Professional Documents

Culture Documents

Mec 124 ND Yr Ii Ee Machine Tools

Mec 124 ND Yr Ii Ee Machine Tools

Uploaded by

mas ud dan jiga0 ratings0% found this document useful (0 votes)

7 views1 pageThis document contains a machine tools exam with 6 questions for ND Year II Electrical/Electrical Engineering students. The exam covers topics related to machine tools, including calculating cutting speeds for drills and milling cutters, discussing metal cutting theory and chip formation, identifying cutting tool materials and machine parts, and performing calculations related to lathe and milling operations.

Original Description:

Note

Original Title

MEC-124-ND-YR-II-EE-MACHINE-TOOLS

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document contains a machine tools exam with 6 questions for ND Year II Electrical/Electrical Engineering students. The exam covers topics related to machine tools, including calculating cutting speeds for drills and milling cutters, discussing metal cutting theory and chip formation, identifying cutting tool materials and machine parts, and performing calculations related to lathe and milling operations.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

7 views1 pageMec 124 ND Yr Ii Ee Machine Tools

Mec 124 ND Yr Ii Ee Machine Tools

Uploaded by

mas ud dan jigaThis document contains a machine tools exam with 6 questions for ND Year II Electrical/Electrical Engineering students. The exam covers topics related to machine tools, including calculating cutting speeds for drills and milling cutters, discussing metal cutting theory and chip formation, identifying cutting tool materials and machine parts, and performing calculations related to lathe and milling operations.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 1

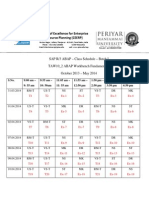

LAGOS CITY POLYTECHNIC, IKEJA

SCHOOL OF ENGINEERING AND APPLIED SCIENCE

DEPARTMENT OF ELECT/ELECT ENGINEERING

2015/2016 SEMESTER EXAMINATION

COURSE TITLE: MACHINE TOOLS NO OF QUESTION:

6

COURSE CODE: MEC 124 TIME: ALLOWED:

2HRS

FOR WHOM: ND YR II EE PT

INSTRUCTIONS: Answer any

4 Questions

1. (a) Find the cutting speed of 50mm diameter drill running at 250rev/min

(b) At what spindle speed would a 450mm diameter High Speed Steel Milling cutter

be

run to machine a steel workpiece, if the cutting speed is 40m/min?

2. (a) Discuss the theory of metal cutting

(b) With labelled diagram show the forces acting on a cutting tool

(c) State two characteristic of Cutting Fluid

3. (a) Mention three chips formed during metal cutting

(b) With diagrams discussed the three chips formation mentioned in 3a above.

(c) With diagrams differentiate between the clearance angle and the rake angle.

4. (a) State five cutting tools materials known to you

(b) With a well labelled diagram show a centre lathe machine.

(c) State four important or advantages of using cutting fluid during machine

operation.

5. (a) Mention four principal parts of a lathe machine

(b) A lathe is set to give a feed of 0.35 mm/rev

Find how far the tool will move in 100 revolutions of the workpiece

(c) List four types of cutting fluid that can be used in machining process.

6. (a) A cylindrical job 100mm diameter is to be turned at a cutting speed of 35m/min,

the feed

being 1.5 mm/rev. If the length of the job is 150mm, find the time required for 1

cut.

(b) A milling cutter has 14 teeth and a feed of 0.12mm per tooth is to be used. If the

cutter

makes 90 rev/min. Calculate

(i) The feed in millimetres per revolution

(ii) The feed in millimeters per minutes

You might also like

- 2018 is-BAO Guidance CH 15Document30 pages2018 is-BAO Guidance CH 15EmNo ratings yet

- LSMW Ca1 Zassd OrdchangeDocument34 pagesLSMW Ca1 Zassd OrdchangevijayjeoNo ratings yet

- MCMT Mid-1 P-QusDocument5 pagesMCMT Mid-1 P-QusN Dhanunjaya Rao BorraNo ratings yet

- Machine Tools Assignments 1 N 2Document3 pagesMachine Tools Assignments 1 N 2Sunkeswaram Deva PrasadNo ratings yet

- 2013Document4 pages2013AmyRapaNo ratings yet

- Cutting Force Thrust ForceDocument1 pageCutting Force Thrust ForcepmagrawalNo ratings yet

- Code No: 35033Document5 pagesCode No: 35033SRINIVASA RAO GANTANo ratings yet

- UG11T2106-UG11T1106-ME mr NavyDocument2 pagesUG11T2106-UG11T1106-ME mr Navynishant.malindaNo ratings yet

- 3.manufacturing Technology IIDocument6 pages3.manufacturing Technology IIprasanthprpNo ratings yet

- rr320303 Machine ToolsDocument4 pagesrr320303 Machine ToolsSRINIVASA RAO GANTA100% (1)

- Manufacturing Processes II Q.B.Document13 pagesManufacturing Processes II Q.B.Aditya PatilNo ratings yet

- Mantech Tie 6122 Assignment Bouquet Oct 2019 PDFDocument4 pagesMantech Tie 6122 Assignment Bouquet Oct 2019 PDFNativity MabasaNo ratings yet

- Assignment 3Document2 pagesAssignment 3M Shahrul IzuanNo ratings yet

- 3-1 MT (Nov 2009 Regular)Document5 pages3-1 MT (Nov 2009 Regular)micmechNo ratings yet

- MCMT Unit-1 PPQDocument2 pagesMCMT Unit-1 PPQN Dhanunjaya Rao BorraNo ratings yet

- FGBXVDocument3 pagesFGBXVRAJANo ratings yet

- Mee 210-Ipe 210.Document2 pagesMee 210-Ipe 210.dreamivory29No ratings yet

- UTA026 Manufacturing Processes Work SheetDocument3 pagesUTA026 Manufacturing Processes Work SheetGUNJAN KHULLARNo ratings yet

- 1616403439362-Subjective Questions On Manufacturing Process MET-03Document4 pages1616403439362-Subjective Questions On Manufacturing Process MET-03Dashmeet SinghNo ratings yet

- Final-Term Examination - First Semester 2018/2019Document3 pagesFinal-Term Examination - First Semester 2018/2019Hossam MohamedNo ratings yet

- انتاج ٢Document9 pagesانتاج ٢khaledfarrag281No ratings yet

- Assignment 4 Due: May 15, 2020 MachiningDocument1 pageAssignment 4 Due: May 15, 2020 MachiningngouoNo ratings yet

- Suresh Gyan Vihar University: τ / P = r (1-µr) /1+rDocument3 pagesSuresh Gyan Vihar University: τ / P = r (1-µr) /1+rSonu ChhipaNo ratings yet

- P.E.S. College of Engineering, Mandya - 571 401Document2 pagesP.E.S. College of Engineering, Mandya - 571 401coolmagaNo ratings yet

- Question Bank (PPII)Document7 pagesQuestion Bank (PPII)Udaiyar BarathadhithyaNo ratings yet

- P.E.S. College of Engineering, Mandya - 571 401Document2 pagesP.E.S. College of Engineering, Mandya - 571 401coolmagaNo ratings yet

- ME1324 Class Test 2Document1 pageME1324 Class Test 2Nipun BandaraNo ratings yet

- Colombo International Nautical & Engineering College: ME1324-Workshop Practice Class Test-2, (Batch - 4)Document1 pageColombo International Nautical & Engineering College: ME1324-Workshop Practice Class Test-2, (Batch - 4)Nipun BandaraNo ratings yet

- Tutorial-2: Manufacturing Science and Technology-II (ME - 322)Document2 pagesTutorial-2: Manufacturing Science and Technology-II (ME - 322)Deepam ShyamNo ratings yet

- Question Bank - All UnitsDocument11 pagesQuestion Bank - All UnitsParamasivam Veerappan100% (1)

- Example 2Document5 pagesExample 2girma workuNo ratings yet

- Slip TestDocument3 pagesSlip TestSaravanan MathiNo ratings yet

- Machine Tools - 1st MID - 3rd B.tech (2009)Document2 pagesMachine Tools - 1st MID - 3rd B.tech (2009)micmechNo ratings yet

- Manufacturing Engineering Guide BookDocument2 pagesManufacturing Engineering Guide BookGiridharan SharmaNo ratings yet

- Btech Mech Plastic 5 Sem Machining Science and Technology Pcme4304 2020Document2 pagesBtech Mech Plastic 5 Sem Machining Science and Technology Pcme4304 2020BAPUJI KUMAR SAHOONo ratings yet

- Bmm4243 (Mt2) - TutorialDocument3 pagesBmm4243 (Mt2) - TutorialNajip TalibinNo ratings yet

- Man ProDocument2 pagesMan ProlividiveNo ratings yet

- MTDM Question PaperDocument6 pagesMTDM Question PaperDude o manNo ratings yet

- Mt-Ii QBDocument10 pagesMt-Ii QBRavi ChandranNo ratings yet

- Mid Rem 2014-15Document2 pagesMid Rem 2014-15pmagrawalNo ratings yet

- EPP201 Pass Paper Revision Questions 1Document9 pagesEPP201 Pass Paper Revision Questions 1Boey Keen HuangNo ratings yet

- ME6402-Manufacturing Technology-IIDocument10 pagesME6402-Manufacturing Technology-IINIVAS S. SNo ratings yet

- EMG 1205 Manufactruing Processes II - Exam 2022-23Document3 pagesEMG 1205 Manufactruing Processes II - Exam 2022-23kiokocurtisNo ratings yet

- R7310304 Machine ToolsDocument1 pageR7310304 Machine ToolssivabharathamurthyNo ratings yet

- TUTORIALS 1 (1) - MergedDocument23 pagesTUTORIALS 1 (1) - MergedRUGERO KeslyneNo ratings yet

- Metal FormingDocument6 pagesMetal FormingHarish Kumar SNo ratings yet

- Problems Sheet Machine Tools 2015 16Document9 pagesProblems Sheet Machine Tools 2015 16Shafiq AhmadNo ratings yet

- Sheet 5Q Manufacturing Processes 1Document1 pageSheet 5Q Manufacturing Processes 1Ahmed Rabie Abd ElazeemNo ratings yet

- R07 Set No. 2Document4 pagesR07 Set No. 2Muhammad Asif Ali0% (1)

- Time: 3 Hours Answer All Questions Maximum: 100 MarksDocument3 pagesTime: 3 Hours Answer All Questions Maximum: 100 MarksAnonymous ZB6qyhD6No ratings yet

- Question Bank For Machining and MetrologyDocument7 pagesQuestion Bank For Machining and MetrologyAbhisheak DineshNo ratings yet

- Home Work No 3Document2 pagesHome Work No 3HarishNo ratings yet

- Q:1 A) (11.drilling) : Write The Advantage of Turning Center Over The Conventional Machine.Document2 pagesQ:1 A) (11.drilling) : Write The Advantage of Turning Center Over The Conventional Machine.Misbah NiamatNo ratings yet

- Be Summer 2023Document2 pagesBe Summer 2023Abc 194748No ratings yet

- EME_1102_WORKSHOP_PRACTICE_I_Supplementary_2021[1]Document5 pagesEME_1102_WORKSHOP_PRACTICE_I_Supplementary_2021[1]brianbett751No ratings yet

- AMP Test-2-Set-1Document2 pagesAMP Test-2-Set-1ManojKumar MNo ratings yet

- Me 5 PT 2021Document3 pagesMe 5 PT 2021SameerNo ratings yet

- 414 TutorialsDocument2 pages414 TutorialsAMOS SIFUNANo ratings yet

- WWW - Manaresults.Co - In: Set - 1 Code No: RT32033Document8 pagesWWW - Manaresults.Co - In: Set - 1 Code No: RT32033Sai RamNo ratings yet

- Assignment 1Document4 pagesAssignment 1antonushany52No ratings yet

- Technical ScheduleDocument138 pagesTechnical Scheduleaakashgupta viaanshNo ratings yet

- Electric Motor 7Document84 pagesElectric Motor 7abdulkadhirNo ratings yet

- Steve Jobs: Presented By-Santosh Vijay Dhamankur Rahul JatinDocument24 pagesSteve Jobs: Presented By-Santosh Vijay Dhamankur Rahul JatinPaul013No ratings yet

- M S Ramaiah School of Advanced StudiesDocument5 pagesM S Ramaiah School of Advanced StudiesRavishankarNo ratings yet

- The Game of Brands Quiz Book Volume 1 8zjta9Document99 pagesThe Game of Brands Quiz Book Volume 1 8zjta9Dibesh Padia100% (2)

- Barcodes CS1Document16 pagesBarcodes CS1harrysan69No ratings yet

- Taw10 2-Schedule3Document5 pagesTaw10 2-Schedule3Murugananthan RamadossNo ratings yet

- Sky Lift Hardware - Solar PanelsDocument4 pagesSky Lift Hardware - Solar PanelsSky Lift HardwareNo ratings yet

- PPF in SAP EWM 1Document10 pagesPPF in SAP EWM 1Neulers0% (1)

- Dubai Water Supply - MajorProjectGuidelines2008 - DEWA WaterDocument11 pagesDubai Water Supply - MajorProjectGuidelines2008 - DEWA Waterhychauhan1100% (5)

- LetterDocument15 pagesLetterSyahrudin BaharsyahNo ratings yet

- SDC 4-5-6 - Draft Consolidated Explanatory Notes For The Second Generation Intact Stability Criteria (United States)Document51 pagesSDC 4-5-6 - Draft Consolidated Explanatory Notes For The Second Generation Intact Stability Criteria (United States)praveench1888No ratings yet

- InstallationGuide SAP SQLDocument31 pagesInstallationGuide SAP SQLCheo GarzaNo ratings yet

- Number of Questions 23 Number of Questions To Answer 20Document4 pagesNumber of Questions 23 Number of Questions To Answer 20Engr. Zahid Ur RehmanNo ratings yet

- 5S - Good HousekeepingDocument39 pages5S - Good Housekeepingrslapena100% (10)

- MAC Pyramid Elements DefinitionsDocument37 pagesMAC Pyramid Elements DefinitionsAnonymous PVXBGg9T100% (5)

- Project Success and FailureDocument18 pagesProject Success and FailureaviNo ratings yet

- Business Intelligence PDFDocument12 pagesBusiness Intelligence PDFRym AlamiNo ratings yet

- Sections H Japonaises: Dimensions: JIS G 3192: 2000 JIS A 5526: 1994 Tolérances: JIS G 3192: 2000Document4 pagesSections H Japonaises: Dimensions: JIS G 3192: 2000 JIS A 5526: 1994 Tolérances: JIS G 3192: 2000Nazar Abdul KareemNo ratings yet

- Oracle Services ProcurementDocument5 pagesOracle Services ProcurementSaurabh SharmaNo ratings yet

- Clark SM 549 Service ManualDocument6 pagesClark SM 549 Service Manualgarry100% (61)

- Specification and Design of A CRM System For Smes: Inderjit Singh MSC Information Systems 2002-2003Document117 pagesSpecification and Design of A CRM System For Smes: Inderjit Singh MSC Information Systems 2002-2003Ranjith MohanNo ratings yet

- JSW Steel Deluxe - LowResolutionDocument196 pagesJSW Steel Deluxe - LowResolutionChiranjit RoyNo ratings yet

- Chauhan 2013, Resource Flexibility For Lean Manufacturing SAP-LAP Analysis of A Case Study PDFDocument19 pagesChauhan 2013, Resource Flexibility For Lean Manufacturing SAP-LAP Analysis of A Case Study PDFapostolos thomasNo ratings yet

- Exception Handling in Java ProgrammingDocument19 pagesException Handling in Java ProgrammingKarthik KartNo ratings yet

- Xuper-6868-XHD Castolin Electrode PDFDocument2 pagesXuper-6868-XHD Castolin Electrode PDFswapneel_kulkarniNo ratings yet

- Operations and Maintenance ManualDocument29 pagesOperations and Maintenance ManualPrabakaran Muniandy100% (1)

- Aace 96r-18 LLTT SampleDocument7 pagesAace 96r-18 LLTT Samplejose pablo riveraNo ratings yet

![EME_1102_WORKSHOP_PRACTICE_I_Supplementary_2021[1]](https://imgv2-2-f.scribdassets.com/img/document/750171727/149x198/52c56cef76/1720871844?v=1)