Professional Documents

Culture Documents

QA-CHK-01.02 Inbound Packing Material Inspection

QA-CHK-01.02 Inbound Packing Material Inspection

Uploaded by

Yazeen 777Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

QA-CHK-01.02 Inbound Packing Material Inspection

QA-CHK-01.02 Inbound Packing Material Inspection

Uploaded by

Yazeen 777Copyright:

Available Formats

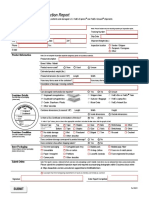

INBOUND Packing Material Inspection

Checklist

DATE: SUPPLIER

Pro Date:

Item Name: Exp Date:

Invoice No: Batch No

Vehicle/Container No: Seal No:

Country of Origin: Net Wt.:

Type/Content: Packaging Type:

Packing Films Polybags Pouches Labels/Stickers

Cartons Canister Plastic Lids Shrink Wrap

Canister Bt/Tp Ends Glass Jars Tin Cans Plastic Tubs

If Others:

VEHICLE INSPECTION

Outside/Undercarriage Structural damage (dents, holes, repairs). Ensure Locking Mechanisms are secured.

Support beams are visible. Ensure vents should be open.

Ensure no foreign objects are mounted on container. Check for door is locked & sealed properly at hinges.

Ensure the Temperature display is functional and Note the Seal is properly affixed, not broken or damaged.

Temperature.

ITEM INSPECTION

Test Parameters Test Results Test Parameters Test Results

Films/Polybags/Pouches/Wraps/Labels Canister Components

Print Quality Core board check

Color Check Dimension (LxWxH) mm

Dimension (LxWxH) mm Lid Fitment

Weight Grammage

GSM g/m2 Lacquer

Odor Odor

Perforations Ovality

Seal Strength Thickness

Cartons Jars/Cans

No. of Ply Glass/Plastic

No. Flutes/Inch Color Check

Dimension (LxWxH) mm Dimension (LxWxH) mm

Structure/Creasing Weight

Print Quality Print Quality

GSM g/m2 Lid Fitment

Artwork/Design Change (if any):

Defects/Damage (if any):

Remarks:

For standards, please refer to reference available and item specification.

Checked by: Verified By:

Title: Inbound Material Inspection Checklist Page 1 of 1

Doc Reference: HFL-QA-CHK - 01.02-PM Revision No: 02 Date: 01.03.2023

You might also like

- Precast ChecklistDocument1 pagePrecast Checklistshahrilzainul77100% (3)

- SAP Handling Unit ManagementDocument61 pagesSAP Handling Unit ManagementSuvendu Bishoyi91% (23)

- MantisDocument12 pagesMantisMirela IancuNo ratings yet

- Bonfiglioli Seris HDP-HDO Manual de MtoDocument88 pagesBonfiglioli Seris HDP-HDO Manual de MtoAlejandro GarciaNo ratings yet

- Introduction Operation ManagementDocument19 pagesIntroduction Operation Managementliya syaffaNo ratings yet

- Shipment Inspection Form - English - 5Document2 pagesShipment Inspection Form - English - 5Tanya KulshresthaNo ratings yet

- QA-CHK-01.02 Inbound Raw Material InspectionDocument1 pageQA-CHK-01.02 Inbound Raw Material InspectionYazeen 777No ratings yet

- Dispensed: SampledDocument3 pagesDispensed: Sampledziaurjewel92No ratings yet

- Packaging Form W705317Document1 pagePackaging Form W705317Hương DươngNo ratings yet

- Packaging Form M120BC013Document1 pagePackaging Form M120BC013Hương DươngNo ratings yet

- WI-I&T01 - Inc Mat Insp & Test Plan R04Document3 pagesWI-I&T01 - Inc Mat Insp & Test Plan R04Fatin NajehahNo ratings yet

- Sample - Inspection & Test Procedure - Rev.A - ADocument8 pagesSample - Inspection & Test Procedure - Rev.A - AJiwoo A-TechNo ratings yet

- 30.sample Pallet Checks - ITCDocument1 page30.sample Pallet Checks - ITCDipak DharaNo ratings yet

- TPWATG2101Document6 pagesTPWATG2101LAKSHMAN MURAMATTINo ratings yet

- Quality Control - Works Inspection: Aluminium SkirtingDocument1 pageQuality Control - Works Inspection: Aluminium SkirtingParasNo ratings yet

- QC Checklist SampleDocument7 pagesQC Checklist SampleĐức PhạmNo ratings yet

- Packing StandardDocument1 pagePacking StandardsathyabalaramanNo ratings yet

- 5121 Garment PP Form Version 2 1Document9 pages5121 Garment PP Form Version 2 1zakaria hossainNo ratings yet

- Rady For DispatchDocument2 pagesRady For Dispatchmohit_sane671317No ratings yet

- Packing Standard For BPW HubDocument4 pagesPacking Standard For BPW HubSachin KumbharNo ratings yet

- Form Inspection Report (Pre Final) - 1Document2 pagesForm Inspection Report (Pre Final) - 1wahyu kurniadyNo ratings yet

- Tex-Agency S.A.C: Qa Final Audit ReportDocument1 pageTex-Agency S.A.C: Qa Final Audit ReportQC TEXAGENCYNo ratings yet

- S# Z47103 First Output - NauticaDocument1 pageS# Z47103 First Output - NauticafcopymelihsanNo ratings yet

- Sanitary WorksDocument5 pagesSanitary Worksnaqibncd.azimNo ratings yet

- Quality Control - Works Inspection: Granite Door FrameDocument1 pageQuality Control - Works Inspection: Granite Door FrameParas100% (1)

- Determination of Moisture Content of Aggregates BS 812 PART 109: 1990Document1 pageDetermination of Moisture Content of Aggregates BS 812 PART 109: 1990Mathias OnosemuodeNo ratings yet

- Check List For Shink WrappingDocument7 pagesCheck List For Shink WrappingPavan SamudralaNo ratings yet

- TPWLJK2101Document6 pagesTPWLJK2101LAKSHMAN MURAMATTINo ratings yet

- SP F22-W2014 W. Push Twist Back TankDocument13 pagesSP F22-W2014 W. Push Twist Back TankKetty TerrelNo ratings yet

- TPWAJK2101Document6 pagesTPWAJK2101LAKSHMAN MURAMATTINo ratings yet

- Final Inspection ReportDocument2 pagesFinal Inspection Reportkrishna.greenhrNo ratings yet

- Cigarette PackDocument1 pageCigarette PackKhoe RonjNo ratings yet

- TPWAJK2102Document6 pagesTPWAJK2102LAKSHMAN MURAMATTINo ratings yet

- Ka2021186-71628b (27'' Big Scruff)Document6 pagesKa2021186-71628b (27'' Big Scruff)Annisa N AzizahNo ratings yet

- Chrysant - HSE PO FixDocument11 pagesChrysant - HSE PO FixTriza KurniawanNo ratings yet

- Final Inspection Report TERBARU TTD SPVDocument6 pagesFinal Inspection Report TERBARU TTD SPVAnnisa N AzizahNo ratings yet

- Sample Report Inspection Report Consumer Grade ProductDocument16 pagesSample Report Inspection Report Consumer Grade ProductBala ksNo ratings yet

- Quality Control - Works Inspection: Acoustic Board PanellingDocument1 pageQuality Control - Works Inspection: Acoustic Board PanellingParasNo ratings yet

- Jack PL SteelMilkFrotherDocument1 pageJack PL SteelMilkFrothernikakadiya95No ratings yet

- Checklist For Safety HarnessDocument2 pagesChecklist For Safety Harnessrajahmad251994No ratings yet

- GeneralDocument5 pagesGeneralladidamdudadidNo ratings yet

- Receipt Inspection Report: Checked As Per Plan and Found SatisfcatoryDocument13 pagesReceipt Inspection Report: Checked As Per Plan and Found Satisfcatorysanjayprakash1979No ratings yet

- 17tre-137 Pi ReportDocument4 pages17tre-137 Pi ReportjuanaaalejandrasalcedosamperNo ratings yet

- TPWSS2102Document6 pagesTPWSS2102LAKSHMAN MURAMATTINo ratings yet

- Job CardDocument1 pageJob Cardavinash.sharmaNo ratings yet

- لابئري)Document2 pagesلابئري)Mohamed SelimNo ratings yet

- Penetrant Oil Test Report - Eff.161114Document1 pagePenetrant Oil Test Report - Eff.161114Jindarat KasemsooksakulNo ratings yet

- Quality Control - Works Inspection: Glazed DoorsDocument1 pageQuality Control - Works Inspection: Glazed DoorsParasNo ratings yet

- AFCشربDocument2 pagesAFCشربMohamed SelimNo ratings yet

- Sample Tag - Front Side (8609912)Document10 pagesSample Tag - Front Side (8609912)dhz.febrianNo ratings yet

- Lab Dip Submittal FormDocument1 pageLab Dip Submittal FormHaseeb AnwarNo ratings yet

- Ameo SL PTCL 00115 GBL Test Order Garment Multi Phase v71Document29 pagesAmeo SL PTCL 00115 GBL Test Order Garment Multi Phase v71Hoa NguyenNo ratings yet

- GeM Bidding 3557657Document4 pagesGeM Bidding 3557657mogijo11dffdfgdfgNo ratings yet

- Ameo SL PTCL 00131.01 GBL Small Order Denim Garment Multi Phase v67Document34 pagesAmeo SL PTCL 00131.01 GBL Small Order Denim Garment Multi Phase v67Hoa NguyenNo ratings yet

- Wa0070Document3 pagesWa0070Marce Morale IsraelNo ratings yet

- Investment Casting SurveyDocument16 pagesInvestment Casting SurveySamip SolankiNo ratings yet

- Spec Safety BoxDocument1 pageSpec Safety BoxPuskesmas GondrongNo ratings yet

- Assembly In-Process Inspection ChecklistDocument2 pagesAssembly In-Process Inspection ChecklistRonnel Leano100% (1)

- PPM TemplateDocument3 pagesPPM TemplateBaharul Islam Bahar100% (1)

- Vineyard Vines - SGS Test Request Form - 7 Feb 2023Document4 pagesVineyard Vines - SGS Test Request Form - 7 Feb 2023Keith ChenNo ratings yet

- Grouting Format Report (Electrical Panel)Document1 pageGrouting Format Report (Electrical Panel)Anas PratamaNo ratings yet

- 707-Shimizu Corporation.Document10 pages707-Shimizu Corporation.linga2014No ratings yet

- Aluminum Low TableDocument14 pagesAluminum Low TableAstri munawarohNo ratings yet

- Packaging Dielines Free Book Design PackDocument120 pagesPackaging Dielines Free Book Design PackLinh LeleNo ratings yet

- Impact of Packaging On Consumer Buying PDFDocument6 pagesImpact of Packaging On Consumer Buying PDFJohn-Ross ReyesNo ratings yet

- Iso11607 Packaging - Sterile 2003 PDFDocument31 pagesIso11607 Packaging - Sterile 2003 PDFhitham shehataNo ratings yet

- Gearex: Gearex Operating/Assembly InstructionsDocument35 pagesGearex: Gearex Operating/Assembly InstructionsCarlos Humberto Arana NovoaNo ratings yet

- 3rd Periodical Test in TLE H.E. VI 2019 2020Document6 pages3rd Periodical Test in TLE H.E. VI 2019 2020Jonathan Paguio Lalican Lpt100% (6)

- Packaging, Marking, and Loading Methods For Steel Products For Domestic ShipmentDocument42 pagesPackaging, Marking, and Loading Methods For Steel Products For Domestic ShipmentManuel IbarraNo ratings yet

- PlasticsExposed 3 PDFDocument60 pagesPlasticsExposed 3 PDFEmer JayNo ratings yet

- Instructions For Use: ES350 - ES361Document86 pagesInstructions For Use: ES350 - ES361Rmk HsdNo ratings yet

- MM II - Product NPDDocument76 pagesMM II - Product NPDMohit Mohanty 16BEM0010No ratings yet

- Aprinnova Simply Solid One Page SummaryDocument2 pagesAprinnova Simply Solid One Page SummaryPatrick FlowerdayNo ratings yet

- Assessment Cover Sheet: Please Complete All Sections BelowDocument26 pagesAssessment Cover Sheet: Please Complete All Sections BelowChetan GargNo ratings yet

- Lansmont Six Step MethodDocument2 pagesLansmont Six Step MethodKatrina Joyce MabanesNo ratings yet

- Ready Pack Information SheetDocument2 pagesReady Pack Information SheetSatish HiremathNo ratings yet

- Business+Problem +Stora+EnsoDocument4 pagesBusiness+Problem +Stora+Ensoadnan ansariNo ratings yet

- Draft Standard For Cloves: 2. Description 2.1 Product DefinitionDocument6 pagesDraft Standard For Cloves: 2. Description 2.1 Product DefinitionArdo DheoNo ratings yet

- Zeeman's Family ExpansionDocument16 pagesZeeman's Family ExpansionColinNo ratings yet

- Cucumber Value Chain Profile: 1. Description of The IndustryDocument24 pagesCucumber Value Chain Profile: 1. Description of The IndustrySubhabrata SharmaNo ratings yet

- Packaging Data SheetDocument29 pagesPackaging Data SheetAlineMeirelesNo ratings yet

- Ift Student Food Packaging Development Competition: Entry KitDocument3 pagesIft Student Food Packaging Development Competition: Entry KitAdhiNo ratings yet

- Pom 07Document61 pagesPom 07asmaaijazkhanNo ratings yet

- Indian Paper Industry - B2B MarketingDocument26 pagesIndian Paper Industry - B2B MarketingTarun Daga50% (2)

- Giotto/Giotto Plus: Use and Maintenance Instructions ManualDocument12 pagesGiotto/Giotto Plus: Use and Maintenance Instructions Manualbrunolechat90No ratings yet

- Cargo Types and PackagingDocument21 pagesCargo Types and PackagingChristian Davidson SantaMariaNo ratings yet

- Approval Standard For Explosion Venting SystemsDocument15 pagesApproval Standard For Explosion Venting Systemsrafael1978No ratings yet

- BFJ 10 2015 0390Document23 pagesBFJ 10 2015 0390Lobna QassemNo ratings yet

- Module BRFT, GDocP & Data Integrity 18 Oct 2022Document55 pagesModule BRFT, GDocP & Data Integrity 18 Oct 2022princeNo ratings yet