Professional Documents

Culture Documents

Projects - FEL2 - Queries 1

Projects - FEL2 - Queries 1

Uploaded by

Sumantra ChattopadhyayOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Projects - FEL2 - Queries 1

Projects - FEL2 - Queries 1

Uploaded by

Sumantra ChattopadhyayCopyright:

Available Formats

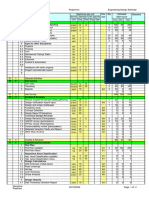

PROJECT LIST

Process

Locati Engineer Type- Growth

Sl. Dept. Project Title Discipline Queries from Piping Queries from Process Queries from Water & Utility Queries from Electrical Queries from I&C Queries from Civil & Structure (C&S)

on ing- (G)/ SDI(S))

involvement Lead from

CU,E&P

from TCE TCE

This is a brown field job which requires over head

lines to be routed through exisitng facilities like racks

across various areas. Our queries

1. It is mentioned that almost 7.5 KM portion of pipes are underground need to be laid on overground. Is it the length of all pipes OR length of

a) How many lines to be taken?

pipe route? Please clarify.

b) Diameter of these lines? 2. Furnish the route of pipe lines finalized in FEL1 along with number of pipe & dia of pipe.

c) Whether laser scan will be available for the whole 3. Are these pipes will be supported in new structure & foundation for over ground route? Please confirm.

route where the line is to be taken? 4. If the route is partly supported in new structure and partly supported on existing structure then please specify the percentage of support to

We feel without laser scan such a work is not be considered for new & existing structure?

possible. Secondly we feel since it means interfacing 5. Are the support system will be individual OR pipe gallery to be considered? Please soecify.

with various areas TSJ's various departments in COMMON FOR ALL PROJECTS:

Making the underground Water lines , to

1. Is detail Civil & Structural (C&S) engineering including complete analysis & design need to be carried out in this FEL-2 level? Please confirm.

Steel Overhead design , for ICW and DCW cooling charge of the respective areas need to be involved

1 TSJ LD#2 Sustenance Otherwise a preliminary analysis will be carried out AND/OR reference data will be used to estimate BOQ with (+/-) 25% variation. Please

making water lines , Fire water Old lines at RCPH of LD2 for discussing and taking concurrences.

feeding to Slab Casters , confirm.

d) Pipe length and route 2. If detail engineering for C&S need to be carried out in this stage then approved assignment need to be furnished to C&S team to carry out

the C&S engineering.

3. If DE need to be carried out then only single line Structural GA drawings without connection detail will be prepared in this stage. Preparation

of any fabrication drawings not considered in this FEL-2 stage. Please confirm.

4. If DE need to be carried out then only concrete out line diagram drawing will be prepared. Reinforcement detail will not be shown in this

stage. Please confirm.

5. Soil report will be shared by client. Please confirm.

6. All the existing "AS-BUILT" Civil & Structural drawings will be shared by client for the applicable area. Please confirm.

7. If only preliminary analysis is carried out then schematic drawings without any member sections will be prepared. Please confirm.

8. Overground survey data need to be shared by client. Otherwise 3D scanning is recomended. Please confirm.

Piping, C&S Piping 9. Underground mapping data need to be shared by client. Please confirm.

a) Which option i.e. option-1 or option - 2 is final. 1.We understand that the nos of pumps, their capacity, head

b) Pipe to be laid on above ground (from existing and type has been finalised by TSL and as indicated in the flow

structure or pedestal) or underground? scheme.

2.We understand that for installation of submersible pumps

inside existing CRM WWTP treated water tank is in the scope

of TCE.

1. We understand that CRM WWTP Treated Effluent

3.We presume that, the construction of Effluent Collection

Utilization in LD#2 Slag Quenching system shall be

Tank and adjacent Pump House will be RCC We understand that 415V Power

Operated, Control and Monitored by Stand alone PLC

4.We assume that there is no requirement for any Mechanical source from a existing switchboard

based Automation system. Please Confirm. 1.Is there any existing pit at existing CRM WWTP Treated water Tank to install new two number submersible pump OR new pit to be

Steel Handling arrangement/hoist in the CRM WWTP treated water spare feeder will be made available

3 TSJ LD#2 Improvement Utilization of CRM Effluent in LD2 Slag Quenching constructured for installation of new two nos. submersible pumps. Please clarify.

making tank. However, for the proposed effluent collection tank inside CRM WWTP plant. Study of

2. We understand that CRM WWTP Treated Effluent 2.Apart from the above, is there any civil & structural work need to be carried out at existing tank? If yes then please specify the same.

adjacent pump house hoisting facility is to be provided. existing Electrical system is not in our

Utilization in LD#2 Slag Quenching Automation system 3. Is this one DN 150 pipe will be supported in new structure & foundation at over ground? Please confirm.

scope of work. Please Confirm.

will be interfaced with CRM WWTP Automation System 4. If the route is partly supported in new structure and partly supported on existing structure then please specify the percentage of support to

Drawings requirement

for Data storage. Please Confirm.

be considered for new & existing structure?

I.Mechanical GA drawing for existing CRM WWTP treated 5. Please specify the material of construction (i.e RCC/STEEL) of new effluent Collection Tank.

water tank and Slag Quenching Water Tank showing minimum, 6. Is the new tank will be underground / overground tank? Please specify.

maximum & normal water level, Bottom level of the tank and 7. Is there any new pump house to be constructed? If yes then please specify the size along with MOC?

Water & top of tank COMMON FOR ALL PROJECTS:

Piping

Piping , C&S, Elect 1.PLEASE REFER ALL C&S QUERIES AS MENTIONED IN SL NO. 1 AND CLARIFY THE SAME.

a) Whether above ground and under ground survey

are required at this stage (FEL-2)? 1.Is there any PFD / P&ID available for this COG distribution

b) Whether stress analysis is required at this stage system for LCP?

(FEL-2)? 2.As per background information two (02 nos.) DN 900 lines

need to be considered, whereas in the Project scope there is a

mention of DN 700 COG line which may please be clarified by

client.

3.It is not clear from the scope whether insolation valves and

We understand that necessary operation, control and

U seal exist in the two (02) nos. DN 900 branch line which are

monitoring along with necessary instruments for DN700

tapped from the main header of DN 1500 (old & New). Please

Steel COG line from from the existing two DN 1500 COG (Old

4 TSJ LCP Safety Installation of New COG for Kiln 1 to 6 clarify.

making & New main) line from Coke Plant to Maerz kilns (MK) 1-

4.Existing layout / construction drawing of COG line with

6 of Lime Calcining Plant (LCP) will be required which will

support structure drawing may please be made available for 1. In scope it is specified that old COG line will be dismantled. Please clarify whether existing supporting structure to be dismantled or not.

be under scope of work. Please Confirm.

assessment of the quantum of the job. 2. From layout it is understood that new support structure along with new foundation will be constructed to support the new COG line between

5.Existing TOP conditions (Pressure, temperature & Flow) for point C &D. Please confirm.

Nitrogen services and its location. 3. Is the total route of new COG line limited to between point A to D? Please confirm.

6.As per Project scope clause no. 7 & 9 we presume that small 4. If the route between point A to point C is partly supported in new structure and partly supported on existing structure then please specify

pipe, fitting and valves are made for nitrogen purging. Please

the percentage of support to be considered for new & existing structure?

confirm.

5. Please share the health study report if any strengthening of existing structure is required.

COMMON FOR ALL PROJECTS:

Utility,C&S, INCUtility 1.PLEASE REFER ALL C&S QUERIES AS MENTIONED IN SL NO. 1 AND CLARIFY THE SAME.

You might also like

- 2014-Reconfigurable Reflectarrays and Array Lenses For Dynamic Antenna Beam Control A ReviewDocument16 pages2014-Reconfigurable Reflectarrays and Array Lenses For Dynamic Antenna Beam Control A Reviewadamhong0109No ratings yet

- Static Metallic Manual - Mts004Document656 pagesStatic Metallic Manual - Mts004ROUSSMAT83% (6)

- Chapter 4 Foundations of Organization DevelopmentDocument49 pagesChapter 4 Foundations of Organization DevelopmentMoses Avinash Andrews0% (1)

- Projects - FEL2 - QueriesDocument6 pagesProjects - FEL2 - QueriesSumantra ChattopadhyayNo ratings yet

- Pre-Construction Staged:: Desk StudyDocument10 pagesPre-Construction Staged:: Desk StudymangjuhaiNo ratings yet

- Ts 2014 109 Matrics RF FpgaDocument4 pagesTs 2014 109 Matrics RF FpgaTarun CousikNo ratings yet

- Exfo Reference-Poster 5g-Ran v1 enDocument2 pagesExfo Reference-Poster 5g-Ran v1 enDjnsilva SilvaNo ratings yet

- Sag and Tension Calculations For Mountainous Terrain: Discussion OnDocument2 pagesSag and Tension Calculations For Mountainous Terrain: Discussion OnTejo AlamNo ratings yet

- Poster Ecoc Rimini 030921Document1 pagePoster Ecoc Rimini 030921Jaya Kumar KbNo ratings yet

- Antenna Half Square ArrayDocument8 pagesAntenna Half Square Arraycarlos_gomes_31No ratings yet

- A Simulation Model For Nakagami-M Fading Channels, M 1: IEEE Transactions On Communications March 2000Document10 pagesA Simulation Model For Nakagami-M Fading Channels, M 1: IEEE Transactions On Communications March 2000Yiğit DURDUNo ratings yet

- A1.0.0.pr - 41-SITE PLAN2 - LD CommentsDocument1 pageA1.0.0.pr - 41-SITE PLAN2 - LD CommentsHarman BoolNo ratings yet

- Corning Fiber Deep Splice Soln GuideDocument2 pagesCorning Fiber Deep Splice Soln GuideThomas IsoaNo ratings yet

- An Interactive Spreadsheet Based Approach To Simplify Method Transfer Between Different Vendor UHPLC and HPLC InstrumentsDocument1 pageAn Interactive Spreadsheet Based Approach To Simplify Method Transfer Between Different Vendor UHPLC and HPLC InstrumentsМихаил ГородковNo ratings yet

- MEUK-TW-001-DRAWS-1-2016-28-01 Rev DDocument1 pageMEUK-TW-001-DRAWS-1-2016-28-01 Rev DbgygNo ratings yet

- ARMA-Based Adaptive Coding Transmission Over MilliDocument12 pagesARMA-Based Adaptive Coding Transmission Over MilliToàn - K2 Nguyễn VănNo ratings yet

- Design of Ka-Band Satellite Links in IndonesiaDocument5 pagesDesign of Ka-Band Satellite Links in Indonesiaaya__ayakNo ratings yet

- OTC 12004 A High-Resolution Survey AUV: Deep-Towed SystemsDocument5 pagesOTC 12004 A High-Resolution Survey AUV: Deep-Towed SystemsThomas ThomasNo ratings yet

- Development of A 500-kV DC XLPE Cable SystemDocument6 pagesDevelopment of A 500-kV DC XLPE Cable SystemalchernNo ratings yet

- Evaluation of Flexible Foundation & Pavement Design According To The DMRBDocument1 pageEvaluation of Flexible Foundation & Pavement Design According To The DMRBAguero AgueroNo ratings yet

- Special: Ieee/Pes Course PipeDocument1 pageSpecial: Ieee/Pes Course PipeRamot GultomNo ratings yet

- Format For Detailed Feasibility StudyDocument14 pagesFormat For Detailed Feasibility StudyAbhayaNo ratings yet

- L-4/T-lIEEE Date: 07/12/2014: Section-ADocument42 pagesL-4/T-lIEEE Date: 07/12/2014: Section-AHolloGramNo ratings yet

- AISC - Steel ConstructionDocument7 pagesAISC - Steel ConstructionMohamed HNo ratings yet

- Conductive Textiles - Final3012Document5 pagesConductive Textiles - Final3012Mirela CimpanuNo ratings yet

- Abdulhussein 2021 J. Phys. Conf. Ser. 2114 012051Document8 pagesAbdulhussein 2021 J. Phys. Conf. Ser. 2114 012051yeyegak481No ratings yet

- Acs Iecr 8b04883Document7 pagesAcs Iecr 8b04883Doctor premsagarNo ratings yet

- Fully Convolutional Networks For Semantic Segmentation: Jonathan Long Evan Shelhamer Trevor Darrell UC BerkeleyDocument10 pagesFully Convolutional Networks For Semantic Segmentation: Jonathan Long Evan Shelhamer Trevor Darrell UC BerkeleyUnaixa KhanNo ratings yet

- JL-92-July-August Design and Construction of Spliced I-Girder BridgesDocument9 pagesJL-92-July-August Design and Construction of Spliced I-Girder BridgesRammiris ManNo ratings yet

- Profile DesignDocument10 pagesProfile DesignMaduranga MalindaNo ratings yet

- Development of Models For The Interpretation of The Dynamic Cone Penetrometer DataDocument14 pagesDevelopment of Models For The Interpretation of The Dynamic Cone Penetrometer DatamohammadNo ratings yet

- Pole FoundationDocument10 pagesPole FoundationbatteekhNo ratings yet

- A Survey of Practical Issues in Underwater NetworksDocument11 pagesA Survey of Practical Issues in Underwater NetworkshuhcenboNo ratings yet

- A Frequency Reconfigurable Tuner Loaded Coupled FeDocument11 pagesA Frequency Reconfigurable Tuner Loaded Coupled FeCung LevanNo ratings yet

- Marggaret SutherDocument15 pagesMarggaret SuthervgopikNo ratings yet

- Smarter Poster AC RevDocument2 pagesSmarter Poster AC RevPromit ChoudhuryNo ratings yet

- An SOI N-P-N Double Gate TFET For Low Power Applications: Abstract - This Article Proposes A Tunnel Field EffectDocument3 pagesAn SOI N-P-N Double Gate TFET For Low Power Applications: Abstract - This Article Proposes A Tunnel Field Effectrui chenNo ratings yet

- Analysis of Water Distribution Network Using Epanet and Vertex MethodDocument11 pagesAnalysis of Water Distribution Network Using Epanet and Vertex MethodJohn Michael Capulla CadienteNo ratings yet

- Achieving Frequency Reuse 1 in Wimax Networks With BeamformingDocument14 pagesAchieving Frequency Reuse 1 in Wimax Networks With Beamformingbulli babuNo ratings yet

- Murex Cored Wire Poster 08Document1 pageMurex Cored Wire Poster 08PCNo ratings yet

- Design of A UWB Slot Antenna With Frequency Band-Notched CharacteristicDocument4 pagesDesign of A UWB Slot Antenna With Frequency Band-Notched CharacteristicavalNo ratings yet

- SPE63928Document14 pagesSPE63928Jose Gregorio Fariñas GagoNo ratings yet

- Channel Capacity Analysis of MIMO System in Correlated Nakagami-M Fading EnvironmentDocument5 pagesChannel Capacity Analysis of MIMO System in Correlated Nakagami-M Fading Environmenthendra lamNo ratings yet

- Design and Analysis of Circular Shape Microstrip Patch Antenna For C-Band ApplicationsDocument3 pagesDesign and Analysis of Circular Shape Microstrip Patch Antenna For C-Band ApplicationsAnkurNo ratings yet

- Propagation Path Loss Models For LTE-Advanced Urban Relaying SystemsDocument4 pagesPropagation Path Loss Models For LTE-Advanced Urban Relaying SystemsYeider ArizaNo ratings yet

- VDF PAPER (Group 3)Document6 pagesVDF PAPER (Group 3)ajay SharmaNo ratings yet

- New Design of Micro-Strip Patch Antenna For Wi-Fi ApplicationsDocument6 pagesNew Design of Micro-Strip Patch Antenna For Wi-Fi ApplicationsBenziane fethi ChihebNo ratings yet

- 30.04 (L&T Reply)Document1 page30.04 (L&T Reply)Senthilkumar KNo ratings yet

- Wireless Signal Processing Research Group: Relays in Wireless Communication SystemsDocument3 pagesWireless Signal Processing Research Group: Relays in Wireless Communication SystemsSOUMYA KANTI SAUNo ratings yet

- A Complete Design Flow For Silicon PhotonicsDocument17 pagesA Complete Design Flow For Silicon PhotonicsnowdayNo ratings yet

- Satcoms Payload EngineeringDocument55 pagesSatcoms Payload EngineeringErfan MahmudNo ratings yet

- 12 05 29 Case Study Boston Mbta SubwayDocument6 pages12 05 29 Case Study Boston Mbta SubwayP HandokoNo ratings yet

- Pipe ConveyorDocument4 pagesPipe ConveyorDIBYENDU MONDALNo ratings yet

- Ieee VlsiDocument7 pagesIeee VlsiSwarupa ReddyNo ratings yet

- Application of Simulation in Trenchless Renewal of Underground Urban InfrastructureDocument8 pagesApplication of Simulation in Trenchless Renewal of Underground Urban InfrastructureakashNo ratings yet

- Kumar Workspace Analysis 4 Cable Driven Spatial Parallel Robot ROMANSY 2018Document9 pagesKumar Workspace Analysis 4 Cable Driven Spatial Parallel Robot ROMANSY 2018RAZIQ YOUSSEFNo ratings yet

- Sub-Basalt Imaging in The Gulf of KutchDocument5 pagesSub-Basalt Imaging in The Gulf of KutchanoopscribdNo ratings yet

- 02.optical Network TestingDocument1 page02.optical Network Testingphuongnt1710No ratings yet

- Red ElectricaDocument2 pagesRed ElectricaFelipe JaramilloNo ratings yet

- Ijeit1412201406 45Document11 pagesIjeit1412201406 45SailajaUngatiNo ratings yet

- Lothal in ABPDocument1 pageLothal in ABPSumantra ChattopadhyayNo ratings yet

- soil resistivityDocument3 pagessoil resistivitySumantra ChattopadhyayNo ratings yet

- Projects - FEL2 - QueriesDocument6 pagesProjects - FEL2 - QueriesSumantra ChattopadhyayNo ratings yet

- IBR Thickness CalDocument8 pagesIBR Thickness CalSumantra ChattopadhyayNo ratings yet

- Buru PDF 1Document4 pagesBuru PDF 1Sumantra ChattopadhyayNo ratings yet

- Finance Closure Calender - Mar 24Document6 pagesFinance Closure Calender - Mar 24Sumantra ChattopadhyayNo ratings yet

- Transaction Successful Acknowledgement Slip: Thank You For Your Concern Towards The Environment by Paying OnlineDocument1 pageTransaction Successful Acknowledgement Slip: Thank You For Your Concern Towards The Environment by Paying OnlinePriyanko ChatterjeeNo ratings yet

- CTR MH Estimate-Mech-MasterDocument4 pagesCTR MH Estimate-Mech-MasterSumantra ChattopadhyayNo ratings yet

- SaddleDocument1 pageSaddleSumantra ChattopadhyayNo ratings yet

- The Secret To Great Health Escaping The Healthcare Matrix - FDocument22 pagesThe Secret To Great Health Escaping The Healthcare Matrix - FSumantra ChattopadhyayNo ratings yet

- MFPFDetailsDocument1 pageMFPFDetailsSumantra ChattopadhyayNo ratings yet

- List of Documents For Item Rate Contract For Consultants - CombinedDocument6 pagesList of Documents For Item Rate Contract For Consultants - CombinedSumantra ChattopadhyayNo ratings yet

- CTR MH Estimate-PipelinesDocument4 pagesCTR MH Estimate-PipelinesSumantra ChattopadhyayNo ratings yet

- Doctor's Presciption. Ahana IX-FDocument1 pageDoctor's Presciption. Ahana IX-FSumantra ChattopadhyayNo ratings yet

- Prachyo ConsentDocument1 pagePrachyo ConsentSumantra ChattopadhyayNo ratings yet

- SKM 226i23092909460 0001Document6 pagesSKM 226i23092909460 0001Sumantra ChattopadhyayNo ratings yet

- WBSEDCL Bill Payment EmailDocument1 pageWBSEDCL Bill Payment EmailSumantra ChattopadhyayNo ratings yet

- Schedule of Quantity - Proposal Schedule of Quantity - EngineeringDocument1 pageSchedule of Quantity - Proposal Schedule of Quantity - EngineeringSumantra ChattopadhyayNo ratings yet

- Daye Amadero Review DeshDocument2 pagesDaye Amadero Review DeshSumantra ChattopadhyayNo ratings yet

- Kishore Bharati Rahasya Romancho 101Document806 pagesKishore Bharati Rahasya Romancho 101Sumantra Chattopadhyay100% (1)

- Binder 1Document2 pagesBinder 1Sumantra ChattopadhyayNo ratings yet

- Review On Drowsy Driving: Becoming Dangerous Problem: Kusuma Kumari B. MDocument3 pagesReview On Drowsy Driving: Becoming Dangerous Problem: Kusuma Kumari B. MSumantra ChattopadhyayNo ratings yet

- Consolidated Valve and Strainer BOQDocument13 pagesConsolidated Valve and Strainer BOQSumantra ChattopadhyayNo ratings yet

- Comparison of Pipe Lengths CS & SSDocument2 pagesComparison of Pipe Lengths CS & SSSumantra ChattopadhyayNo ratings yet

- RAM RAJYA 2.0 Final PresentationDocument18 pagesRAM RAJYA 2.0 Final PresentationSumantra ChattopadhyayNo ratings yet

- Aberdeen SpendAnalysis ReviewDocument8 pagesAberdeen SpendAnalysis ReviewnlgargNo ratings yet

- At-Site and Regional Flood Frequency Analysis of The Upper Awash Sub Basin in The Ethiopian PlateauDocument15 pagesAt-Site and Regional Flood Frequency Analysis of The Upper Awash Sub Basin in The Ethiopian PlateauRahulKumarSinghNo ratings yet

- RelationshipDocument3 pagesRelationshipAkim LncpNo ratings yet

- Tecplot 360 2013 Scripting ManualDocument306 pagesTecplot 360 2013 Scripting ManualThomas KinseyNo ratings yet

- Elective ReportDocument3 pagesElective ReportBanu ThuraisingamNo ratings yet

- Final BMTU As On 28.06.19Document103 pagesFinal BMTU As On 28.06.19Rahul N PatelNo ratings yet

- 87-351 Lecture 11 NotesDocument10 pages87-351 Lecture 11 NotesAmritpal GillNo ratings yet

- PL Toolbox Talk 5 Minute HousekeepingDocument1 pagePL Toolbox Talk 5 Minute HousekeepingRomanuSNo ratings yet

- Aerospace Industry - ChennaiDocument4 pagesAerospace Industry - ChennaiKarthi ThiyagarajanNo ratings yet

- NH Màn Hình 2022-10-26 Lúc 07.55.12Document4 pagesNH Màn Hình 2022-10-26 Lúc 07.55.12Thuy Quynh BuiNo ratings yet

- S&S Quarterly, Inc. Guilford PressDocument16 pagesS&S Quarterly, Inc. Guilford Pressaf2496No ratings yet

- Journal of Air Transport Management Volume 28 Issue 2013 (Doi 10.1016 - J.jairtraman.2012.12.010) Daft, Jost Albers, Sascha - A Conceptual Framework For Measuring Airline Business Model Converge PDFDocument8 pagesJournal of Air Transport Management Volume 28 Issue 2013 (Doi 10.1016 - J.jairtraman.2012.12.010) Daft, Jost Albers, Sascha - A Conceptual Framework For Measuring Airline Business Model Converge PDFPhan Thành TrungNo ratings yet

- Coen3114 Compsysorg Lab01 PDFDocument4 pagesCoen3114 Compsysorg Lab01 PDFjocansino4496No ratings yet

- Course Title: Fundamentals of Entrepreneurship Course Code: ENTR301 Credit Units: 3 Course Level: UG Course ObjectivesDocument3 pagesCourse Title: Fundamentals of Entrepreneurship Course Code: ENTR301 Credit Units: 3 Course Level: UG Course ObjectiveskaranNo ratings yet

- Sap PP SyllabusDocument4 pagesSap PP SyllabusZaheer AhamedNo ratings yet

- TR DNP3 EngDocument48 pagesTR DNP3 EngJasson ChavezNo ratings yet

- Sans 3001-Ag4Document11 pagesSans 3001-Ag4Sergio VianaNo ratings yet

- Class VII - Lesson 1Document8 pagesClass VII - Lesson 1saranya ajaNo ratings yet

- Engineering HydrologyDocument2 pagesEngineering Hydrology11520035100% (1)

- Oracle R12 P2P by Dinesh Kumar SDocument158 pagesOracle R12 P2P by Dinesh Kumar SHarimakeshwaran Rengaraju100% (1)

- Iron Ore Body ModelingDocument45 pagesIron Ore Body ModelingNurul MagfirahNo ratings yet

- MLWB User ManualDocument35 pagesMLWB User ManualManish ShahNo ratings yet

- BH3303 Contemporary Issues in HRM Module OutlineDocument4 pagesBH3303 Contemporary Issues in HRM Module OutlineriddhiNo ratings yet

- Future Trends in Fiber Optics CommunicationDocument6 pagesFuture Trends in Fiber Optics CommunicationSupri GunNo ratings yet

- Circular 2Document31 pagesCircular 2prakashkerurNo ratings yet

- Activity 2Document2 pagesActivity 2Cherry Ann Marcial NabascaNo ratings yet

- Price List of BooksDocument32 pagesPrice List of BooksUtc ChattanoogaNo ratings yet

- From Theory To Practice of Ecotourism: Major Obstacles That Stand in The Way and Best Practices That Lead To SuccessDocument12 pagesFrom Theory To Practice of Ecotourism: Major Obstacles That Stand in The Way and Best Practices That Lead To SuccessMarie BeloNo ratings yet