Professional Documents

Culture Documents

Approval Document ASSET DOC LOC 716

Approval Document ASSET DOC LOC 716

Uploaded by

fazil yoosufOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Approval Document ASSET DOC LOC 716

Approval Document ASSET DOC LOC 716

Uploaded by

fazil yoosufCopyright:

Available Formats

S IFI

AS

WJ 4072

CL

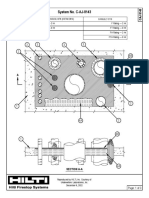

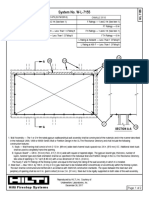

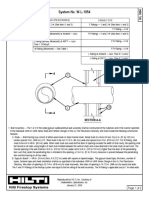

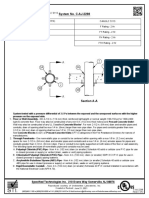

System No. W-J-4072

ED

C US

ANSI/UL1479 (ASTM E814) CAN/ULC S115

Classified by

Underwriters Laboratories, Inc. F Rating —2 Hr F Rating — 2 Hr

to UL 1479 and CAN/ULC-S115

T Rating — 0 Hr FT Rating — 0 Hr

FH Rating — 2 Hr

FTH Rating — 0 Hr

4C

1

3

2

4A

4B

SECTION A-A

1. Wall Assembly — Min 5 in. (127 mm) thick reinforced lightweight or normal weight (100-150 pcf) concrete. Wall may also be constructed of any

solid or filled UL Classified Concrete Blocks*. Max area of opening is 900 sq in. (5806 sq. cm) with max dimension of 30 in. (762 mm).

See Concrete Blocks (CAZT) category in the Fire Resistance Directory for names of manufacturers.

2. Cable Tray* — Max 24 in (610 mm) wide by 4 in. (102 mm) deep open-ladder or solid-back cable tray with channel-shaped side rails formed of

0.10 in. (2.54 mm) thick aluminum or 0.060 in. (1.52 mm) thick steel and with 1 in. (25 mm) wide by 1 in. (25 mm) deep tubular channel-shaped

rungs spaced 9 in. (229 mm) OC or a 0.029 in. (.074 mm) thick steel solid back, respectively. The annular space between the periphery of the

opening shall be min 0 in. (point contact) to max 26 in. (660 mm). Cable tray to be rigidly supported on both sides of wall assembly.

3. Cables — Aggregate cross-sectional area of cables in cable tray to be max 45 percent of the cross-sectional area of the cable tray. Any

combination of the following types and sizes of copper conductor cables may be used:

A. 1/C, 750 kcmil (or smaller) power cable with EPR insulation and polyvinyl chloride (PVC) jacket.

B. 300 pair - No. 24 AWG telephone cable with PVC insulation and jacket.

C. 24 fiber optic cable with PVC outer and subunit jacket.

D. 3/C No. 12 AWG PVC insulated steel Metal Clad+ cable with PVC insulation.

Reproduced by HILTI, Inc. Courtesy of

Underwriters Laboratories, Inc.

January 25, 2016

Hilti Firestop Systems Page: 1 of 2

WJ 4072

System No. W-J-4072

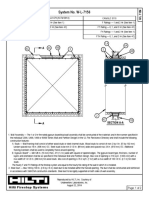

4. Firestop System — The firestop system shall consist of the following:

A. Fill, Void or Cavity Material* - Fire Blocks — Fire blocks installed with 5 in. (127 mm) dimension projecting through and centered or flush

with one surface of the wall in the opening. In concrete block walls, fire block to fill entire thickness of wall opening unless wall is solid

filled. Blocks to be firmly packed to completely fill the entire height and width of opening.

HILTI CONSTRUCTION CHEMICALS, DIV OF HILTI INC — CFS-BL Firestop Block

B. Fill Void or Cavity Materials* — Fill material to be forced into interstices of cables, between cables and cable tray and in voids between

blocks and between blocks and the periphery of the opening to the max extent possible on both surfaces of wall.

HILTI CONSTRUCTION CHEMICALS, DIV OF HILTI INC — FS-ONE Sealant, FS-ONE MAX Intumescent Sealant, CP 618 Putty Stick, CP

660 Firestop Foam or CP 620 Fire Foam

C. Wire Mesh — When the annular space exceeds 12 in. (305 mm) to the periphery above or below the cable tray, or 12 in. (305 mm)

between tray and the side of opening, a nom 2 in. (51 mm) by 2 in. (51 mm) wire fencing shall be used to keep the blocks in place. The

wire fencing shall be fabricated from min No. 16 SWG (0.060 in.) (1.52 mm) galv steel wire. The wire mesh shall begin max 2-1/2 in. (64

mm) above, below or to the sides of the cable tray and overlap min 3 in. (76 mm) beyond the periphery of the opening. Wire fencing

secured to both surfaces of the wall assembly by means of 1/4 in. (6 mm) diam by 1 in. (25 mm) long steel concrete anchors and 1/4 in. (6

mm) by 1-1/2 in. (38 mm) diam fender washers spaced max 8 in. (203 mm) OC.

C1. Wire Mesh — (As an alternative to Item 4C) - When the annular space exceeds 12 in. (305 mm) to the periphery above or below the

cable tray, or 12 in. (305 mm) between tray and the side of opening, a nom 1 in. (25 mm) hexagonal wire fencing shall be used to keep

the blocks in place. The wire fencing shall be fabricated from No. 20 SWG (0.036 in. or 0.9 mm) or heavier galv steel wire. The wire mesh

shall begin max 2-1/2 in. (64 mm) above, below or to the sides of the cable tray and overlap min 3 in. (76 mm) beyond the periphery of the

opening. Wire fencing secured to both surfaces of the wall assembly by means of 1/4 in. (6 mm) diam by 1 in. (25 mm) long steel concrete

anchors and 1/4 in. (6 mm) by 1-1/2 in. (38 mm) diam fender washers spaced max 8 in. (203 mm) OC.

C2. Steel Plate/Steel Strut System — (Not Shown)—As an alternative to wire mesh, when the annular space exceeds 12 in. (305 mm) to

the periphery above or below the cable tray, or 12 in. (305 mm) between tray and the side of opening, a min 22 MSG steel plate shall be

used to keep the blocks in place. The steel plate is attached to nom 13/16 in. (0.81 mm) deep, 12 MSG steel struts with 1/4 in. (6 mm)

diam strut nuts, spaced 8 in. (203 mm) OC. The plate shall begin max 2-1/2 in. (64 mm) above, below or to the sides of the cable tray and

overlap min 3 in. (76 mm) beyond the periphery of the opening. The struts shall be secured to both surfaces of the wall assembly by

means of 1/4 in. (6 mm) diam by 1 in. (25 mm) long steel concrete anchors with steel nuts spaced max 12 in. (305 mm) OC.

+Bearing the UL Listing Mark

* Indicates such products shall bear the UL or cUL Certification Mark for jurisdictions employing the UL or cUL Certification (such as Canada),

respectively.

Reproduced by HILTI, Inc. Courtesy of

Underwriters Laboratories, Inc.

January 25, 2016

Hilti Firestop Systems Page: 2 of 2

You might also like

- D502Document5 pagesD502Gustavo Adolfo Quintero RuizNo ratings yet

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsFrom Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsRating: 4 out of 5 stars4/5 (1)

- Blast Jet NLB CatalogueDocument102 pagesBlast Jet NLB CatalogueiansomanNo ratings yet

- Approval Document ASSET DOC LOC 709Document2 pagesApproval Document ASSET DOC LOC 709fazil yoosufNo ratings yet

- System No. C-AJ-2898Document2 pagesSystem No. C-AJ-2898darwish.hiltiNo ratings yet

- Holti System No. C-AJ-8143Document3 pagesHolti System No. C-AJ-8143S. Priscila Castillo V.No ratings yet

- Ul Fs On Max Rectangular Duct Block WallDocument2 pagesUl Fs On Max Rectangular Duct Block WallhossamNo ratings yet

- HILTI - Approval-document-ASSET-DOC-LOC-722Document1 pageHILTI - Approval-document-ASSET-DOC-LOC-722david messierNo ratings yet

- Approval Document ASSET DOC LOC 145Document2 pagesApproval Document ASSET DOC LOC 145Amir IqbalNo ratings yet

- System PDF Files - 1. UL and cUL Systems - fc2253 - DL PDFDocument2 pagesSystem PDF Files - 1. UL and cUL Systems - fc2253 - DL PDFEmanuel PastlNo ratings yet

- Caj 4107Document2 pagesCaj 4107Jorge OropezaNo ratings yet

- Fire Sealant C-AJ-4054Document1 pageFire Sealant C-AJ-4054Ezhil AnandNo ratings yet

- XHEZ.f-a-2043 - Through-Penetration Firestop Systems - UL Product IQDocument4 pagesXHEZ.f-a-2043 - Through-Penetration Firestop Systems - UL Product IQMd. Atiqul IslamNo ratings yet

- UntitledDocument2 pagesUntitledandy_ramblaNo ratings yet

- Approval Document ASSET DOC LOC 953Document2 pagesApproval Document ASSET DOC LOC 953andy_ramblaNo ratings yet

- System PDF Files - 1. UL and cUL Systems - wl7025 - DLDocument2 pagesSystem PDF Files - 1. UL and cUL Systems - wl7025 - DLEmanuel PastlNo ratings yet

- HWD0134Document2 pagesHWD0134Edwin Jalanoca LlaulliNo ratings yet

- C Aj 2586 PDFDocument1 pageC Aj 2586 PDFEmanuel PastlNo ratings yet

- System PDF Files - 1. UL and cUL Systems - Caj8113 - DLDocument4 pagesSystem PDF Files - 1. UL and cUL Systems - Caj8113 - DLEmanuel PastlNo ratings yet

- Approval Document ASSET DOC LOC 340Document2 pagesApproval Document ASSET DOC LOC 340aNo ratings yet

- Approval Document ASSET DOC LOC 939Document2 pagesApproval Document ASSET DOC LOC 939andy_ramblaNo ratings yet

- Camuffamento Antenna Pino NeroDocument12 pagesCamuffamento Antenna Pino NeroAnonymous 1aHRPIIFfINo ratings yet

- System WJ 2256Document1 pageSystem WJ 2256Manoj SamNo ratings yet

- Marine Firestop SealantDocument4 pagesMarine Firestop SealantGilberto ZamudioNo ratings yet

- System No. C-AJ-2342: F Rating - 3 HR T Rating - 0 HR W Rating - Class 1 (See Item 3B)Document2 pagesSystem No. C-AJ-2342: F Rating - 3 HR T Rating - 0 HR W Rating - Class 1 (See Item 3B)darwish.hiltiNo ratings yet

- Schedule of QuantityDocument9 pagesSchedule of Quantityexecutive engineerNo ratings yet

- Basic Info TK-U.B.I Sleeves3Document17 pagesBasic Info TK-U.B.I Sleeves3Saradhi MedapureddyNo ratings yet

- Home Members Technical Bulletins Codes & Standards Contact Us InstallationsDocument11 pagesHome Members Technical Bulletins Codes & Standards Contact Us InstallationsArshad AamirNo ratings yet

- Firestop Application Handbook (Macau) - Part-9 PDFDocument40 pagesFirestop Application Handbook (Macau) - Part-9 PDFSharoon S raoNo ratings yet

- C-AJ-2834 - Through-Penetration Firestop Systems - UL Product IqDocument3 pagesC-AJ-2834 - Through-Penetration Firestop Systems - UL Product Iqchatgpt MohitNo ratings yet

- System PDF Files - 1. UL and cUL Systems - cws0002Document2 pagesSystem PDF Files - 1. UL and cUL Systems - cws0002Emanuel Almeida PastlNo ratings yet

- Duct Bank InformationDocument19 pagesDuct Bank InformationGaneshNo ratings yet

- Er-5414 (2001)Document7 pagesEr-5414 (2001)m0172No ratings yet

- Firstop DesignDocument2 pagesFirstop DesignAmir IqbalNo ratings yet

- Trfricate Kit For 3C Cold Shrink TerminationDocument4 pagesTrfricate Kit For 3C Cold Shrink Terminationdes1982No ratings yet

- CWD1004 - Curtain Wall Design - Firestopping - STIDocument2 pagesCWD1004 - Curtain Wall Design - Firestopping - STIMDNo ratings yet

- F A 1017Document3 pagesF A 1017shama093No ratings yet

- Macalloy Cable StructuresDocument12 pagesMacalloy Cable Structuresjmcc2No ratings yet

- Stopping StuffDocument28 pagesStopping StuffaNo ratings yet

- Ontrac Wire Mesh Cable Tray System: Product Data SheetDocument6 pagesOntrac Wire Mesh Cable Tray System: Product Data SheetNithin AbrahamNo ratings yet

- BXUV.P204 Fire Resistance Ratings - ANSI/UL 263Document5 pagesBXUV.P204 Fire Resistance Ratings - ANSI/UL 263AlexNo ratings yet

- W-L-1054 Pipe Through Gyp Board AssemblyDocument2 pagesW-L-1054 Pipe Through Gyp Board AssemblyJason StelleNo ratings yet

- How To Install and Erect TrunkingDocument13 pagesHow To Install and Erect TrunkingDaniel Madulu CharlesNo ratings yet

- Technical 2Document154 pagesTechnical 2vrsub80No ratings yet

- Appendix 10 Technical SpecificationDocument71 pagesAppendix 10 Technical SpecificationMd. Abid Hossain TapuNo ratings yet

- System PDF Files - 1. UL and cUL Systems - Caj2298 - DL PDFDocument2 pagesSystem PDF Files - 1. UL and cUL Systems - Caj2298 - DL PDFEmanuel PastlNo ratings yet

- Cluster 2 Study GuideDocument17 pagesCluster 2 Study GuideShavoy RichardsonNo ratings yet

- Cable TraysDocument13 pagesCable TrayssabeerNo ratings yet

- Guard Rails For Cargo ShipDocument8 pagesGuard Rails For Cargo ShipLyudmyla Bobina100% (1)

- HDPE Pipe SpecificationsDocument2 pagesHDPE Pipe SpecificationsTonoy BanikNo ratings yet

- AEC MC007 McGill Lamp ProtectionDocument6 pagesAEC MC007 McGill Lamp ProtectionkimiesmithNo ratings yet

- Enquiry - Extranal LightDocument12 pagesEnquiry - Extranal Lightrkpatel40No ratings yet

- Electric Poles SpecificationsDocument6 pagesElectric Poles SpecificationsInderjit GhaiNo ratings yet

- Cable Glands For Armoured and Non-Armoured CablesDocument6 pagesCable Glands For Armoured and Non-Armoured CablesmustardbassmanNo ratings yet

- Schedule 40 Pipe, Galvanized: ASTM F1043 Group I-A, Federal Specification RR-F-191 Type 1, Grade A, AASHTO M-181 Grade 1Document2 pagesSchedule 40 Pipe, Galvanized: ASTM F1043 Group I-A, Federal Specification RR-F-191 Type 1, Grade A, AASHTO M-181 Grade 1Caolboy ButchNo ratings yet

- Fabrication Standard of Duct-AcDocument5 pagesFabrication Standard of Duct-AcVicky KumarNo ratings yet

- Schedule 40 PipeDocument2 pagesSchedule 40 Piperasnowmah2012No ratings yet

- Fire Stop Design 673Document4 pagesFire Stop Design 673raviNo ratings yet

- LP Solid Start I-Joists Fire Endurance GuideDocument25 pagesLP Solid Start I-Joists Fire Endurance Guidemonkey47dmbNo ratings yet

- MFJ 2990Document11 pagesMFJ 2990Arthur Gevaerd NetoNo ratings yet

- Cable Selection Guide Gtc020212Document4 pagesCable Selection Guide Gtc020212MEGA_ONENo ratings yet

- HD AFFF 3F-C6 - UL Product IqDocument10 pagesHD AFFF 3F-C6 - UL Product Iqfazil yoosufNo ratings yet

- Introduction LetterDocument1 pageIntroduction Letterfazil yoosufNo ratings yet

- Process Plant PumpDocument4 pagesProcess Plant Pumpfazil yoosufNo ratings yet

- Project Summary - FF Foam Implement FS RoadmapDocument2 pagesProject Summary - FF Foam Implement FS Roadmapfazil yoosufNo ratings yet

- C-9101 (Ex) Conventional IS Multi Sensor Issue2.02Document2 pagesC-9101 (Ex) Conventional IS Multi Sensor Issue2.02fazil yoosufNo ratings yet

- Catalogue FireStop en ScreenDocument82 pagesCatalogue FireStop en Screenfazil yoosufNo ratings yet

- FMDS0200Document181 pagesFMDS0200fazil yoosufNo ratings yet

- ReceiptDocument1 pageReceiptfazil yoosufNo ratings yet

- A6V10336866 enDocument16 pagesA6V10336866 enfazil yoosufNo ratings yet

- DI-3 Detector - Ionization Detector BanDocument1 pageDI-3 Detector - Ionization Detector Banfazil yoosufNo ratings yet

- A6V10366084 enDocument5 pagesA6V10366084 enfazil yoosufNo ratings yet

- XHEZ.C-AJ-7029 - UL Product IqDocument3 pagesXHEZ.C-AJ-7029 - UL Product Iqfazil yoosufNo ratings yet

- Helping Job Seekers 30 November 2023Document18 pagesHelping Job Seekers 30 November 2023fazil yoosufNo ratings yet

- NFPA 30 Workflow Job Aid 04 2021Document1 pageNFPA 30 Workflow Job Aid 04 2021fazil yoosufNo ratings yet

- Dau Phun Sprinkler Tyco Ty FRB Ty313ty323 Tfp172!07!2017Document4 pagesDau Phun Sprinkler Tyco Ty FRB Ty313ty323 Tfp172!07!2017fazil yoosufNo ratings yet

- Desigo Fire Safety Modular Planning PosterDocument2 pagesDesigo Fire Safety Modular Planning Posterfazil yoosufNo ratings yet

- Section-1025-Code - Luminous Egress Path MarkingDocument4 pagesSection-1025-Code - Luminous Egress Path Markingfazil yoosufNo ratings yet

- The Firetrace Fire Suppression System For Electrical Panels and Server RacksDocument10 pagesThe Firetrace Fire Suppression System For Electrical Panels and Server Racksfazil yoosufNo ratings yet

- 10 VESDA Pipe Network Design Guide A4 IE LoresDocument56 pages10 VESDA Pipe Network Design Guide A4 IE Loresfazil yoosufNo ratings yet

- B10 OSID Product Guide A4 IE LoresDocument51 pagesB10 OSID Product Guide A4 IE Loresfazil yoosufNo ratings yet

- 05 Vesda-E Ves-A00-p Product Guide A4 Ie LoresDocument123 pages05 Vesda-E Ves-A00-p Product Guide A4 Ie Loresfazil yoosuf100% (1)

- Vital Fire Detection For ODE: Johnson Controls Solutions Monitor 75,000sqm Manufacturing PlantDocument3 pagesVital Fire Detection For ODE: Johnson Controls Solutions Monitor 75,000sqm Manufacturing Plantfazil yoosufNo ratings yet

- Installation Sheet - OSID Smoke Detection System: Standard Distance From Ceiling (H) Maximum Spacing (S)Document2 pagesInstallation Sheet - OSID Smoke Detection System: Standard Distance From Ceiling (H) Maximum Spacing (S)fazil yoosufNo ratings yet

- Data Sheet: Dupont™ Fm-200® or Hfc-227Ea Agent Storage ContainersDocument2 pagesData Sheet: Dupont™ Fm-200® or Hfc-227Ea Agent Storage Containersfazil yoosufNo ratings yet

- Material Usage KPC SangattaDocument35 pagesMaterial Usage KPC SangattaDeddy PratamaNo ratings yet

- Photocatalysts Chart DiRoccoDocument1 pagePhotocatalysts Chart DiRoccoDevin FergusonNo ratings yet

- Design, Fabrication, Supply, Installation & Commissioning of Passenger Lift For ITMT Building at CREST, HosakoteDocument25 pagesDesign, Fabrication, Supply, Installation & Commissioning of Passenger Lift For ITMT Building at CREST, HosakoteAbhinav SinghNo ratings yet

- Forming ProcessesDocument8 pagesForming ProcessesKishor PatilNo ratings yet

- Coaxial DipoleDocument2 pagesCoaxial Dipolejregmalos1No ratings yet

- 5S 3M KaizenDocument111 pages5S 3M KaizenLakshit Seth100% (2)

- Pneumatic Technology: Learning Outcome Application of Pneumatic Pneumatic CircuitDocument44 pagesPneumatic Technology: Learning Outcome Application of Pneumatic Pneumatic CircuitHafiz RadzaliNo ratings yet

- STPDocument6 pagesSTPDennis ManabatNo ratings yet

- AWWA M11 - 4th Edition - Steel Pipe - A Guide For Design and Installation (PREVIEW)Document17 pagesAWWA M11 - 4th Edition - Steel Pipe - A Guide For Design and Installation (PREVIEW)vuong17% (12)

- Graduation-Project Panayiotis NicolaouDocument106 pagesGraduation-Project Panayiotis NicolaouHotib PerwiraNo ratings yet

- 1 s2.0 S0959652620348630 MainDocument15 pages1 s2.0 S0959652620348630 MainCum LaudeNo ratings yet

- Startup Time Reduction For Combined Cycle Power PlantsDocument8 pagesStartup Time Reduction For Combined Cycle Power PlantsEnrique TamayoNo ratings yet

- Cable Termination 11kV Heat Shrink TerminationDocument8 pagesCable Termination 11kV Heat Shrink TerminationmontadaaNo ratings yet

- 7 BOQ For Furnishing Work Bahadurganj BranchDocument1 page7 BOQ For Furnishing Work Bahadurganj BranchRashedNo ratings yet

- D180 CRAWLER DOZER Workshop ManualDocument261 pagesD180 CRAWLER DOZER Workshop Manualelshind100% (1)

- Autokast LTDDocument33 pagesAutokast LTDEdward WarnerNo ratings yet

- Nanodentistry and Its Applications in ProsthodonticsDocument65 pagesNanodentistry and Its Applications in ProsthodonticsNiharika Sabharwal100% (1)

- Operational Level Lesson 2 Presentation: Hazardous Materials For First Responders, 3 EdDocument29 pagesOperational Level Lesson 2 Presentation: Hazardous Materials For First Responders, 3 EdJuliano André Petry100% (1)

- Anderol 1255Document1 pageAnderol 1255Anonymous oAbjbl4HNo ratings yet

- SPM Chemistry Paper 2 ExerciseDocument16 pagesSPM Chemistry Paper 2 ExerciseMohd HaidilNo ratings yet

- Creative Recycling: ProjectsDocument5 pagesCreative Recycling: ProjectsV S MadhavanNo ratings yet

- The Story of ElectricityDocument71 pagesThe Story of ElectricityBruce KarpeNo ratings yet

- Flowsheet 800QEPU-QualistockPlus (Configuration 1 To 6) - 23-Rev009 Oct 2022Document1 pageFlowsheet 800QEPU-QualistockPlus (Configuration 1 To 6) - 23-Rev009 Oct 2022tavocelyNo ratings yet

- Threaded Rod ManufacturersDocument1 pageThreaded Rod ManufacturersBd WireNo ratings yet

- Mil STD 1537CDocument19 pagesMil STD 1537CfdcarazoNo ratings yet

- Spaulding Lighting Cordova II Spec Sheet 4-86Document2 pagesSpaulding Lighting Cordova II Spec Sheet 4-86Alan MastersNo ratings yet

- TD Propan Epoxy Cast Ec 973 2K 1Document2 pagesTD Propan Epoxy Cast Ec 973 2K 1Yogi PranataNo ratings yet

- TDS - Total Nevastane EP 220 - ENDocument1 pageTDS - Total Nevastane EP 220 - ENAnonymous AdvX6A4No ratings yet

- The Corrugated Process - Rick Duke Presentation 4-8-20Document29 pagesThe Corrugated Process - Rick Duke Presentation 4-8-20GTpianomanNo ratings yet