Professional Documents

Culture Documents

Typo 1321 N

Typo 1321 N

Uploaded by

Vikas Patel0 ratings0% found this document useful (0 votes)

5 views1 pageThis document provides information on Type 01321 globe valves and globe/check valves made of stainless steel and bronze for cryogenic applications. It lists various part numbers for valves with butt weld or socket weld connections in nominal sizes from 10mm to 150mm. The valves are approved for air, gases, and cryogenic liquefied gases including LNG at temperatures from -196C to +120C. Technical specifications are provided including materials of construction, dimensions, flow rates, and pressure ratings.

Original Description:

docs of valvecatalgoue

Original Title

Typo1321n

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document provides information on Type 01321 globe valves and globe/check valves made of stainless steel and bronze for cryogenic applications. It lists various part numbers for valves with butt weld or socket weld connections in nominal sizes from 10mm to 150mm. The valves are approved for air, gases, and cryogenic liquefied gases including LNG at temperatures from -196C to +120C. Technical specifications are provided including materials of construction, dimensions, flow rates, and pressure ratings.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

5 views1 pageTypo 1321 N

Typo 1321 N

Uploaded by

Vikas PatelThis document provides information on Type 01321 globe valves and globe/check valves made of stainless steel and bronze for cryogenic applications. It lists various part numbers for valves with butt weld or socket weld connections in nominal sizes from 10mm to 150mm. The valves are approved for air, gases, and cryogenic liquefied gases including LNG at temperatures from -196C to +120C. Technical specifications are provided including materials of construction, dimensions, flow rates, and pressure ratings.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 1

Globe Valves

Type 01321 - Globe Valve

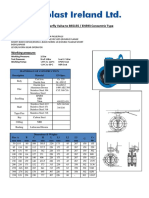

Cryogenic-Globe and Globe/Check Valves, PN50 (DN65=PN45, DN150=PN40)

Stainless steel body and bronze topwork

" live loaded " gland packing

" cleaned and degreased for oxygen service "

Part No. 01321.X.001* (H = 270mm)

Part No. 01321.X.002* (H = 370mm)

Part No. 01321.X.501* (H = 270mm) Globe/Check Valve

Part No. 01321.X.502* (H = 370mm) Globe/Check Valve

*Butt weld connection for stainless steel pipes acc. to ISO 1127 or ASTM A312

Part No. 01321.X.0014 (H = 270mm)

Part No. 01321.X.0024 (H = 370mm)

Part No. 01321.X.5014 (H = 270mm) Globe/Check Valve

Part No. 01321.X.5024 (H = 370mm) Globe/Check Valve

Socket weld connection for stainless steel pipes acc. to ISO 1127 or ASTM A312

Available options - on request only:

· Welded stainless steel stubs acc. to ISO 1127 or ASTM A312 - length FF + 200mm

· Extension H up to 900mm

· Valve with control disc (tapered design)

· Further pipe wall thicknesses

Applications:

Approved for air gases, vapours and cryogenic liquefied gases incl. LNG.

Working temperature: -196°C / -321°F (77K) up to +120°C / +248°F (393K)

Materials DIN EN ASTM

1 Body 1.4308 A 351 CF8

2 Valve seal up to DN50 PTFE / Carbon filled (25%)

2a Valve seal from DN65 PTFE

3 Disc CW614N B 283 UNS C38500

4 Bonnet gasket PTFE

5 Headpiece CC493K B 505 UNS C93200

6 Bolts 1.4301/A2 A 194 B8

7 Elongation tube 1.4541 A 213 TP 321

8 Stem 1.4301 A 276 Grade 304

9 Gland packing Graphite / PTFE

10 Gland nut CW614N B 283 UNS C38500

11 Handwheel Aluminium alloy

12 Spring CW452K B 159 UNS C51900

Type 01321 - Standard design Technical data

Nominal size DN 10 15 15 20 25 32 40 40 50 65 80 100 150

Dimension code .X. 1012 1517 1521 2026 2533 3238 4042 4048 5060 657x 8088 0114 0168

Face-to-face dimension FF 70 85 85 100 115 115 130 130 155 205 245 280 400

Height H 270mm or 370mm 320/370 320/370 370 420

Outside pipe-Ø ISO 1127 RA 12.0 17.2 21.3 26.9 33.7 38.0 42.4 48.3 60.3 76.1 88.9 114.3 168.3

Wall thickness pipe ISO 1127 a 1.0 1.6 2.0 2.0 2.0 2.0 2.0 2.0 2.0 2.9 3.2 6.0 7.1

Outside pipe-Ø ASTM A312 RA 13.72 17.15 21.34 26.67 33.40 - 42.16 48.26 60.32 73.02 88.90 114.30 168.27

Wall thickness pipe ASTM A312 a dimensions acc. to S10 or S40

Socket depth b 6 10 10 13 13 - 13 13 16 16 16 20 20

Handwheel-Ø B 100 100 100 100 100 125 125 125 125 200 250 315 360

Wrench size across flats S1 7 7 7 7 7 10 10 10 10 10 10 12 15

Wrench size across flats S2 30 30 30 30 30 36 36 36 36 36 36 41 41

Weight ca. kg 1.4 1.65 1.7 2.1 2.4 3.3 4.7 4.7 5.7 12.7 17.0 24.5 54.0

Kvs-Value m3 /h 1.6 3.8 4.3 6.7 11.5 14.0 20.6 22.6 37.1 71.1 104.0 170.0 350.0

Cv-Value gal/min 1.9 4.4 5.0 7.8 13.4 16.2 23.9 26.3 43.2 82.9 121.3 198.3 408.4

Dimensions in mm. Compliance of tightness requirements acc. to EN 1626 for DN150 up to 20 bar differential pressure. In the range of >20-40

bar, 350-700ml per second (1 bar, 20°C [68°F]) are reached.

HEROSE GMBH Phone +49 4531 509-0 Fax +49 4531 509 120 info@herose.com www.herose.com Edition 2024-01

You might also like

- PB - D-Type DecanterDocument24 pagesPB - D-Type DecanterShark1971100% (1)

- CPIC InstructionDocument4 pagesCPIC InstructionHenryNo ratings yet

- Type 01321 - Globe ValveDocument1 pageType 01321 - Globe ValveJoan ReigNo ratings yet

- Type 01262 - Bellow Sealed Globe Valve: Fire Safe ValvesDocument1 pageType 01262 - Bellow Sealed Globe Valve: Fire Safe ValvesArun BabuNo ratings yet

- HEROSEDocument9 pagesHEROSEpt tabNo ratings yet

- Typ 08417 1 enDocument1 pageTyp 08417 1 enSanthoesh srinivasanNo ratings yet

- Bola CriogenicaDocument1 pageBola CriogenicaagrovadoNo ratings yet

- Type 15082, Type 15083 - Ball Valve Full BoreDocument1 pageType 15082, Type 15083 - Ball Valve Full BoreJay Van BuurninkNo ratings yet

- BS HWC4 PN16 2Document8 pagesBS HWC4 PN16 2Norman MendozaNo ratings yet

- Butterfly Valves EgeplastDocument4 pagesButterfly Valves EgeplastdsyashankaNo ratings yet

- Rubber Expansion Joint Double Sphere (Flanged End) PN16 911-2Document2 pagesRubber Expansion Joint Double Sphere (Flanged End) PN16 911-2Ariane Joy LucasNo ratings yet

- Double Eccentric BFVDocument2 pagesDouble Eccentric BFVJhonson PintoNo ratings yet

- Tico Pipe GripsDocument4 pagesTico Pipe GripsBilel MarkosNo ratings yet

- MasterSeries 850 Specification SheetDocument2 pagesMasterSeries 850 Specification SheetFEBCONo ratings yet

- Gate Valve: Engineering AdvantageDocument4 pagesGate Valve: Engineering AdvantageAbderrazek ziedNo ratings yet

- Butterfly ValveDocument10 pagesButterfly ValvevtpsNo ratings yet

- RSERV21GTW400-Gateway J Valves S14 S15 ISODocument11 pagesRSERV21GTW400-Gateway J Valves S14 S15 ISOgfdgdfgdfNo ratings yet

- Cryogenic Bola Ac. Inox.Document2 pagesCryogenic Bola Ac. Inox.Sergio DjbucaneroNo ratings yet

- En 10241 FittingsDocument6 pagesEn 10241 FittingsDhavalNo ratings yet

- 26 HHW Katalog 2010 Eng UniversaleDocument10 pages26 HHW Katalog 2010 Eng Universalecos2012No ratings yet

- Joh. Heinr. Bornemann GMBH Postfach 1162, D-31676 Obernkirchen Phone: +49 5724 390-0 Fax +49 5724 390 290Document6 pagesJoh. Heinr. Bornemann GMBH Postfach 1162, D-31676 Obernkirchen Phone: +49 5724 390-0 Fax +49 5724 390 290vuthanhNo ratings yet

- FK 21.63 (3) GB Wedge Gate Valves: Primary CharacteristicsDocument2 pagesFK 21.63 (3) GB Wedge Gate Valves: Primary CharacteristicsNguyen KhaNo ratings yet

- Typ 01343 3 enDocument1 pageTyp 01343 3 enEntropay UserNo ratings yet

- BS5163 Cast Irton Gate Valve ISO Top PDFDocument2 pagesBS5163 Cast Irton Gate Valve ISO Top PDFhung0% (1)

- 910 21 001 PDFDocument3 pages910 21 001 PDFMatt SterlingNo ratings yet

- Process Datasheet For Relief ValveDocument3 pagesProcess Datasheet For Relief Valvemadhu8087No ratings yet

- Resilient Seat Gate ValveDocument2 pagesResilient Seat Gate Valvekhai ruleNo ratings yet

- Spur Gears 9: Series 101Document52 pagesSpur Gears 9: Series 101Aiam PandianNo ratings yet

- Series TDV Specification SheetDocument2 pagesSeries TDV Specification SheetWattsNo ratings yet

- AMRI ISORIA Broad Market Type Series Booklet DataDocument12 pagesAMRI ISORIA Broad Market Type Series Booklet Datarudiskw456No ratings yet

- 250 PSI CWP Iron Body Gate Valve: 250 PSI/17.2 Bar Non-Shock Cold Working PressureDocument1 page250 PSI CWP Iron Body Gate Valve: 250 PSI/17.2 Bar Non-Shock Cold Working PressureStephanie AdkinsNo ratings yet

- Keystone F4060 enDocument2 pagesKeystone F4060 enRezi SyahputraNo ratings yet

- XC Flanged CouplingsDocument6 pagesXC Flanged Couplingstexwan_No ratings yet

- Data Sheet For Metal Seated Gate Valves: ManufacturerDocument11 pagesData Sheet For Metal Seated Gate Valves: ManufacturerAHSAN GGCNo ratings yet

- Crane Bronze StrainerDocument1 pageCrane Bronze StrainerstephenlongislandNo ratings yet

- PVH Sight Glass Data SheetDocument11 pagesPVH Sight Glass Data SheetANIKET PATILNo ratings yet

- Liv BFV Di DFM 001Document1 pageLiv BFV Di DFM 001romel tilakNo ratings yet

- Metal Seated Gate Valve - BS5163 (Type B) : PN16 Temp 0ºC To 70ºC DN450 To DN1200Document2 pagesMetal Seated Gate Valve - BS5163 (Type B) : PN16 Temp 0ºC To 70ºC DN450 To DN1200ROHIT ARYANo ratings yet

- BS HWC4 PN25 2Document4 pagesBS HWC4 PN25 2Norman MendozaNo ratings yet

- Type 06520 - Diverter Valve: Changeover ValvesDocument1 pageType 06520 - Diverter Valve: Changeover ValvesJoan ReigNo ratings yet

- General Purpose Butterfly ValvesDocument2 pagesGeneral Purpose Butterfly Valvesphe zenNo ratings yet

- PDS03.01.001 - Dynaxe - W201Document3 pagesPDS03.01.001 - Dynaxe - W201klikkeribuskenNo ratings yet

- V-Cone Ficha TécnicaDocument2 pagesV-Cone Ficha TécnicaIrving Uc Fernandez100% (1)

- PG 43-44 Butterfly Valve PDFDocument2 pagesPG 43-44 Butterfly Valve PDFChamitha MadushanNo ratings yet

- FM451Document1 pageFM451javier perezNo ratings yet

- Knife Gate Valve: Product DescriptionDocument2 pagesKnife Gate Valve: Product Descriptionviki851No ratings yet

- ECON 3-Piece Firesafe Ball ValveDocument6 pagesECON 3-Piece Firesafe Ball ValveKunming WangNo ratings yet

- KVC Ball ValvesDocument1 pageKVC Ball ValvesAlex VarHerNo ratings yet

- Butterfly Valve Lug TypeDocument6 pagesButterfly Valve Lug TypeMr. ANo ratings yet

- Valves Bb-EDocument4 pagesValves Bb-EMindrutauCosminNo ratings yet

- Typ 01341 2 enDocument1 pageTyp 01341 2 enEntropay UserNo ratings yet

- Butterfly Valve DatasheetDocument2 pagesButterfly Valve DatasheetKanthan DevanNo ratings yet

- HEROSE Typ - 06418-2Document2 pagesHEROSE Typ - 06418-2Gaiu George Lucian100% (1)

- Howell Bunger Valve 05 HBGR Text New Cover PDFDocument4 pagesHowell Bunger Valve 05 HBGR Text New Cover PDFRoger Labra LlanoNo ratings yet

- Pin Through Shaft Concentric Butterfly Valve Series: Weather Seal Mounting FlangeDocument4 pagesPin Through Shaft Concentric Butterfly Valve Series: Weather Seal Mounting Flangeshashikanth79No ratings yet

- Valvula Borboleta Lug z614 ADocument6 pagesValvula Borboleta Lug z614 AWellington S. FrançaNo ratings yet

- Ball Valve Weight For Nutech Control ValveDocument11 pagesBall Valve Weight For Nutech Control Valveanandbhanushali1541991No ratings yet

- Dim of Pipes Flanges and FittingsDocument9 pagesDim of Pipes Flanges and FittingsArindomNo ratings yet

- Catalogo GROFE IngDocument50 pagesCatalogo GROFE IngAlvaro Antonio Cristobal AtencioNo ratings yet

- Name Sap Abap Technical Consultant & Sap Vistex Techno-Functional ConsultantDocument6 pagesName Sap Abap Technical Consultant & Sap Vistex Techno-Functional ConsultantKiran NelluruNo ratings yet

- Form Pemeriksaan Genset: PT. MNA SerangDocument3 pagesForm Pemeriksaan Genset: PT. MNA Serangmd_anwarNo ratings yet

- Computer Organization and ArchitectureDocument48 pagesComputer Organization and Architecturefreedom mutepfeNo ratings yet

- Chapter Twoo SimplexDocument34 pagesChapter Twoo SimplexAyalew Lake100% (2)

- En-Stim 4: Enraf-Nonius Enraf-NoniusDocument3 pagesEn-Stim 4: Enraf-Nonius Enraf-NoniusRudolf KerekesNo ratings yet

- ADS Sem Test1 MEMODocument7 pagesADS Sem Test1 MEMOSiphesihle HopeNo ratings yet

- Custom Menus With DescriptionDocument7 pagesCustom Menus With DescriptionPankaj AhujaNo ratings yet

- Steel NewDocument19 pagesSteel NewMark Jendel TomoNo ratings yet

- LC30 Compact Relay Controller ManualDocument6 pagesLC30 Compact Relay Controller ManualfarisazharuNo ratings yet

- Module 7 - Course Culminating Task - Susanna WalthamDocument4 pagesModule 7 - Course Culminating Task - Susanna Walthamapi-531717646No ratings yet

- NV - EulaDocument1 pageNV - EulaBia NovaisNo ratings yet

- Roland Berger Report On Key Enablers For Hydrogen in MENA 1673535736Document16 pagesRoland Berger Report On Key Enablers For Hydrogen in MENA 1673535736MohamedNo ratings yet

- ATS Sanity Check Timeline v2Document3 pagesATS Sanity Check Timeline v2Ante IvančevićNo ratings yet

- 12 Bit Angular Magnetic Encoder IC: Data Sheet Issue 9, 30 November 2021Document28 pages12 Bit Angular Magnetic Encoder IC: Data Sheet Issue 9, 30 November 2021ELAVARASANTHAMIZHNo ratings yet

- TMSP 1Document2 pagesTMSP 1Zia UddinNo ratings yet

- 101final AssignmentDocument2 pages101final AssignmenthowlerstarNo ratings yet

- Magenetic Chip Collector New 2Document27 pagesMagenetic Chip Collector New 2Hemasundar Reddy JolluNo ratings yet

- Hurricane Product Range: Air or NitrogenDocument2 pagesHurricane Product Range: Air or NitrogenY.EbadiNo ratings yet

- Asme b3017 2020 CompressDocument57 pagesAsme b3017 2020 CompressCarmen Rosa Montes MarcosNo ratings yet

- Bi OPDocument25 pagesBi OPhaifariahi02No ratings yet

- Group C Module 2 PracticalDocument10 pagesGroup C Module 2 PracticalLevi MuromboNo ratings yet

- Principles of Marketing Chapter-4Document23 pagesPrinciples of Marketing Chapter-4Mahmud AhmedNo ratings yet

- Bomba de Infusion SK-600II Guia de CalibracionDocument5 pagesBomba de Infusion SK-600II Guia de CalibracionDayanna Buenahora BocanegraNo ratings yet

- Master Thesis Ibm ZurichDocument8 pagesMaster Thesis Ibm Zurichfjfyj90y100% (2)

- Show Attend and TellDocument10 pagesShow Attend and Tellbhavishya mittalNo ratings yet

- 3GPP 23010-300Document61 pages3GPP 23010-300mzyptNo ratings yet

- SAP ABAP Interview Questions and AnswersDocument11 pagesSAP ABAP Interview Questions and AnswersSubhas Chandra SantraNo ratings yet

- Load Flow and Contingency Analysis For Transmission Line OutageDocument14 pagesLoad Flow and Contingency Analysis For Transmission Line OutageNoutouy DUANGTANo ratings yet