Professional Documents

Culture Documents

33100

33100

Uploaded by

murad0 ratings0% found this document useful (0 votes)

6 views16 pagesCopyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

6 views16 pages33100

33100

Uploaded by

muradCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 16

ape} (Widles) — G2) ole AS yh

JORDAN WATER COMPANY — MIYAHUNA LLC

PURCHASING DEPARTMENT

P.O. Box 922918, Amman 11194 Jordan

: 962-6-5680819 & 5666111 Ext. 1623, 1621 Fax #: 962-6- 5680854

Mmajali@MIY AHUNA com jo, ksghaireen@miyahuna.com.jo

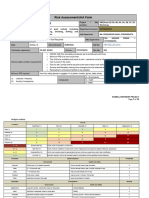

(33100) # Jou) Gaye Gib

ga te 2021/11/17 | a is

I | FL a

es sae =)

2 2 cae - Clea gill ws oS | old

Gebale | BEV SEL yO) eal iwhain

(Ble de Tle VACLT LT 2024/11/25 gall consid vassal pale aay

aol | saad | ays Fouad

fa | om | "| alily ald) Ginay #

se | 200 "2A dal wore | 1

oe 65 NS CAnal dal ye ys | 2

- AGB yall Log ply Cina gall Ca

(stn) Egan -

Sate fn Sia aed gee) ns $88 1000 gn ca ey me are -

ABS Gab 8) Hb oly at GA ay all

Malye Cea ate al (L3H 5 Daal) y dna Lai 3) Gaal yp pu NAS ALLS is uy a

Bjyeat P10 REE hal BM eM ghee oS ease .

(Clie sila JS) Hb ia ys pt mm

+ %10 aks Oe geal Ge canst Fh BH 5 in 6,000 Ge And an ol oh pl GY cll: A Cua AILS «

AAY\ el) pine pl 10 JOS tb pil Tags gl MY! ge MMe Ga el pall al Las

Mans 588 ell pall ak oe 15 eal an 5 pel g gual US Ye % 0.5 sty sill LL

ea Ne aes Lada cg! HY 2021/11/23 SI Ludi A

ERM OLD Gated Leaky gL daa) GLB) Aaa et iy IVI Ball ee adi a Ge GY

co pal hasta ple lS Ly GET cay

RnB gh 2019 21 (28) hy Rye Sally ih Cady As Sas

P21 8 1000 ge ah ae al gh es Se 8a Sy 8 Gl ly .

Hada bag fae 3

Sais ay AN ARS, ANY Spl

TECHNICAL SPECIFICATION

Repair Clamps

Ug-Hhslbae piss Ay gllnall a gall Lise psi Cyd gall (gle

Aga Aa) ub Gye Laud pall 5d e LU Ug yay

Contents

1. SCOPE

2. APPLICATION

3. MATERIALS

4, DESIGN

5. Potable water certificate

6. PACKAGING AND MARKING

6.1 Packing and Protection

6.2 Identification

6. 3 Transport and Deliveries

Table 4

aka RwBONNN

Error! Bookmark not defined.

TECHNICAL SPECIFICATION

Repair Clamps

1. SCOPE

This Specification specifies the requirements for the design, materials and in-service

performance of mechanical stainless steel repair clamps for waterworks purposes.

This Specification designated for applications involving rigid pipes, typically ductile iron

(D1), grey cast iron (CI), and steel (S). Also, for applications involving flexible pipes,

typically un-plasticized polyvinIchloried (PVC-U) and high-density polyethylene (HDPE).

All materials and equipments shall be in every respect suitable for storage, installation,

use and operation in the conditions of temperature, humidity and The PH and water

quality appertaining in Jordan.

Atmospheric temperature in Jordan varies between -10°C and 50°C.

2. APPLICATION

Stainless steel repair clamps complying with this specification are intended for use in

repair of water supply pipelines of the size designated in Table 1, with a maximum

service temperature of 50°C and up to an allowable operating pressure of 16 bars for

ranges diameter up to 250 mm and 10 bar for diameters larger than 250 mm. Repair

clamps have limited ability to accommodate axial deflection and are, therefore, not

generally intended for use as couplings to join tow pipes together. However, they are

commonly utilized for repair situations at full pipe break, where the pipe ends are

considered stable. In addition, repair clamps complying with this specification are

intended to provide a permanent means of preventing loss from or contamination of

pipelines that have been affected by corrosion or mechanical damage in both above-

ground and buried applications.

3. MATERIALS

The material of Clamps shall be

Bands: Stainless Steel Grade Als! 304(A2) to BS1449:1991: part 2 or Grade AISI 316(A4)

stainless steel to BS 1449:1991:part 2, for corrosion resistance.

Bolts shall be Stainless Stee! A2, Teflon coated, or mild steel. Nuts & washers shall be

Stainless Steel A2, or mild steel class 4.6 to BS EN20898: Part 1. Receiver bars shall be

TIG- welded to shell to form strong fusion, and fully passivated after welding,

Gasket shall have a gridded pattern for positive sealing, and to be made of specially

compounded NBR rubber specially formulated for water service or EPDM. Compound

Grade E to BS2494:1990

4, DESIGN

The Clamps shall be used for permanent repair of cracks, holes, or complete breakages

of steel, ductile Iron, PVC and HDPE pipes.

The Clamps shall be suitable for potable water for Temperature range (-10 to 50) C.

potable water certificate must be submitted

Repair Clamps shall be standard full circle single band for diameter 150mm or less.

And full circle double band for diameter more than 150mm, length and number of

bolts not less than the values in Table 1 for each diameter.

Gasket shall provide a 360° sealing surface and of such size and shape to provide an

adequate compressive force against the pipe after assembling to affect a positive seal

under all combinations of joint and gasket tolerances. And heavy gauge Type 304

stainless Steel bridge plate shall be attached into the gasket end to span the lug area

and to make installation quick and easy.

Bolt retainer assembly or lugs shall be of a type 304 stainless steel, and shall be MIG

welded to receiver bar and fully passivated after welding. Lugs may be cast, forged or

cold formed of type 304 stainless steel, and may include a high impact polycarbonate

plastic, non corrosive retainer. Lug design shall be such that the band fully compresses

the gasket to the complete working width of the repair clamp without deformation of

the band.

5. Potable water certificate

Repair Clamp and rubber materials shall be certified for potable water use, and should

be certified as safe for transporting potable water by an independent testing

laboratory. All material in contact with or likely to come into contact with water for

public shall introduced with the requirements of BS 6920 (suitability for non metallic

products for use in contact with drinking water) or any equivalent standard as well as.

the Jordanian standard (JS 286/2008) and the requirements of EN 15664 ( influence of

metallic materials on water intended for human consumption ) or any equivalent

standard and the World Health Organization standard (WHO), and whenever the

regulation is changed it is the supplier responsibility to ensure conformity with any

new requirements.

Potable water certificate submitted must be for the same batch delivered to

Miyahuna, certificates must be in English

6. PACKAGING AND MARKING

6.1 Packing and Protection

* All materials shall be bundled or packaged in such a manner as to provide adequate

support and protection for the ends during transportation from the manufacturer to the

Purchaser. All special provisions for ocean shipment shall be provided.

* The packaging of materials by the manufacturer is normally consistent with the

requirement to prevent damage and to comply with safety considerations. Usually repair

clamps are delivered strapped into convenient package or box.

6.2 Identification

‘The supplier shall be responsible to ensure that each separate item, crate, or package has

permanently attached to it, in a conspicuous position, an identification plate of weather -

resistant material on wihich are engraved or stamped;

+ The Manufacturers Name and country of origin

+ Contents Description and Quantity

+ Serial Number or Reference Number Identifiable on the Delivery Note

and Cross Referenced to the Purchase Order Item References.

+ Weight

The shipment containers shall be marked with the following address;

Jordan Water Co. ~ MIYAHUNA L.L.C.

Tender Number - variable

In addition the container shall be marked with the following information;

+ Total gross weight

* Total net weight

+ Packing list reference number

All clamps shall be indelibly marked; the mar

information:

ng shall show at least the following

* “MIYAHUNA"

* Manufacture's name, logo and/or trade mark

* country of origin

* Dimensions (nominal diameter, range, length)

For direct purchase procurements order the marking depends on the value of the

procurements order

6.3 Transport and Deliveries

The supplier shall send to the Purchasers, one-week advance notice of all

consignments of materials. Every consignment shall be accompanied by a detailed

delivery note.

The supplier shall deliver to and off load the materials onto the storage area as.

directed by the Purchasers. All materials delivered will be examined and inspected

by the Purchaser and taken over by him,

‘The Supplier shall provide necessary details to the shipping line on precautions

to be taken during loading/unloading, handling & transport of the materials,

and other components. Supplier shall provide to the purchaser a set of

recommendations of manufacturer for handling, loading, unloading,

transporting and storing.

The Purchaser shall arrange reception and storage areas only. The supplier shall be

responsible for off-loading all materials

‘The materials shall be delivered to the Purchaser at Miyahuna stores, Amman or

any other place chosen by the Purchaser.

The supplier shall also be responsible for all handling and transport activities up to

Miyahuna store-yard, Amman

The (DDP) price shall include all costs relating to above-mentioned requirements.

tails S55 alyall byes! o55 Gm Hagllaall Sle! ator AWA! Agel le

Agel Cre!

Table 1

2 Nominal % :

= Pipe Size ees eee! Quantity ent No. bolts

a (Inch) yp

HDPE

2 Gi 150 2

DI

3 150 2

2 UPVC

8 ce

3 4 150 2

£ Dl

° HDPE

UPVC

6 ol 200 3

HDPE

8 DI 300 3

10 DI 300 x

»

= 12 DI 500 5°

9 16 DI 600 6

2B

3 24 DI 600 e

a

32 DI 800 8

36 DI 1000 10°

“Number of bolts for each band side

SCHEDULE (A)

SCHEDULE REQUIREMENT:

SCHEDULE (B)

SCHEDULE OF DELIVERY TERMS

SCHEDULE (C)

TECHNICAL DATA

SCHEDULE (D )

DEVIATIONS FROM SPECIFICATIONS

SCHEDULE (A)

Schedule of Requirements

Table 1

o Nominal 4 5

= Pipe Size aes Meer Quantity eo No. bolts

a (Inch) yp

ey 2 HDPE 200 150 2

26 -

oo 5 | BDFE 65 150 2

east) any Uthage Upoands sbgall Laat alae *

Aga Leja Liat JB a Yypsiplld Ane aya byidy *

- Number of bolts for each band side

- MIYAHUNA has the right to award the contract by

Item .

- Signature & Stamp of the Supplier: .........++ ceeseeneseneetee

SCHEDULE (B)

‘TIME PERIODS FOR DELIVERY

-

Tet Description QTY UNIT Delivery

1 |2"Repair Clamp 200 Each Immediately

2 |5" Repair Clamp 65 Each

- MIYAHUNA has the right to award the contract by

Item.

SCHEDULE (C )Technical Data

Place of

Inspect

tem# | Description | UNIT | Manufacturer eee ne ion

Testing

2"Repair Clamp Hach

2

5"Repair Clamp Each

- MIYAHUNA has the right to award the contract by

Item .

- Signature & Stamp of the Supplier:

tis assumed that the goods offered shall conform to the technical specifications listed hecein,

unless deviations are listed explicitly in this schedule.

‘The Purchaser may waive any minot informality, non-conformity or itregularity in an offer that

does not constitute a material deviation, provided such waiver does not prejudice ot affect the

sanking of any Tendetet. Major deviations in the opinion of the Evaluating Committee will

tender the bid non-responsive.

12

SCHEDULE OF PRICES

ee Description QTY UNIT UP) TP

1, | 2" Repair Clamp 200 Each

5"Repait Clamp 65

| Each

Total

- MIYAHUNA has the right to award the contract by Item or

combination of items.

Si s £ the Supplier:

File byt

SHAS Ally POLS) "elk sl 6 lane (Chine) Gale ly ol 2) pal ll LEY) pS Ge HUAI

I MAS SEI 6 yh yal janes lh AS 5 ge sny Moy gall™ geaga ol dll yal all do yee gill Yast

co ey "Lah gle pip SAH Saath y ees Qa ab ally Glanall eatery og stall”

Uhh lly tia @ oll UY Ge ye J chgball J cial gall gle Shaul fad

tal Aa ey

ASAD SS SS) ASSN galas Spal a es gl aya pit Oly Ty Same Jaa) gual

Soe ee ae

«La lh sana Ayn ly Sb Ge lal ls

Eb SS ky gh Gal AS eh aad ah G8 Ll ls Ge yall OS 1) 5 Aa La hy

th All yal Aah coe 1 Sal ang & stl IV el pBIh sal dogs Gs 160.5 dees 2 gall pa ph

pete ale al ue el pill al gi olla Uy gla Sa GUS sb AS Sy 2 gal ase a

Hine Si gual atin y LM] OS UI pitiny FAY Leleay ll gall Wels UA Gall) I pall

ola yal clad

aa I ol gb 2 pl gill og glia aes ce reba slats

REA a fehl) INCOTERMS hg Sis eb yeah =

NSU gb Gp clined yall tithes ye J Cue Uy ala a 4S 28

sols galshlly Cal all gaan Je Say Galan a! Gy0 yall GS ipl Gala add

Calyee Galaad 452 yd) GS pay gg ital Up CJR Lay idl Gull Ge Wey Gad a Guy

oY hl ps os oF Maa 9s TE. gly asd DI ay ppl Cal cll an Ge aS

eh galh jal gh anal 2S pl ad ya

fang Ble faye is a gs Sty Sal pl te 8g lal Gf yall cay aka aye

5 Apia y slyly ppenal gS geal US Gu GE GS clay « Lele Ba ell OLD Dy eae ty

Betas Sadan al soa cilay gba pal Ge Lye Spe ILS had ye Aaa ode Gling

SoS la gle EIS SURE Y lal gu lal J Cel gn Fe DIS TS

A ginall de lly fa ie ais le sy ol 2) al

1h AS 20 sal mga yl Ly ol 2 al LAS Aaa lal Sods ie Sgualaly pas

pgued) ds a ls py Gala Gay hs opal pies GLK, Ulich Lab ell) al Qaas

EM gstil paciy Gill ya Len 80

Ge Uygeee YS5 NAS yA of ub epsha Se sly Cal gall past Gay AS pl adap a 5 ye a

ee ALS 5 psy Mal pe AS 5 HS IU opt al 85 SM AY Ge lel Gs gal Lidl eal

12D sal day py Sal CS May yh gly yl als lg ht a I Ua Gy ais pall La ls

PUSS phe heally ob Gud Glace, Miles Gillie ish oly Ulaall 4 phi Qua syde alti

“el allyl

OB Qe oh yi) pal day pty (Sal Sigtly 5A De al le Si ur dle) Alli) Gulatyde gly

BGR che Lain gh all | ALlaall ut Ghul gee ads Yehe oj gh oda ol yl pal lady AS pill 9 gs a 2 yal

By 98) pe Gye Hilal Lal ag ty lal ibe yaks 5 Dhyal f ap G9 fy 9 yall A yuany

Ane Lalaill pre 5 ola gull Laila gle oy yall aeiny Gay AS tlh Ueda y LS 6 ayy) Glue le di gs

Sis

OS oA oe inp Si gf US! Oe jue yl 5S RAN ys HE Gu

Ha M0 ASLaa gh phen yall pls gb yh gh gl oy Da a yall Syrgu gl Le etl

158 LED ed Ga pe ayy gD lad gape oan Oa chip 2S Ube Ide Of sh allyl

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5825)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Risk Assessment: Erection, Altering and Dismantling of Scaffolding WorksDocument8 pagesRisk Assessment: Erection, Altering and Dismantling of Scaffolding WorksmuradNo ratings yet

- Al Karama School, Phase 2, Abu Dhabi, UAE Risk Assessment Record ActivityDocument11 pagesAl Karama School, Phase 2, Abu Dhabi, UAE Risk Assessment Record ActivitymuradNo ratings yet

- Risk Assessment/JHA Form: Hot WorkDocument16 pagesRisk Assessment/JHA Form: Hot WorkmuradNo ratings yet

- 54545555Document4 pages54545555muradNo ratings yet

- Vehicle Fuel Report 10Document3 pagesVehicle Fuel Report 10muradNo ratings yet

- Vehicle Fuel Report - 10Document2 pagesVehicle Fuel Report - 10muradNo ratings yet

- Insignificant (2) Minor (3) Moderate (4) Major (5) CatastrophicDocument6 pagesInsignificant (2) Minor (3) Moderate (4) Major (5) CatastrophicmuradNo ratings yet

- Vehicle Fuel Report - 6Document2 pagesVehicle Fuel Report - 6muradNo ratings yet

- Vehicle Fuel Report - 2Document2 pagesVehicle Fuel Report - 2muradNo ratings yet

- Pocurement & Contracting SectionDocument2 pagesPocurement & Contracting SectionmuradNo ratings yet

- Vehicle Fuel Report 2Document2 pagesVehicle Fuel Report 2muradNo ratings yet

- 3000000Document2 pages3000000muradNo ratings yet

- Vehicle Fuel Report 3Document2 pagesVehicle Fuel Report 3muradNo ratings yet

- Vehicle Fuel Report 1Document2 pagesVehicle Fuel Report 1muradNo ratings yet

- FooodddDocument1 pageFooodddmuradNo ratings yet

- 789999Document2 pages789999muradNo ratings yet

- MLHQ RQM 1 14Document2 pagesMLHQ RQM 1 14muradNo ratings yet

- 23221Document3 pages23221muradNo ratings yet

- 25748Document2 pages25748muradNo ratings yet

- DW LT 1Document2 pagesDW LT 1muradNo ratings yet

- 24284Document2 pages24284muradNo ratings yet

- 34353Document12 pages34353muradNo ratings yet