Professional Documents

Culture Documents

ES9736 - N (002) Zinc Norma 3

ES9736 - N (002) Zinc Norma 3

Uploaded by

fernando.zabdiOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ES9736 - N (002) Zinc Norma 3

ES9736 - N (002) Zinc Norma 3

Uploaded by

fernando.zabdiCopyright:

Available Formats

HONEYWELL INC.

West Coast Operations

San Diego, CA

ENGINEERING SPECIFICATION

ES 9736

ZINC PLATING

I. GENERAL SPECIFICATIONS

A. This specification covers all requirements for Zinc plated parts and unless noted concurs with ES 21,

ES 767, ES 638, MS 12075. Unless otherwise specified the standard finish will be shown as ES 9736

and will be interpreted as ES 9736C2.

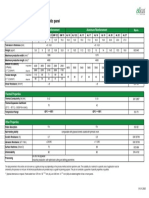

B. Code system for prints, reference, etc.

Basic Spec. Code Thickness (*) Code Supplementary Treatment (**)

9736 A 0.00050-0.00100 1 None

B 0.00030-0.0009 2 Colored Chromate: ES9727K

Clr/white-blue to greenish/yellow

C 0.00020-0.0008 3 Colored Chromate: ES9727L

Yellow

D 0.00015-0.0009 4 Bright Dip: ES9725

E 0.00005-0.0008 5 Colored Dichromate: ES9727R

Royal Blue

Example: 9736B2 is specification number for zinc plate. .00030-.00060 thick with clear/white-blue chromate

conversion coating.

* Unless otherwise specified, the thickness of zinc shall be based on above coded table on all visible

surfaces which can be touched by a 0.75 inch diameter ball. When thickness is not specified it will be

.0002 to .0008.

** Springs, screws or other parts subject to flexure high stresses, or repeated impact and have a hardness

greater than Rockwell C30 (including case hardening) shall be heated at 375°F ± 25°F, for not less than

three hours and prior to supplementary coatings where such coating is required for any other purpose

than as a brightener. The elapsed time between plating and baking not to exceed 8 hours. Parts shall

not be flexed or stressed prior to the baking operation.

Rev: E.O.# Date: For: Zinc Plating

M Retyped To Word Format 97-W124 06/12/97

N Rev Max. Plating Thickness 0017217 11/18/05 Apprd By:

Sheet: 1 of 2

HONEYWELL INC.

West Coast Operations

San Diego, CA

ENGINEERING SPECIFICATION

ES 9736

ZINC PLATING

II. Inspection:

1. Check appearance, particularly on parts visible on exterior of finished product. Slight water

rinse stains are permissible. The coating shall be adherent and free from blisters.

2. Supplementary coatings (chromate conversion) should be dispersed evenly across the plated

surfaces. See ES9727 for testing of these coatings.

3. Parts must be fully dry and in clean dry containers.

Rev: E.O.# Date: For: Zinc Plating

H Retyped To Word Format 97-W124 06/12/97

N Rev Max. Plating Thickness 0017217 11/18/05 Apprd By:

Sheet: 2 of 2

You might also like

- MS22045 - 00E 12V 16V 2000 M84 M94 Instructions For Exchange of AssembliesDocument298 pagesMS22045 - 00E 12V 16V 2000 M84 M94 Instructions For Exchange of Assembliesmar100% (16)

- LENGTH .010 D E: Bombardier Standards ManualDocument4 pagesLENGTH .010 D E: Bombardier Standards ManualJohn CollinsNo ratings yet

- Paseo Curtain Wall Strutural Calculation Ver. 2 March 18 2020 PDFDocument93 pagesPaseo Curtain Wall Strutural Calculation Ver. 2 March 18 2020 PDFVictor Dlreyes100% (1)

- Chapter - II Review of Literature Review of LiteratureDocument24 pagesChapter - II Review of Literature Review of LiteratureeshuNo ratings yet

- 2600, 2400, 2300 FOGGERS: User'S ManualDocument2 pages2600, 2400, 2300 FOGGERS: User'S Manualver_at_work100% (1)

- Manual Parts Drives Mercruiser PDFDocument99 pagesManual Parts Drives Mercruiser PDFJOSE100% (4)

- Epf Pass Book Avula VaraprasadDocument1 pageEpf Pass Book Avula VaraprasadvaraprasadNo ratings yet

- Elm 3Document1 pageElm 3ralice5022No ratings yet

- MTC-ENERGY-DN 97Document1 pageMTC-ENERGY-DN 97cmanrekNo ratings yet

- 4AD126TI - Dooson - EM'CY GENERATORDocument62 pages4AD126TI - Dooson - EM'CY GENERATORLeonid KolesnikovNo ratings yet

- MS20001 - Hinge StandardDocument5 pagesMS20001 - Hinge StandardSooraj V VNo ratings yet

- 107.WI - Anodizing - EC 004 - Lower ReceiverDocument7 pages107.WI - Anodizing - EC 004 - Lower ReceiverRknight BNo ratings yet

- Job No. ContractDocument1 pageJob No. ContractQuitzs QuitzsNo ratings yet

- Design Calculations From Engineering Assessment: 165 219 8.10 10.35 Owner Contact Diamondwrap® ContactDocument2 pagesDesign Calculations From Engineering Assessment: 165 219 8.10 10.35 Owner Contact Diamondwrap® ContactManikandan MNo ratings yet

- K-Flex Ic Clad JacketingDocument1 pageK-Flex Ic Clad JacketinggetashishvaidNo ratings yet

- 160 WHEEL Block: UPN 300 Cutting DetailDocument1 page160 WHEEL Block: UPN 300 Cutting DetailpawanNo ratings yet

- Power S Qbiss GS 200 070 050 5520-ADocument9 pagesPower S Qbiss GS 200 070 050 5520-APrimož KozlevčarNo ratings yet

- MS20001 MS20001: Structural Extruded HingeDocument1 pageMS20001 MS20001: Structural Extruded Hingerobiny100% (1)

- La Copia Stampata Non E' Soggetta A Controllo: Electrostatic Painting With Epoxy-Polyester Powder PaintsDocument3 pagesLa Copia Stampata Non E' Soggetta A Controllo: Electrostatic Painting With Epoxy-Polyester Powder PaintsdmejiaNo ratings yet

- MCGB - Data Sheet For Suppliers Old MAT Nos.: - , - , - : Bright Steel, Unalloyed, MachinedDocument3 pagesMCGB - Data Sheet For Suppliers Old MAT Nos.: - , - , - : Bright Steel, Unalloyed, Machinedbaskaran ayyapparajNo ratings yet

- West Damietta Simple Cycle Power Plant Contract No. 10069-CP-101Document3 pagesWest Damietta Simple Cycle Power Plant Contract No. 10069-CP-101ahffg nnffNo ratings yet

- MCGB - Data Sheet For Suppliers Old MAT Nos.: 143, - , - : Bright Steel Unalloyed, Cold DrawnDocument3 pagesMCGB - Data Sheet For Suppliers Old MAT Nos.: 143, - , - : Bright Steel Unalloyed, Cold Drawnbaskaran ayyapparajNo ratings yet

- 2 MM × 2 MM Solder Tail Straight & Right Angle, Surface Mount StraightDocument5 pages2 MM × 2 MM Solder Tail Straight & Right Angle, Surface Mount StraightVan HuynhNo ratings yet

- CBH-21-012 Stud Bolt M12 X 2000 HDG 8.8Document1 pageCBH-21-012 Stud Bolt M12 X 2000 HDG 8.8qualityNo ratings yet

- Jed-739 008 GDocument5 pagesJed-739 008 GPaulo Henrique NascimentoNo ratings yet

- Job No. ContractDocument1 pageJob No. ContractQuitzs QuitzsNo ratings yet

- Cuzn37 Industrial RolledDocument6 pagesCuzn37 Industrial RolledcvgfgNo ratings yet

- Eva - RenewsysDocument1 pageEva - RenewsysShashwata ChattopadhyayNo ratings yet

- 1 - Static System: CT-TechnologiesDocument7 pages1 - Static System: CT-TechnologiesNedžadDžokoNo ratings yet

- Jaw Type Buckle Suitable For 20 X 0.7 MM Thick Ss Strap: Material: Stainless Steel (Ss304)Document1 pageJaw Type Buckle Suitable For 20 X 0.7 MM Thick Ss Strap: Material: Stainless Steel (Ss304)Nimish TaterhNo ratings yet

- MS20001PDocument5 pagesMS20001PthomasNo ratings yet

- Din 1-3207Document3 pagesDin 1-3207Ornella MancinelliNo ratings yet

- Asml Gi 42-24 RadiantDocument1 pageAsml Gi 42-24 RadiantAamir GhaffarNo ratings yet

- MCGB - Data Sheet For Suppliers Old MAT Nos.: - , - , - : Bright Steel Unalloyed, MachinedDocument3 pagesMCGB - Data Sheet For Suppliers Old MAT Nos.: - , - , - : Bright Steel Unalloyed, Machinedbaskaran ayyapparajNo ratings yet

- MS20001MDocument5 pagesMS20001MthomasNo ratings yet

- 08.05.2019 Npu 400Document2 pages08.05.2019 Npu 400Yasin BaturNo ratings yet

- brochures__DX51D - DX52D ENDocument2 pagesbrochures__DX51D - DX52D ENSuttisak SuriyachanhomNo ratings yet

- DX51D en 2 PDFDocument2 pagesDX51D en 2 PDFОливер АндовскиNo ratings yet

- Address: Southern Pan Ofllaidong Industjy ParkDocument1 pageAddress: Southern Pan Ofllaidong Industjy ParkRiaan PretoriusNo ratings yet

- Product Data Sheet OK 92.18: E 'Manual Metal-Arc Welding'Document2 pagesProduct Data Sheet OK 92.18: E 'Manual Metal-Arc Welding'Cesar ObesoNo ratings yet

- Nickel Based ElectrodeDocument1 pageNickel Based Electrodewalter091011No ratings yet

- Ibis EhsDocument26 pagesIbis EhsRolando IbañezNo ratings yet

- Pages From Curtain Wall (BD Submission) - 2Document6 pagesPages From Curtain Wall (BD Submission) - 2Con CanNo ratings yet

- Roundness Check Record of 1St Shell CourseDocument1 pageRoundness Check Record of 1St Shell CourseRhannie GarciaNo ratings yet

- Unit MasonryDocument14 pagesUnit MasonryTito GarciaNo ratings yet

- 2811 Additional Parts 2Document2 pages2811 Additional Parts 2Danı PrasNo ratings yet

- Quality Test Certificate: Al-Rashid Trading & Contacting CompanyDocument1 pageQuality Test Certificate: Al-Rashid Trading & Contacting CompanyMAHMOUD YOUNISNo ratings yet

- 01ES00002 - Acabamento de Proteção Contra CorrosãoDocument2 pages01ES00002 - Acabamento de Proteção Contra CorrosãoRafah1212No ratings yet

- DC54D ZDocument4 pagesDC54D ZGustavoNo ratings yet

- MTC-ENERGY-DN 100Document1 pageMTC-ENERGY-DN 100cmanrekNo ratings yet

- Durability: Hot Dip Galvanised Steel Sheet & CoilDocument8 pagesDurability: Hot Dip Galvanised Steel Sheet & CoilDin TcmNo ratings yet

- DN Dat001 001Document4 pagesDN Dat001 001Abdur RehmanNo ratings yet

- Final Progress Report PDFDocument3 pagesFinal Progress Report PDFTaufik BaihaqiNo ratings yet

- Saudi Aramco Oil Company: SECTION 07620 Sheet Metal Flashing and TrimDocument4 pagesSaudi Aramco Oil Company: SECTION 07620 Sheet Metal Flashing and Trimsaneela bibiNo ratings yet

- Fiber Glass Wool Insulation 100MM THKDocument12 pagesFiber Glass Wool Insulation 100MM THKmahmoud husseinNo ratings yet

- Private Villa - KSADocument25 pagesPrivate Villa - KSAMd Mukarram RezaNo ratings yet

- 01 Power T FTV V2S 200 06-05-5,77m - CornerDocument9 pages01 Power T FTV V2S 200 06-05-5,77m - CornerPrimož KozlevčarNo ratings yet

- Turmosynthgrease A 1002-EngDocument1 pageTurmosynthgrease A 1002-EngOmin PostingNo ratings yet

- Raychem: Specification Control DrawingDocument1 pageRaychem: Specification Control Drawingqwe123No ratings yet

- Jyoti Engineering Works: Chemical AnalysisDocument8 pagesJyoti Engineering Works: Chemical AnalysisKristin CrawfordNo ratings yet

- Technical Characteristics 2020 ENDocument1 pageTechnical Characteristics 2020 ENezzularabNo ratings yet

- Defects Primary ReportDocument9 pagesDefects Primary ReportniginpNo ratings yet

- SINOXX 4006 Steel: Designation by StandardsDocument3 pagesSINOXX 4006 Steel: Designation by StandardsKiranNo ratings yet

- 1.6523 20nicrmo2-2 - Aisi 8620Document3 pages1.6523 20nicrmo2-2 - Aisi 8620zhenyupanNo ratings yet

- Machines 07 00042 PDFDocument21 pagesMachines 07 00042 PDFguterresNo ratings yet

- Presentation 1Document27 pagesPresentation 1Nayab SyedNo ratings yet

- Extending The Life of Aging Assets: Asset ManagementDocument3 pagesExtending The Life of Aging Assets: Asset ManagementRRANo ratings yet

- 9 - Napilas Integrated School Secondary - Rehabilitation of Ceiling Ivan PudaderaDocument14 pages9 - Napilas Integrated School Secondary - Rehabilitation of Ceiling Ivan PudaderaWerty Gigz DurendezNo ratings yet

- Emilio Aguinaldo College - Cavite Campus School of Business AdministrationDocument9 pagesEmilio Aguinaldo College - Cavite Campus School of Business AdministrationKarlayaanNo ratings yet

- A Practical Approach To Truck Dispatch For Open Pit Mines: January 2011Document14 pagesA Practical Approach To Truck Dispatch For Open Pit Mines: January 2011Miloš SimonovićNo ratings yet

- Screencast 4Document16 pagesScreencast 4ardanmorisNo ratings yet

- Advanced Auditing and Professional Ethics: Final Course Study Material P 3Document21 pagesAdvanced Auditing and Professional Ethics: Final Course Study Material P 3vandv printsNo ratings yet

- TM Promo NameDocument10 pagesTM Promo NameCristel Simbol TinguhaNo ratings yet

- N.Q Event Management Services: "For Events As Unique As You"Document40 pagesN.Q Event Management Services: "For Events As Unique As You"Carlos Baul DavidNo ratings yet

- Pgdis and AciseDocument67 pagesPgdis and AcisebhutrotterNo ratings yet

- Comparative Approach of Licensing and Franchising: MBM-208 Business EnvironmentDocument33 pagesComparative Approach of Licensing and Franchising: MBM-208 Business Environmentvermaanjali100% (5)

- SAE Steel Grades: Iron Alloy PhasesDocument5 pagesSAE Steel Grades: Iron Alloy Phaseshirenkumar patelNo ratings yet

- CV Rajamohan P - Project Manager MEPDocument4 pagesCV Rajamohan P - Project Manager MEPDheeraj Chowdary DhanekulaNo ratings yet

- S02 Rock Drill, Flushing HeadDocument28 pagesS02 Rock Drill, Flushing HeadrolandNo ratings yet

- PCR Measur Tektronix PDFDocument24 pagesPCR Measur Tektronix PDFGrzegorz ZissNo ratings yet

- Executive Diploma in Network & Cyber SecurityDocument10 pagesExecutive Diploma in Network & Cyber SecurityKYAW SHWE WINNo ratings yet

- 9365-AN/910 Manual of All-Weather Operations Second Edition - 1991Document67 pages9365-AN/910 Manual of All-Weather Operations Second Edition - 1991Fran Rodriguez SanchezNo ratings yet

- Pe 323Document42 pagesPe 323Farhan SafdarNo ratings yet

- 181-82 - Election Agent - Polling Agent - Relirf Agent - ECI - InstructionsDocument17 pages181-82 - Election Agent - Polling Agent - Relirf Agent - ECI - InstructionsChanduNo ratings yet

- Optimization of The Setup Position of A Workpiece For Five-Axis Machining To Reduce Machining TimeDocument13 pagesOptimization of The Setup Position of A Workpiece For Five-Axis Machining To Reduce Machining TimeHungTranNo ratings yet

- (Retail - HW2) LuuNguyenMinhThu - IELSIU20124Document7 pages(Retail - HW2) LuuNguyenMinhThu - IELSIU20124Jay LeeNo ratings yet

- Module 1 Long Term Financing DecisionsDocument9 pagesModule 1 Long Term Financing Decisionscha11100% (1)

- E 8 10n en (Efb)Document4 pagesE 8 10n en (Efb)Tomy Abad AbadNo ratings yet

- Vortex Bladeless Wind TurbineDocument3 pagesVortex Bladeless Wind TurbineLokesh Kumar GuptaNo ratings yet