Professional Documents

Culture Documents

Hand and Power Tool Safety Program: 6 February 2018 Page 1 of 15

Hand and Power Tool Safety Program: 6 February 2018 Page 1 of 15

Uploaded by

kalkalina63Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hand and Power Tool Safety Program: 6 February 2018 Page 1 of 15

Hand and Power Tool Safety Program: 6 February 2018 Page 1 of 15

Uploaded by

kalkalina63Copyright:

Available Formats

Hand and Power Tool Safety Program

1. Purpose: Virginia Commonwealth University Department of Safety and Risk

Management (SRM) has developed this Program to ensure the safety of

employees working with hand and portable powered tools and other hand-held

equipment. The program was created in accordance with the Occupational

Safety and Health Administration (OSHA) standards contained in 29 CFR

1910.241-244.

2. Scope / Applicability: This program applies to all VCU employees who may use

hand and portable powered tools and equipment during the course of work.

Employees must be able to use hand and portable powered tools and

equipment safely and will comply with manufacturer guidelines.

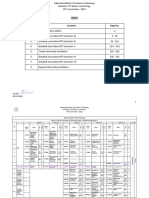

3. Table of Contents:

Purpose Page 1

Scope/Applicability 1

Responsibilities 1

General Safety Requirements 2

Hazard Control 3

Hand Tools 3

Power Tools 4

Power Saws 5

Drills 6

Abrasive Sanders and Wheels 6

Pneumatic Tools 7

Jack and Hydraulic Power Tools 8

Operating Controls and Switches 9

Powder-Actuated Tools 10

Grounds Equipment 10

Training and Recordkeeping 14

References 15

4. Responsibilities:

a. Safety and Risk Management (SRM) is responsible for:

Developing the Hand and Power Tool Safety Program and revising

the program as necessary;

Developing and delivering a general training program;

6 February 2018 Page 1 of 15

Hand and Power Tool Safety Program

Validating program implementation; and

Maintaining training records.

b. Departments/Supervisors are responsible for:

Ensuring that hand and power tool safety measure are in place

according to this Program and the applicable OSHA standards;

Ensuring that tools are free from defects and are working and

maintained properly;

Ensuring that tools are used in accordance with manufacturer

recommendations;

Ensuring that all affected employees have been trained in

accordance to the manufacturer recommendations and to the

applicable standards outlined in the appendices of this Program;

Providing personal protective equipment;

Taking damaged tools out of service immediately if they are

defective; and

Conducting periodic inspections of work areas.

c. Employees are responsible for:

Attending required training programs;

Inspecting hand and portable powered tools and equipment for

defects and possible hazards prior to use;

Tagging any defective tools as out of service immediately and/or

reporting defects to their supervisor;

If applicable, wearing personal protective equipment; and

Using hand and portable powered tools and equipment safely and in

accordance to manufacturer’s recommendations.

5. General Safety Requirements: Tools and equipment shall be kept in safe

condition. The following help prevent hazards associated with the use of hand

and power tools:

Keep all tools in good condition with regular maintenance;

Use the right tool for the job;

Inspect each tool for damage before use;

Never use a damaged tool – take damaged tools out of service

immediately;

Operate tools according to the manufacturer’s instructions;

Use the proper personal protective equipment (PPE);

Compressed air shall not be used for cleaning purposes except where

reduced to less than 30 p.s.i and then only with effective chip guarding

and personal protective equipment.

6 February 2018 Page 2 of 15

Hand and Power Tool Safety Program

6. Hazard Control

a. Guards: The exposed moving parts of power tools shall be guarded per

VCU’s Machine/Machinery Guarding Program and 29CFR 1910.243. Safety

guards must never be removed when a tool is being used. Belts, gears,

shafts, pulleys, sprockets, spindles, drums, chains, or other reciprocating,

rotating, or moving parts of equipment must be guarded. Machine guards

must be provided to protect the operator and others from the following:

• Point of operation;

• In-running nip points;

• Rotating parts; and

• Flying chips and sparks.

b. Personal Protective Equipment (PPE): Employees who use hand and power

tools and are exposed to the hazards of vibration, falling, flying abrasive,

and splashing objects, or to harmful dusts, fumes, mists, vapors, or gases

must be provided with the appropriate personal protective equipment.

The following considerations should be evaluated at a minimum in the

selection and use of PPE when using hand and power tools:

• Safety glasses or goggles must be worn at all times when using

hand and power tools;

• A face-shield may be used in addition to safety glasses or goggles to

protect the face and neck;

• Composite or steel-toe shoes must be worn while working with

power tools to prevent injury from dropped tools.

7. Hand tools: Hand tools are tools that are powered manually. Examples include

axes, chisels, files, hammers, pliers, saws, scissors and wrenches. Hazards

associated with hand tools result from misuse and improper maintenance. To

prevent injury, follow the guidelines listed below:

• Hand tools shall be used for their intended purpose. For example, if a

screwdriver is used as a chisel, the tip of the screwdriver may break and fly

off, hitting the user and other employees;

• Inspect tools for damage prior to use;

• Hand tools shall be maintained in good condition free of damage. For

example, wooden handles on tools, such as a hammer or an axe, shall be

tight and free of splinters and cracks;

• Bent screwdrivers or screwdrivers with chipped edges shall be replaced;

• Always direct tools such as knives, saw blades, etc. away from aisle areas

and away from other employees working in close proximity;

6 February 2018 Page 3 of 15

Hand and Power Tool Safety Program

Knives and scissors must be sharp; dull tools can cause more hazards that

sharp ones;

Cracked saw blades must be removed from service;

Wrenches must not be used when jaws are sprung to the point that slippage

occurs;

Impact tools such as drift pins, wedges, and chisels must be kept free of

mushroomed heads;

Iron or steel hand tools may produce sparks that can be an ignition source

around flammable substances. Spark-resistant tools made from non-

ferrous materials should be used where flammable gases, highly volatile

liquids, and other explosive substances are stored or used;

Keep the work area and tools clean. Dirty, greasy tools and floor may

cause accidents;

Tools shall be stored in a dry secure location;

Carry and store tools properly. All sharp tools shall be carried and stored

with the sharp edge down. Do not carry sharp tools in a pocket; and

Wear the proper personal protective equipment (PPE).

8. Power tools (General Safety): Power tools must be equipped with guards and

safety switches. They can be hazardous when used improperly. Types of power

tools are determined by their power source: electric, pneumatic, liquid fuel,

hydraulic, and powder-actuated. To prevent hazards associated with the use of

power tools, workers should observe the following general precautions:

Read the owner’s manual to understand the tool’s proper applications,

limitations, operation, and hazards;

Never carry a tool by the cord or hose;

Never yank the cord or hose to disconnect it from the receptacle;

Keep cords and hoses away from heat, oil, and sharp edges;

Ensure tools are properly grounded; use Ground Fault Circuit Interrupter

(GFCI) for corded tools;

Disconnect tools when not using them, before servicing and cleaning, and

when changing accessories such as blades, bits and cutters;

Keep all people not involved with the work at a safe distance from the work

area;

Secure work with clams or a vise, freeing both hands to operate the tool;

Avoid accidental starting. Do not hold fingers on the switch button while

carrying a plugged-in tool;

Maintain tools sharp and clean;

Be sure to keep good footing and maintain good balance when operating

power tools;

Wear proper apparel for the task. Loose clothing, ties, or jewelry can

become caught in moving parts;

6 February 2018 Page 4 of 15

Hand and Power Tool Safety Program

Inspect tools for damage before each use. Remove all damaged portable

electric tools from use and tag them: “Do Not Use”;

Ensure the cords from electric tools do not present a tripping hazard;

Keep work areas well-lit when operating electric tools;

Store electric tools in a dry place when not in use; and

Wear PPE and appropriate footwear when using electric tools.

9. Power Saws:

a. Circular Saws

Powered circular saws having a blade greater than 2 inches in

diameter must be equipped at all times with guards. An upper

guard must cover the entire blade of the saw. A retractable

lower guard must cover the teeth of the saw, except where it

makes contact with the work material. The lower guard must

automatically return to the covering position when the tool is

withdrawn from the work material;

Ensure the blade is sharp, undamaged, and secured; and

Ensure that all guards are attached and working properly.

b. Table Saws

Adjust the blade to project 1/8 inch above the wood;

Ensure that the work piece does not contact the blade when

starting or stopping the saw;

Keep body away from the saw;

Use a push stick when cutting narrow pieces;

When the saw is not in use, make sure the saw blade is lowered

below the tabletop;

Ensure the blade is sharp, undamaged, and secure; and

Ensure that all guards are attached and working properly.

c. Saber Saws

Select the proper blade for the job;

Do not turn on the saw when the blade is in contact with the

work piece;

Hold the saw firmly with one hand and hold the work piece with

the other;

Keep hands and other objects clear of the blade;

Ensure the blade is sharp, undamaged, and secured; and

Ensure that all guards are attached and working properly.

d. Radial Arm Saws

Lay the wood on the table and against the saw’s back guide.

The blade should rotate downward. Pull the saw with one hand

and hold the wood with the other. Never reach across the line of

6 February 2018 Page 5 of 15

Hand and Power Tool Safety Program

the cut. Return the saw to the rear position after completing a

cut;

Ensure the blade is sharp, undamaged, and secured; and

Ensure that all guards are attached and working properly.

e. Miter Saws

Miter saws use a downward cutting motion. User must keep

hands and fingers away from the blade’s path;

Use only the recommended size and rpm rated blades;

When installing or changing a blade, make sure that the blade

and all fasteners are correctly positioned and secured to the

saw;

Ensure the blade is sharp, undamaged, and secured; and

Ensure that all guards are attached and working properly.

f. Band Saws

Set the blade evenly and with the correct tension;

For large pieces to be cut, push the cutting item through the

blade with the hands on both sides of the line to be cut;

For small pieces to be cut, use rip or crosscut fences and a push

stick;

Lower the band guard to just above the piece to be cut;

Ensure the blade is sharp, undamaged, and secured; and

Ensure that all guards are attached and working properly.

10. Drills: When operating a drill:

Use the proper size and type of bit for the job. Make sure that it is

sharp and not damaged;

Ensure that the chuck is secured to the spindle;

Tighten the bit securely as outlined in the owner’s manual;

Remove the chuck key prior to starting the drill;

Ensure that handles are securely attached;

When drilling clockwise (forward), brace the drill to prevent a

counterclockwise reaction;

Never force a drill. Forcing a drill can cause a motor to overheat and

damage the bit;

Apply the appropriate pressure for the job. If the drill slows, relieve

the pressure; and

When operating a drill press, ensure that the quill guard is in place and

functioning (if equipped by the manufacturer).

11. Abrasive Sanders and Wheels:

a. Belt Sanders

6 February 2018 Page 6 of 15

Hand and Power Tool Safety Program

Belt sanding machines shall be provided with guards at each nip point

where there sanding belt runs onto a pulley;

The guards shall prevent the hands or fingers of the operator from

coming in contact with the nip points; and

The unused run of the sanding belt shall be guarding against

accidental contact.

b. Abrasive Wheel Tools

Powered abrasive grinding cutting, polishing, and wire buffing wheels

may throw off flying fragments. Abrasive wheel tools must be

equipped with guards that:

1. Cover the spindle end, nut, and flange projections;

2. Maintain proper alignment with the wheel; and

3. Do not exceed the strength of the fastenings.

Before an abrasive wheel is mounted, it must be inspected for damage

and should be sound or ring-tested to ensure that it is free from cracks

or defects. Wheels should be tapped gently with a light, non-metallic

instrument. If the wheels sound cracked or dead, they could fly apart

during operation and must not be used. A stable and undamaged

wheel, when tapped, will give a clear metallic tone or “ring”;

To prevent an abrasive wheel from cracking, it must fit freely on the

spindle. The spindle nut must be tightened to hold the wheel in place

without distorting the flange;

Always follow the manufacturer’s recommendations;

Ensure that the spindle speed of the machine will not exceed the

maximum operating speed marked on the wheel. An abrasive wheel

may disintegrate or explode during start-up. Allow the tool to come

up to operating speed prior to grinding or cutting;

The employee should never stand in the plane of rotation of the wheel

as it accelerates to full operating speed;

Powered grinding tools shall be equipped with guards to protect

workers from the moving wheel surface also from flying fragments in

case of wheel breakage;

The work rest shall be within 1/8 inch of the wheel. The adjustable

tongue on the top of the grinder must be within ¼ inch of the wheel;

When using a power grinder always use eye or face protection, turn off

the power when not in use, and never clamp a hand-held grinder in a

vise.

12. Pneumatic Tools: Pneumatic tools are powered by compressed air and

include chippers, drills, hammers, and sanders. Some hazards associated with

pneumatic tools include noise, vibration, fatigue, and stairs. Additional hazards

are listed below:

6 February 2018 Page 7 of 15

Hand and Power Tool Safety Program

Eye protection must be work in order to avoid being hit by one of the

tool’s attachments or by a fastener used with the tool;

Pneumatic tools must be checked to ensure that they are fastened

securely to the air hose to prevent them from becoming disconnected.

A short wire or positive locking device attaching the air hose to the

tool must also be used and will serve as an added safeguard;

If an air hose is more than ½ inch in diameter, a safety excess flow

valve must be installed at the source of the air supply to shut off the

air automatically in case the hose breaks;

When connecting lengths of high pressure hose together, safety clips

or wire shall be used to secure couplings together;

When using pneumatic tools, a safety clip or retainer must be installed

to prevent attachments such as chisels on a chipping hammer from

being ejected during tool operation;

Pneumatic tools that shoot nails, rivets, staples, or similar fasteners

and operate at pressures more than 100 pounds per square inch

(consult manufacturer’s recommendations for proper pressure setting)

must be equipped with a special device to keep fasteners from being

ejected, unless the muzzle is pressed against the work surface;

Airless spray guns that atomize paints and fluids at pressures of 1,000

pounds or more per square inch must be equipped with automatic or

visible manual safety devices that will prevent pulling the trigger until

the safety device is manually released;

Screens must be set up to protect nearby workers from being struck

by flying fragments around chippers, riveting guns, staplers, or air

drills; and

Compressed air guns shall never be pointed toward anyone. Workers

shall never “dead-end” them against themselves or anyone else.

13. Jack and Hydraulic Power Tools

a. General Requirements for all jacks (lever and ratchet jacks, screw jacks, and

hydraulic jacks):

Must have a stop indicator and the stop limit must not be exceeded.

Manufacturer’s load limit must be permanently marked in a prominent

place on the jack and the load limit must not be exceeded.

The operator shall make sure that the jack has a rating sufficient to lift

and sustain the load.

A jack shall never be used to support a lifted load. Once the load has

been lifted, it must immediately be blocked up. Place a block under the

base of the jack when the foundation is not firm, and place a block

between the jack capacity and load if the cap might slip.

To set up a jack:

1. The base of the jack shall rest on a firm, level surface;

6 February 2018 Page 8 of 15

Hand and Power Tool Safety Program

2. The jack must be correctly centered;

3. The jack head must bear against a level surface; and

4. The lift force must be applied evenly.

All jacks must be lubricated regularly.

Each jack must be inspected according to the following schedule: (1)

for jacks used continuously or intermittently at one site—inspected at

least once every 6 months, (2) for jacks sent out of the shop for

special work—inspected when sent out and inspected when returned,

and (3) for jacks subjected to abnormal loads or shock— inspected

before use and immediately thereafter. Inspection records shall be

maintained within using department and retained for 3 years.

Jacks which are out of order shall be tagged accordingly, and shall not

be used until repairs are made.

b. Hydraulic Jacks

Hydraulic jacks exposed to freezing temperatures shall be supplied

with an adequate antifreeze liquid.

c. Hydraulic Power Tools

The fluid used in hydraulic power tools must be an approved fire-

resistant fluid and must retain its operating characteristics at the most

extreme temperatures to which it will be exposed. The exception to

fire-resistant fluid involves all hydraulic fluids used for the insulated

sections of derrick trucks, aerial lifts, and hydraulic tools that are used

on or around energized lines. This hydraulic fluid shall be of the

insulating type.

The manufacturer’s recommended safe operating pressure for hoses,

valves, pipes, filters, and other fittings must not be exceeded.

14. Operating Controls and Switches:

a. The following hand-held power tools must be equipped with a constant-

pressure switch or control that shuts off the power when pressure is released

(tools may also be equipped with a “lock-on” control, if it allows the worker

to also shut off the control in a single motion using the same finger or

fingers):

Drills;

Tappers;

Fastener drivers;

Horizontal, vertical, and angle grinders with wheels more than 2 inches

in diameter;

Disc sanders with discs greater than 2 inches;

Belt sanders;

Reciprocating saws;

Saber saws, scroll saws, and jigsaws with blade shanks greater than

1/4-inch wide; and

6 February 2018 Page 9 of 15

Hand and Power Tool Safety Program

Other similar tools.

b. The following hand-held power tools must be equipped with either a positive

“on-off” control switch, a constant pressure switch, or a “lock-on” control

(Note: The constant-pressure control switch should be regarded as the

preferred device. Other hand-held power tools such as circular saws having

a blade diameter greater than 2 inches, chain saws, and percussion tools

with no means of holding accessories securely must be equipped with a

constant-pressure switch):

Disc sanders with discs 2 inches or less in diameter;

Grinders with wheels 2 inches or less in diameter;

Platen sanders, routers, planers, laminate trimmers, nibblers, shears,

and scroll saws; and

Jigsaws, saber, and scroll saws with blade shanks a nominal 1/4-inch

or less in diameter.

15. Powder-Actuated Tools: Powder-actuated tools are considered very

dangerous, and shall only be operated by employees who have received

training. Powder-actuated tools operate very much like a loaded gun and must

be treated with such respect. When using powder-actuated tools, the user

must:

Wear ear, eye and face protection.

Ensure that the muzzle protective shield is in place and centered

perpendicular to and concentric with the barrel to confine any

projectile fragments that could be launched when the tool is fired.

Hold the tool in the operation position for at least 30 seconds before

trying to re-fire it if misfired.

Not use in an explosive or flammable atmosphere.

Inspect the powder-actuated tool before using it, make sure it is clean,

that all moving parts operate freely, that the barrel is free from

obstruction, and that the barrel has the proper shield, guard, and

attachments as recommended by the manufacturer.

Not load the tool unless it is to be used immediately.

Not leave a loaded tool unattended.

Keep hand clear of the barrel end.

Never point the tool at anyone.

Not fire fasteners into materials that would allow the fasteners to pass

through to the other side.

Not drive fasteners into brittle materials that might chip or splatter

which could cause the fastener to ricochet.

Always use an alignment guide when shooting fasteners into existing

holes.

6 February 2018 Page 10 of 15

Hand and Power Tool Safety Program

16. Grounds Equipment

a. Weed Trimmers

Wear appropriate protective clothing, long pants, gloves, safety shoes,

goggles or safety glasses, and ear plugs. If working in close proximity

to vehicular traffic, a visibility vest shall also be worn.

Ensure that pedestrians are not in the work zone prior to starting

work.

Don’t remove protective guards or string guides from the equipment

unless you are performing maintenance where removal of the device is

necessary.

Monitor the string length. Automatic-feed and bump-feed trimmers

may let out more string than necessary which could cause the string to

strike the operator.

If using an electric trimmer, inspect all extension cords for cuts, nicks,

scrapes, and exposed wire that may pose an electrical hazard. Replace

damaged cords immediately.

Don’t operate electric trimmers when conditions are wet or working in

close proximity to standing water. If work must be performed in wet

conditions, a GFCI shall be used.

Disable electric trimmers and gas-powered trimmers before inspecting,

cleaning, adjusting, or replacing string.

Never leave an electric trimmer plugged in or a gas-powered trimmer

running while unattended.

When refueling gas-powered trimmers, shut the engine off, utilize a

funnel or gas can with a nozzle extension that fits into the gas tank

opening.

Remove debris such as glass, limbs, rocks, and trash that could

possibly become a projectile before trimming.

Watch out for exposed electrical wires, communication lines, and

extension cords that could be damaged by the trimmer string.

Follow the manufacturer’s guidelines for the equipment you are

operating.

b. Lawn Edgers

Wear appropriate protective clothing, long pants, gloves, safety shoes,

goggles or safety glasses, and ear plugs. If working in close proximity

to vehicular traffic, a visibility vest shall also be worn.

Ensure that pedestrians are not in the work zone prior to starting

work.

Don’t start an edger if the blade is touching the ground. It could move

causing contact with the operator.

Don’t remove protective guards or shields from the equipment unless

you are performing maintenance where removal of the device is

necessary.

6 February 2018 Page 11 of 15

Hand and Power Tool Safety Program

Operate the edger blade at full speed.

When edging along roadways, stay as close to the curb as possible to

avoid contact with vehicular traffic.

Disable electric edgers and gas-powered edgers before inspecting,

cleaning, adjusting, or replacing the blade.

Never leave an electric edger plugged in or a gas-powered edger

running while unattended.

When refueling gas-powered lawn edgers, shut the engine off, utilize

a funnel or gas can with a nozzle extension that fits into the gas tank

opening.

Watch out for exposed electrical wires, communication lines, and

extension cords that could be damaged by the edger.

Follow the manufacturer’s guidelines for the equipment you are

operating.

c. Hedge Trimmers

Wear appropriate protective clothing, long pants, gloves, safety shoes,

goggles or safety glasses, and ear plugs. If working in close

proximity to vehicular traffic, a visibility vest shall also be worn.

Ensure that pedestrians are not in the work zone prior to starting

work.

Ensure that all screws, blades, and/or chains are secure. Vibrating

equipment can cause screws to loosen which may create a hazard.

Disable electric trimmers and gas-powered trimmers before inspecting,

cleaning, adjusting, or replacing the blade.

Never leave hedge trimmers unattended.

When refueling gas-powered hedge trimmers, shut the engine off,

utilize a funnel or gas can with a nozzle extension that fits into the gas

tank opening.

Do not use electric hedge trimmers overhead.

If trimmers become lodged in something, disconnect the power source

before attempting to dislodge it.

With electric hedge trimmers, keep extension cords clear of blades.

Watch out for exposed electrical wires, communication lines, and

extension cords that could be damaged by the trimmer.

Follow the manufacturer’s guidelines for the equipment you are

operating.

d. Leaf Blowers

Wear appropriate protective clothing, long pants, gloves, safety shoes,

goggles or safety glasses, and ear plugs. If working in close proximity

to vehicular traffic, a visibility vest shall also be worn.

Ensure that pedestrians are not in the work zone prior to starting

work.

6 February 2018 Page 12 of 15

Hand and Power Tool Safety Program

If using an electric blower, inspect all extension cords for cuts, nicks,

scrapes, and exposed wire that could pose an electrical hazard.

Replace damaged cords immediately.

Don’t operate electric blowers when conditions are wet or working in

close proximity to standing water. If work must be performed in wet

conditions, a GFCI shall be used.

Disable electric blowers and gas-powered blowers before inspecting,

cleaning, or adjusting.

When refueling gas-powered blowers, shut the engine off, utilize a

funnel or gas can with a nozzle extension that fits into the gas tank

opening.

Don’t use the blower to clean yourself.

Follow the manufacturer’s guidelines for the equipment you are

operating.

e. Chain Saw

Before starting the chain saw:

1. Wear appropriate protective clothing, gloves, safety shoes, long

pants, chaps, goggles or safety glasses, face shield and ear

plugs. If working in close proximity to vehicular traffic, a

visibility vest shall also be worn.

2. Check controls, chain tension, and all bolts and handles to

ensure they are functioning properly and adjusted according to

the manufacturer's instructions.

3. Fuel the saw at least 10 feet from sources of ignition.

4. Start the saw at least 10 feet from fueling area, with chain brake

engaged, and with the chainsaw on the ground or otherwise

firmly supported.

While running the chain saw

1. Keep hands on the handles, and maintain secure footing while

operating the chainsaw.

2. If you are retreating from a fall hazard or out of a danger zone,

disable the chain saw or release the throttle prior to retreating.

3. Disable or ensure that the chain brake is engaged whenever the

saw is carried more than 50 feet, or if carried on hazardous

terrain.

4. Disable electric chain saws and gas-powered chain saws before

inspecting, cleaning, adjusting, or replacing the chain.

5. When refueling gas-powered chain saws, shut the engine off,

utilize a funnel or gas can with a nozzle extension that fits into

the gas tank opening.

6. Clear the area of obstacles that might interfere with cutting the

tree or using the retreat path.

7. Do not cut directly overhead.

6 February 2018 Page 13 of 15

Hand and Power Tool Safety Program

8. Follow the manufacturer’s guidelines for the equipment you are

operating.

f. Snow Thrower

Wear appropriate protective clothing, long pants, gloves, safety shoes,

goggles or safety glasses, and ear plugs. If working in close proximity

to vehicular traffic, a visibility vest shall also be worn.

Always keep hands and feet away from all moving parts of the

machine.

If the machine clogs while removing snow, shut the machine off and

wait for all moving parts to stop. Remove the clogged snow with a

stick or suitable instrument. Take caution as the machine may jump

once the obstruction has been cleared.

Never leave a running snow thrower unattended.

Some machine are capable of throwing snow distance of 30 feet or

greater. These machines can also propel rocks or other objects at

great velocity. Operators shall ensure they discharge the snow away

from people, buildings, or vehicles.

If using an electric snow thrower, be aware of the location of the

power cord. In addition, power cords shall be GFCI rated and or be

plugged into a GFCI outlet.

Disable electric snow throwers and gas-powered snow throwers before

inspecting, cleaning, or adjusting.

When refueling gas-powered snow throwers, shut the engine off,

utilize a funnel or gas can with a nozzle extension that fits into the gas

tank opening

Follow the manufacturer’s guidelines for the equipment you are

operating.

17. Training and Recordkeeping

a. Training requirements: All employees shall be trained in the proper use of

tools prior to using hand and power tools and other hand-held equipment.

Awareness training is provided by Safety and Risk Management. Employees

shall be trained in the following:

Recognition of the hazards associated with different types of tools and

the safety precautions necessary for use;

PPE requirements while using hand and power tools; and

The proper use of hand and power tools and other hand-held

equipment.

Departments are responsible for conducting training that is specific to the

hand and power tools being used.

b. Recordkeeping: Training records will be maintained by SRM. Maintenance

and repair records must be documented and kept by the department.

6 February 2018 Page 14 of 15

Hand and Power Tool Safety Program

18. References:

• OSHA Regulations 29 CFR 1910.241-244

• Environmental Health and Safety and Risk Management policy: located

in VCU Policy Library

• VCU Machine/Machinery Guarding Program

6 February 2018 Page 15 of 15

You might also like

- Construction Tool Safety Checklist RevDocument2 pagesConstruction Tool Safety Checklist Reveast75% (4)

- Bridgeport VMC1022 PDFDocument98 pagesBridgeport VMC1022 PDFKrassi GlogovskiNo ratings yet

- Submissive ChecklistDocument19 pagesSubmissive ChecklistAndrew Rutledge100% (4)

- Focus1 2E MiniMatura Unit4 GroupA 2kolDocument4 pagesFocus1 2E MiniMatura Unit4 GroupA 2koljafc jumNo ratings yet

- Standard Operating Procedures of Hand Tools 2Document4 pagesStandard Operating Procedures of Hand Tools 2singenaadamNo ratings yet

- (The DeLuca Family) Unofficial Game GuideDocument25 pages(The DeLuca Family) Unofficial Game GuideTiburcio Maldonado100% (1)

- Tools Safety and Machine GuardingDocument13 pagesTools Safety and Machine GuardingEfereutrio SolariotoNo ratings yet

- 12.hand & Power Tools Safety, Hands & Finger Safety & Abrassive Wheel UDocument57 pages12.hand & Power Tools Safety, Hands & Finger Safety & Abrassive Wheel URaghavendra Kiran AJE - SHES Technical CoordinatorNo ratings yet

- Hand and Power Tools DCCSPDocument16 pagesHand and Power Tools DCCSPLion DayNo ratings yet

- Tools and Equipt. SafetyDocument27 pagesTools and Equipt. SafetyJericho DagamiNo ratings yet

- S014 - Hand & Oower ToolsDocument30 pagesS014 - Hand & Oower Toolsmalik jahanNo ratings yet

- Toolbox Talk Form Safe Use of Hand and Portable Power Tools 003Document6 pagesToolbox Talk Form Safe Use of Hand and Portable Power Tools 003Anwar AhmedNo ratings yet

- Hand and Power Tools FHM COVERDocument28 pagesHand and Power Tools FHM COVERS BNo ratings yet

- Chapter 14 - Shop SafetyDocument11 pagesChapter 14 - Shop Safetymega87_2000No ratings yet

- Safe Use of Power ToolsDocument91 pagesSafe Use of Power ToolshARINo ratings yet

- Weekly Safety Slogan - Week 43 - Power Tool SafetyDocument7 pagesWeekly Safety Slogan - Week 43 - Power Tool SafetyAbdejelil ChokriNo ratings yet

- Tool Safety & Inspection: Company Name HereDocument6 pagesTool Safety & Inspection: Company Name HereEl KhanNo ratings yet

- Powered Hand ToolsDocument4 pagesPowered Hand Toolssile15No ratings yet

- Method Statement For Working With Hand ToolsDocument4 pagesMethod Statement For Working With Hand ToolsRynoNo ratings yet

- RT3422 Tapping Tool ManualDocument48 pagesRT3422 Tapping Tool ManualLeonard100% (1)

- Hand and Portable Power Tools Safety Marafiq OHSMS Procedure No. 54 17 February 2019 (EME)Document10 pagesHand and Portable Power Tools Safety Marafiq OHSMS Procedure No. 54 17 February 2019 (EME)Sarfraz RandhawaNo ratings yet

- Osha 3080Document32 pagesOsha 3080Geofrey Oscar Yangali LimacoNo ratings yet

- RT3422 Tapping Tool ManualDocument48 pagesRT3422 Tapping Tool ManualJesus amésquitaNo ratings yet

- Hand and Power ToolsDocument32 pagesHand and Power Toolsdil1717No ratings yet

- Safe Use of Power Tools Rev0Document92 pagesSafe Use of Power Tools Rev0mohapatrarajNo ratings yet

- Safe Use of Power Tools Rev0Document92 pagesSafe Use of Power Tools Rev0Vaibhav Vithoba NaikNo ratings yet

- Tools and EquipmentDocument27 pagesTools and EquipmentRich MondNo ratings yet

- 01 3.1. Safety HazardsDocument14 pages01 3.1. Safety Hazardsيوسف خضر النسورNo ratings yet

- Using Work Equipment Safely PDFDocument9 pagesUsing Work Equipment Safely PDFsile15No ratings yet

- Recommended Guidelines For Safe Use of Tools at Height April 2011Document11 pagesRecommended Guidelines For Safe Use of Tools at Height April 2011Paul RuckNo ratings yet

- Tool Safety. Portable and Power ToolsDocument55 pagesTool Safety. Portable and Power ToolsJohn Lloyd GenerosoNo ratings yet

- 4.1-2 Hand Tools and Its UsesDocument14 pages4.1-2 Hand Tools and Its UsesTabata Qbz TawinNo ratings yet

- Power Tools 2Document20 pagesPower Tools 2Brijgopal YadavNo ratings yet

- Arman Health & Safety-2Document22 pagesArman Health & Safety-2Suleman ZahoorNo ratings yet

- Power Tool TrainingDocument20 pagesPower Tool TrainingToyota MatinaNo ratings yet

- FY06 46c6-Ht21 English B 7 Hand Power ToolsDocument35 pagesFY06 46c6-Ht21 English B 7 Hand Power Toolstu100% (1)

- Hand & Power ToolDocument32 pagesHand & Power ToolNur Syafiqah Mat RapieNo ratings yet

- Hand Power Tool and Equipment Safety-Toolbox TalkDocument4 pagesHand Power Tool and Equipment Safety-Toolbox TalkKROS EffectsNo ratings yet

- VMC 560-22 TNC 2500cmaintenance Manualsiemens 1801235 PDFDocument90 pagesVMC 560-22 TNC 2500cmaintenance Manualsiemens 1801235 PDFAmir JuttNo ratings yet

- Nsid 415 Manual T15Document17 pagesNsid 415 Manual T15Sebastian GutiérrezNo ratings yet

- HandSafetyBook PDFDocument100 pagesHandSafetyBook PDFahmar javedNo ratings yet

- Instruction Manual AND Safety Instructions FOR Cordless Hammer DrillDocument24 pagesInstruction Manual AND Safety Instructions FOR Cordless Hammer DrillMuthu RajanNo ratings yet

- Safety Instruction For Using Threaded MachineDocument3 pagesSafety Instruction For Using Threaded MachineKhaled AnwarNo ratings yet

- 2nd Sem CSS Module 5Document12 pages2nd Sem CSS Module 5Deey Lanne Casuga RufintaNo ratings yet

- Work Equipment 20727Document3 pagesWork Equipment 20727epicrichenNo ratings yet

- What Are The Dangers of Hand and Power Tools?Document6 pagesWhat Are The Dangers of Hand and Power Tools?rian hidayatNo ratings yet

- Section G Hand&powertools08Document36 pagesSection G Hand&powertools08MirwaliNo ratings yet

- VMC 56022Document99 pagesVMC 56022wirot deelamanNo ratings yet

- 4.1 2 Hand Tools and Its Uses Full PermissionDocument12 pages4.1 2 Hand Tools and Its Uses Full PermissionLathea Daiser TheaNise TesalunaNo ratings yet

- Tools and Equipment: Hand and Power: Tool and Equipment Safety Is Everyone's Job and The Employer's Responsibility!Document13 pagesTools and Equipment: Hand and Power: Tool and Equipment Safety Is Everyone's Job and The Employer's Responsibility!El LlacunaNo ratings yet

- #Safety Equipment and PrecautionsDocument44 pages#Safety Equipment and PrecautionsMarvin PattyNo ratings yet

- Seatwork No.1 PDFDocument4 pagesSeatwork No.1 PDFRecel Ann RiveraNo ratings yet

- 2010-1105 11 Hand & Power ToolsDocument35 pages2010-1105 11 Hand & Power Toolsbinas nasarNo ratings yet

- Sécurité de Base Des OutilsDocument1 pageSécurité de Base Des OutilsKelly MputuNo ratings yet

- ITEEA SafetyPresentation 2014 Part1Document83 pagesITEEA SafetyPresentation 2014 Part1Diana RUNo ratings yet

- 22 Hand Tool SafetyDocument8 pages22 Hand Tool SafetyAlma Tomas-CafeNo ratings yet

- Comm Malfunction Grade 8Document7 pagesComm Malfunction Grade 8Leonard100% (1)

- 2.5-Hand and PowerTools Safety-35 Slides PDFDocument35 pages2.5-Hand and PowerTools Safety-35 Slides PDFᜇᜒᜌᜓᜈᜎ᜔ᜇ᜔ ᜊᜒᜇᜓᜌ᜔No ratings yet

- 22 Hand Tool SafetyDocument8 pages22 Hand Tool SafetyAlma Tomas-CafeNo ratings yet

- PONCHADORADocument9 pagesPONCHADORAJulio Cesar MendozaNo ratings yet

- The Construction Safety Guide: Injury and Illness Prevention through DesignFrom EverandThe Construction Safety Guide: Injury and Illness Prevention through DesignRating: 4 out of 5 stars4/5 (6)

- LysistrataDocument65 pagesLysistrataElizabeth JeghedeNo ratings yet

- Notre Dame University Cotabato CityDocument8 pagesNotre Dame University Cotabato CityJannah MasturaNo ratings yet

- PROJECT REPORT - Ready Made GarmentsDocument2 pagesPROJECT REPORT - Ready Made GarmentsJai Bhushan BharmouriaNo ratings yet

- Perigos City of MistDocument20 pagesPerigos City of MistPabloNo ratings yet

- UOE Use of English I: Read The Text and Decide Which Answer A, B, C or D Best Fits Each SpaceDocument11 pagesUOE Use of English I: Read The Text and Decide Which Answer A, B, C or D Best Fits Each SpaceCarlos CarrascosaNo ratings yet

- TOBAL Company Limited by ShareDocument8 pagesTOBAL Company Limited by ShareHobong SofianNo ratings yet

- Yakan People: Jump To Navigation Jump To SearchDocument4 pagesYakan People: Jump To Navigation Jump To SearchRonaldNo ratings yet

- Prop List: Item Description Actor/Location NotesDocument2 pagesProp List: Item Description Actor/Location NotesEmily Preston LandeenNo ratings yet

- Reading and WritingDocument16 pagesReading and WritingIrma Sanchez EspinosaNo ratings yet

- STK5NoticeAhmedabad 10052018Document123 pagesSTK5NoticeAhmedabad 10052018AnandNo ratings yet

- Detailed Exp Report July 2016 (Voc Port)Document199 pagesDetailed Exp Report July 2016 (Voc Port)QqqwertNo ratings yet

- Final Curriculum - BFT (17.02.2020)Document417 pagesFinal Curriculum - BFT (17.02.2020)ANWESHA SAMANTANo ratings yet

- HighNote3 U1-6 Cumulative Test ADocument2 pagesHighNote3 U1-6 Cumulative Test AJsbinwijwinf Awjfjfn9ammNo ratings yet

- Case Study On Dragon Sweater AndolonDocument31 pagesCase Study On Dragon Sweater AndolonTashfiqur Rahman Khan 1411446630No ratings yet

- Point of Care Risk Assessment (PCRA) : Assess The Task, The Patient and The Environment Prior To Each Patient InteractionDocument1 pagePoint of Care Risk Assessment (PCRA) : Assess The Task, The Patient and The Environment Prior To Each Patient InteractionchrisNo ratings yet

- Ew 20Document49 pagesEw 20Kalaivani KalaiselramNo ratings yet

- The Best Streetwear Brands On The PlanetDocument27 pagesThe Best Streetwear Brands On The PlanetRajkumar LodhaNo ratings yet

- Spanish Army of The Napoleonic Wars 2 1808 1813Document49 pagesSpanish Army of The Napoleonic Wars 2 1808 1813vladoanta71No ratings yet

- Revo Stitching Machine PDFDocument33 pagesRevo Stitching Machine PDFMaintenance Unit Anil GroupNo ratings yet

- The Queen's BundleDocument90 pagesThe Queen's BundleMarta EscamillaNo ratings yet

- Magic StoriesDocument367 pagesMagic StoriesNalini SinghNo ratings yet

- Slave Market - Episode 05 - English PDFDocument69 pagesSlave Market - Episode 05 - English PDFsameh essamNo ratings yet

- Arrow Merchandise Mix FinalDocument24 pagesArrow Merchandise Mix FinalPooja JaiswalNo ratings yet

- HOSPITAL Uniforms E-CatalogueDocument59 pagesHOSPITAL Uniforms E-CatalogueranukhadeNo ratings yet

- Siegfrieds MasculinityDocument23 pagesSiegfrieds MasculinityAnthony PapaeconomouNo ratings yet

- The Lady ChangDocument1 pageThe Lady ChangXhaytih Garcia75% (8)

- Cambridge IGCSE: Literature in English 0475/01Document26 pagesCambridge IGCSE: Literature in English 0475/01neindiwe mmasaNo ratings yet