Professional Documents

Culture Documents

ZA 35 MOULD FAST Technical Data Sheet ING2

ZA 35 MOULD FAST Technical Data Sheet ING2

Uploaded by

Szelestey Tamás "ToME"Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ZA 35 MOULD FAST Technical Data Sheet ING2

ZA 35 MOULD FAST Technical Data Sheet ING2

Uploaded by

Szelestey Tamás "ToME"Copyright:

Available Formats

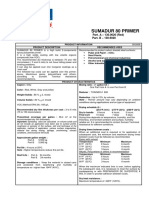

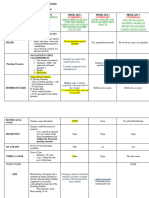

ZHERMACK S.P.A.

HI - TECH DIVISION

Via Bovazecchino, 100 – 45021 Badia Polesine (RO)

Tel 0425.597611 - Fax 0425.53596

ZA 35 MOULD FAST : Technical Data Sheet

1. Description and Main Features

ZA 35 MOULD FAST is a bicomponent (base and catalyst) addition RTV silicone rubber that vulcanizes at room

temperature.

Indicated for the duplication of models with small recesses.

The main property of the product to be vulcanized is its remarkable fluidity.

The main properties of the vulcanized product are:

- High chemical resistance to the aggressive components of some types of resin;

- Extremely high tear strength (this feature guarantees high resistance to wear and tear);

- High accuracy in reproducing very small details;

- High dimensional stability in time and indeformability;

- Remarkable resistance to high temperatures and aging;

- Excellent anti-stick effect.

2. Main Fields of Application

• Mould-making and model-making (for its remarkable reproduction accuracy, high dimensional stability and

high mechanical strength)

• Art Ceramic (for its high dimensional stability and fluidity. Suggested for the reproduction of mother shape /

form).

3. Instructions for use

Take the two bi-component products supplied by Zhermack (base and catalyst) and shake before use. Weigh an equal

amount of catalyst and base (ex. 100 grams of catalyst and 100 grams of base; within a 5% error range the end result is

not altered). When extraditing the product from the container it is necessary to use two different spoons for each

component to prevent contamination of the product. Once the product is weighed and it is assured that the base and

catalyst are equal, the two components are inserted in a recipient and mixed thoroughly. It is important to check while

mixing that no residue remains on the base and sides of the recipient. Mix energetically until the colour of the product

is homogeneous. Once the product is mixed it is poured, preferably 30cm above the recipient into the mould. The

working time is approximately WT (see table below) from the beginning of the mixing at 23°C. It is advised to

vacuum the mixture to prevent air pockets. If the quantity used is less than what is needed to complete the duplication,

complete the hardening of the silicone and than proceed with the addition of the remaining silicone needed. The

material attaches to the silicone without altering the final result.

The setting time (time the silicone needs to vulcanize) is about ST at 23°C (see table below). After the ST is complete,

from the start of the mixing, we can separate the model from the mould. If necessary use compress air to facilitate this

separation. It is important not to force this separation with sharp objects that can deform the final stamp. The silicon

rubber is compatible with all gypsums, coatings, polyurethane resins and acrylic resins

Note: The working time and thus the setting time are reduced if the temperature exceeds 23°C (ex. If the temperature is

40°C, the working time is halved and the setting time is approximately halved). If the temperature is less than 23°C

ZHERMACK S.P.A. HI - TECH DIVISION

Via Bovazecchino, 100 – 45021 Badia Polesine (RO)

Tel 0425.597611 - Fax 0425.53596

both the working time and setting time increase considerably. (ex. If the temperature is 4°C, the working time doubles

and the Setting time increases three times the minutes indicated at 23°C ).

4. Important Recommendations

The exact proportions 1 : 1 must be respected to obtain the correct times and not to alter the final characteristics of the

product. The surfaces with which the material enters in contact must be perfectly clean, free of grease and dry.

NB: before use, we recommend the two components be homogenized so as to avoid sedimentation.

5. Chemical and Physical Properties

Vulcanized product

Mixing ratio 1:1

Specific weight 1.16-1.18 g/cc

Viscosity of pre-catalization mixture 4100 ± 300 cP

Mixing time at 23 °C (73 °F) 1’

Working time at 23 °C (73 °F) WT= 6’

Setting time at 23 °C (73 °F) ST= 20’

Shore A hardness after 24 hours 35 ± 2 shA

Breaking load 3.0±0.2 N/mm2

Elongation at break 300±20 %

Tear strength DIE B 7±1 N/mm

Tear strength DIE C 9±1 N/mm

6. Available Packages

Zhermack code Packages

DT23312 5 kg + 5 kg

7. Safety Data Sheets

The safety data sheets are available at Zhermack SpA.

The preparation is not to be considered hazardous in accordance with directive 88/379/CEE and subsequent

amendments.

8. Shelf Life

The ZA 35 MOULD FAST is guaranteed for a period of 18 months if stored correctly at a temperature of between 5° -

27°C (41° - 80°F).

Close the bottles after use, do not invert the caps or lids between the base and catalyst.

IMPORTANT OBSERVATIONS

The advice given verbally, in writing or through demonstrations on the use of the products are based on our knowledge. The use and

application of the product by the user lie beyond the control of the company and are therefore the user’s own responsibility.

You might also like

- Wake Traverse Experiment-ABEE1027Document11 pagesWake Traverse Experiment-ABEE1027Luyao ZHANG0% (1)

- Pds Hempadur 35900 En-GbDocument2 pagesPds Hempadur 35900 En-Gbluisbarrios104No ratings yet

- Soldering electronic circuits: Beginner's guideFrom EverandSoldering electronic circuits: Beginner's guideRating: 4.5 out of 5 stars4.5/5 (9)

- Design of Packed Column (3q Sy2010-11)Document65 pagesDesign of Packed Column (3q Sy2010-11)Lin Xian XingNo ratings yet

- enDocument2 pagesenSalih HasNo ratings yet

- Primer enDocument2 pagesPrimer enSalih HASNo ratings yet

- Surface Evolution - enDocument2 pagesSurface Evolution - enRio Purwo SembodoNo ratings yet

- Sikafloor - 290 PrimerDocument4 pagesSikafloor - 290 PrimerMaha MuflehNo ratings yet

- Sigacoat 111: Technical Data SheetDocument2 pagesSigacoat 111: Technical Data SheetAmirhossein LotfiNo ratings yet

- Handling Guide & Instructions:: Z01 UD PrepregDocument10 pagesHandling Guide & Instructions:: Z01 UD PrepregSamora Tooling EngineerNo ratings yet

- Intersleek 425: Elastomeric Foul Release CoatingDocument4 pagesIntersleek 425: Elastomeric Foul Release CoatingTrịnh Minh KhoaNo ratings yet

- PDS Hempadur Multi-Strength 35842 en-GBDocument2 pagesPDS Hempadur Multi-Strength 35842 en-GBIfrahimNo ratings yet

- UR5041 Encapsulation Resins EN 03feb22 TBDocument5 pagesUR5041 Encapsulation Resins EN 03feb22 TBscorpionbadshahNo ratings yet

- Intersleek 1100SR: Advanced Fluoropolymer Foul Release CoatingDocument4 pagesIntersleek 1100SR: Advanced Fluoropolymer Foul Release CoatingYanyan2009No ratings yet

- Sikadur®-52 ZA: Product Data SheetDocument4 pagesSikadur®-52 ZA: Product Data SheetAmar Babu ChNo ratings yet

- Sikadur - 42 MP inDocument4 pagesSikadur - 42 MP inJU SHUANGNo ratings yet

- 751 Epoxy Zinc Primer TDS enDocument2 pages751 Epoxy Zinc Primer TDS enAgoritsaNo ratings yet

- Jotatemp 1000 Ceramic: Technical Data SheetDocument5 pagesJotatemp 1000 Ceramic: Technical Data Sheetebastien2No ratings yet

- Sabatack® Fast PDS EngDocument2 pagesSabatack® Fast PDS Engc.ceccarelliNo ratings yet

- Sikagrout - 200 PtidDocument3 pagesSikagrout - 200 Ptidfandy sipataNo ratings yet

- Jazeera Barrel CoatingDocument2 pagesJazeera Barrel Coatingsalam nazarNo ratings yet

- Pds Ipd Sikafast3121 Us MW 3.22.12Document4 pagesPds Ipd Sikafast3121 Us MW 3.22.12robox514No ratings yet

- Metallon E 2602: Technical Data SheetDocument4 pagesMetallon E 2602: Technical Data SheetAnabelNo ratings yet

- Kanepox Masticoat: 15550 KANEPOX MASTICOAT Is An Epoxy-Polyamine Based, Two Component, Zinc PhosphateDocument3 pagesKanepox Masticoat: 15550 KANEPOX MASTICOAT Is An Epoxy-Polyamine Based, Two Component, Zinc PhosphateSalih HASNo ratings yet

- Perma-Glaze Series G435: Product ProfileDocument2 pagesPerma-Glaze Series G435: Product ProfileR. Raziel Vergara Z.No ratings yet

- Sikadur - 43 TaDocument3 pagesSikadur - 43 TaSylvester WafulaNo ratings yet

- Hempadur Zinc 17360Document2 pagesHempadur Zinc 17360Bang OchimNo ratings yet

- TDS - ELECTROLUBE - UR5083 - Eng GELDocument3 pagesTDS - ELECTROLUBE - UR5083 - Eng GELscorpionbadshahNo ratings yet

- Hempel'S Vinyl Ester GF 35910: Description: Recommended UseDocument2 pagesHempel'S Vinyl Ester GF 35910: Description: Recommended UseSurendra KumarNo ratings yet

- Sikadur - 53 Uf GroutDocument3 pagesSikadur - 53 Uf GroutJU SHUANGNo ratings yet

- Eh6280 (HS)Document2 pagesEh6280 (HS)anminsungNo ratings yet

- Micron 300 Eng A4 20180720Document2 pagesMicron 300 Eng A4 20180720nikenNo ratings yet

- 130.0020 - Sumadur 80 PrimerDocument2 pages130.0020 - Sumadur 80 Primerhelioxavier2No ratings yet

- Sikadur 42 Vle PlusDocument4 pagesSikadur 42 Vle PlusMohammed AwfNo ratings yet

- Sikagrout®-200 PT Id: Product Data SheetDocument3 pagesSikagrout®-200 PT Id: Product Data SheetCbeztNo ratings yet

- Carboguard 89dfsfs0 PDSDocument2 pagesCarboguard 89dfsfs0 PDSMayur PatelNo ratings yet

- Cmp0000410 Dc1 Jotamastic 87Document5 pagesCmp0000410 Dc1 Jotamastic 87Akhiruddin AbasNo ratings yet

- Technical Dat A SheetDocument2 pagesTechnical Dat A SheetWasif Azim100% (2)

- Sikadur - 42 ZaDocument4 pagesSikadur - 42 ZaPatrickKisulaNo ratings yet

- Carboguard 890 PDSDocument2 pagesCarboguard 890 PDSLinnie McleodNo ratings yet

- Mastertop 1325: Seamless, Self-Smoothing Flexible Polyurethane Based Flooring SystemDocument3 pagesMastertop 1325: Seamless, Self-Smoothing Flexible Polyurethane Based Flooring SystemFrancois-No ratings yet

- Out of Autoclave Epoxy Component Prepreg: Typical Applications: General Purpose - VisualDocument3 pagesOut of Autoclave Epoxy Component Prepreg: Typical Applications: General Purpose - VisualJohnnyNo ratings yet

- Sikadur®-42 Grout Pak LE: Pre-Proportioned, Precision Epoxy Grouting SystemDocument2 pagesSikadur®-42 Grout Pak LE: Pre-Proportioned, Precision Epoxy Grouting Systemraunak upadhyayaNo ratings yet

- TDS 01ofg V08 enDocument2 pagesTDS 01ofg V08 enDenisTarasNo ratings yet

- Scotch KoteDocument4 pagesScotch KoteJavier Gomez ReyesNo ratings yet

- KCC - DATASHEET - Korethan Topcoat UT6581 (Two-Component) - EngDocument2 pagesKCC - DATASHEET - Korethan Topcoat UT6581 (Two-Component) - EngIsabelo AbaoNo ratings yet

- Hempadur Multi-Strength GF 35870 PDFDocument3 pagesHempadur Multi-Strength GF 35870 PDFAnuar SalehNo ratings yet

- Sikagard®-62: Product Data SheetDocument4 pagesSikagard®-62: Product Data Sheetantonsugiarto20_7049No ratings yet

- 113.007 - Zinc Clad Xi WB BR PDFDocument2 pages113.007 - Zinc Clad Xi WB BR PDFFernando VittoNo ratings yet

- TDS - HZ 01CPR - V02 - enDocument2 pagesTDS - HZ 01CPR - V02 - enFakhreddine BousninaNo ratings yet

- PDS PC88 Adhesive US enDocument4 pagesPDS PC88 Adhesive US enHung Mai VanNo ratings yet

- Protective & Marine Coatings: Magnalux 40VDocument2 pagesProtective & Marine Coatings: Magnalux 40VMd Usama100% (1)

- M Seal PhataphatDocument2 pagesM Seal PhataphatKuldeep KumarNo ratings yet

- Tds 8330 2partsDocument2 pagesTds 8330 2partsgrasia77No ratings yet

- TS8833 (Electronic Thermal Silicone Potting) - 2Document6 pagesTS8833 (Electronic Thermal Silicone Potting) - 2ana.luiza.nanyNo ratings yet

- HEMPADUR 47182 47182 en-GB PDFDocument3 pagesHEMPADUR 47182 47182 en-GB PDFwilfran villegasNo ratings yet

- Aquaarm Topguard Aquaarm Topguard Aquaarm TopguardDocument2 pagesAquaarm Topguard Aquaarm Topguard Aquaarm TopguardmadhavNo ratings yet

- ATYS-EAM-106Document4 pagesATYS-EAM-106Endang SunartiNo ratings yet

- Product Data Sheet: Transpoxy Masterbond 4.68Document2 pagesProduct Data Sheet: Transpoxy Masterbond 4.68rajeshNo ratings yet

- 3M Neoprene High Performance Rubber & Gasket Adhesive 1300LDocument6 pages3M Neoprene High Performance Rubber & Gasket Adhesive 1300LIventNo ratings yet

- PAVISINT SEALER 45 - enDocument2 pagesPAVISINT SEALER 45 - enrjmscNo ratings yet

- Delta0014 - Test Program and Instruction For RT 1-3kVA - PDFDocument10 pagesDelta0014 - Test Program and Instruction For RT 1-3kVA - PDFWalter Achaya LevaNo ratings yet

- Design of SteelDocument34 pagesDesign of Steelarun11/1984100% (4)

- 12 Audiometic TestingDocument99 pages12 Audiometic TestingAashish SinghNo ratings yet

- 28642 論文Document173 pages28642 論文javierzmorNo ratings yet

- Antenna Log Periodic DipoleDocument4 pagesAntenna Log Periodic DipoleMariam AhmedNo ratings yet

- Fick LawDocument8 pagesFick LawHalimahNo ratings yet

- Invention Spotting For Defeathering FinalDocument6 pagesInvention Spotting For Defeathering FinalJohairah GumampongNo ratings yet

- HexPly 8552Document4 pagesHexPly 8552DaniloNo ratings yet

- Nut Sorting Machine Model GNS-100Document68 pagesNut Sorting Machine Model GNS-100Jose Gregorio Hernandez SuarezNo ratings yet

- EGYLUX Outdoor Lighting 2 - 2Document6 pagesEGYLUX Outdoor Lighting 2 - 2mowhead adelNo ratings yet

- ScienceDocument7 pagesScienceMelissa Joyce SunicoNo ratings yet

- RexrothDocument12 pagesRexrothigorNo ratings yet

- KV of BitumenDocument10 pagesKV of Bitumendhanesh kumarNo ratings yet

- Mathematics: Tower, Road No.1, IPIA, Kota (Raj.), PH: 0744-2434159Document6 pagesMathematics: Tower, Road No.1, IPIA, Kota (Raj.), PH: 0744-2434159Subrata KarmakarNo ratings yet

- Induction Hardening (Bayu-Bowo)Document22 pagesInduction Hardening (Bayu-Bowo)zaid sulaimanNo ratings yet

- Procedure and Specifications FOR: Wind Load AnalysisDocument29 pagesProcedure and Specifications FOR: Wind Load Analysismatthew cometaNo ratings yet

- Derivation Bragg's Snell Law PDFDocument4 pagesDerivation Bragg's Snell Law PDFVaswati BiswasNo ratings yet

- Physics Part 2 Guess 2023Document19 pagesPhysics Part 2 Guess 2023Mehran ChaudryNo ratings yet

- The Hot Bypass Pressure Control Rev. Agosto 2018Document12 pagesThe Hot Bypass Pressure Control Rev. Agosto 2018luiz.henriqueNo ratings yet

- Abstract - The Magnetic Current - NatureDocument3 pagesAbstract - The Magnetic Current - NatureBozidar KemicNo ratings yet

- Watches PublicationDocument72 pagesWatches PublicationNguyen Nhan TrungNo ratings yet

- Quiz HT105: ProblemsDocument17 pagesQuiz HT105: ProblemsZERINA ŠKULJNo ratings yet

- Solved - The State of Plane Stress Shown Is Expected in An Alu-I... PDFDocument3 pagesSolved - The State of Plane Stress Shown Is Expected in An Alu-I... PDFTafseer-e-QuranNo ratings yet

- Grass Cutter ThesisDocument4 pagesGrass Cutter Thesistit0feveh1h3100% (2)

- Almahmoud - Jouhara - 2019 - Experimental and Theoretical Investigation On A Radiative Flat Heat Pipe Heat ExchangerDocument13 pagesAlmahmoud - Jouhara - 2019 - Experimental and Theoretical Investigation On A Radiative Flat Heat Pipe Heat Exchangerjuan martinezNo ratings yet

- Line of Pull: Go To The Online Video and Watch Video Versus Long LeversDocument2 pagesLine of Pull: Go To The Online Video and Watch Video Versus Long LeversWaldir Martins NetoNo ratings yet

- Vakev Physics S5 Teacher GuideDocument297 pagesVakev Physics S5 Teacher Guidevigiraneza0No ratings yet

- UntitledDocument18 pagesUntitledmarcinNo ratings yet