Professional Documents

Culture Documents

KRTB LFLP71.32

KRTB LFLP71.32

Uploaded by

Ranadheer BOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

KRTB LFLP71.32

KRTB LFLP71.32

Uploaded by

Ranadheer BCopyright:

Available Formats

www.osram-os.

com

Produktdatenblatt | Version 1.1

KRTB LFLP71.32

KRTB LFLP71.32

DISPLIX ® P2828

This device is especially designed for full color video

walls. The 6-lead technology allows for an additive

mixture of color stimuli by independent driving of

each chip. Very compact package size fits best for

high resolution narrow pitch video walls.

Applications

—Video Walls Signage

Features:

—Chip technology: InGaAlP / InGaN on Sapphire

—Typ. Radiation: 120°

—Color: λdom = 622 nm (● red); λdom = 528 nm (● true green); λdom = 472 nm (● blue)

—ESD: 500V acc. to ANSI/ESDA/JEDEC JS-001 (HBM, Class 1B)

1 Version 1.1 | 2021-12-06

KRTB LFLP71.32

Ordering Information

Type Brightness 1) Ordering Code

KRTBLFLP71.32-UVUZ-GP+VYAU-JS+SVSZ-SZ Q65112A9639

● red ● Iv = 529 ... 900 mcd (IF = 15 mA) Q65112A9639

● true green ● Iv = 1000 ... 1692 mcd (IF = 10 mA) Q65112A9639

● blue ● Iv = 212 ... 355 mcd (IF = 10 mA) Q65112A9639

2 Version 1.1 | 2021-12-06

KRTB LFLP71.32

Maximum Ratings

Parameter Symbol Values Values Values

● red ● true green ● blue

Operating Temperature Top min. -40 °C -40 °C -40 °C

max. 85 °C 85 °C 85 °C

Storage Temperature Tstg min. -40 °C -40 °C -40 °C

max. 100 °C 100 °C 100 °C

Junction Temperature Tj max. 110 °C 110 °C 110 °C

Forward Current IF max. 20 mA 20 mA 20 mA

TS = 25 °C

Forward Current pulsed IF pulse max. 40 mA 40 mA 40 mA

D = 0.125 ; TS = 25 °C

Reverse voltage 2) VR max. 5V 5V 5V

TS = 25 °C

ESD withstand voltage VESD 500 V 500 V 500 V

acc. to ANSI/ESDA/JEDEC JS-001

(HBM, Class 1B)

3 Version 1.1 | 2021-12-06

KRTB LFLP71.32

Characteristics

IF = 15 mA (red chip); IF = 10 mA (true green and blue chip); TS = 25 °C

Parameter Symbol Values Values Values

● red ● true green ● blue

Peak Wavelength λpeak typ. 629 nm 518 nm 467 nm

Dominant Wavelength 3) λdom min. 618 nm 524 nm 470 nm

typ. 622 nm 528 nm 472 nm

max. 625 nm 532 nm 476 nm

Viewing angle at 50% IV 2φ typ. 110 ° 110 ° 110 °

Forward Voltage 4) VF min. 1.60 V 2.30 V 2.40 V

IF = 15 mA (red chip); IF = 10 mA (true typ. 2.10 V 2.50 V 2.75 V

green and blue chip); TS = 25 °C max. 2.60 V 3.50 V 3.30 V

Reverse current 2) IR typ. 0.01 µA 0.01 µA 0.01 µA

VR = 10 V max. 1 µA 1 µA 1 µA

Real thermal resistance junction/sol- RthJS real typ. 230 K / W 300 K / W 250 K / W

derpoint 5) max. 270 K / W 350 K / W 310 K / W

Remark Reverse Current:

This product is intended to be operated applying a forward current within the specified range. Applying any continuous reverse

bias or forward bias below the voltage range of light emission shall be avoided because it may cause migration which can

change the electro-optical characteristics or damage the LED.

4 Version 1.1 | 2021-12-06

KRTB LFLP71.32

Brightness Groups

● red

Group Luminous Intensity 1) Luminous Intensity 1)

IF = 15 mA IF = 15 mA

min. max.

Iv Iv

UV 529 mcd 710 mcd

UW 560 mcd 754 mcd

UX 594 mcd 800 mcd

UY 630 mcd 849 mcd

UZ 669 mcd 900 mcd

Brightness Groups

● true green

Group Luminous Intensity 1) Luminous Intensity 1)

IF = 10 mA IF = 10 mA

min. max.

Iv Iv

VY 1000 mcd 1323 mcd

VZ 1058 mcd 1400 mcd

AS 1120 mcd 1492 mcd

AT 1183 mcd 1590 mcd

AU 1250 mcd 1692 mcd

5 Version 1.1 | 2021-12-06

KRTB LFLP71.32

Brightness Groups

● blue

Group Luminous Intensity 1) Luminous Intensity 1)

IF = 10 mA IF = 10 mA

min. max.

Iv Iv

SV 212 mcd 280 mcd

SW 224 mcd 297 mcd

SX 237 mcd 315 mcd

SY 250 mcd 334 mcd

SZ 265 mcd 355 mcd

6 Version 1.1 | 2021-12-06

KRTB LFLP71.32

Wavelength Groups

● red

Group Dominant Wavelength 3) Dominant Wavelength 3)

min. max.

λdom λdom

GP 618 nm 625 nm

Wavelength Groups

● true green

Group Dominant Wavelength 3) Dominant Wavelength 3)

min. max.

λdom λdom

JP 524 nm 529 nm

MS 527 nm 532 nm

Wavelength Groups

● blue

Group Dominant Wavelength 3) Dominant Wavelength 3)

min. max.

λdom λdom

SW 470 nm 474 nm

UZ 472 nm 476 nm

7 Version 1.1 | 2021-12-06

KRTB LFLP71.32

Chromaticity Coordinate Groups

JP

MS

550 nm

500 nm

600 nm

GP

700 -

750 nm

UZ

SW

400 -

380 nm

8 Version 1.1 | 2021-12-06

KRTB LFLP71.32

Chromaticity Coordinate Groups

● red

Group Cx Cy

GP 0.6703 0.3136

0.6873 0.3126

0.7006 0.2993

0.6822 0.3010

Chromaticity Coordinate Groups

● true green

Group Cx Cy

JP 0.1515 0.7300

0.1203 0.7979

0.1563 0.7861

0.1805 0.7240

MS 0.1691 0.7267

0.1423 0.7908

0.1763 0.7794

0.1968 0.7210

Chromaticity Coordinate Groups

● blue

Group Cx Cy

SW

0.1363

0.1258

0.0738

0.0600

0.1159 0.0834

0.1276 0.0969

UZ 0.1327 0.0851

0.1211 0.0708

0.1099 0.0983

0.1222 0.1112

9 Version 1.1 | 2021-12-06

KRTB LFLP71.32

Relative Spectral Emission 6)

Irel = f (λ); IF = 15 mA; TS = 25 °C

KRTB LFLP71.32

1.0

Irel

: Vλ

: red

: true green

0.8

: blue

0.6

0.4

0.2

0.0

350 400 450 500 550 600 650 700 750 800

λ / nm

10 Version 1.1 | 2021-12-06

KRTB LFLP71.32

Radiation Characteristic (horizontal) 6)

Irel = f (ϕ); TS = 25 °C

1.0

Irel

0.8

0.6

0.4

0.2

0.0

-100 -80 -60 -40 -20 0 20 40 60 80 100

ϕ/°

Radiation Characteristic (vertical) 6)

Irel = f (ϕ); TS = 25 °C

KRTB LFLP71.32

1.0

Irel

: red

: true green

: blue

0.8

0.6

0.4

0.2

0.0

-100 -80 -60 -40 -20 0 20 40 60 80 100

ϕ/°

11 Version 1.1 | 2021-12-06

KRTB LFLP71.32

Forward current 6) Forward current 6)

IF = f(VF); TS = 25 °C IF = f(VF); TS = 25 °C

KRTB LFLP71.32 KRTB LFLP71.32

40 40

IF / mA IF / mA

: red : true green

30 30

20 20

10 10

0 0

1,4 1,6 1,8 2,0 2,2 2,42,5 1,9 2,2 2,4 2,6 2,8 3,0 3,2

VF / V VF / V

Forward current 6)

IF = f(VF); TS = 25 °C

KRTB LFLP71.32

40

IF / mA

: blue

30

20

10

0

2,2 2,4 2,6 2,8 3,0 3,2 3,4

VF / V

12 Version 1.1 | 2021-12-06

KRTB LFLP71.32

Relative Luminous Intensity 6), 7) Relative Luminous Intensity 6), 7)

Iv/Iv(15 mA) = f(IF); TS = 25 °C Iv/Iv(10 mA) = f(IF); TS = 25 °C

KRTB LFLP71.32

IV IV

KRTB LFLP71.32

3.0

IV(15mA) : red

IV(10mA)

2.5 : true green

2.5

2.0

2.0

1.5

1.5

1.0

1.0

0.5

0.5

0.0

0.0

1

5

10

15

20

25

30

35

40

00

0

5

10

15

20

25

30

35

40

0.

IF / mA IF / mA

Relative Luminous Intensity 6), 7)

Iv/Iv(10 mA) = f(IF); TS = 25 °C

KRTB LFLP71.32

IV

IV(10mA) 3.0 : blue

2.5

2.0

1.5

1.0

0.5

0.0

0

5

10

15

20

25

30

35

40

IF / mA

13 Version 1.1 | 2021-12-06

KRTB LFLP71.32

Dominant Wavelength 6) Dominant Wavelength 6)

λdom = f(IF); TS = 25 °C λdom = f(IF); TS = 25 °C

KRTB LFLP71.32 KRTB LFLP71.32

λ dom / nm λ dom / nm

532 : true green : blue

474

530

528 473

526

472

524

471

522

520 470

518

469

10

15

20

25

30

35

40

0

10

15

20

25

30

35

40

IF / mA IF / mA

14 Version 1.1 | 2021-12-06

KRTB LFLP71.32

Forward Voltage 6) Forward Voltage 6)

ΔVF = VF - VF(25 °C) = f(Tj); IF = 15 mA ΔVF = VF - VF(25 °C) = f(Tj); IF = 10 mA

KRTB LFLP71.32 KRTB LFLP71.32

0,3 0.25

∆VF / V ∆VF / V

: red : true green

0.20

0,2

0.15

0,1 0.10

0.05

0,0

0.00

-0,1 -0.05

-0.10

-0,2

-40 -20 0 20 40 60 80 100 -40 -20 0 20 40 60 80 100

Tj / °C Tj / °C

Forward Voltage 6)

ΔVF = VF - VF(25 °C) = f(Tj); IF = 10 mA

KRTB LFLP71.32

0.25

∆VF / V

: blue

0.20

0.15

0.10

0.05

0.00

-0.05

-0.10

-0.15

-40 -20 0 20 40 60 80 100

Tj / °C

15 Version 1.1 | 2021-12-06

KRTB LFLP71.32

Relative Luminous Intensity 6) Relative Luminous Intensity 6)

Iv/Iv(25 °C) = f(Tj); IF = 15 mA Iv/Iv(25 °C) = f(Tj); IF = 10 mA

KRTB LFLP71.32 KRTB LFLP71.32

Iv 1,6 Iv 1.2

Iv(25°C) : red Iv(25°C) : true green

1,4

1.0

1,2

0.8

1,0

0,8 0.6

0,6

0.4

0,4

0.2

0,2

0,0 0.0

-40 -20 0 20 40 60 80 100 -40 -20 0 20 40 60 80 100

Tj / °C Tj / °C

Relative Luminous Intensity 6)

Iv/Iv(25 °C) = f(Tj); IF = 10 mA

KRTB LFLP71.32

Iv 1.2

Iv(25°C) : blue

1.0

0.8

0.6

0.4

0.2

0.0

-40 -20 0 20 40 60 80 100

Tj / °C

16 Version 1.1 | 2021-12-06

KRTB LFLP71.32

Dominant Wavelength 6) Dominant Wavelength 6)

Δλdom = λdom - λdom(25 °C) = f(Tj); IF = 15 mA Δλdom = λdom - λdom(25 °C) = f(Tj); IF = 10 mA

KRTB LFLP71.32 KRTB LFLP71.32

10 8

∆λ dom / nm ∆λ dom / nm

: red : true green

5

4

2

0

0

-2

-5

-4

-10 -6

-40 -20 0 20 40 60 80 100 -40 -20 0 20 40 60 80 100

Tj / °C Tj / °C

Dominant Wavelength 6)

Δλdom = λdom - λdom(25 °C) = f(Tj); IF = 10 mA

KRTB LFLP71.32

8

∆λ dom / nm

: blue

6

-2

-4

-6

-40 -20 0 20 40 60 80 100

Tj / °C

17 Version 1.1 | 2021-12-06

KRTB LFLP71.32

Max. Permissible Forward Current Max. Permissible Forward Current

IF = f(T); ● red IF = f(T); ● true green

one chip on KRTB LFLP71.32

one chip on KRTB LFLP71.32

22 22

IF / mA IF / mA

20 20

18 18

16 16

14 14

true green

12 12

red

: Ts : Ts

10 10

8 8

6 6

4 4

2 2

0 0

0 20 40 60 80 0 20 40 60 80

Ts / °C Ts / °C

Max. Permissible Forward Current

IF = f(T); ● blue 2.0

one chip on KRTB LFLP71.32

22

IF / mA

20 1.5

18

16 1.0

14

12

blue

: Ts

10 0.5

6

0.0

4

2

0 10 20 30 40

0

0 20 40 60 80

Ts / °C

18 Version 1.1 | 2021-12-06

KRTB LFLP71.32

Permissible Pulse Handling Capability Permissible Pulse Handling Capability

IF = f(tp); D: Duty cycle; ● red IF = f(tp); D: Duty cycle; ● true green

KRTB LFLP71.32 KRTB LFLP71.32

TS = 0°C ... 85°C TS = 0°C ... 85°C

0.05 0.05

IF / A IF / A

0.04 : D = 1.0

0.04 : D = 1.0

: D = 0.5 : D = 0.5

true green

: D = 0.2 : D = 0.2

: D = 0.1 : D = 0.1

red

: D = 0.05 : D = 0.05

: D = 0.02 : D = 0.02

0.03 : D = 0.01 0.03 : D = 0.01

: D = 0.005 : D = 0.005

0.02 0.02

10-6 10-5 10-4 10-3 0.01 0.1 1 10 10-6 10-5 10-4 10-3 0.01 0.1 1 10

Pulse time / s Pulse time / s

Permissible Pulse Handling Capability

IF = f(tp); D: Duty cycle; ● blue

KRTB LFLP71.32

TS = 0°C ... 85°C

0.05

IF / A

0.04 : D = 1.0

: D = 0.5

: D = 0.2

blue

: D = 0.1

: D = 0.05

: D = 0.02

0.03 : D = 0.01

: D = 0.005

0.02

10-6 10-5 10-4 10-3 0.01 0.1 1 10

Pulse time / s

19 Version 1.1 | 2021-12-06

KRTB LFLP71.32

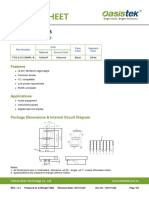

Dimensional Drawing 8)

Further Information:

Approximate Weight: 33.0 mg

20 Version 1.1 | 2021-12-06

KRTB LFLP71.32

Electrical Internal Circuit

21 Version 1.1 | 2021-12-06

KRTB LFLP71.32

Recommended Solder Pad 8)

For superior solder joint connectivity results we recommend soldering under standard nitrogen atmosphere. Package not

suitable for ultra sonic cleaning.

22 Version 1.1 | 2021-12-06

KRTB LFLP71.32

Reflow Soldering Profile

Product complies to MSL Level 4 acc. to JEDEC J-STD-020E

OHA04525

300

˚C

T 250

240 ˚C Tp 245 ˚C

217 ˚C tP

200

tL

150

tS

100

50

25 ˚C

0

0 50 100 150 200 250 s 300

t

Profile Feature Symbol Pb-Free (SnAgCu) Assembly Unit

Minimum Recommendation Maximum

Ramp-up rate to preheat*) 2 3 K/s

25 °C to 150 °C

Time tS tS 60 100 120 s

TSmin to TSmax

Ramp-up rate to peak*) 2 3 K/s

TSmax to TP

Liquidus temperature TL 217 °C

Time above liquidus temperature tL 80 100 s

Peak temperature TP 245 260 °C

Time within 5 °C of the specified peak tP 10 20 30 s

temperature TP - 5 K

Ramp-down rate* 3 6 K/s

TP to 100 °C

Time 480 s

25 °C to TP

All temperatures refer to the center of the package, measured on the top of the component

* slope calculation DT/Dt: Dt max. 5 s; fulfillment for the whole T-range

23 Version 1.1 | 2021-12-06

KRTB LFLP71.32

Taping 8)

24 Version 1.1 | 2021-12-06

KRTB LFLP71.32

Tape and Reel 9)

Reel Dimensions

A W Nmin W1 W2 max Pieces per PU

355.6 mm 8 + 0.3 / - 0.1 mm 79.3 mm 8.7 + 0.3 mm 14.4 mm 8000

25 Version 1.1 | 2021-12-06

KRTB LFLP71.32

Barcode-Product-Label (BPL)

Dry Packing Process and Materials 8)

Moisture-sensitive label or print

N s E RS

L

E

re

V

E

tiv

If

e

la ared ag

fr

in pa

L

hu

ck

an

m

id

k,

bl r co

ba

e

de

e be

sela

ity

30

l

˚C

).

(R

/6

R

H

0%

.

Barcode label

TIO

<

_

in IV O % k

IT T of

nta

90 to rs

S C < d ea s ). rs

N U ou

U coSEND d te (p on ,

or de H rs

iti ou

an bjec ng

ou rs

Ais bUagRMEICO ˚C co 72 H

si nd 5 H ou

˚C su es te 48

CThIS co ± e H

y da e 24 6

T E 40 be oc

or ˚C tim e

S < ill pr). ith or tim

O w nt ct 23 w tim e

M TO

at fa lo or

s at le ˚C at at e. al F lo or tim

P th th va l tic F lo or

O on s ui be if: read

ur F lo

m ce eq la lo

w ed

id

en l 4 5 F

vi g, n oc ve l

24 or de be in pr is 5a

de , e nt whe Le ve l 6

te

g: , w

r

co

se ou ke e Le ve l

da Le ve

ba ed flo

ba e m % ba al st

ur e

en re r ur e Le

ed e e tim re> 10 fo se oi st ur e

al op se fo M oi st ur

se is as or . is 33 k, M oi st

k, lo H bed

in g ph , -0 an M oi

e r- an in F R ng ar D bl M

ba

lif is po If bl ith % ki r C. S

T (if r

lf th va p. w 10 ba to et J- ea r ks

he r w, m <

_ m Y ea rs

S te ed iredicat d, EC 1 Y ee

1.

fte

A flody

nt

d

at

qu In no ire D > 1 W Hou

ou e 4 8

2. re

bo M re reity is qu/JE e

to es id 2b re C : tim e 16

a) S tim

ic is IP ed loor tim e

b) ev Humor e or

en F

D 2a king nc te F

lo or tim

a) op lo or

3. b) ba re da e F lo

If fe

al l 1 2 F

re tim ve l

4. se d l 2a

Le ve 3

ag an e Le ve l

B e ur e Le ve

at st ur e

D Le

oi st ur e

M oi st ur

M oi st

M oi

M

M

RA

OS

Humidity indicator

Barcode label

Do not eat.

Avoid metal contact.

Discard if circles overrun.

bag opening.

Please check the HIC immidiately after

check dot WET

Comparator

bake units

examine units, if necessary 15%

If wet,

bake units

examine units, if necessary 10%

If wet,

change desiccant

parts still adequately dry. 5%

If wet,

MIL-I-8835

Humidity Indicator

Desiccant

AM

OSR

OHA00539

Moisture-sensitive product is packed in a dry bag containing desiccant and a humidity card according JEDEC-STD-033.

26 Version 1.1 | 2021-12-06

KRTB LFLP71.32

Notes

The evaluation of eye safety occurs according to the standard IEC 62471:2006 (photo biological safety of

lamps and lamp systems). Within the risk grouping system of this IEC standard, the device specified in this

data sheet fall into the class exempt group (exposure time 10000 s). Under real circumstances (for expo-

sure time, conditions of the eye pupils, observation distance), it is assumed that no endangerment to the

eye exists from these devices. As a matter of principle, however, it should be mentioned that intense light

sources have a high secondary exposure potential due to their blinding effect. When looking at bright light

sources (e.g. headlights), temporary reduction in visual acuity and afterimages can occur, leading to irrita-

tion, annoyance, visual impairment, and even accidents, depending on the situation.

Subcomponents of this device contain, in addition to other substances, metal filled materials including silver.

Metal filled materials can be affected by environments that contain traces of aggressive substances. There-

fore, we recommend that customers minimize device exposure to aggressive substances during storage,

production, and use. Devices that showed visible discoloration when tested using the described tests above

did show no performance deviations within failure limits during the stated test duration. Respective failure

limits are described in the IEC60810.

Changes to the content of this datasheet may occur without further notification. JEDEC 46C constitutes the

guideline of the change management for the device specified in this document.

For further application related information please visit www.osram-os.com/appnotes

27 Version 1.1 | 2021-12-06

KRTB LFLP71.32

Disclaimer

Attention please!

The information describes the type of component and shall not be considered as assured characteristics.

Terms of delivery and rights to change design reserved. Due to technical requirements components may

contain dangerous substances.

For information on the types in question please contact our Sales Organization.

If printed or downloaded, please find the latest version on the OSRAM OS website.

Packing

Please use the recycling operators known to you. We can also help you – get in touch with your nearest

sales office. By agreement we will take packing material back, if it is sorted. You must bear the costs of

transport. For packing material that is returned to us unsorted or which we are not obliged to accept, we

shall have to invoice you for any costs incurred.

Product and functional safety devices/applications or medical devices/applications

OSRAM OS components are not developed, constructed or tested for the application as safety relevant

component or for the application in medical devices.

OSRAM OS products are not qualified at module and system level for such application.

In case buyer – or customer supplied by buyer – considers using OSRAM OS components in product safety

devices/applications or medical devices/applications, buyer and/or customer has to inform the local sales

partner of OSRAM OS immediately and OSRAM OS and buyer and /or customer will analyze and coordi-

nate the customer-specific request between OSRAM OS and buyer and/or customer.

28 Version 1.1 | 2021-12-06

KRTB LFLP71.32

Glossary

1)

Brightness: Brightness groups are tested at a current pulse duration of 25 ms and a tolerance of

±11 %.

2)

Reverse Operation: This product is intended to be operated applying a forward current within the

specified range. Applying any continuous reverse bias or forward bias below the voltage range of light

emission shall be avoided because it may cause migration which can change the electro-optical char-

acteristics or damage the LED.

3)

Wavelength: Wavelengths are tested at a current pulse duration of 25 ms and a tolerance of ±1 nm.

4)

Forward Voltage: Forward voltages are tested at a current pulse duration of 1 ms and a tolerance of

±0.1 V.

5)

Thermal Resistance: Rth max is based on statistic values (6σ).

6)

Typical Values: Due to the special conditions of the manufacturing processes of semiconductor devic-

es, the typical data or calculated correlations of technical parameters can only reflect statistical figures.

These do not necessarily correspond to the actual parameters of each single product, which could dif-

fer from the typical data and calculated correlations or the typical characteristic line. If requested, e.g.

because of technical improvements, these typ. data will be changed without any further notice.

7)

Characteristic curve: In the range where the line of the graph is broken, you must expect higher differ-

ences between single devices within one packing unit.

8)

Tolerance of Measure: Unless otherwise noted in drawing, tolerances are specified with ±0.1 and

dimensions are specified in mm.

9)

Tape and Reel: All dimensions and tolerances are specified acc. IEC 60286-3 and specified in mm.

29 Version 1.1 | 2021-12-06

KRTB LFLP71.32

Revision History

Version Date Change

1.0 2020-08-12 Initial Version

1.1 2021-12-06 Taping

30 Version 1.1 | 2021-12-06

KRTB LFLP71.32

Published by OSRAM Opto Semiconductors GmbH

Leibnizstraße 4, D-93055 Regensburg

www.osram-os.com © All Rights Reserved.

31 Version 1.1 | 2021-12-06

You might also like

- 1956-1957 Fordomatic TransmissionsDocument65 pages1956-1957 Fordomatic TransmissionsDanny Rakes100% (5)

- PRD Pim Datasheet 5987492 EN PDFDocument28 pagesPRD Pim Datasheet 5987492 EN PDFRanadheer BNo ratings yet

- KRTB LSLPS1.32 - enDocument29 pagesKRTB LSLPS1.32 - ensalih dağdurNo ratings yet

- LRTB GVSR enDocument32 pagesLRTB GVSR enOzel Ders YasarNo ratings yet

- LE RTDUW S2WP - EN - LedDocument30 pagesLE RTDUW S2WP - EN - LedLeon MartinezNo ratings yet

- Kw2 Hil532.Tk enDocument25 pagesKw2 Hil532.Tk enPiero PorielliNo ratings yet

- KB Delps2.12 - enDocument23 pagesKB Delps2.12 - enHardware HbeonlabsNo ratings yet

- Chipled 0603: Produktdatenblatt - Version 1.1Document21 pagesChipled 0603: Produktdatenblatt - Version 1.1VictorNo ratings yet

- PRD Pim Datasheet 13582420 EN pdf-3314480Document29 pagesPRD Pim Datasheet 13582420 EN pdf-3314480maxmoron600No ratings yet

- Ky DMLS31.23Document21 pagesKy DMLS31.23Saulius StasysNo ratings yet

- LS+T67F enDocument22 pagesLS+T67F ensajko.ahmetovicNo ratings yet

- LT Q39G - enDocument24 pagesLT Q39G - enSreedhar Naidu KNo ratings yet

- Chip LED 0805: Produktdatenblatt - Version 1.1Document21 pagesChip LED 0805: Produktdatenblatt - Version 1.1maxmoron600No ratings yet

- Chipled 0603: Produktdatenblatt - Version 1.1Document22 pagesChipled 0603: Produktdatenblatt - Version 1.1Ziyad AkchouchNo ratings yet

- Ly G6SP - enDocument21 pagesLy G6SP - enHanu 1973No ratings yet

- KW H2l531.te - en 2Document24 pagesKW H2l531.te - en 2fredtranNo ratings yet

- Ly+etsf enDocument22 pagesLy+etsf enAndrey PolupanNo ratings yet

- Gw+pusta1.pm enDocument26 pagesGw+pusta1.pm enMohammed AliNo ratings yet

- LR T67F - enDocument22 pagesLR T67F - en(-e'rzgfdNo ratings yet

- Ly G6SP.02 - enDocument22 pagesLy G6SP.02 - enAndrey PolupanNo ratings yet

- La G6SP.01 - enDocument21 pagesLa G6SP.01 - enJonny HenriqueNo ratings yet

- Sideled: Produktdatenblatt - Version 1.1Document22 pagesSideled: Produktdatenblatt - Version 1.1bhf_86No ratings yet

- La G6SP.01 - enDocument21 pagesLa G6SP.01 - ensrinivas raoNo ratings yet

- LR H9PP - en PDFDocument22 pagesLR H9PP - en PDFAjinkya JagtapNo ratings yet

- GW Pusra1.Pm: Osconiq P 3737 (2W)Document24 pagesGW Pusra1.Pm: Osconiq P 3737 (2W)Stefce PetrovNo ratings yet

- Osram SFH 7015 - enDocument20 pagesOsram SFH 7015 - enromumarNo ratings yet

- LR W5SM - enDocument22 pagesLR W5SM - enzebusNo ratings yet

- OSLON Black FlatDocument24 pagesOSLON Black FlatHasanErkelNo ratings yet

- Ly E67f - enDocument22 pagesLy E67f - enAndrey PolupanNo ratings yet

- LR Y8sf - enDocument22 pagesLR Y8sf - enCarlos MarcialNo ratings yet

- LED Argentina Alumbrado PublicoDocument4 pagesLED Argentina Alumbrado PublicoAle NqnNo ratings yet

- La H9GP - enDocument22 pagesLa H9GP - enbhf_86No ratings yet

- LW A6sg - enDocument24 pagesLW A6sg - enelttech666No ratings yet

- BPW 21 - enDocument13 pagesBPW 21 - enMichael MitchellNo ratings yet

- Metal Can TO39: Produktdatenblatt - Version 1.1Document13 pagesMetal Can TO39: Produktdatenblatt - Version 1.1abc bNo ratings yet

- GW Pllra1.Pm: Osconiq C 2424Document24 pagesGW Pllra1.Pm: Osconiq C 2424xeisteexNo ratings yet

- GW CS8PM1.PM - enDocument22 pagesGW CS8PM1.PM - enHasanErkelNo ratings yet

- GW Jtlps2.Em: DatasheetDocument25 pagesGW Jtlps2.Em: DatasheetDayti JuniorNo ratings yet

- 4 Chip Built in RGBW Smd5050Document5 pages4 Chip Built in RGBW Smd5050ZmecleuPeBatzNo ratings yet

- LS SF67 (8) 1usd24Document7 pagesLS SF67 (8) 1usd24Nexor PocztaNo ratings yet

- KW Cslnm1.Tg: Osram Ostar Projection CompactDocument26 pagesKW Cslnm1.Tg: Osram Ostar Projection CompactfredtranNo ratings yet

- AC5920 Series: 1550 NM MQW-DFB 2.5Gbps Direct Modulation LaserDocument5 pagesAC5920 Series: 1550 NM MQW-DFB 2.5Gbps Direct Modulation LaserHudson M. CerriNo ratings yet

- OSRAM Opto Semicon KW DMLN33 SG 7J7K ebvFfcbB46 8E8G 200 S - C2892070Document22 pagesOSRAM Opto Semicon KW DMLN33 SG 7J7K ebvFfcbB46 8E8G 200 S - C2892070lolNo ratings yet

- BPW 34 S - enDocument17 pagesBPW 34 S - enRajesh KumarNo ratings yet

- LW Q38G - enDocument24 pagesLW Q38G - encorazzaedwardNo ratings yet

- Tod 5261ame BDocument2 pagesTod 5261ame Bx-wire OfficialsNo ratings yet

- Tos 23101bmrl BDocument2 pagesTos 23101bmrl BAnonymous Im6zx7xiyNo ratings yet

- WCN 5721SR Da13Document4 pagesWCN 5721SR Da13Nathalia CaladoNo ratings yet

- GW Daspa2.ec - enDocument26 pagesGW Daspa2.ec - enbhf_86No ratings yet

- Specification: 5.0mm ROUND Bi-Color Lamp (2 Leads)Document6 pagesSpecification: 5.0mm ROUND Bi-Color Lamp (2 Leads)ShawonNo ratings yet

- OSRAM Opto Semicon KB DMLN31 13 7D8F 36 15B5 200 R18 - C2892072Document21 pagesOSRAM Opto Semicon KB DMLN31 13 7D8F 36 15B5 200 R18 - C2892072İbrahim DemircioğluNo ratings yet

- BPV10NFDocument5 pagesBPV10NFהליכות ג'יין נהריהNo ratings yet

- Of smd2012bDocument4 pagesOf smd2012bIoanaa BadiuNo ratings yet

- TLCS510., TLCR510., Tlco510., Tlcy510., Tlcyg510., TLCPG510Document14 pagesTLCS510., TLCR510., Tlco510., Tlcy510., Tlcyg510., TLCPG510cepimasterodroNo ratings yet

- KW CSLNM1.TG - enDocument21 pagesKW CSLNM1.TG - enМихайло ЧернегаNo ratings yet

- WCN2-1056SR-A16R Specification: World Components Network Service LTDDocument3 pagesWCN2-1056SR-A16R Specification: World Components Network Service LTDmarcioNo ratings yet

- GW P9LR34.PM - enDocument25 pagesGW P9LR34.PM - enTaufiq ZubairiNo ratings yet

- 9.blue (Clear Transparent) 5mmDocument3 pages9.blue (Clear Transparent) 5mmthoronlithNo ratings yet

- Photointerrupters (Reflective) SG-2BCDocument2 pagesPhotointerrupters (Reflective) SG-2BCjanghyunpNo ratings yet

- SDM P10RGB Osab1s 3216 PDFDocument17 pagesSDM P10RGB Osab1s 3216 PDFKrish Rock KishoreNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsRating: 5 out of 5 stars5/5 (1)

- DSE 0023016 HNB2727W OS06 (EMM) - v4Document12 pagesDSE 0023016 HNB2727W OS06 (EMM) - v4Ranadheer BNo ratings yet

- MX25L6433F, 3V, 64Mb, v1.8Document85 pagesMX25L6433F, 3V, 64Mb, v1.8Ranadheer BNo ratings yet

- RdsoDocument2 pagesRdsoRanadheer BNo ratings yet

- Rites A1Document4 pagesRites A1Ranadheer BNo ratings yet

- RDSO ApprovalDocument2 pagesRDSO ApprovalRanadheer BNo ratings yet

- Poster PresentationDocument1 pagePoster PresentationPilla SatishNo ratings yet

- Assignment 1 2 PumpDocument2 pagesAssignment 1 2 PumpAnkit0% (1)

- Mechanisms of Fracture in MetalsDocument10 pagesMechanisms of Fracture in Metalsaap1No ratings yet

- Eros and Psyche Print 2 PDFDocument8 pagesEros and Psyche Print 2 PDFNizzy Hope Nulada CartagoNo ratings yet

- Major Project Report ON (Corporate Social Responsibility of Tata)Document103 pagesMajor Project Report ON (Corporate Social Responsibility of Tata)Amar PandaNo ratings yet

- John Blue - DP 139 Diaphragm Pump - Parts and Instruction Manual - 7 M 17 - 0622Document12 pagesJohn Blue - DP 139 Diaphragm Pump - Parts and Instruction Manual - 7 M 17 - 0622Dung PhamNo ratings yet

- TDE9540 09 WhitePaperDocument56 pagesTDE9540 09 WhitePaperdarkoskr84No ratings yet

- Compass NotesDocument55 pagesCompass NotesEngr XsadNo ratings yet

- Explanation Text 2023Document4 pagesExplanation Text 2023NursalinaNo ratings yet

- Funnel Bulk SMS-GVNDocument6 pagesFunnel Bulk SMS-GVNJamie JordanNo ratings yet

- Final Year Project SPYBOTDocument7 pagesFinal Year Project SPYBOTFaizanAhmedNo ratings yet

- Artikel Dalam Bahasa InggrisDocument9 pagesArtikel Dalam Bahasa InggrisEfrinaldiNo ratings yet

- BTL5-P/I/K/L/M - M - A/B/Z-S32/KA - Micropulse Linear Transducer - Rod StyleDocument8 pagesBTL5-P/I/K/L/M - M - A/B/Z-S32/KA - Micropulse Linear Transducer - Rod StyleGerardo Navarro CastilloNo ratings yet

- Determining The Susceptibility of Stainless Steels and Related Nickel-Chromium-Iron Alloys To Stress-Corrosion Cracking in Polythionic AcidsDocument3 pagesDetermining The Susceptibility of Stainless Steels and Related Nickel-Chromium-Iron Alloys To Stress-Corrosion Cracking in Polythionic AcidsIvan AlanizNo ratings yet

- 16.21.1814 EbookDocument442 pages16.21.1814 EbookSutadi Triputra100% (1)

- Categorization PCABDocument2 pagesCategorization PCABleonard dela cruzNo ratings yet

- Example The Inductance of A SolenoidDocument3 pagesExample The Inductance of A SolenoidMuhamad YusupNo ratings yet

- Measuring Your Carbon Footprint PowerPointDocument16 pagesMeasuring Your Carbon Footprint PowerPointpremquilonNo ratings yet

- (Template) As WEEK 5&6Document3 pages(Template) As WEEK 5&6Jaemee Agnes BoadoNo ratings yet

- Roblox Admins Free WorkingDocument483 pagesRoblox Admins Free WorkingCrazy SodaNo ratings yet

- FSSC Iac PTM-02Document1 pageFSSC Iac PTM-02Faisal RehmanNo ratings yet

- Selina Concise Physics Solutions Class 6 Chapter 1 MatterDocument22 pagesSelina Concise Physics Solutions Class 6 Chapter 1 MatterAltaf TalpurNo ratings yet

- Intro To SS Lecture 2Document21 pagesIntro To SS Lecture 2Muhammad HusnainNo ratings yet

- DGA Comparison Between Ester and Mineral Oils: C. Perrier, M. Marugan, M. Saravolac A. BeroualDocument4 pagesDGA Comparison Between Ester and Mineral Oils: C. Perrier, M. Marugan, M. Saravolac A. BeroualJhon Fredy Vallejo GiraldoNo ratings yet

- Medical Management of Intractable Constipation (FINAL) 2Document63 pagesMedical Management of Intractable Constipation (FINAL) 2Akbar WidoNo ratings yet

- Beermom Ism c10Document164 pagesBeermom Ism c10joão victor carvalho100% (1)

- Chemical Recycling of Postconsumer Poly (Ethylene-Terephthalate) Bottles - Depolymerization StudyDocument8 pagesChemical Recycling of Postconsumer Poly (Ethylene-Terephthalate) Bottles - Depolymerization StudyKhaledAhmedNo ratings yet

- Paper 2Document15 pagesPaper 2lutfi istiqomahNo ratings yet

- Acustica Ruby EbonyDocument1 pageAcustica Ruby EbonyZizja TurtleNo ratings yet