Professional Documents

Culture Documents

CL GL Hal Ni 207

CL GL Hal Ni 207

Uploaded by

LismiantoOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CL GL Hal Ni 207

CL GL Hal Ni 207

Uploaded by

LismiantoCopyright:

Available Formats

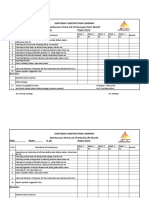

Nitrogen Tank – Pre-Job Inspection CL-GL-HAL-NI-207

CUSTOMER NAME WELL & LOCATION DATE

OCS-G / Well # / Field & Block

Skid#

Tank# INSTRUCTIONS: = Pass

F = Fail (note failures in Failed Line Items section)

N/A = Not Applicable (note reason for N/A in Comments section)

PRE-JOB ACTIVITIES Pass / Initial

Fail

1 Ensure nitrogen tank is clean and drip pan and all frame surface areas are clean and free of

debris.

2 Ensure tank is equipped with proper assigned lift sling and safety shackles. Must be Nut

and Pin with Cotter Pin, no screw type allowed.

3

Record Sling CERT# _________________ CERT DATE: __________________

4 Perform DROPS inspections

5 Ensure HES, regulatory decals and location tags are clearly identifiable and placard 1977 is

clearly visible on all (4) sides on nitrogen tank.

6 Verify Tare Weight, WLL/Payload Weight, and Max Gross Weight (MGW) are on the

equipment.

TANK / CRYOGENIC PLUMBING Pass / Initial

Fail

(Note: these items to be inspected during filling operations)

7 Visually inspect for damage and ensure ALL valves are fully functional.

8 Fill tank to 95% Full Try Cock level with blow down valve opened.

9 Visually inspect all cryogenic plumbing and hoses for nitrogen leaks.

10 Inspect all Line Relief safety valves and risers for damage, leaks and ensure outlets are

directed into the drip pan.

11 Ensure the Traveling Regulator works properly by opening the valve and pressuring up the

tank to 1.5 BAR

12 Ensure the Tank Pressure gauge and liquid level gauge are properly working and visually

inspect for damage and/or leaks. Note: liquid level gauge pointer bouncing indicates a leak

in the gauge line(s)

13 If equipped, Ensure the main tank dual burst disc(s) are not blown.

14 Visually inspect main tank safety relief valves to ensure proper installation and are not

leaking. Ensure wire tag is intact and UV stamp is visible.

15 Ensure Blow Down, Fill, Return and Pressure Build valves are closed and road relief valve

is opened prior to shipping.

16 All Plug / hatch and CGA Fill Line and Return connection caps are installed and secured

with lanyards, (after filling complete)

Approved By: Global Operations Manager Revision Date: 10/4/2022

Nitrogen Tank – Pre-Job Inspection CL-GL-HAL-NI-207

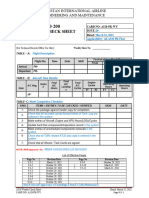

REQUIRED PAPERWORK Pass / Initial

Fail

17 Ensure this PRE-JOB EQUIPMENT REPORT is completed as required and signed off.

Remit to Equipment Coordinator and report any damages and/or failed items (noted within

Comment section).

18 Equipment Coordinator to create RPM Maintenance Order(s) to address any failed line

items.

COMMENTS (attach additional sheets if necessary)

Performed by: Employee #

Performed by: Employee #

FAILED LINE ITEMS

List all defects that were found during the PM inspection with an appropriate explanation.

This list will be used to create RPM (Result from Preventative Maintenance) orders as required.

PM Checklist Line Item: RPM Order#:

Description of issue:

PM Checklist Line Item: RPM Order#:

Description of issue:

PM Checklist Line Item: RPM Order#:

Description of issue:

PM Checklist Line Item: RPM Order#:

Description of issue:

PM Checklist Line Item: RPM Order#:

Approved By: Global Operations Manager Revision Date: 10/4/2022

Nitrogen Tank – Pre-Job Inspection CL-GL-HAL-NI-207

Description of issue:

PM Checklist Line Item: RPM Order#:

Description of issue:

PM Checklist Line Item: RPM Order#:

Description of issue:

PM Checklist Line Item: RPM Order#:

Description of issue:

Approved By: Global Operations Manager Revision Date: 10/4/2022

You might also like

- Mi-17 ChecklistDocument32 pagesMi-17 Checklistpilot digital100% (11)

- 737 Performance Reference Handbook - EASA EditionFrom Everand737 Performance Reference Handbook - EASA EditionRating: 4.5 out of 5 stars4.5/5 (3)

- Helicopter Pilot Oral Exam Guide: When used with the corresponding Oral Exam Guide, this book prepares you for the oral portion of the Private, Instrument, Commercial, Flight Instructor, or ATP Helicopter CheckrideFrom EverandHelicopter Pilot Oral Exam Guide: When used with the corresponding Oral Exam Guide, this book prepares you for the oral portion of the Private, Instrument, Commercial, Flight Instructor, or ATP Helicopter CheckrideNo ratings yet

- Tank Farm OperationsDocument77 pagesTank Farm OperationsAnyarogbu Uchenna87% (23)

- Attachment 12.7 - QA - QC Checklist - MCC & CBDocument6 pagesAttachment 12.7 - QA - QC Checklist - MCC & CBehteshamNo ratings yet

- Equipement Checklist (Hoist & Lift)Document2 pagesEquipement Checklist (Hoist & Lift)Bapusaheb GuthaleNo ratings yet

- (Temp) Checklist For Inspection & Functional Acceptance Tests in Factory and Pre-Commissioning Test On Site (Green V 3.0)Document12 pages(Temp) Checklist For Inspection & Functional Acceptance Tests in Factory and Pre-Commissioning Test On Site (Green V 3.0)pdrichNo ratings yet

- CL GL Hal Ni 208Document4 pagesCL GL Hal Ni 208LismiantoNo ratings yet

- SATR-A-2011 Rev 2 - Re-Instatement Checklist (Form)Document2 pagesSATR-A-2011 Rev 2 - Re-Instatement Checklist (Form)deepa narayanNo ratings yet

- Punch List For Fire Water Pump & Foam Pump PackageDocument4 pagesPunch List For Fire Water Pump & Foam Pump PackageGomathyselviNo ratings yet

- JIMT &NBSP Pre Com Water Plumbing System Punch List (Changing Room, Bin Centre, Grasswatering PT)Document6 pagesJIMT &NBSP Pre Com Water Plumbing System Punch List (Changing Room, Bin Centre, Grasswatering PT)GomathyselviNo ratings yet

- Attachment 12.5 - QA - QC Checklist - SMDBDocument6 pagesAttachment 12.5 - QA - QC Checklist - SMDBehteshamNo ratings yet

- 737-05-20-02-JT - PRE FLIGHT Iss 01 Rev 02Document2 pages737-05-20-02-JT - PRE FLIGHT Iss 01 Rev 02samyghallabNo ratings yet

- Load Shedding - Function TestDocument9 pagesLoad Shedding - Function TestratheeshkumardNo ratings yet

- Daily Check A320 (Issue 02 Rev 04)Document8 pagesDaily Check A320 (Issue 02 Rev 04)Junaid YounusNo ratings yet

- QA/QC Checklist - Installation of MDB Panel BoardsDocument6 pagesQA/QC Checklist - Installation of MDB Panel Boardsehtesham100% (1)

- Neo-Pre-Flight-Check R1 PDFDocument5 pagesNeo-Pre-Flight-Check R1 PDFLE THAI HONG VINHNo ratings yet

- 737-05-20-02-NG - PRE FLIGHT Iss 13Document2 pages737-05-20-02-NG - PRE FLIGHT Iss 13samyghallabNo ratings yet

- Comment SheetDocument2 pagesComment SheetmidhunvarNo ratings yet

- Inspection For Hiab Cranes: APC 11/2012 Rev. 0Document2 pagesInspection For Hiab Cranes: APC 11/2012 Rev. 0Muhammad Ahmed Abd ElmonemNo ratings yet

- Ceo - Insa320ttw019 - Issue - 01 - Pre Flight Check PDFDocument2 pagesCeo - Insa320ttw019 - Issue - 01 - Pre Flight Check PDFLE THAI HONG VINHNo ratings yet

- Weekly Check A320 (Issue 02 Rev 05)Document13 pagesWeekly Check A320 (Issue 02 Rev 05)Junaid YounusNo ratings yet

- Internal Audit Report 2011-Final-For ManagersDocument42 pagesInternal Audit Report 2011-Final-For Managerszaq rewNo ratings yet

- Halliburton: Initials OK F Fail (Create RPM Order) Not ApplDocument4 pagesHalliburton: Initials OK F Fail (Create RPM Order) Not ApplKhalfan Al HabsiNo ratings yet

- A320 Daily Check Sheet (N) Issue 20 Dated Oct 29,2021 With NOV 2021 Task CardsDocument32 pagesA320 Daily Check Sheet (N) Issue 20 Dated Oct 29,2021 With NOV 2021 Task CardsnobertadilNo ratings yet

- Saf51 Monthly Oily Overboard Discharge Systems Functionality TestDocument3 pagesSaf51 Monthly Oily Overboard Discharge Systems Functionality TestDmytroNo ratings yet

- Diesel TankDocument1 pageDiesel TankRejo AbrahamNo ratings yet

- Forms According To Owner's Requirement.: Check ListDocument2 pagesForms According To Owner's Requirement.: Check Listramel sigueNo ratings yet

- Aircraft Reg: Worksheet No:: Ad/Sb Numbers Last Compliance Next Due AD's-ReoccurringDocument17 pagesAircraft Reg: Worksheet No:: Ad/Sb Numbers Last Compliance Next Due AD's-Reoccurringcarl reevesNo ratings yet

- Walk Down Punch ListDocument7 pagesWalk Down Punch ListGomathyselviNo ratings yet

- Nav Iii Phase 1Document20 pagesNav Iii Phase 1carl reevesNo ratings yet

- E-380kVA KOEL DG Set drg.-R1 15.09.2022Document2 pagesE-380kVA KOEL DG Set drg.-R1 15.09.2022Electrical RadicalNo ratings yet

- MC-10129671-9999 DetroitDocument13 pagesMC-10129671-9999 DetroitBEARNo ratings yet

- DWG Ti 2198 A - 008 - 01Document52 pagesDWG Ti 2198 A - 008 - 01fadilNo ratings yet

- Transit Pre Flight Task Card AirbusDocument8 pagesTransit Pre Flight Task Card AirbusAbhijeet ChinchaneNo ratings yet

- Neo-Stayover-Check R5 PDFDocument11 pagesNeo-Stayover-Check R5 PDFLE THAI HONG VINHNo ratings yet

- A320 Weekly Check Sheet (N) Issue 16 Dated Mar 31,2022Document67 pagesA320 Weekly Check Sheet (N) Issue 16 Dated Mar 31,2022nobertadilNo ratings yet

- QC-109 R0 End of Job ChecklistDocument1 pageQC-109 R0 End of Job ChecklistCamilo JorqueraNo ratings yet

- Line Diff - p546Document9 pagesLine Diff - p546shanthikumaravel100% (1)

- Spec Upt Page 41Document58 pagesSpec Upt Page 41midhunvarNo ratings yet

- Etops Pre-Departure Service CheckDocument2 pagesEtops Pre-Departure Service CheckHerix Ferrer100% (1)

- Observations & Comments Sheet (OCS) : Qatar Olympic CommitteeDocument2 pagesObservations & Comments Sheet (OCS) : Qatar Olympic CommitteeIbrahim SirpiNo ratings yet

- Saudi Aramco Inspection Checklist: Final Insp of Tank Installation (Tanks) SAIC-D-2021 1-Dec-06 MechDocument4 pagesSaudi Aramco Inspection Checklist: Final Insp of Tank Installation (Tanks) SAIC-D-2021 1-Dec-06 Mechரமேஷ் பாலக்காடுNo ratings yet

- 10095163H00 - PB560 Assembly Procedure 3Document25 pages10095163H00 - PB560 Assembly Procedure 3Daniel MarquesNo ratings yet

- E - C Manual - R1 - 28.8.18Document86 pagesE - C Manual - R1 - 28.8.18Bruno LopezNo ratings yet

- Satr A 2007Document2 pagesSatr A 2007usmanNo ratings yet

- Mr-333272dailycheck - 1 100Document34 pagesMr-333272dailycheck - 1 100Tia MaiaNo ratings yet

- Taskcard: A. Accomplishment of The Pre-Flight Must Be Performed by TheDocument5 pagesTaskcard: A. Accomplishment of The Pre-Flight Must Be Performed by TheAji HudallilNo ratings yet

- Hazira Site - Control Valve Calibration SheetDocument3 pagesHazira Site - Control Valve Calibration Sheet8103 Anshu Patil100% (1)

- 2AB Daily Check A319Document8 pages2AB Daily Check A319Umer JavedNo ratings yet

- Demo Report SLOFECDocument64 pagesDemo Report SLOFECAnup NairNo ratings yet

- Rolls-Royce': Record of Temporary RevisionsDocument5 pagesRolls-Royce': Record of Temporary RevisionsAnonymous 298xlo3uUNo ratings yet

- 00 Truck Crane Inspection FormDocument10 pages00 Truck Crane Inspection FormRiza DSNo ratings yet

- Nav Ii Phase 2Document24 pagesNav Ii Phase 2carl reevesNo ratings yet

- Acdb - Function TestDocument4 pagesAcdb - Function TestDinesh Pitchaivel0% (1)

- DAILY CHECK LIST Tyre Mounted CraneDocument1 pageDAILY CHECK LIST Tyre Mounted CraneAditya Enterprise100% (1)

- Halliburton: Power Pack Hydraulic Quick Disconnect Skid S12A Suggested Interval: 120 DAYSDocument4 pagesHalliburton: Power Pack Hydraulic Quick Disconnect Skid S12A Suggested Interval: 120 DAYSKhalfan Al HabsiNo ratings yet

- TEN 6 CO PRW 0115 - ComentariosDocument1 pageTEN 6 CO PRW 0115 - ComentariosCésar ValdebenitoNo ratings yet

- Nav Iii Phase 2Document30 pagesNav Iii Phase 2carl reevesNo ratings yet

- Saudi Aramco Test Report Pre-Pressure Test Checklist (Form) : SATR-A-2007 22-Jan-18 MechDocument2 pagesSaudi Aramco Test Report Pre-Pressure Test Checklist (Form) : SATR-A-2007 22-Jan-18 MechaneeshNo ratings yet

- HM000682 Fe2 MTR CLP1 enDocument11 pagesHM000682 Fe2 MTR CLP1 enLismiantoNo ratings yet

- Gear Lube 85W 140 May 2018Document6 pagesGear Lube 85W 140 May 2018LismiantoNo ratings yet

- ES56 Dual Combi BOPDocument24 pagesES56 Dual Combi BOPLismiantoNo ratings yet

- CL GL Hal Ni 206Document3 pagesCL GL Hal Ni 206LismiantoNo ratings yet

- PROTEX VALVES - Compressed Air & VacuumDocument404 pagesPROTEX VALVES - Compressed Air & VacuumDEANHYDNo ratings yet

- The Emergency Stop - 2012 Ver 2.0Document27 pagesThe Emergency Stop - 2012 Ver 2.0Arturs StangainisNo ratings yet

- Commercial: Pricing 2018Document52 pagesCommercial: Pricing 2018Sohaib Faraz KhanNo ratings yet

- Check Valve Parker Serie CDocument4 pagesCheck Valve Parker Serie CRamiro EspinozaNo ratings yet

- Fire Hydrant2Document1 pageFire Hydrant2Mehman NasibovNo ratings yet

- Installation and Servicing InstructionsDocument40 pagesInstallation and Servicing InstructionsOwain JonesNo ratings yet

- Microlab 600 Advanced Technical ManualDocument104 pagesMicrolab 600 Advanced Technical Manualsava88No ratings yet

- Fores GroupDocument5 pagesFores GrouppnaronaNo ratings yet

- Api 576 .Document4 pagesApi 576 .sheikmoinNo ratings yet

- SPAGNOL Technical CatalogueDocument170 pagesSPAGNOL Technical CatalogueSteel WayNo ratings yet

- Case CX TrainingDocument20 pagesCase CX Traininghoward100% (26)

- 2097-1-G-G0-027 LDO and HFO System - Rev 00Document12 pages2097-1-G-G0-027 LDO and HFO System - Rev 00lightsonsNo ratings yet

- Argus Automatic Pigging BrochureDocument6 pagesArgus Automatic Pigging BrochureKehinde AdebayoNo ratings yet

- Pro-Control GC 2023Document32 pagesPro-Control GC 2023said.guerroutNo ratings yet

- Series4200 111 R2Document16 pagesSeries4200 111 R2Nitin AggarwalNo ratings yet

- ITAPTECH AUTOMATIC-AIR-VENT EngDocument14 pagesITAPTECH AUTOMATIC-AIR-VENT EngCarlos EspNo ratings yet

- Flowmax 90 Condensing Water HeaterDocument93 pagesFlowmax 90 Condensing Water HeaterRogers ShawNo ratings yet

- R10-E01 Rev 1 Mar 2017 Instrument Piping and Tubing Systems CriteriaDocument10 pagesR10-E01 Rev 1 Mar 2017 Instrument Piping and Tubing Systems CriteriaSALMANNo ratings yet

- Abma Guide 2013-14 WebDocument64 pagesAbma Guide 2013-14 WebAdolfo Perez MonteroNo ratings yet

- Commissioning Field OpDocument4 pagesCommissioning Field Opjohn MNo ratings yet

- MRS Suni Geri Tepme Aparatı ENGDocument41 pagesMRS Suni Geri Tepme Aparatı ENGnevinkaya2005No ratings yet

- Spirax Sarco Sp500Document68 pagesSpirax Sarco Sp500Mário SantosNo ratings yet

- Dresser 1900Document104 pagesDresser 1900Ildefonso FloresNo ratings yet

- Installation and User'S Manual 820 LX: Numero de SerieDocument32 pagesInstallation and User'S Manual 820 LX: Numero de SerieAntWonxxxNo ratings yet

- PIUSI PANTHER 56 72 IfdDocument2 pagesPIUSI PANTHER 56 72 IfdDouglas McDouglasNo ratings yet

- 07061-Company brochureCZ - ENG - Full PDFDocument72 pages07061-Company brochureCZ - ENG - Full PDFJan PaloučekNo ratings yet

- Bucher RSP RSW - 300 P 9050071 enDocument7 pagesBucher RSP RSW - 300 P 9050071 eneguren_91No ratings yet

- Cast Steel Price List Gate, Globe & Check ValvesDocument11 pagesCast Steel Price List Gate, Globe & Check ValvesronnyNo ratings yet

- Type 1061DD Damper Control Drive AssemblyDocument6 pagesType 1061DD Damper Control Drive AssemblyDatt NguyenNo ratings yet