Professional Documents

Culture Documents

Production Department

Production Department

Uploaded by

Vinod BhaskarCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Production Department

Production Department

Uploaded by

Vinod BhaskarCopyright:

Available Formats

PRODUCTION DEPARTMENT The function of this department is very much important. This department is headed by the production Manager.

Under this unit manager, Supervisors, workers are working. The main important aspects of this department are to ensure about the quality assurance of the each product that were making at their own premises. Production is the bigger picture of various functions that affect the overall process and quality of an organizations service or manufacturing. The production management deals with processes, resource allocation, and quality to run the business day to day in an efficient and effective manner production management techniques are used in both manufacturing and service industries. The production manager are responsible for managing both physical materials doing a wonderful job to make their effort worthfulness.

OBJECTIVES OF PRODUCTION DEPARTMENT

Production is an organized activity in a manufacturing organization. Each organized activity must spell out its objectives so that its existence can be justified on the basis of the degree of attainment of these objectives. 1. The unit cast of the product should be estimated carefully and efforts should be made to stick to the cost standards. 2. The industrys production department should take utmost care in maintaining quality levels. 3. Setting of proper manufacturing quality levels. 4. Setting of proper manufacturing schedules to ensure time lines. 5. Optimum utilization of inputs of production like men, material and machines. PRODUCTION PROFILE AND ITS PROCESS. PRODUCTION MANAGER

SUPERVISOR

OTHER STAFFS

ARTISANS

The supply of cotton to the Kerala Khadi and Village Industries Association is mainly from the cotton growers co-operative Society in Pollachi and Thripura in Taminadu. This cotton is processed at KVIC Central Silver Plant at Kuttor and silver roving supplied to Khadi institutions. However, cotton for NMC ( Non Metric Charka) 50 count is processed at Avinissery silver unit of Kerala Khadi and village Industry Association for other societies, silvers are supplied by KVIC Kuttur. Association is also purchasing silvers from KVIC Kuttur directly. Silver are converted in to yarn by spinners of the association and spinners of other societies. Kerala Khadi and village industries association have a mini warping unit at Avinissery. However this unit is not able to meet the warp requirements fully chemicals for the dying unit are brought mainly from Kannur and bleaching of cloth is done in the Avinissery complex. PRODUCTION PROCESS There are two main processes in production of Khadi. They are Spinning Weaving Spinning Spinning process includes cleaning of cotton, lap making and making ravings/ silvers. These silvers are then converted in to yarn. Weaving In weaving there are two motions, primary potions and secondary motions. Primary motions include shedding, picking and beating motions are performed in successions, which are in total called as weaving. Secondary motions are let off of warp and taken up of cloth. For every insertion of the pick, the cloth length grown up. The cloth woven is wound on the cloth roller continuously or immediately to keep the fall of the cloth in constant position. This called take up of cloth. The preparatory processes chiefly employed for the warp may be classified into winding, warping, sizing and looming.

a) Winding This is the process of connecting the yarn from one packages form to other convenient package form. The object of this process is to convert the packages containing less length yarn in to packages longer length yarn. Normally for the Khadi industry, the yarn is received in the form spinning mills and converted in the form of bobbin / cone / cheese winding machines.

b) Warping In the warping process, the individual yarn form the longer length packages combined and drawn together as a sheet containing certain number of threads of definite length. The individual thread in the warp sheet is called ENO. The sheet of warp is either converted in to ball form or directly wound on to another packages called warp beam as per the next sequence of process. c) Sizing Sizing is the most important process in the preparatory sequence while weaving lave yarn is subject to more stress and strain than weft yarn. Hence yarn used in warp should have more strength than the weft. If folded yarn is used in warp, there is no necessity of sizing because folded yarn has got more strength than the single yarn. When single yarn is used in wrap, it is most to size it to make smoother, round, stronger yarn. For the khadi industry, sizing is carried in the yarn or bank or wrap sheet form. d) Looming The end from the wrap beam is either joined with old wrap by twisting I knotting of old draft is continued or it is passed through the heated and reed of the loom if the new draft is required. The operation is called Drafting and Denting respectively. Then the wrap sheet kept in proper alignment and tension between wrap beam and cloth by the process called gaiting. Now the wrap is ready in the loom for weaving.

Weaving When a fabric containing size is received at the gye house the through removal of size is essential to make the fabric easily and completely wet. During scouring and bleaching which are regular features of the processing, the size cannot be removed. The presence of size in the fabric reduces the efficiency of the subsequent purification processes and hinders the dying apart from making the material water impermeable. Hence resizing process in very important with cotton fabrics. As the dying activity is to be undertaken on a very pollution can be assessed only when the dying unit becomes operational. Processing at street weaver level Spinners get readymade silvers. This silver is converted into hanks and hanks are supplied to the society The yarn hanks are first socked in water for 2 days and stumped to remove the yellowness / impurities from the yarn. This process is repeated for few days. Some of the weavers boil the yarn in water to quicken the process of soaking. Then the yarn is dries and run on the warping machine for definite length and number of threads and sizing is done with starch outside the worksheet (street warping). The preparatory work is either done by the

weaver in the area a job work basis. The whole process takes 7 8 days. The prepared warp is then knotted (jointing). After weaving, the final product is taken to the society.

Machinery / Equipment / Loom Charka There is different type of charkas used for spinning viz 6 spindles, 8 spindles. Looms Mostly frame looms are in operation in the organization. In the case of Kuppadam, a single design box (pettu) is used. Frame loom A loom with all the required accessories kept together is a frame. Normally this loom will be place on the ground without any fittings or foundation bolt. The loom remains stable on the variety of cloth to be woven. The loom will have a rest, slay, and head to sit. In most cases the loom is used to weave coarser verities of fabric. Product Line A product line is an expression used to describe a group of closely related products. It is a part of the product strategy to determine whether an organization will have a single product or more than one product. It is a group of products that are related in the same way be being alternatives to fulfilling the same customer need by being marketed to the same target markets on through the same distribution network or by being in common price category. A product line is able to satisfy a class of need to be used together to be sold to the same customer groups, to be moved through the same distribution channels or fall within given price changes. The product line of khadi industry include Muslin Khadi, Medium Khadi, polyvastra, silk, weaving machinery, new model charka-muslin and poly thread, cane furniture, honey, soarp, oil. Types of Products The Khadi and village industry (K. V. I.) sector products a wide range of exclusive products, which are having distinct characteristics. These products are as under. (A) Khadi Handspun and hand woven khadi is very comfortable to wear compared to the artificially made synthetic fibers like Nylon, Rayon and Terylen etc. The products are cotton, woolen, silk and polyvastra khadi. Cotton khadi is 100% of cotton, which was a great demand abroad, and it is available in different shades and colours. Attractive readymade garments are being designed in the form of Kurta paijama, shirt, ghagra, choli, salvar kammis and other attractive garments.

Types of Khadi. (i) Cotton Khadi:It is one of the types of Khadi, which include 100% of cotton. Dhothies. Lungies, towels, shawls etc are included in this category. (ii) Silk Khadi :Silk khadi comes in various categories like tussar, matka etc.Silk khadi can be converted into shirting, into attractive saris with sari boarder or printed sari such as balucuchari saris, which has rich embroidery or Kanjeepuram with its intricate designs woven in silver or golden. (iii)Woolen Khadi :Woolen khadi items consisting of sweaters, mufflers, blankets and socks. (iv) Polyvastra khadi :Polyvastra hadi consisting of shirting and suiting in attractive shades and designs including dress materials and saris. (v) Muslin Khadi This type of khadi is very thin, which comes under 90s, 150s and 100s. (B) Fiber Fiber utility items are made out of sisal banana, pineapple, palm and other fibers. Some of the products include bags, table mats, wall hanging, carpets, floor mats, floor plot, holdersets. Palm fiber products like fancy bags, baskets, mats etc. are in great demand. (C) Leather Leather products range include footwear, like Kolapury chappals, sandals, shoes, purses, brief case, jewels bags, attractive readymade garments etc. (D) Cane and bamboo Fancy utility articles by using cane and bamboo as raw materials are produced in the north eastern parts of country. The items like furniture, sofa sets, partition wall, mats, handy crafts items etc. can be supplied in bulk quantity. (E) Agarbatti Incense sticks with fragrance are available in different verities, which has good demand in India and abroad. Women workers make incense sticks. In foreign country, agarbatti is used as incense in place of artificial air purifier. (F) Processed fruit products This is one of the activities taken up by the institutions and co-operative societies and financed by the commission. Products like mango pulp, juices, chatni etc are exported in large quantity. The products are covered by FPO (Food Product Organization) license.

(G) Handmade paper This is a beautiful product which was the cloth rags and waste paper as raw material for production, thus contributing in saving the trees and hence preservation of ecology. The strengths of handmade paper are as follows; Long product life (100 years or more) Uniqueness in texture Eco friendly, does not use wood pulp as raw materials and hence save trees. Convert waste into wealth, through recycling nature. Handmade paper product range from stationary items like files, letter pads, envelops, fancy bags, visiting cards, greeting cards, watermark, certificate and decoration materials, photo album etc. There is a market for this product in particular. (H) Honey Honey is natural syrup collected y honey bees. There are two types of honey produced. One by the bees produced in forest and another apiary honey produced by installing colonies of bees and maintaining this in systematic manner. Honey is also used as cough syrup, blood purifier and as a general tonic. The honey in India is costlier than in the International market. However, this can be overcome by minimizing wastage and increasing the productivity. (I) Pottery and stone wear items Clay articles produced in rural areas by potters known a prajapaties are in great demand in the country as well as abroad. In market, fancy pottery items and terra cotta are in great demand. (J) Papad and Masalaa Papad and Masala are in great demand in India and abroad. Mahila Hriha Udyog Lijjat Papad of Khadi and Village Industry, exports papd and masala to UK, USA, Gulf Countries and Newsland. (K) Herbal products K. V. I. produce a number of herbal products like herbal shampoo, tooth powder, health tonic like Chyavana prash and Churnas.

PRODUCTION UNITS The main production units are situated at Avinissery, Choorakkatukara, Erumapetty, Kadavallur, Kodakara, Mayannur, Thrikkur, Peringottukara and Thrissur.

FUNCTIONS AND RESPONSIBILITIES OF PRODUCTION MANAGER Functions The important functions of production manager are :1. Manage and control the logistic function to ensure supplies of raw-materials, finished goods, parts and accessories are available within required time frames and budgets. 2. With the planning and controlling production manager, develop, direct the implementation of production business strategies and activities to enable the production to achieve output and quality objectives. 3. With the R & D Engineering Manager, develop, direct the research and development/engineering activities to ensure products and Techniques achieve business needs within the standard. Set by the market and the regulatory standards bodies. 4. With the warehouse and Distribution Manger, develop, direct and control the workhouse and distribution activities to ensure the efficient and economical utilization of facilities for storing and distributing the finished goods. 5. The Production Manger, develops, directs the implementation of manufacturing sustainability strategies / action plans and continues improvement programs. 6. The Production Manger must also monitor operations to ensure that planned output levels, cost levels and quality objectives are met. 7. The maintain and efficiency production process with a a workforce that can readily adapt to new equipment and schedules. Responsibilities 1. Responsible for directing the production activities to ensure the current and future plans of the organization are met. 2. Report to the Managing Director on major production issues and results. 3. Participates in group corporate planning and budgeting workshop. 4. Responsible for establishing production organization structure / management process. 5. Responsible for implementation of policies or procedures throughout the production department. 6. Responsible for recruitment / selection / orientation training of seniors personnel of the production department. 7. Responsible for purchase of capital goods / production operation equipment. 8. Responsible for production planning / budgeting 9. Responsible for cost control programs. 10. Responsible for individual relation or union negotiation 11. Responsible for building maintenance 12. Assist in creation of efficient process through hands on development and training.

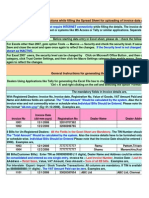

PRODUCTION DEPARTMENT STRUCTURE

CHAIRMAN VICE CHAIRMAN SECRETARY PRODUCTION MANAGER

UNIT MANAGER

SUPERVISOR WORKERS

You might also like

- System Design Data Flow Diagrams (DFD) of Job PortalDocument10 pagesSystem Design Data Flow Diagrams (DFD) of Job PortalVinod Bhaskar89% (38)

- Project On Linear Programming ProblemsDocument29 pagesProject On Linear Programming ProblemsVinod Bhaskar67% (130)

- SOP 003 - Fabric Inspection Procedure NewDocument11 pagesSOP 003 - Fabric Inspection Procedure NewSharif OmarNo ratings yet

- Summar Training ReportDocument35 pagesSummar Training ReportSuruli Ganesh100% (1)

- Traning ReportDocument80 pagesTraning ReportAmar Nath Prasad100% (1)

- ProjectDocument66 pagesProjectHarichandran KarthikeyanNo ratings yet

- Textile IndustryDocument31 pagesTextile IndustryMamta Shah88% (16)

- Biodata For MarriageDocument1 pageBiodata For MarriageVinod Bhaskar50% (2)

- Resume - Curriculum Vitae Normal SampleDocument1 pageResume - Curriculum Vitae Normal SampleVinod Bhaskar82% (11)

- Form For Claim of Balance in The Savings Bank Account of Deceased DepositorDocument2 pagesForm For Claim of Balance in The Savings Bank Account of Deceased DepositorVinod Bhaskar76% (62)

- Textile ProjectDocument38 pagesTextile Projectsathyamoorthisasu75% (4)

- Bharat Spinning Mills .PRGDocument14 pagesBharat Spinning Mills .PRGVignesh Durairaj100% (1)

- South India Spinning Mills PVT LTD Swot Analysis: StrengthsDocument5 pagesSouth India Spinning Mills PVT LTD Swot Analysis: StrengthsananthakumarNo ratings yet

- Arvind Textiles Internship Report PDFDocument107 pagesArvind Textiles Internship Report PDFOmkar Jadhav100% (1)

- Textile Internship at OCM India LTDDocument73 pagesTextile Internship at OCM India LTDHaqiqat Ali100% (4)

- Akshara Spinning MillsDocument42 pagesAkshara Spinning MillsbalaNo ratings yet

- ReportDocument45 pagesReportkokiladuraisamyNo ratings yet

- Textile Internship at OCM India LTD PDFDocument73 pagesTextile Internship at OCM India LTD PDFMohit kolliNo ratings yet

- Industrial Training FORMAT OF THE REPORTDocument26 pagesIndustrial Training FORMAT OF THE REPORT19BCO543 Rubalakshmi B100% (1)

- Project ReportDocument48 pagesProject ReportShreyas SabarinathNo ratings yet

- Objectives of The StudyDocument47 pagesObjectives of The Study12boss100% (1)

- Internship ProjectDocument25 pagesInternship ProjectMithra SubramaniamNo ratings yet

- Introduction of Coir: Coir Industry in IndiaDocument25 pagesIntroduction of Coir: Coir Industry in IndiaMithun KiruthiNo ratings yet

- Tirupur KnitwearDocument68 pagesTirupur KnitwearYuva PraveenNo ratings yet

- Final ProjectDocument77 pagesFinal ProjecttrainingandplacementNo ratings yet

- Textile Internship: BSL Suitings LTDDocument51 pagesTextile Internship: BSL Suitings LTDAnushka KhandelwalNo ratings yet

- Arvind ReportDocument17 pagesArvind Reportaneri31791100% (1)

- Impact of Logistics On Textile IndustryDocument30 pagesImpact of Logistics On Textile IndustryEminent ProjectsNo ratings yet

- Summer Training ProjectDocument50 pagesSummer Training ProjectNeha SinglaNo ratings yet

- Textile IndustryDocument70 pagesTextile Industryalkanm750No ratings yet

- Summer Training Project in Textile by Vikas HedaDocument206 pagesSummer Training Project in Textile by Vikas Hedavikasheda68% (25)

- OCM IntershipDocument69 pagesOCM IntershipArjun BhatiaNo ratings yet

- Company ProfileDocument8 pagesCompany Profileananthakumar100% (1)

- Ocm ProjectDocument59 pagesOcm ProjectAmit Mansotra80% (5)

- Insutrial Training: A Report On KG Denim Ltd. CoimbatoreDocument11 pagesInsutrial Training: A Report On KG Denim Ltd. CoimbatorePrabhakar Manoharan100% (2)

- Malabar Spinning and Weaving MillsDocument51 pagesMalabar Spinning and Weaving MillsMelvinNo ratings yet

- Coir ProjectDocument18 pagesCoir ProjectSelva KumarNo ratings yet

- Industrial Visit Report: Alok IndustriesDocument3 pagesIndustrial Visit Report: Alok IndustriesAual100% (1)

- Weaving MILL Summer Training ReportDocument41 pagesWeaving MILL Summer Training ReportArjun100% (1)

- Textile IndustryDocument37 pagesTextile IndustryArun_Shankar_K_5239No ratings yet

- Study On Employee Health, Safety and Welfare Measures at L.S Mills LimitedDocument22 pagesStudy On Employee Health, Safety and Welfare Measures at L.S Mills LimitedAnand ChristudasNo ratings yet

- Power Looms Summer Training ProjectDocument100 pagesPower Looms Summer Training ProjectSagar Virani100% (1)

- Objective of Internship: Assignment - 1Document111 pagesObjective of Internship: Assignment - 1divyagaba2150% (2)

- A Project On The Spinning Industry of India: BY Deepak Luniya Roll No: 290Document45 pagesA Project On The Spinning Industry of India: BY Deepak Luniya Roll No: 290deepakluniyaNo ratings yet

- (Head of Textile) : Submitted ToDocument77 pages(Head of Textile) : Submitted ToDivya Thakur100% (1)

- Introduction To Bombay Dyeing & Mfg. Co. Ltd.Document23 pagesIntroduction To Bombay Dyeing & Mfg. Co. Ltd.deepika2416No ratings yet

- Nithesh Final Report PDFDocument48 pagesNithesh Final Report PDFShreyas SabarinathNo ratings yet

- Nagammal MillsDocument15 pagesNagammal Millsbala krisNo ratings yet

- Literature ReviewDocument27 pagesLiterature ReviewRaja Muhammad Talha BhattiNo ratings yet

- Internship MM KnitwearDocument81 pagesInternship MM KnitwearMd. Rejaul Karim0% (1)

- Final+Report +++Raymond+Chhindwara1 1Document94 pagesFinal+Report +++Raymond+Chhindwara1 1Neeraj Kumar40% (5)

- Arvind Textile Internship Report-Final 2015Document44 pagesArvind Textile Internship Report-Final 2015Divyanshu Sagar0% (2)

- ChapterDocument47 pagesChapterThe Style ProjectNo ratings yet

- Industry ProfileDocument22 pagesIndustry ProfileVishnu Vichu0% (1)

- Os Final PDFDocument76 pagesOs Final PDFAdersh Saju ChackoNo ratings yet

- Open End SpinningDocument8 pagesOpen End SpinningVikrant Kanugonda100% (2)

- Summer Training Project of Textile Industry"manjinder Singh"Document89 pagesSummer Training Project of Textile Industry"manjinder Singh"manjinder1933% (3)

- Alok Internship ReportDocument98 pagesAlok Internship ReportShivani JayanthNo ratings yet

- The Spinning ProcessDocument4 pagesThe Spinning ProcessArslan BandukdaNo ratings yet

- Functioning of An Export House Gokaldas ExportsDocument84 pagesFunctioning of An Export House Gokaldas ExportsDeepthi Sonu100% (1)

- Moi University School of Engineering Department of Mechanical and Production EngineeringDocument8 pagesMoi University School of Engineering Department of Mechanical and Production Engineeringhr maNo ratings yet

- Chapter - 1 Introduction of The Company: The NVS GARMENT Is One of The Leading Indian Companies in The Field ofDocument71 pagesChapter - 1 Introduction of The Company: The NVS GARMENT Is One of The Leading Indian Companies in The Field ofJanani KalyanNo ratings yet

- Textile IndustryDocument25 pagesTextile IndustryArjun VishwakarmaNo ratings yet

- Textile Industry: Submitted By: Unnati PatelDocument31 pagesTextile Industry: Submitted By: Unnati Patelpalak rathoreNo ratings yet

- Fabric Fundamentals: (Industrial Visit)Document23 pagesFabric Fundamentals: (Industrial Visit)NISHTHANo ratings yet

- Roll No 5, 10, 11, 20 Case StudyDocument16 pagesRoll No 5, 10, 11, 20 Case StudyPrabhat Kiran ChaulagainNo ratings yet

- Computerised AccountingDocument4 pagesComputerised AccountingVinod Bhaskar100% (1)

- Marriage Certificate ApplicationDocument1 pageMarriage Certificate ApplicationVinod BhaskarNo ratings yet

- Keral PSC Model 100 Questions - PSC Model Question Papers in MalayalamDocument4 pagesKeral PSC Model 100 Questions - PSC Model Question Papers in MalayalamVinod Bhaskar50% (2)

- General Instructions While Filling The Spread Sheet For Uploading of Invoice Data Along With EreturnsDocument10 pagesGeneral Instructions While Filling The Spread Sheet For Uploading of Invoice Data Along With EreturnsVinod Bhaskar0% (1)

- Assignment: Strategic Financial ManagementDocument7 pagesAssignment: Strategic Financial ManagementVinod BhaskarNo ratings yet

- Nuclear and Hydel Power PlantsDocument15 pagesNuclear and Hydel Power PlantsVinod BhaskarNo ratings yet

- Microprocessor LAB MANUALDocument129 pagesMicroprocessor LAB MANUALChandrakantha K100% (2)

- Sample - Memorandum Report Memo ReportDocument6 pagesSample - Memorandum Report Memo ReportVinod BhaskarNo ratings yet

- English 2011-2012 10th (XTH)Document2 pagesEnglish 2011-2012 10th (XTH)Vinod BhaskarNo ratings yet

- English 2011-2012 10th (XTH)Document2 pagesEnglish 2011-2012 10th (XTH)Vinod BhaskarNo ratings yet

- SEMINAR REPORT On Swap Space Management For NAND Flash MemoryDocument23 pagesSEMINAR REPORT On Swap Space Management For NAND Flash MemoryVinod BhaskarNo ratings yet

- Higher Secondary Model Computerised Accounting Practical ExaminationDocument3 pagesHigher Secondary Model Computerised Accounting Practical ExaminationVinod BhaskarNo ratings yet

- RadioactivityDocument16 pagesRadioactivityVinod BhaskarNo ratings yet

- Liquid-Drop ModelDocument14 pagesLiquid-Drop ModelVinod BhaskarNo ratings yet

- States of Matter - Entrance Exam Model Question Paper 2012Document3 pagesStates of Matter - Entrance Exam Model Question Paper 2012Vinod BhaskarNo ratings yet

- General Science & Chemistry - Achievement Test July 2011 Question Paper - VIII - 7th - MalayalamDocument3 pagesGeneral Science & Chemistry - Achievement Test July 2011 Question Paper - VIII - 7th - MalayalamVinod BhaskarNo ratings yet

- Experience Certificate - SampleDocument1 pageExperience Certificate - SampleVinod Bhaskar0% (1)

- Green Revolution in IndiaDocument1 pageGreen Revolution in IndiaVinod BhaskarNo ratings yet

- Strength and Weakness of Khadi and Village IndustriesDocument3 pagesStrength and Weakness of Khadi and Village IndustriesVinod Bhaskar67% (3)

- Company Profile of Kerala Lakshmi MillsDocument11 pagesCompany Profile of Kerala Lakshmi MillsVinod Bhaskar86% (7)

- Biodata Design Mode - Sample Biodata - ResumeDocument2 pagesBiodata Design Mode - Sample Biodata - ResumeVinod Bhaskar75% (8)

- Statement of Fixation of PayDocument2 pagesStatement of Fixation of PayVinod BhaskarNo ratings yet

- Age of Industrialisation Worksheet Padhleakshay PDFDocument24 pagesAge of Industrialisation Worksheet Padhleakshay PDFGAMING beastNo ratings yet

- RevathiDocument64 pagesRevathiTom NaveenNo ratings yet

- Yarn GeometryDocument36 pagesYarn Geometryabdejoysikder1999No ratings yet

- Suitability of Natural Fibres in Geotextile Applications: IGC 2009, Guntur, INDIADocument5 pagesSuitability of Natural Fibres in Geotextile Applications: IGC 2009, Guntur, INDIASandipNo ratings yet

- Nisha SaheraDocument99 pagesNisha Saheradeepika rajNo ratings yet

- Encyclopedia of Textile Finishing PDFDocument2,777 pagesEncyclopedia of Textile Finishing PDFFERNANDO JOSE NOVAES100% (1)

- Capital and Labour in Bombay City 1928-29Document38 pagesCapital and Labour in Bombay City 1928-29Blessy AbrahamNo ratings yet

- MMDocument71 pagesMMGangadhara RaoNo ratings yet

- Yarn Manufacturing ListDocument31 pagesYarn Manufacturing Listimteaz00No ratings yet

- Yarn CountDocument7 pagesYarn CountImrul QuiesNo ratings yet

- Cotton QualityDocument13 pagesCotton QualityWaqas AkramNo ratings yet

- Yarn Manufacturing-II Lecture 1-12 Prof. DR Farooq Ahmed and Dr. Pardeep Kumar OnlineDocument113 pagesYarn Manufacturing-II Lecture 1-12 Prof. DR Farooq Ahmed and Dr. Pardeep Kumar OnlineDaniyal AhadNo ratings yet

- Cotton FibreDocument26 pagesCotton Fibrekavi RAJ SenNo ratings yet

- Tiruppur DatabaseDocument5 pagesTiruppur DatabaseGOWTHAM CHANDRUNo ratings yet

- TNPSC TopicDocument11 pagesTNPSC TopicM PraveenNo ratings yet

- International Cotton Industry Statistics, Vol. 58/2015Document28 pagesInternational Cotton Industry Statistics, Vol. 58/2015Juan Francisco Rubio JovelNo ratings yet

- Project Work On Textile IndustryDocument36 pagesProject Work On Textile Industrybabu_910% (1)

- ARI Pioneer Forging-V3Document70 pagesARI Pioneer Forging-V3Dhinakar AnnaduraiNo ratings yet

- 136USTER® TESTER 4 - Determination of The Trash and Dust Content in YarnsDocument15 pages136USTER® TESTER 4 - Determination of The Trash and Dust Content in YarnsShahrukhNo ratings yet

- 9 Influence of Spinning Processing Parameters On Yarn Cross Sectional Area PDFDocument5 pages9 Influence of Spinning Processing Parameters On Yarn Cross Sectional Area PDFsagarkanzarkarNo ratings yet

- Birla-Century Parichay InductionDocument53 pagesBirla-Century Parichay InductionMahesh KumarNo ratings yet

- Gandhi - Collected Works Vol 64Document462 pagesGandhi - Collected Works Vol 64Nrusimha ( नृसिंह )No ratings yet

- Compact SpinningDocument51 pagesCompact SpinningKathirrveluSubramainan100% (1)

- Sitara Publication ListDocument4 pagesSitara Publication Listarjmandquest0% (1)

- Training ProjectDocument89 pagesTraining ProjectChidambaram AramNo ratings yet

- Textile Ebook FreeDocument10 pagesTextile Ebook FreeMazharul IslamNo ratings yet

- Concept of High Volume Instrument (HVI) HVI Used in Bale MDocument15 pagesConcept of High Volume Instrument (HVI) HVI Used in Bale MS.m. MahasinNo ratings yet

- E CharkhaDocument4 pagesE Charkhazaya sarwarNo ratings yet

- The Gospel of SwadeshiDocument110 pagesThe Gospel of SwadeshiAvantgardens100% (1)