Professional Documents

Culture Documents

Inspection & Testing Requirements

Inspection & Testing Requirements

Uploaded by

Muhammad Rizwan0 ratings0% found this document useful (0 votes)

24 views1 pageThe document outlines inspection and testing requirements for shop-applied coatings for tanks, piping, pipelines, structures, and process equipment. It specifies that visual inspections must be performed and certificates checked by an inspector. It also requires certificates and data to be provided by the vendor or manufacturer documenting various pre-fabrication, in-process inspection and testing, application, and final inspection requirements as outlined in specifications SAES-H-001, -002, -100, and -101. Among other things, these include surface preparation, coating application atmospheric conditions, thickness readings, and holiday testing.

Original Description:

Original Title

175-091900

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document outlines inspection and testing requirements for shop-applied coatings for tanks, piping, pipelines, structures, and process equipment. It specifies that visual inspections must be performed and certificates checked by an inspector. It also requires certificates and data to be provided by the vendor or manufacturer documenting various pre-fabrication, in-process inspection and testing, application, and final inspection requirements as outlined in specifications SAES-H-001, -002, -100, and -101. Among other things, these include surface preparation, coating application atmospheric conditions, thickness readings, and holiday testing.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

24 views1 pageInspection & Testing Requirements

Inspection & Testing Requirements

Uploaded by

Muhammad RizwanThe document outlines inspection and testing requirements for shop-applied coatings for tanks, piping, pipelines, structures, and process equipment. It specifies that visual inspections must be performed and certificates checked by an inspector. It also requires certificates and data to be provided by the vendor or manufacturer documenting various pre-fabrication, in-process inspection and testing, application, and final inspection requirements as outlined in specifications SAES-H-001, -002, -100, and -101. Among other things, these include surface preparation, coating application atmospheric conditions, thickness readings, and holiday testing.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 1

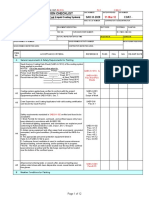

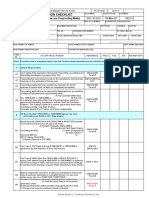

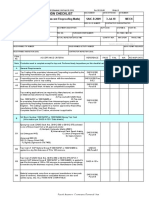

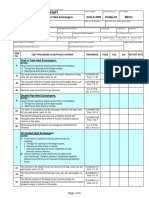

INSPECTION & TESTING REQUIREMENTS REVISION: 09/98 CODE NUMBER: PAGE

SAUDI ARAMCO FORM-175 REPLACES: 12/94 091900 1 of 1

SCOPE: COATING: SHOP APPLIED; For Tanks, Piping, Pipelines (and PURCHASE ORDER NUMBER:

Associated Appurtenances & Fittings) Structures, ,Process Equipment;

Internal & External; Onshore, Offshore and/or Subsea.

TEST and INSPECTION PER: SAES-H-001 & -002, SAES H-100 & - ITEM NUMBER(s):

101, PO Requirements and Specifications As Noted Below

(1) VISUAL INSPECTION / WITNESSING BY INSPECTOR (Note 1 & 2)

(2) CERTIFICATES / RECORDS TO BE CHECKED BY INSPECTOR (Note 1)

LINE

NO (3) CERTIFICATES / DATA TO BE PROVIDED BY VENDOR / SUPPLIER / MANUFACTURER

Pre-Fabrication / Pre-Production Requirements Specification Details / Notes:

01

02 X X Abrasive Type, Performance and Storage SAES-H-100 & SIS-05-59-00

03

In-Process Inspection & Testing Requirements

04

05 Surface Preparation: SAES-H-100.

06 I. Pre-Blast Check; See SAES-H-100 for hand brush details when/if used.

07 X a) Solvent or Detergent Cleaning before Abrasive Blast If required shall be per SAES-H-100 & SSPC-SP1.

08 X X b) Temperature & Dew Point

09 X c) Surface condition Removal of Rough Welds, cut-offs, weld spatter, and arc strikes.

10

11 II. Equipment;

Free of oil, moisture and contamination. As a minimum, t he inspector shall check

12 X X a) Compressed Air Supply Blotter Test

and approve air quality at the start, mid-point of each 8 hour shift.

13 X b) Operational ‘Deadman’ Remote Control Valve Used

14 X c) Adequate Lighting Used (If required)

15 X d) Interior Coating Personal Gear (If applicable) See SAES-H-100 for details.

16 X III. Cleaning; Spent Abrasive Removal

17 X IV. Primer on Abrasive Cleaned Surfaces

18

19 X Storage of Paints / Thinners, Dates of Manufacture, Leakage See SAES-H-100 for details.

20 X Paint & Coatings Preparation See SAES-H-100.

21

22 Paint & Coatings Application: SAES-H-100.

23 X X a) Atmospheric Conditions & Substrate Temperature

24 X b) Substrate Surface Inspection

25 X c) Stripe Coating Performed (If applicable)

26 X d) Paints filtered through a 30 to 60-mesh screen

27 X e) Continuous Agitation During Coating Process

28 X X f) Wet & Dry Film Coating Thickness’ Readings Dry Film to be checked in accordance with SSPC-PA2.

29 X g) Recoating Intervals Adhered To. Note: Contrasting colors may be required for primer, intermediate and top coats.

30

Final Inspection & Testing Requirements

31

32 “Internal/Immersion” Coatings (if applicable): Note: SAES-H-100 general requirements differ slightly for this application.

33 X a) Paint Thickness Near (2m) Anode Connections Per SAES-H-100.

34 X X b) Holiday Testing SAES-H-100: Those not Cathodically protected shall be holiday inspected.

35 X c) Repair Procedure for Immersion Coatings SAES-H-100.

36

37 X Paint Certification Review paint documentation (cert’s, data sheets,etc)

38 X Visual Inspection of Finished Coatings SAES-H-100: See specification for details of acceptance and rejection criteria.

Notes:

(1) May only be waived by the responsible Saudi Aramco, ASC, AOC Inspection Offices.

(2) 100% witnessing by Manufacturer Inspector, Random by Company Inspector unless otherwise specified by the responsible Inspection Office.

You might also like

- Gr11 Geography Learner Activities Term 1Document65 pagesGr11 Geography Learner Activities Term 1YONDELA Mbandezelo100% (2)

- SAIC-H-2032 Rev 7Document4 pagesSAIC-H-2032 Rev 7Satheesh Rama SamyNo ratings yet

- Saic H 2082Document8 pagesSaic H 2082jerin100% (1)

- Quality Control Civil InspectorDocument2 pagesQuality Control Civil InspectorNadeem91% (11)

- Review Test 6: READING (10 Marks)Document4 pagesReview Test 6: READING (10 Marks)Sebass PPNo ratings yet

- Saic H 1003Document4 pagesSaic H 1003NASIR SYEDNo ratings yet

- Saic H 2014Document2 pagesSaic H 2014Ansar Ali VemmullyNo ratings yet

- Saudi Aramco Inspection Checklist: Concrete Coatings Pre-Installation Inspection SAIC-H-1003 15-Nov-17Document2 pagesSaudi Aramco Inspection Checklist: Concrete Coatings Pre-Installation Inspection SAIC-H-1003 15-Nov-17Abdul HannanNo ratings yet

- Saudi Aramco Inspection Checklist: Concrete Coatings Pre-Installation Inspection SAIC-H-1003 1-Nov-09 CivilDocument3 pagesSaudi Aramco Inspection Checklist: Concrete Coatings Pre-Installation Inspection SAIC-H-1003 1-Nov-09 CivilWaleed MedhatNo ratings yet

- Saudi Aramco Inspection Checklist: Concrete Coatings Pre-Installation Inspection SAIC-H-1003 15-Nov-17Document8 pagesSaudi Aramco Inspection Checklist: Concrete Coatings Pre-Installation Inspection SAIC-H-1003 15-Nov-17Abdul HannanNo ratings yet

- Saic H 1003Document3 pagesSaic H 1003Anish V NairNo ratings yet

- Saudi Aramco Inspection Checklist: In-Process Inspection of Intumescent Fireproofing Mat'ls SAIC-B-2007 30-Apr-13 MechDocument4 pagesSaudi Aramco Inspection Checklist: In-Process Inspection of Intumescent Fireproofing Mat'ls SAIC-B-2007 30-Apr-13 Mechpookkoya thangalNo ratings yet

- 175 091300Document2 pages175 091300Abu Anas M.SalaheldinNo ratings yet

- Saudi Aramco Inspection Checklist: In-Process Inspection of Intumescent Fireproofing Mat'ls SAIC-B-2007 3-Jul-18 MechDocument3 pagesSaudi Aramco Inspection Checklist: In-Process Inspection of Intumescent Fireproofing Mat'ls SAIC-B-2007 3-Jul-18 Mechkarthi51289No ratings yet

- Saudi Aramco Inspection ChecklistDocument8 pagesSaudi Aramco Inspection ChecklistAnantha PadmanabhanNo ratings yet

- Saic-H-2028Document11 pagesSaic-H-2028mominNo ratings yet

- Inspection & Testing Requirements Scope:: Test and Inspection PerDocument2 pagesInspection & Testing Requirements Scope:: Test and Inspection PerAbu Anas M.SalaheldinNo ratings yet

- Liquid CoatingsDocument12 pagesLiquid CoatingsSUNIL RAJPUTNo ratings yet

- Saudi Aramco Inspection Checklist: Post-Application Insp of Intumescent Fireproofing Mat'l SAIC-B-2008 3-Jul-18 MechDocument1 pageSaudi Aramco Inspection Checklist: Post-Application Insp of Intumescent Fireproofing Mat'l SAIC-B-2008 3-Jul-18 Mechkarthi51289No ratings yet

- Saic H 1003Document3 pagesSaic H 1003Afzal HussainNo ratings yet

- Saic A 1001Document3 pagesSaic A 1001Ansar Ali VemmullyNo ratings yet

- Dfy - Coating Quality Key PointsDocument1 pageDfy - Coating Quality Key PointsMohammed SadiqNo ratings yet

- Ciclo Di Verniciatura: Proprietà TecnicheDocument9 pagesCiclo Di Verniciatura: Proprietà TecnicheMaffone NumerounoNo ratings yet

- Saic H 1003Document2 pagesSaic H 1003Hussain Nasser Al- NowiesserNo ratings yet

- Saudi Aramco Inspection ChecklistDocument6 pagesSaudi Aramco Inspection Checklistaamirapi100% (1)

- Saudi Aramco Inspection Checklist: Top Coating Application (Intumescent Fireproofing Matls) SAIC-B-2009 30-Apr-13 MechDocument5 pagesSaudi Aramco Inspection Checklist: Top Coating Application (Intumescent Fireproofing Matls) SAIC-B-2009 30-Apr-13 Mechpookkoya thangalNo ratings yet

- MST-CO-001-01 (MS For General Painting)Document9 pagesMST-CO-001-01 (MS For General Painting)Delta akathehuskyNo ratings yet

- Saudi Aramco Inspection Checklist: Post-Application Insp of Intumescent Fireproofing Mat'l SAIC-B-2008 30-Apr-13 MechDocument2 pagesSaudi Aramco Inspection Checklist: Post-Application Insp of Intumescent Fireproofing Mat'l SAIC-B-2008 30-Apr-13 Mechpookkoya thangalNo ratings yet

- Home Interior Exterior - Civil Inspector Interview Question and AnswerDocument5 pagesHome Interior Exterior - Civil Inspector Interview Question and AnswerZeeshanAliNo ratings yet

- SAIC-H-1003 Rev 7 (Final)Document4 pagesSAIC-H-1003 Rev 7 (Final)ryann mananquilNo ratings yet

- Saic-N - 2019Document3 pagesSaic-N - 2019SUNIL RAJPUTNo ratings yet

- Special-4 Instrumentation For Package UnitsDocument1 pageSpecial-4 Instrumentation For Package UnitsAbu Anas M.SalaheldinNo ratings yet

- Saudi Aramco Inspection Checklist: Top Coating Application (Intumescent Fireproofing Matls) 15-Nov-17Document5 pagesSaudi Aramco Inspection Checklist: Top Coating Application (Intumescent Fireproofing Matls) 15-Nov-17Abdul HannanNo ratings yet

- Saudi Aramco Inspection Checklist: Top Coating Application (Intumescent Fireproofing Matls) SAIC-B-2009 3-Jul-18 MechDocument5 pagesSaudi Aramco Inspection Checklist: Top Coating Application (Intumescent Fireproofing Matls) SAIC-B-2009 3-Jul-18 Mechkarthi51289No ratings yet

- Saudi Aramco Inspection Checklist: Soil Sampling, Testing and Review of Test Reports SAIC-A-1001 24-Mar-16 CivilDocument3 pagesSaudi Aramco Inspection Checklist: Soil Sampling, Testing and Review of Test Reports SAIC-A-1001 24-Mar-16 CivilSajid ShaikhNo ratings yet

- Saudi Aramco Inspection Checklist: 1-Dec-06 Mech-Post-Application Insp of Intumescent Fireproofing Mat'l SAIC-B-2008Document2 pagesSaudi Aramco Inspection Checklist: 1-Dec-06 Mech-Post-Application Insp of Intumescent Fireproofing Mat'l SAIC-B-2008ரமேஷ் பாலக்காடுNo ratings yet

- Saic D 2016Document2 pagesSaic D 2016razzak.me.enggNo ratings yet

- Saic A 1001Document2 pagesSaic A 1001pradeepthalava97No ratings yet

- Saudi Aramco Inspection Checklist: Soil Sampling, Testing and Review of Test Reports SAIC-A-1001 31-Nov-2019 CivilDocument2 pagesSaudi Aramco Inspection Checklist: Soil Sampling, Testing and Review of Test Reports SAIC-A-1001 31-Nov-2019 CivilyazNo ratings yet

- Saic D 2016Document2 pagesSaic D 2016Shahzad HussainNo ratings yet

- Saudi Aramco Inspection ChecklistDocument2 pagesSaudi Aramco Inspection Checklistkarthi51289No ratings yet

- Saic A 1001Document3 pagesSaic A 1001Rauf ChaudharyNo ratings yet

- Saic N 2029Document6 pagesSaic N 2029aamirapi100% (1)

- Saic A 1001Document3 pagesSaic A 1001ansar aliNo ratings yet

- Saudi Aramco Inspection ChecklistDocument3 pagesSaudi Aramco Inspection ChecklistZia ur RehmanNo ratings yet

- Saudi Aramco Inspection Checklist: Pre-Application Insp of Intumescent Fireproofing Mat'ls SAIC-B-2006 3-Jul-18 MechDocument3 pagesSaudi Aramco Inspection Checklist: Pre-Application Insp of Intumescent Fireproofing Mat'ls SAIC-B-2006 3-Jul-18 Mechkarthi51289No ratings yet

- Special-3 Pressure Vessel (HPLP Accumulator)Document1 pageSpecial-3 Pressure Vessel (HPLP Accumulator)Abu Anas M.SalaheldinNo ratings yet

- SAIC-A-2021 Rev 6 Pnematic Test - 3Document4 pagesSAIC-A-2021 Rev 6 Pnematic Test - 3pookkoya thangalNo ratings yet

- Saic A 1001Document3 pagesSaic A 1001QCI MYOUSIFNo ratings yet

- Saudi Aramco Inspection Checklist: Soil Sampling, Testing and Review of Test Reports SAIC-A-1001 8-Nov-15 CivilDocument3 pagesSaudi Aramco Inspection Checklist: Soil Sampling, Testing and Review of Test Reports SAIC-A-1001 8-Nov-15 CivilAhsaan MughalNo ratings yet

- Saudi Aramco Inspection Checklist: Inspection of Pneumatic Test (Strength & Service) SAIC-A-2021 3-Jul-18 MechDocument3 pagesSaudi Aramco Inspection Checklist: Inspection of Pneumatic Test (Strength & Service) SAIC-A-2021 3-Jul-18 Mechkarthi51289No ratings yet

- Saudi Aramco Inspection Checklist: Receiving Inspection of Pressure Vessels-Internal SAIC-D-2003 24-Jul-18 MechDocument4 pagesSaudi Aramco Inspection Checklist: Receiving Inspection of Pressure Vessels-Internal SAIC-D-2003 24-Jul-18 Mechnisha_khan100% (1)

- Saudi Aramco Inspection Checklist: Cast-In-Place Concrete Grade & Site Preparation SAIC-Q-1011 15-Nov-17 MAH-SA-RFI-C2626Document3 pagesSaudi Aramco Inspection Checklist: Cast-In-Place Concrete Grade & Site Preparation SAIC-Q-1011 15-Nov-17 MAH-SA-RFI-C2626Abdul HannanNo ratings yet

- Saudi Aramco Inspection ChecklistDocument4 pagesSaudi Aramco Inspection Checklistaamirapi100% (2)

- Saic H 2024Document2 pagesSaic H 2024usmanNo ratings yet

- Saic A 1001Document3 pagesSaic A 1001Tayyab KhanNo ratings yet

- Shic A 0005Document2 pagesShic A 000501095902062ahmedNo ratings yet

- Daily Check: Exterior Walkaround Inspection and ServicingDocument6 pagesDaily Check: Exterior Walkaround Inspection and ServicingDev JadhavNo ratings yet

- Saic A 1001Document3 pagesSaic A 1001Shazab NawazNo ratings yet

- SAIC-E-2009 Intrnal Cleanliness Insp of HEDocument2 pagesSAIC-E-2009 Intrnal Cleanliness Insp of HEAnonymous S9qBDVkyNo ratings yet

- Residential Asphalt Roofing Manual Design and Application Methods 2014 EditionFrom EverandResidential Asphalt Roofing Manual Design and Application Methods 2014 EditionNo ratings yet

- Mechanical Properties and Performance of Engineering Ceramics and Composites X: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesFrom EverandMechanical Properties and Performance of Engineering Ceramics and Composites X: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesDileep SinghNo ratings yet

- Tbqm-Zamil-406-Coat-010Document3 pagesTbqm-Zamil-406-Coat-010Muhammad RizwanNo ratings yet

- Mir - 914 Date Nov-26 Grit Blast Abrasive Slag Type 100 3-Ply Paper BagDocument7 pagesMir - 914 Date Nov-26 Grit Blast Abrasive Slag Type 100 3-Ply Paper BagMuhammad RizwanNo ratings yet

- Packing List # C#66238-07-St00wh-00-Fr-032937-Falcon PearlDocument1 pagePacking List # C#66238-07-St00wh-00-Fr-032937-Falcon PearlMuhammad RizwanNo ratings yet

- 04 Jan 2022Document2 pages04 Jan 2022Muhammad RizwanNo ratings yet

- MSDS Gta 220 ThinnerDocument10 pagesMSDS Gta 220 ThinnerMuhammad RizwanNo ratings yet

- Garnet Packing List #3006014419-003 With Different P.O.#Document1 pageGarnet Packing List #3006014419-003 With Different P.O.#Muhammad RizwanNo ratings yet

- 19.02.28 Test Report - QG19000646-JS Abrasives SB-Sibelco VasilgritDocument5 pages19.02.28 Test Report - QG19000646-JS Abrasives SB-Sibelco VasilgritMuhammad RizwanNo ratings yet

- Garnet Arabia Batch No. 6230-1481-C MIR NO.21-090 With Different P.O.#Document1 pageGarnet Arabia Batch No. 6230-1481-C MIR NO.21-090 With Different P.O.#Muhammad RizwanNo ratings yet

- 1656 - LNT RPM1656Document1 page1656 - LNT RPM1656Muhammad RizwanNo ratings yet

- Aug26 ConcreteWeb2Document4 pagesAug26 ConcreteWeb2Muhammad RizwanNo ratings yet

- MSDS Carboguard 893 SG Part BDocument10 pagesMSDS Carboguard 893 SG Part BMuhammad RizwanNo ratings yet

- 001Document1 page001Muhammad RizwanNo ratings yet

- MSDS Bitumastic 300M Part ADocument10 pagesMSDS Bitumastic 300M Part AMuhammad RizwanNo ratings yet

- Carbocholor 3630 Primer-HBDocument2 pagesCarbocholor 3630 Primer-HBMuhammad RizwanNo ratings yet

- Carboline 3630 HB Aluminum PDS EngDocument2 pagesCarboline 3630 HB Aluminum PDS EngMuhammad RizwanNo ratings yet

- Carbocholor 3630 FinishDocument2 pagesCarbocholor 3630 FinishMuhammad RizwanNo ratings yet

- Falcon Pearl Transmittal-38-2022Document1 pageFalcon Pearl Transmittal-38-2022Muhammad RizwanNo ratings yet

- FP Transmittal #002Document1 pageFP Transmittal #002Muhammad RizwanNo ratings yet

- Carboline 3630 Finish PDS EngDocument2 pagesCarboline 3630 Finish PDS EngMuhammad RizwanNo ratings yet

- CHOKE VALVE Data SheetDocument4 pagesCHOKE VALVE Data SheetMuhammad RizwanNo ratings yet

- Ecoblast EB70 B# EW38 (405MT)Document1 pageEcoblast EB70 B# EW38 (405MT)Muhammad RizwanNo ratings yet

- Transmittal No.7 Old Airless MachineDocument1 pageTransmittal No.7 Old Airless MachineMuhammad RizwanNo ratings yet

- IFC Drawing For Zuluf-5 Drain Line Drg. No. RB-600625, Sht. No. 001, Rev. No. 00Document3 pagesIFC Drawing For Zuluf-5 Drain Line Drg. No. RB-600625, Sht. No. 001, Rev. No. 00Muhammad RizwanNo ratings yet

- NR Hempathane 55219 Safety Red (RAL 3020) 57200 - 831050604-TDocument1 pageNR Hempathane 55219 Safety Red (RAL 3020) 57200 - 831050604-TMuhammad RizwanNo ratings yet

- CSD Response To CRM-ESR No. 4043464386 Dated Jan 07, 2021 Proposal To Apply APCS-22A On Inconel 625 (Recd Jan 10, 2021)Document4 pagesCSD Response To CRM-ESR No. 4043464386 Dated Jan 07, 2021 Proposal To Apply APCS-22A On Inconel 625 (Recd Jan 10, 2021)Muhammad RizwanNo ratings yet

- Blasted Surface Code ComparisonDocument1 pageBlasted Surface Code ComparisonMuhammad RizwanNo ratings yet

- Eb70 BBB-2020-01-14 3780. 3784, 3792 & 3795Document1 pageEb70 BBB-2020-01-14 3780. 3784, 3792 & 3795Muhammad RizwanNo ratings yet

- Eb70 BBB-2020-14-05 BBB-2020-03-06 BBB-2020-18-06 BBB-2020-01-07 BBB-2020-03-07 BBB-2020-06-07Document1 pageEb70 BBB-2020-14-05 BBB-2020-03-06 BBB-2020-18-06 BBB-2020-01-07 BBB-2020-03-07 BBB-2020-06-07Muhammad RizwanNo ratings yet

- Eb70 BBB-2020-01-27 4004 & 4008Document1 pageEb70 BBB-2020-01-27 4004 & 4008Muhammad RizwanNo ratings yet

- Eb70 BBB-2020-06-05 BBB-2020-06-08 BBB-2020-06-30 BBB-2020-07-03 2020-07-12Document1 pageEb70 BBB-2020-06-05 BBB-2020-06-08 BBB-2020-06-30 BBB-2020-07-03 2020-07-12Muhammad RizwanNo ratings yet

- Study Guide - of MomentumDocument2 pagesStudy Guide - of Momentumyue gaoNo ratings yet

- Experiment 5 (Calibration of Pressure Measuring Devices - A4)Document17 pagesExperiment 5 (Calibration of Pressure Measuring Devices - A4)Jamiel Catapang100% (1)

- Design Inset-Fed Microstrip Patch Antennas PDFDocument8 pagesDesign Inset-Fed Microstrip Patch Antennas PDFsorinproiecteNo ratings yet

- Chapter 1 The Nature of The Economic ProblemDocument6 pagesChapter 1 The Nature of The Economic ProblemWeirdoNo ratings yet

- Swot Analysis: S W O TDocument17 pagesSwot Analysis: S W O TPratham TadasareNo ratings yet

- Domain 3 - Diversity of Learners: Learning Task 4: The Learners' Strengths, Needs, and Interest Learning ActivitiesDocument4 pagesDomain 3 - Diversity of Learners: Learning Task 4: The Learners' Strengths, Needs, and Interest Learning ActivitiesAlondra SambajonNo ratings yet

- Iso 14122 2 2016Document11 pagesIso 14122 2 2016FengGuang LuNo ratings yet

- RicohDocument2 pagesRicohJuan HurtadoNo ratings yet

- CLASA 7 - Subiecte Si BaremDocument4 pagesCLASA 7 - Subiecte Si Baremmira sanduNo ratings yet

- (T. Mandiri & T. Presentasi) (PerPan I C-TM4310) Genap 2021-2022Document2 pages(T. Mandiri & T. Presentasi) (PerPan I C-TM4310) Genap 2021-2022Ari Meliasta Ginting04No ratings yet

- Schools Division Office of Cagayan OfficialsDocument1 pageSchools Division Office of Cagayan OfficialsMARY ANN QUIZZAGANNo ratings yet

- Güntürkün, Bugnyar (2016) Cognition Without CortexDocument13 pagesGüntürkün, Bugnyar (2016) Cognition Without CortexMak PavičevićNo ratings yet

- How To Solve A Rubik's Cube, Step by Step - WIREDDocument18 pagesHow To Solve A Rubik's Cube, Step by Step - WIREDt_rajith1179No ratings yet

- Catching The Sun Aa v13 I1Document4 pagesCatching The Sun Aa v13 I1Julio NoseNo ratings yet

- Admission22 23 UGInformationBrochureDocument46 pagesAdmission22 23 UGInformationBrochureTejas KannampuzhaNo ratings yet

- Activities CompletedDocument4 pagesActivities Completedウィリアムズ アンディNo ratings yet

- Syllabus Scheme: MATS University RaipurDocument16 pagesSyllabus Scheme: MATS University RaipurHarsh SahuNo ratings yet

- The Book of Enoch and New MoonDocument7 pagesThe Book of Enoch and New MoonGavin BeckerNo ratings yet

- COVID-19, Communication and Culture - Beyond The Global WorkplaceDocument277 pagesCOVID-19, Communication and Culture - Beyond The Global WorkplaceEvelyn PuycanNo ratings yet

- Module Introduction:: 1.5 HoursDocument5 pagesModule Introduction:: 1.5 HoursJessie TindoyNo ratings yet

- Charging Lithium Batteries Using Lead Acid ChargersDocument2 pagesCharging Lithium Batteries Using Lead Acid Chargersحسن علی کاشمیریNo ratings yet

- #740 Lot.85870 EinsertDocument5 pages#740 Lot.85870 Einsertjnyng222No ratings yet

- Class 12 Going Places SDC NotesDocument36 pagesClass 12 Going Places SDC NotesAndree SrivastavaNo ratings yet

- Simulation of Charged Particles in Earths MagnetoDocument7 pagesSimulation of Charged Particles in Earths Magnetoeze_firmatenseNo ratings yet

- Video 1Document9 pagesVideo 1Siti Hajar AjaNo ratings yet

- Distribution of Chalcophile and Platinum-Group EleDocument19 pagesDistribution of Chalcophile and Platinum-Group EleMarcio AlbuquerqueNo ratings yet

- Predicting Condensate Collection From HVAC Air Handling UnitsDocument14 pagesPredicting Condensate Collection From HVAC Air Handling UnitsAhamed Saleel CNo ratings yet

- Universitas Pamulang: (Unpam)Document2 pagesUniversitas Pamulang: (Unpam)Elin EvangelineayuNo ratings yet