Professional Documents

Culture Documents

CJ Form Tie Waterstop Brochure 050422 Compressed

CJ Form Tie Waterstop Brochure 050422 Compressed

Uploaded by

Habib ArifnurCopyright:

Available Formats

You might also like

- P&ID - Legend SheetDocument12 pagesP&ID - Legend SheetMinh Sang Phạm HuỳnhNo ratings yet

- HAZOP ExampleDocument5 pagesHAZOP ExampleAnonymous QqE5tcEa100% (6)

- Contractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerFrom EverandContractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerRating: 5 out of 5 stars5/5 (1)

- Bomba Gardner Denver TeeDocument56 pagesBomba Gardner Denver Teejulioramca100% (2)

- PSC Girder MethodologyDocument12 pagesPSC Girder MethodologySaurabh KumarNo ratings yet

- How to Build a Global Model Earthship Operation II: Concrete WorkFrom EverandHow to Build a Global Model Earthship Operation II: Concrete WorkNo ratings yet

- SPC - CR - UR - 510 - 3, Urea GradeDocument35 pagesSPC - CR - UR - 510 - 3, Urea Gradesaadpervaiz14No ratings yet

- RFA-TECH Waterproofing BrochureDocument48 pagesRFA-TECH Waterproofing Brochuresilvereyes18No ratings yet

- Bitustop PVC Edge Tie Waterstops: DescriptionDocument2 pagesBitustop PVC Edge Tie Waterstops: DescriptionTuntun TatNo ratings yet

- Advastop TDSDocument2 pagesAdvastop TDSMohammed AbugharbiehNo ratings yet

- PVC Waterstop DatasheetsDocument2 pagesPVC Waterstop DatasheetssfgfhgfjNo ratings yet

- Electrical Installation ManualDocument142 pagesElectrical Installation ManualEi Ei PhyoNo ratings yet

- Bridge Expansion JointDocument46 pagesBridge Expansion JointSiva Prasad MamillapalliNo ratings yet

- SAES-Q-001 (Criteria For The Design & Construction of Concrete Structures)Document5 pagesSAES-Q-001 (Criteria For The Design & Construction of Concrete Structures)Nino Celso Astillero100% (1)

- BCA Design External Wall PDFDocument15 pagesBCA Design External Wall PDFSiow TingNo ratings yet

- Ground Bearing Slab - What Are The Options - Joseph Khoo - Part 5Document79 pagesGround Bearing Slab - What Are The Options - Joseph Khoo - Part 5Fransisca WijayaNo ratings yet

- Waterbar Application ManualDocument6 pagesWaterbar Application ManualbarouniamineNo ratings yet

- Squeeze Cementing: Forces Cement Slurry, Under Pressure, Through Perforations or Holes in The Casing or Liner .Document41 pagesSqueeze Cementing: Forces Cement Slurry, Under Pressure, Through Perforations or Holes in The Casing or Liner .Mehdi AlizadehNo ratings yet

- Figure 10-10 Pipe Cast in ConcreteDocument1 pageFigure 10-10 Pipe Cast in Concretenorman moralesNo ratings yet

- Flashing Systems 10 Book 0 - 1 CompressedDocument26 pagesFlashing Systems 10 Book 0 - 1 CompressedSam SNo ratings yet

- General Waterstop BrochureDocument8 pagesGeneral Waterstop Brochureomar112233No ratings yet

- 1 Groundwater Monitoring Bore MaterialsDocument10 pages1 Groundwater Monitoring Bore MaterialsAadil KhanNo ratings yet

- Armstrong DIYDocument2 pagesArmstrong DIYJelaiNo ratings yet

- BestPractices Thermoplastic Sep08Document10 pagesBestPractices Thermoplastic Sep08geverett2765No ratings yet

- Keihin Fie Factory Project: Dry Wall ConceptDocument58 pagesKeihin Fie Factory Project: Dry Wall ConceptsonuchakdeNo ratings yet

- POLYKEN Polypropylene Coating TapeDocument3 pagesPOLYKEN Polypropylene Coating TapeHamid HamidouNo ratings yet

- Euclid Chemical Euco Waterstop PVC FC AsiaDocument4 pagesEuclid Chemical Euco Waterstop PVC FC AsiarosarioNo ratings yet

- FL - Sleeves and Sleeve Seals For Plumbing Piping - BudDocument5 pagesFL - Sleeves and Sleeve Seals For Plumbing Piping - BudAntonius HarrisNo ratings yet

- Fire Water System Design PDFDocument22 pagesFire Water System Design PDFktejankarNo ratings yet

- GRP Pipes Fittings CatalogDocument8 pagesGRP Pipes Fittings CatalogAAF0% (1)

- cOVER BLOCKSDocument4 pagescOVER BLOCKSPrashant Mankar100% (1)

- Sure Stop PVC Waterstops TDSDocument3 pagesSure Stop PVC Waterstops TDSrosarioNo ratings yet

- Conex Cuprofit TechnicalDocument24 pagesConex Cuprofit TechnicalLawrence FoxNo ratings yet

- 0915 Oil and Gas UK Guidelines J Schoenmakers Shell OGUK WDocument14 pages0915 Oil and Gas UK Guidelines J Schoenmakers Shell OGUK WLinh TranNo ratings yet

- CPWD - Brick Bat CobaDocument3 pagesCPWD - Brick Bat CobaJayaprakash Srinivasan67% (3)

- PDS - Hydrotite CJ 0725 - 2018.04.02Document5 pagesPDS - Hydrotite CJ 0725 - 2018.04.02SBW ReportingNo ratings yet

- Sika Epoxy Injection Methods PDFDocument77 pagesSika Epoxy Injection Methods PDFjet toledoNo ratings yet

- Architectural Treatment For Joint GapsDocument25 pagesArchitectural Treatment For Joint GapsRoze-Anne JopsonNo ratings yet

- Presentation On Plasmolite - FTSDocument14 pagesPresentation On Plasmolite - FTSVikram DhabaleNo ratings yet

- Fiberglass Manholes: Sanitary Sewer LinesDocument10 pagesFiberglass Manholes: Sanitary Sewer LinesshagogalNo ratings yet

- High Pressure Clear PVC Pipe: Submittal Data SheetDocument12 pagesHigh Pressure Clear PVC Pipe: Submittal Data Sheethunain hyderNo ratings yet

- Diaphragm Wall Construction WorkDocument41 pagesDiaphragm Wall Construction Workjodemode100% (2)

- 230517-Sleeves and Sleeve Seals for Hvac PipingDocument6 pages230517-Sleeves and Sleeve Seals for Hvac PipingMohamed SokarNo ratings yet

- Jointing Systems: - PVC Pipe Jointing - Rubber Ring Jointing - Solvent Cement JointingDocument16 pagesJointing Systems: - PVC Pipe Jointing - Rubber Ring Jointing - Solvent Cement JointingFrancisco M. RamosNo ratings yet

- Mea Polybit Tds Polybit Polystop CJ en MeaDocument2 pagesMea Polybit Tds Polybit Polystop CJ en MeaVaittianathan MahavapillaiNo ratings yet

- Specification For Reinforced Soil WallDocument8 pagesSpecification For Reinforced Soil WallChin Thau WuiNo ratings yet

- RFA-TECH Waterproofing Brochure PDFDocument48 pagesRFA-TECH Waterproofing Brochure PDFsilvereyes18No ratings yet

- VSIL PT SLAB (Compatibility Mode)Document21 pagesVSIL PT SLAB (Compatibility Mode)amit_saxena_10No ratings yet

- Pipe SleeveDocument12 pagesPipe Sleeveparthasarathy2812No ratings yet

- ACPPA TechSeries 03 Tunnel Installations 1Document4 pagesACPPA TechSeries 03 Tunnel Installations 1padmajareddyNo ratings yet

- 02720Document9 pages02720uddinnadeemNo ratings yet

- Section - 2800: Expansion /sepration / Isolation Joints 2800.1 GeneralDocument5 pagesSection - 2800: Expansion /sepration / Isolation Joints 2800.1 Generalkartick adhikaryNo ratings yet

- uPVC Tubewell Casing Screen Pipe SystemsDocument6 pagesuPVC Tubewell Casing Screen Pipe Systemssaadpervaiz14No ratings yet

- SIS Integrated - Pre-Stressing (Latest)Document8 pagesSIS Integrated - Pre-Stressing (Latest)Wong Kiang SeongNo ratings yet

- Repair Procedures Durai MaruthuDocument17 pagesRepair Procedures Durai MaruthurexdindigulNo ratings yet

- Water StopDocument2 pagesWater StopvertigoNo ratings yet

- Piping MaterialsDocument6 pagesPiping MaterialsMichael LangatNo ratings yet

- Why Buildings Leak UVADocument94 pagesWhy Buildings Leak UVAy2kareinNo ratings yet

- X4o0Z5CxUpSv - BOQ FOR LITENDocument19 pagesX4o0Z5CxUpSv - BOQ FOR LITENsunjeyNo ratings yet

- Cgij Corp - Company Profile 2022 UpdatedDocument13 pagesCgij Corp - Company Profile 2022 UpdatedCHOTIENo ratings yet

- Singapore - GCCM Talk SlidesDocument115 pagesSingapore - GCCM Talk SlidesChimhuee ChuaNo ratings yet

- Bending PVC ASTM D3034Document4 pagesBending PVC ASTM D3034Oscar PachecoNo ratings yet

- Advances in Ceramic Armor XFrom EverandAdvances in Ceramic Armor XJerry C. LaSalviaNo ratings yet

- Sewage Disposal Works: Their Design and ConstructionFrom EverandSewage Disposal Works: Their Design and ConstructionNo ratings yet

- APPENDIX Topping Slab 04 Desember 2022 46-48 B-EDocument4 pagesAPPENDIX Topping Slab 04 Desember 2022 46-48 B-EHabib ArifnurNo ratings yet

- APPENDIX Lt. Mezanine 08 Desember 2022 53-56 B-FDocument4 pagesAPPENDIX Lt. Mezanine 08 Desember 2022 53-56 B-FHabib ArifnurNo ratings yet

- APPENDIX Topping Slab 26 Desember 2022 41-44 B-EDocument4 pagesAPPENDIX Topping Slab 26 Desember 2022 41-44 B-EHabib ArifnurNo ratings yet

- APPENDIX Topping Slab 17 Desember 2022 56-58 B-EDocument4 pagesAPPENDIX Topping Slab 17 Desember 2022 56-58 B-EHabib ArifnurNo ratings yet

- Astm F714Document9 pagesAstm F714JUAN DAVID GOMEZ PATIÑONo ratings yet

- Calculation-Strainer-Crude Edible OilDocument4 pagesCalculation-Strainer-Crude Edible OilHasmukh DaveNo ratings yet

- Dyna Star OilDocument24 pagesDyna Star Oiltomo.sulaimanNo ratings yet

- Ebs1 Aaaa00 Saqa Plin 0006Document31 pagesEbs1 Aaaa00 Saqa Plin 0006SERT-QA/QC- BUZNo ratings yet

- Installation, Operation, and Maintenance ManualDocument54 pagesInstallation, Operation, and Maintenance ManualIsmael Berlanga ResNo ratings yet

- Float and Tape Type Level Gauge - Endress Hauser - Operating InstructionsDocument76 pagesFloat and Tape Type Level Gauge - Endress Hauser - Operating InstructionsKamal SkNo ratings yet

- Goulds Vertical Lineshaft and Submersible PumpsDocument16 pagesGoulds Vertical Lineshaft and Submersible Pumpsiam_drn1024No ratings yet

- Manualul Pentru Incalzire Danfoss - Chapter8Document25 pagesManualul Pentru Incalzire Danfoss - Chapter8valicanNo ratings yet

- Drillers Handout Manual SDocument76 pagesDrillers Handout Manual SKHALEDFEKAIRNo ratings yet

- Guideline For GRE Pipe Stress Analysis - T SrinivasanDocument5 pagesGuideline For GRE Pipe Stress Analysis - T Srinivasansri06No ratings yet

- WTP Equipment List: Material Inspection Report (Mir) at SiteDocument20 pagesWTP Equipment List: Material Inspection Report (Mir) at SiteDinand Hazbin JadidNo ratings yet

- Alaa-Pipeline Mechanical DesignDocument106 pagesAlaa-Pipeline Mechanical DesignDavid Muñoz Castro100% (1)

- Work Procedure For Plumbing and Sanitary Wor1Document5 pagesWork Procedure For Plumbing and Sanitary Wor1krmchari100% (1)

- 1 s2.0 S1350630722000826 MainDocument15 pages1 s2.0 S1350630722000826 MainenggardbNo ratings yet

- Plant Piping Systems Operations, Maintenance and Repairs Training Outline Dub PDFDocument3 pagesPlant Piping Systems Operations, Maintenance and Repairs Training Outline Dub PDFRizqy PranataNo ratings yet

- Ejemplo Piping Class PDFDocument5 pagesEjemplo Piping Class PDFDagoberto CerrudNo ratings yet

- Section 28: Landscaping 02: Irrigation System: AppendicesDocument48 pagesSection 28: Landscaping 02: Irrigation System: AppendicesJaijeev PaliNo ratings yet

- Metaland CatalogueDocument95 pagesMetaland CatalogueTimothy LovettNo ratings yet

- Pipe and Fittings CatalogueDocument22 pagesPipe and Fittings Catalogueأحمد محمد قدري100% (1)

- Pipe Thread NPT and BSPT Fittings Compatibility PDFDocument5 pagesPipe Thread NPT and BSPT Fittings Compatibility PDFrefaeNo ratings yet

- Hyundai Pipe CatalogueDocument36 pagesHyundai Pipe Cataloguefelram100% (2)

- Tuv Rheinland Morocco Voc Productlist en v2Document92 pagesTuv Rheinland Morocco Voc Productlist en v2scagiranNo ratings yet

- Metraflex Fireloop™: Down Have The 180 Return Supported. (See Installation Instructions.)Document4 pagesMetraflex Fireloop™: Down Have The 180 Return Supported. (See Installation Instructions.)ANTONIO GUTIERREZ MIRANDANo ratings yet

- 05 - Ips-C-Pi-350Document21 pages05 - Ips-C-Pi-350Integrity EngineerNo ratings yet

- Kal Cret 2005Document16 pagesKal Cret 2005TECHNO CASTNo ratings yet

CJ Form Tie Waterstop Brochure 050422 Compressed

CJ Form Tie Waterstop Brochure 050422 Compressed

Uploaded by

Habib ArifnurOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CJ Form Tie Waterstop Brochure 050422 Compressed

CJ Form Tie Waterstop Brochure 050422 Compressed

Uploaded by

Habib ArifnurCopyright:

Available Formats

CJ FORM-TIE WATERSTOP

HYDROPHILIC RUBBER FORM-TIE WATERSTOP

PRODUCT DESCRIPTION

CJ Form-Tie Waterstops are produced from a unique hydrophilic rubber sealing compound which expands in

a controlled fashion when exposed to moisture. This forms a compression seal inside or around the form-tie

system in the concrete structure, giving a permanent flexible watertight seal.

Available in a number of different sizes and profiles to suit the form-tie system. Once installed, CJ Form-Tie

Waterstops forms a continuous barrier, making it ideal for preventing water penetration or egress.

CJ FORM-TIE PLUG CJ FORM-TIE RING

ADVANTAGES

Excellent sealing capabilities and available in many different sizes, shapes and profiles to suit the

formwork form-tie system to be used. Custom profiles available upon request.

Provides a permanent, flexible gasket and compression seal inside the concrete.

High quality, non-biodegradable compounded hydrophilic rubber that provides long-term durability

and integrity.

Ability to expand up to 200% in contact with potable water and over 150% expansion in salt water.

Has been tested to withstand over 50 metres of hydrostatic water head pressure. (Test report available

upon request)

For use in many different types of applications but especially suited for water retaining structures

where direct water pressure is applied against the concrete and the form-tie system.

Non-toxic and can be used in potable water structures.

Unaffected by repeated wet and dry cycles.

Fast and simple to install.

Expansion is controlled via the built-in expansion delay system. The product does not pre-expand from

the water in the freshly laid concrete of the wall, allowing the concrete to gain strength first.

info@corkjoint.com | corkjoint.com Page 1

AREAS OF APPLICATION

Water retaining structures : Water excluding structures :

Water Tanks Basement areas

Reservoirs Underground Car Parks

Dams Tunnels

Water Treatment Plants Stations & Subways

Sewage Treatment Plants Retaining Walls

Swimming Pools Pits & Manholes

Bund Walls

Note : The product’s design and performance, its intended use, installation and final confirmation and approval for

use, must be provided by the project’s Design Engineer and Project Manager.

LIMITATIONS

Due to the expansive forces of the hydrophilic rubber compound, CJ Form-Tie Rings need to be

installed with a minimum concrete cover of 75mm from any outside edge.

Increase concrete cover when using lightweight or low strength concrete.

Expansion rate can vary in potable water and salt water environments.

TYPICAL APPLICATIONS

1. FORM-TIE CONDUIT SPACER 2. FORM-TIE RODS

HOLE

Concrete Wall

CJ Form-Tie Foam

Plug CJ25 Plug

Non-shrink

Grout

Concrete Wall

Insert CJ Form-Tie Plug into the Place the CJ Form-Tie Ring over the outside of the metal form-tie rod

hole to a minimum depth of and position it approximately in the middle section.

75mm. Apply an application of a

non-shrink grout flush to the

outer surface of the concrete.

info@corkjoint.com | corkjoint.com Page 2

INSTALLATION PROCEDURES

1. FORM-TIE CONDUIT SPACER HOLE

Concrete Wall Concrete Wall

Hammer

CJ Form-Tie Plug CJ25

Plastic Conduit Cone 25mm Ø Steel or Timber Rod 25mm Ø 25mm

75mm

Concrete Wall Concrete Wall

a. Fully remove the Form-Tie Conduit Cone and b. Insert CJ Form-Tie Plug CJ25 into the hole

Conduit Sleeve. to a minimum depth of 75mm.

Concrete Wall Concrete Wall

CJ Form-Tie Plug CJ25 CJ Form-Tie Plug CJ25

Non-shrink

Grout

Foam Plug Foam Plug

Concrete Wall Concrete Wall

c. Insert a low-density foam plug to a minimum d. Apply an application of a non-shrink grout

depth of 20mm. flush to the outer surface of the concrete.

2. FORM-TIE RODS

a. Thoroughly clean the outside surface of the form-tie rod, free of any dust, debris & foreign matter.

b. Place the CJ Form-Tie Ring over the outside face of the form-tie rod and slide it along to approximately

the middle section.

c. A minimum concrete cover of 75mm from any outside edge of the concrete to the CJ Form-Tie Ring

should be followed.

d. Check and make sure that the CJ Form-Tie Ring has a tight and secure fit around the sleeve or rod. If

it is loose, then a smaller diameter ring should be used.

e. The CJ Form-Tie Ring is now ready for the concrete to be placed.

info@corkjoint.com | corkjoint.com Page 3

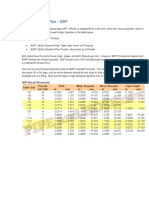

PROFILE SELECTION

TYPE OF PROFILE FORM-TIE SYSTEM USE

CJ Form-Tie Plug Externally inserted into the Form-Tie Conduit Sleeve hole

CJ Form-Tie Ring Externally applied around the Form-Tie Conduit Sleeve or the Form-Tie Rod

CJ20 CJ25 CJ3512 CJ4016

CJ FORM-TIE PLUGS CJ FORM-TIE RINGS

PROFILE TYPE & CODE SIZE OF PRODUCT APPLICATION SEALING SIZE

CJ Form-Tie Plug CJ20 O.D 20mm x 40mm long Conduit sleeve with O.D 20mm

CJ Form-Tie Plug CJ25 O.D 25mm x 40mm long Conduit sleeve with O.D 25mm

CJ Form-Tie Ring CJ3512 O.D 35mm x I.D 12mm Sleeve or rod O.D 12mm to 15mm

CJ Form-Tie Ring CJ4016 O.D 40mm x I.D 16mm Sleeve or rod O.D 16mm to 20mm

The above profile types are standard and custom profiles are available upon request to suit the form-tie

system to be used. Selecting the profile type is dependent upon the type of form-tie system being used and

if needed, please consult CORKJOINT for further information.

Note : The product’s design and performance, its intended use, installation and final confirmation and approval for

use, must be provided by the project’s Design Engineer and Project Manager.

PACKAGING

PACKAGING In sealed plastic bags and boxes

WEIGHT & QUANTITY Dependent upon profile type and size

PHYSICAL PROPERTIES

HYDROPHILIC RUBBER

DESCRIPTION UNIT TEST METHOD

SPEC. RESULT

Hardness - A45 ± 5 48 JIS K 6253

Tensile Strength MPa min. 4.9 7.9 JIS K 6251

Elongation % min. 600 790 JIS K 6251

Note: Above values are typical measured values and not specific values.

info@corkjoint.com | corkjoint.com Page 4

SWELLING PROPERTIES

Test water : Distilled Water

Temperature : 23°C & 50% RH

Immersion terms : 28 Days

DESCRIPTION TEST METHOD RESULT

Volume Expansion Rate (%) In house test 200

Note : 100% indicates original size. Expansion can vary between batches up to 10% - 20%.

Expansion rate can vary in salt or contaminated water.

TECHNICAL FEATURES

ITEM TYPE DESCRIPTION & INFORMATION

Material Type - Rubber for plugs and rings Chloroprene Rubber compound containing special

hydrophilic polymers

Color - Rubber for plugs Blue

- Rubber for rings Black

Expansion Capability 200% in potable water and 150% in salt water

Hydrostatic Water Pressure Resistance Over 5 Bar (50 metres)

Chemical Resistance In general, good resistance to Acids, Alkalis and most

Aqueous solutions. Be careful with solvents and

hydrocarbons and refer to our chemical resistance

chart.

Service Temperatures -30°C to +90°C

Storage Conditions/Shelf Life 5 years from date of production if stored properly and

in original unopened and undamaged sealed

packaging in dry conditions, out of direct sunlight, not

exposed to moisture and kept at temperatures

between +10°C to +40°C.

TEST REPORTS - INDEPENDENT LABORATORY

Exposure & Water Immersion Expansion in Potable Water

Exposure & Hydrostatic Head Pressure (cyclic wet & dry) in Potable Water

Water Immersion Expansion in Salt Water (In-house)

Note : The above test reports are available upon request.

WRITTEN SPECIFICATION

The Form-Tie Waterstop shall be CJ Form-Tie Waterstop (State profile number required) as supplied by

CORKJOINT. The Form-Tie Waterstop shall be produced from Chloroprene Rubber and compounded with

special hydrophilic polymers to be able to achieve a minimum expansion capability of 200% in potable water

and a minimum of 150% expansion in salt water. The Form-Tie Waterstop must be able to withstand a

hydrostatic water head pressure of not less than 5 Bar and an independent laboratory test report must be

provided to prove the product material type, the water immersion expansion percentage and the

hydrostatic water head pressure capabilities.

info@corkjoint.com | corkjoint.com Page 5

HEALTH AND SAFETY INFORMATION

For further information or advice on health and safety precautions, safe handling, storage and correct disposal

of products, please refer to the most recent product Safety Data Sheet (SDS), which is available upon request.

DISCLAIMER

The information and the recommendations relating to the application and end use of this product are given

in good faith and are based on the information provided by the manufacturer of the product and/or the

Company’s current knowledge and experience in connection with the product when properly stored, handled

and applied under normal conditions and no liability of final function at the job site is assumed. In practice,

the differences in materials, substrates and actual site conditions are such that no warranty in respect of

merchantability of, or fitness for, particular purpose, nor any liability arising out of any legal relationship

whatsoever, can be inferred either from this information, or from any written and/or oral recommendations, or

from any other advice offered by the Company. The Company also has no express or implied knowledge of any

particular purpose for which the product is required and any such information given will not be taken into

account in the supply of this product. No responsibility or liability by the Company will be accepted for misuse,

misreading or derivation from recommended guidelines in respect of this product and the user shall

determine the suitability of the product for his intended use and assume all risks and liability in connection

therewith. The information contained in our brochure may change at any time without notice. Any use of this

product, CJ Form-Tie Waterstop, in any application should be approved as suitable for use/application by the

Design Engineer and Project Manager.

Effective Date: 05 APRIL 2022

CORKJOINT (MALAYSIA) SDN BHD 383102-H CORKJOINT (SINGAPORE) PTE LTD 200716724-K

No. 51, Jalan BRP 8/2, Bukit Rahman Putra Industrial No. 10 Buroh Street #02-26 & 27, West Connect

Park, 47000 Sungai Buloh, Selangor, MALAYSIA Building, SINGAPORE 627564

+603 6148 8010 +65 6455 9331

+603 6148 8020 +65 6455 8535

info@corkjoint.com | corkjoint.com © Corkjoint 2022. All Rights Reserved. Page 6

You might also like

- P&ID - Legend SheetDocument12 pagesP&ID - Legend SheetMinh Sang Phạm HuỳnhNo ratings yet

- HAZOP ExampleDocument5 pagesHAZOP ExampleAnonymous QqE5tcEa100% (6)

- Contractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerFrom EverandContractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerRating: 5 out of 5 stars5/5 (1)

- Bomba Gardner Denver TeeDocument56 pagesBomba Gardner Denver Teejulioramca100% (2)

- PSC Girder MethodologyDocument12 pagesPSC Girder MethodologySaurabh KumarNo ratings yet

- How to Build a Global Model Earthship Operation II: Concrete WorkFrom EverandHow to Build a Global Model Earthship Operation II: Concrete WorkNo ratings yet

- SPC - CR - UR - 510 - 3, Urea GradeDocument35 pagesSPC - CR - UR - 510 - 3, Urea Gradesaadpervaiz14No ratings yet

- RFA-TECH Waterproofing BrochureDocument48 pagesRFA-TECH Waterproofing Brochuresilvereyes18No ratings yet

- Bitustop PVC Edge Tie Waterstops: DescriptionDocument2 pagesBitustop PVC Edge Tie Waterstops: DescriptionTuntun TatNo ratings yet

- Advastop TDSDocument2 pagesAdvastop TDSMohammed AbugharbiehNo ratings yet

- PVC Waterstop DatasheetsDocument2 pagesPVC Waterstop DatasheetssfgfhgfjNo ratings yet

- Electrical Installation ManualDocument142 pagesElectrical Installation ManualEi Ei PhyoNo ratings yet

- Bridge Expansion JointDocument46 pagesBridge Expansion JointSiva Prasad MamillapalliNo ratings yet

- SAES-Q-001 (Criteria For The Design & Construction of Concrete Structures)Document5 pagesSAES-Q-001 (Criteria For The Design & Construction of Concrete Structures)Nino Celso Astillero100% (1)

- BCA Design External Wall PDFDocument15 pagesBCA Design External Wall PDFSiow TingNo ratings yet

- Ground Bearing Slab - What Are The Options - Joseph Khoo - Part 5Document79 pagesGround Bearing Slab - What Are The Options - Joseph Khoo - Part 5Fransisca WijayaNo ratings yet

- Waterbar Application ManualDocument6 pagesWaterbar Application ManualbarouniamineNo ratings yet

- Squeeze Cementing: Forces Cement Slurry, Under Pressure, Through Perforations or Holes in The Casing or Liner .Document41 pagesSqueeze Cementing: Forces Cement Slurry, Under Pressure, Through Perforations or Holes in The Casing or Liner .Mehdi AlizadehNo ratings yet

- Figure 10-10 Pipe Cast in ConcreteDocument1 pageFigure 10-10 Pipe Cast in Concretenorman moralesNo ratings yet

- Flashing Systems 10 Book 0 - 1 CompressedDocument26 pagesFlashing Systems 10 Book 0 - 1 CompressedSam SNo ratings yet

- General Waterstop BrochureDocument8 pagesGeneral Waterstop Brochureomar112233No ratings yet

- 1 Groundwater Monitoring Bore MaterialsDocument10 pages1 Groundwater Monitoring Bore MaterialsAadil KhanNo ratings yet

- Armstrong DIYDocument2 pagesArmstrong DIYJelaiNo ratings yet

- BestPractices Thermoplastic Sep08Document10 pagesBestPractices Thermoplastic Sep08geverett2765No ratings yet

- Keihin Fie Factory Project: Dry Wall ConceptDocument58 pagesKeihin Fie Factory Project: Dry Wall ConceptsonuchakdeNo ratings yet

- POLYKEN Polypropylene Coating TapeDocument3 pagesPOLYKEN Polypropylene Coating TapeHamid HamidouNo ratings yet

- Euclid Chemical Euco Waterstop PVC FC AsiaDocument4 pagesEuclid Chemical Euco Waterstop PVC FC AsiarosarioNo ratings yet

- FL - Sleeves and Sleeve Seals For Plumbing Piping - BudDocument5 pagesFL - Sleeves and Sleeve Seals For Plumbing Piping - BudAntonius HarrisNo ratings yet

- Fire Water System Design PDFDocument22 pagesFire Water System Design PDFktejankarNo ratings yet

- GRP Pipes Fittings CatalogDocument8 pagesGRP Pipes Fittings CatalogAAF0% (1)

- cOVER BLOCKSDocument4 pagescOVER BLOCKSPrashant Mankar100% (1)

- Sure Stop PVC Waterstops TDSDocument3 pagesSure Stop PVC Waterstops TDSrosarioNo ratings yet

- Conex Cuprofit TechnicalDocument24 pagesConex Cuprofit TechnicalLawrence FoxNo ratings yet

- 0915 Oil and Gas UK Guidelines J Schoenmakers Shell OGUK WDocument14 pages0915 Oil and Gas UK Guidelines J Schoenmakers Shell OGUK WLinh TranNo ratings yet

- CPWD - Brick Bat CobaDocument3 pagesCPWD - Brick Bat CobaJayaprakash Srinivasan67% (3)

- PDS - Hydrotite CJ 0725 - 2018.04.02Document5 pagesPDS - Hydrotite CJ 0725 - 2018.04.02SBW ReportingNo ratings yet

- Sika Epoxy Injection Methods PDFDocument77 pagesSika Epoxy Injection Methods PDFjet toledoNo ratings yet

- Architectural Treatment For Joint GapsDocument25 pagesArchitectural Treatment For Joint GapsRoze-Anne JopsonNo ratings yet

- Presentation On Plasmolite - FTSDocument14 pagesPresentation On Plasmolite - FTSVikram DhabaleNo ratings yet

- Fiberglass Manholes: Sanitary Sewer LinesDocument10 pagesFiberglass Manholes: Sanitary Sewer LinesshagogalNo ratings yet

- High Pressure Clear PVC Pipe: Submittal Data SheetDocument12 pagesHigh Pressure Clear PVC Pipe: Submittal Data Sheethunain hyderNo ratings yet

- Diaphragm Wall Construction WorkDocument41 pagesDiaphragm Wall Construction Workjodemode100% (2)

- 230517-Sleeves and Sleeve Seals for Hvac PipingDocument6 pages230517-Sleeves and Sleeve Seals for Hvac PipingMohamed SokarNo ratings yet

- Jointing Systems: - PVC Pipe Jointing - Rubber Ring Jointing - Solvent Cement JointingDocument16 pagesJointing Systems: - PVC Pipe Jointing - Rubber Ring Jointing - Solvent Cement JointingFrancisco M. RamosNo ratings yet

- Mea Polybit Tds Polybit Polystop CJ en MeaDocument2 pagesMea Polybit Tds Polybit Polystop CJ en MeaVaittianathan MahavapillaiNo ratings yet

- Specification For Reinforced Soil WallDocument8 pagesSpecification For Reinforced Soil WallChin Thau WuiNo ratings yet

- RFA-TECH Waterproofing Brochure PDFDocument48 pagesRFA-TECH Waterproofing Brochure PDFsilvereyes18No ratings yet

- VSIL PT SLAB (Compatibility Mode)Document21 pagesVSIL PT SLAB (Compatibility Mode)amit_saxena_10No ratings yet

- Pipe SleeveDocument12 pagesPipe Sleeveparthasarathy2812No ratings yet

- ACPPA TechSeries 03 Tunnel Installations 1Document4 pagesACPPA TechSeries 03 Tunnel Installations 1padmajareddyNo ratings yet

- 02720Document9 pages02720uddinnadeemNo ratings yet

- Section - 2800: Expansion /sepration / Isolation Joints 2800.1 GeneralDocument5 pagesSection - 2800: Expansion /sepration / Isolation Joints 2800.1 Generalkartick adhikaryNo ratings yet

- uPVC Tubewell Casing Screen Pipe SystemsDocument6 pagesuPVC Tubewell Casing Screen Pipe Systemssaadpervaiz14No ratings yet

- SIS Integrated - Pre-Stressing (Latest)Document8 pagesSIS Integrated - Pre-Stressing (Latest)Wong Kiang SeongNo ratings yet

- Repair Procedures Durai MaruthuDocument17 pagesRepair Procedures Durai MaruthurexdindigulNo ratings yet

- Water StopDocument2 pagesWater StopvertigoNo ratings yet

- Piping MaterialsDocument6 pagesPiping MaterialsMichael LangatNo ratings yet

- Why Buildings Leak UVADocument94 pagesWhy Buildings Leak UVAy2kareinNo ratings yet

- X4o0Z5CxUpSv - BOQ FOR LITENDocument19 pagesX4o0Z5CxUpSv - BOQ FOR LITENsunjeyNo ratings yet

- Cgij Corp - Company Profile 2022 UpdatedDocument13 pagesCgij Corp - Company Profile 2022 UpdatedCHOTIENo ratings yet

- Singapore - GCCM Talk SlidesDocument115 pagesSingapore - GCCM Talk SlidesChimhuee ChuaNo ratings yet

- Bending PVC ASTM D3034Document4 pagesBending PVC ASTM D3034Oscar PachecoNo ratings yet

- Advances in Ceramic Armor XFrom EverandAdvances in Ceramic Armor XJerry C. LaSalviaNo ratings yet

- Sewage Disposal Works: Their Design and ConstructionFrom EverandSewage Disposal Works: Their Design and ConstructionNo ratings yet

- APPENDIX Topping Slab 04 Desember 2022 46-48 B-EDocument4 pagesAPPENDIX Topping Slab 04 Desember 2022 46-48 B-EHabib ArifnurNo ratings yet

- APPENDIX Lt. Mezanine 08 Desember 2022 53-56 B-FDocument4 pagesAPPENDIX Lt. Mezanine 08 Desember 2022 53-56 B-FHabib ArifnurNo ratings yet

- APPENDIX Topping Slab 26 Desember 2022 41-44 B-EDocument4 pagesAPPENDIX Topping Slab 26 Desember 2022 41-44 B-EHabib ArifnurNo ratings yet

- APPENDIX Topping Slab 17 Desember 2022 56-58 B-EDocument4 pagesAPPENDIX Topping Slab 17 Desember 2022 56-58 B-EHabib ArifnurNo ratings yet

- Astm F714Document9 pagesAstm F714JUAN DAVID GOMEZ PATIÑONo ratings yet

- Calculation-Strainer-Crude Edible OilDocument4 pagesCalculation-Strainer-Crude Edible OilHasmukh DaveNo ratings yet

- Dyna Star OilDocument24 pagesDyna Star Oiltomo.sulaimanNo ratings yet

- Ebs1 Aaaa00 Saqa Plin 0006Document31 pagesEbs1 Aaaa00 Saqa Plin 0006SERT-QA/QC- BUZNo ratings yet

- Installation, Operation, and Maintenance ManualDocument54 pagesInstallation, Operation, and Maintenance ManualIsmael Berlanga ResNo ratings yet

- Float and Tape Type Level Gauge - Endress Hauser - Operating InstructionsDocument76 pagesFloat and Tape Type Level Gauge - Endress Hauser - Operating InstructionsKamal SkNo ratings yet

- Goulds Vertical Lineshaft and Submersible PumpsDocument16 pagesGoulds Vertical Lineshaft and Submersible Pumpsiam_drn1024No ratings yet

- Manualul Pentru Incalzire Danfoss - Chapter8Document25 pagesManualul Pentru Incalzire Danfoss - Chapter8valicanNo ratings yet

- Drillers Handout Manual SDocument76 pagesDrillers Handout Manual SKHALEDFEKAIRNo ratings yet

- Guideline For GRE Pipe Stress Analysis - T SrinivasanDocument5 pagesGuideline For GRE Pipe Stress Analysis - T Srinivasansri06No ratings yet

- WTP Equipment List: Material Inspection Report (Mir) at SiteDocument20 pagesWTP Equipment List: Material Inspection Report (Mir) at SiteDinand Hazbin JadidNo ratings yet

- Alaa-Pipeline Mechanical DesignDocument106 pagesAlaa-Pipeline Mechanical DesignDavid Muñoz Castro100% (1)

- Work Procedure For Plumbing and Sanitary Wor1Document5 pagesWork Procedure For Plumbing and Sanitary Wor1krmchari100% (1)

- 1 s2.0 S1350630722000826 MainDocument15 pages1 s2.0 S1350630722000826 MainenggardbNo ratings yet

- Plant Piping Systems Operations, Maintenance and Repairs Training Outline Dub PDFDocument3 pagesPlant Piping Systems Operations, Maintenance and Repairs Training Outline Dub PDFRizqy PranataNo ratings yet

- Ejemplo Piping Class PDFDocument5 pagesEjemplo Piping Class PDFDagoberto CerrudNo ratings yet

- Section 28: Landscaping 02: Irrigation System: AppendicesDocument48 pagesSection 28: Landscaping 02: Irrigation System: AppendicesJaijeev PaliNo ratings yet

- Metaland CatalogueDocument95 pagesMetaland CatalogueTimothy LovettNo ratings yet

- Pipe and Fittings CatalogueDocument22 pagesPipe and Fittings Catalogueأحمد محمد قدري100% (1)

- Pipe Thread NPT and BSPT Fittings Compatibility PDFDocument5 pagesPipe Thread NPT and BSPT Fittings Compatibility PDFrefaeNo ratings yet

- Hyundai Pipe CatalogueDocument36 pagesHyundai Pipe Cataloguefelram100% (2)

- Tuv Rheinland Morocco Voc Productlist en v2Document92 pagesTuv Rheinland Morocco Voc Productlist en v2scagiranNo ratings yet

- Metraflex Fireloop™: Down Have The 180 Return Supported. (See Installation Instructions.)Document4 pagesMetraflex Fireloop™: Down Have The 180 Return Supported. (See Installation Instructions.)ANTONIO GUTIERREZ MIRANDANo ratings yet

- 05 - Ips-C-Pi-350Document21 pages05 - Ips-C-Pi-350Integrity EngineerNo ratings yet

- Kal Cret 2005Document16 pagesKal Cret 2005TECHNO CASTNo ratings yet