOAS - AHU Unit-Clin 3Document24 pagesSH-Testing and Commissioning of DOAS - AHU Unit-Clin 3Ali ElHelfawyNo ratings yet

- VP-2025JV0P10147-000-P82-002 - 3 - (Actuator PAINTING PROCEDURE)Document18 pagesVP-2025JV0P10147-000-P82-002 - 3 - (Actuator PAINTING PROCEDURE)Vasilica BArbarasaNo ratings yet

- PFMEA OF ABB TankDocument12 pagesPFMEA OF ABB Tankrohit mathanker100% (3)

- Oil Skimmer Technical Submittal CZF - 028Document68 pagesOil Skimmer Technical Submittal CZF - 028muhamedNo ratings yet

- Focus Assessment FADocument2 pagesFocus Assessment FAkousick sundararajanNo ratings yet

- PMT Machines LTD Inspection and Test Plan For Bogie Frame FabricationDocument6 pagesPMT Machines LTD Inspection and Test Plan For Bogie Frame FabricationAMIT SHAHNo ratings yet

- QRM Product Transfer To Glatt GC PilotDocument5 pagesQRM Product Transfer To Glatt GC PilotMithu SarkerNo ratings yet

- Visit Report: TUV Control No.: TUV SAP No: 8115236437 (Branch: Report NoDocument4 pagesVisit Report: TUV Control No.: TUV SAP No: 8115236437 (Branch: Report NoVinay YadavNo ratings yet

- R272PFCM85 RDG Ic Pro 0007 A5Document72 pagesR272PFCM85 RDG Ic Pro 0007 A5NikhilNo ratings yet

- VG-F-46 Factory Audit Report - Rev 05Document17 pagesVG-F-46 Factory Audit Report - Rev 05navisha golayNo ratings yet

- Report IQ GV Line 2 (Ongoing)Document13 pagesReport IQ GV Line 2 (Ongoing)Anthony ProdeniantaNo ratings yet

- Preliminary Report Tgm1Document56 pagesPreliminary Report Tgm1SIAD SALIMNo ratings yet

- 545 7489 (Eag349) - PSWDocument2 pages545 7489 (Eag349) - PSWDurai NaiduNo ratings yet

- Approved By:: Calibration Procedure For Torque WrenchesDocument7 pagesApproved By:: Calibration Procedure For Torque Wrenchesvinsensius rasaNo ratings yet

- Vendor Document Review Sheet (DECAL) : J3 Program-Offsites & Utilities, Jamnagar, India Project TitleDocument6 pagesVendor Document Review Sheet (DECAL) : J3 Program-Offsites & Utilities, Jamnagar, India Project TitlenisargkedarNo ratings yet

- DRS SheetDocument2 pagesDRS SheetKarthick NatrajanNo ratings yet

- Water Flow Meter OkDocument3 pagesWater Flow Meter OkAaron Matthew BasteNo ratings yet

- Control Plan - Tie Rod 1.375'-12-2A UNFX12.78, 84B515663ADP1.Document4 pagesControl Plan - Tie Rod 1.375'-12-2A UNFX12.78, 84B515663ADP1.Himanshu MishraNo ratings yet

- Nmif 2022pip Ado CL Rfi Qir P 007Document3 pagesNmif 2022pip Ado CL Rfi Qir P 007parangkilalakitaNo ratings yet

- Quality Plan Fabrication and Installation of Silencer For BN4 & BN5Document1 pageQuality Plan Fabrication and Installation of Silencer For BN4 & BN5Aldrin HernandezNo ratings yet

- Pmi ProcedureDocument4 pagesPmi ProcedureChandrasekhar mishraNo ratings yet

- 4144 Sat Z1Document24 pages4144 Sat Z1Mohammad alahdalNo ratings yet

- The Dow Chemical Company Administrative Guideline Instrumentation G6A-0041-01 Global 15-OCT-2003 Page 1 of 2Document2 pagesThe Dow Chemical Company Administrative Guideline Instrumentation G6A-0041-01 Global 15-OCT-2003 Page 1 of 2Angelo Carlo MalabananNo ratings yet

- Comments Resolution Sheet (CRS)Document31 pagesComments Resolution Sheet (CRS)SrinivasNo ratings yet

- Fabrication of Steel Structure and Steel Equipmentitp PDF FreeDocument4 pagesFabrication of Steel Structure and Steel Equipmentitp PDF FreeAhmed GhareebNo ratings yet

- 3-23 - Painting Works Inspection and Test Plan (PL212533-SP-ETG-5231-00)Document2 pages3-23 - Painting Works Inspection and Test Plan (PL212533-SP-ETG-5231-00)Walid Amdouni100% (1)

- Nit 2800 3 PDFDocument7 pagesNit 2800 3 PDFAnonymous uXdS9Y7No ratings yet

- QSP-05 Procedure - For - Non-Conforming - ProductDocument3 pagesQSP-05 Procedure - For - Non-Conforming - Productsigmaqcs02No ratings yet

- 0503223-01-Pro-Sp-1302 Specification For Skid-Mounted Flare Knockout Drum For Tipu Processing FacilityDocument68 pages0503223-01-Pro-Sp-1302 Specification For Skid-Mounted Flare Knockout Drum For Tipu Processing FacilityAbdur RehmanNo ratings yet

- Performance Re-Qualification Blister Alu AluDocument13 pagesPerformance Re-Qualification Blister Alu AluJaswant SinghNo ratings yet

- Dye Penetrant Test Procedure HRRLDocument4 pagesDye Penetrant Test Procedure HRRLAshok TiwariNo ratings yet

- DGCA Approved Capability List (DQ-001)Document837 pagesDGCA Approved Capability List (DQ-001)Irfan FauziNo ratings yet

- DQ Ahu G01Document24 pagesDQ Ahu G01santosh yadavNo ratings yet

- WI-INSP-01 R2 Work Instruction-Pressure Vessel InspDocument8 pagesWI-INSP-01 R2 Work Instruction-Pressure Vessel InspRakesh Mishra100% (2)

- Nmif 2022pip Ado CL Rfi Qir P 009Document3 pagesNmif 2022pip Ado CL Rfi Qir P 009parangkilalakitaNo ratings yet

- MGP1 CP2 KMS Qa 6050 0003 007 Site Positive Material IdentificationDocument16 pagesMGP1 CP2 KMS Qa 6050 0003 007 Site Positive Material IdentificationKarrar TalibNo ratings yet

- Itp - HV MotorsDocument5 pagesItp - HV MotorsidontlikeebooksNo ratings yet

- Approved FQAPDocument11 pagesApproved FQAPprasadbharatibharati5No ratings yet

- Quality Management ProcedureDocument12 pagesQuality Management ProcedurePankaj KumarNo ratings yet

- Annual Product Quality Review (APQR) in Pharmaceutical ManufacturingFrom EverandAnnual Product Quality Review (APQR) in Pharmaceutical ManufacturingNo ratings yet

- Total Quality Process Control for Injection MoldingFrom EverandTotal Quality Process Control for Injection MoldingRating: 5 out of 5 stars5/5 (1)

- The Sarbanes-Oxley Section 404 Implementation Toolkit: Practice Aids for Managers and AuditorsFrom EverandThe Sarbanes-Oxley Section 404 Implementation Toolkit: Practice Aids for Managers and AuditorsNo ratings yet

- Maxam Price ListDocument2 pagesMaxam Price Listmapyk100% (1)

- Vijay ResumeDocument2 pagesVijay ResumeVijay japalaNo ratings yet

- Customer Measurement MetricsDocument59 pagesCustomer Measurement Metricsmothicy100% (1)

- HHHHHHHHHHHHHHHHHHHHDocument1 pageHHHHHHHHHHHHHHHHHHHHGh UnlockersNo ratings yet

- Robert Mondavi Case StudyDocument3 pagesRobert Mondavi Case StudyKrithika NaiduNo ratings yet

- Economics XII KVS SQP-3 MS by CUET & CBSE CoterieDocument3 pagesEconomics XII KVS SQP-3 MS by CUET & CBSE CoterieTanishkaNo ratings yet

- Annual Return Fy 2020 21Document154 pagesAnnual Return Fy 2020 21Response ExtraNo ratings yet

- CHP 7 Strategy and StructureDocument21 pagesCHP 7 Strategy and StructureBBHR20-A1 Wang Jing TingNo ratings yet

- Tenders: Tender No. Description Last Date of Buying Date of Submission Tender Price R. O THE NotesDocument2 pagesTenders: Tender No. Description Last Date of Buying Date of Submission Tender Price R. O THE NotesAli MustafaNo ratings yet

- Chapter 3: The Basic Accounting Equation and Double Entry SystemDocument3 pagesChapter 3: The Basic Accounting Equation and Double Entry SystemZwelithini MtsamaiNo ratings yet

- LLP Act.2008Document30 pagesLLP Act.2008Aman KumarNo ratings yet

- Proposed Design of A Storage Warehouse in Quezon CityDocument35 pagesProposed Design of A Storage Warehouse in Quezon CityChichi Saturinas Balasta100% (1)

- Assignment 1 Project ManagementDocument7 pagesAssignment 1 Project ManagementRihame Khodor HdedeNo ratings yet

- Sustainability Reporting and Corporate Reputation: The Moderating Effect of CEO Opportunistic BehaviorDocument28 pagesSustainability Reporting and Corporate Reputation: The Moderating Effect of CEO Opportunistic BehaviorShahin AkandaNo ratings yet

- Manufacturing Analytics Journey EbookDocument12 pagesManufacturing Analytics Journey EbookerdaltekinNo ratings yet

- UMANG - One App, Many Government ServicesDocument1 pageUMANG - One App, Many Government Servicessuraj.sNo ratings yet

- This Study Resource Was: Review of Financial Accounting Theory and PracticeDocument2 pagesThis Study Resource Was: Review of Financial Accounting Theory and PracticeKez MaxNo ratings yet

- Netflix Project EconomicsDocument5 pagesNetflix Project EconomicsNayan ChudasamaNo ratings yet

- Agile ModelDocument19 pagesAgile ModelRainNo ratings yet

- Financing Your Franchised BusinessDocument17 pagesFinancing Your Franchised BusinessDanna Marie BanayNo ratings yet

- Ergun 20 Feb 24Document10 pagesErgun 20 Feb 24GuilhermeNo ratings yet

- Benefit Structure AnalysisDocument11 pagesBenefit Structure AnalysisSandeep RainaNo ratings yet

- PAS 33 Test BankDocument4 pagesPAS 33 Test BankJake ScotNo ratings yet

- Successful Project Management Gido 6th Edition Solutions ManualDocument21 pagesSuccessful Project Management Gido 6th Edition Solutions ManualJoannFreemanwnpd100% (49)

- Addis Ababa University College of Business and Economics School of Commerce Department of Project ManagementDocument6 pagesAddis Ababa University College of Business and Economics School of Commerce Department of Project ManagementMekdes AshenafiNo ratings yet

- Aanimal Health EconomicsDocument12 pagesAanimal Health EconomicsMisaw KasyeNo ratings yet

- Soil Investigation and Topographical Works Rev ADocument5 pagesSoil Investigation and Topographical Works Rev ARiko Bin ZulkifliNo ratings yet