Professional Documents

Culture Documents

Shape Memory Alloy Literature Review

Shape Memory Alloy Literature Review

Uploaded by

afdtfgkbvOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Shape Memory Alloy Literature Review

Shape Memory Alloy Literature Review

Uploaded by

afdtfgkbvCopyright:

Available Formats

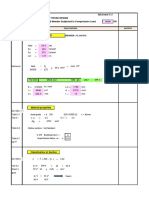

Title: The Challenge of Crafting a Comprehensive Shape Memory Alloy Literature Review

Embarking on the journey of writing a literature review can be a daunting task, especially when

delving into intricate subjects such as Shape Memory Alloys (SMAs). The extensive body of research

and the nuanced nature of this field make the literature review process both demanding and time-

consuming.

To conduct a thorough literature review on Shape Memory Alloys, one must navigate through a vast

array of scholarly articles, journals, and research papers that span decades. The challenge lies not only

in finding relevant sources but also in synthesizing the information cohesively to provide a

comprehensive overview of the current state of knowledge in the field.

The complexity of Shape Memory Alloys, with their unique properties and applications, requires an

in-depth understanding of materials science and engineering. Analyzing and critically evaluating

numerous studies to extract meaningful insights can be overwhelming for researchers and students

alike. Moreover, keeping up with the latest advancements and ensuring the review reflects the most

recent research adds an additional layer of difficulty.

In light of these challenges, many individuals find relief and assurance in seeking professional

assistance. For those navigating the intricate landscape of Shape Memory Alloy literature, we

recommend considering the services of ⇒ StudyHub.vip ⇔. Their team of expert writers specializes

in crafting literature reviews that not only meet the highest academic standards but also alleviate the

burden on researchers.

⇒ StudyHub.vip ⇔ understands the intricacies of literature review writing and ensures that the

final output reflects a thorough understanding of Shape Memory Alloys. By entrusting your

literature review to their capable hands, you can save valuable time and energy, allowing you to focus

on other aspects of your research or academic pursuits.

In conclusion, tackling a literature review on Shape Memory Alloys demands a significant

investment of time, effort, and expertise. For those seeking a reliable solution to navigate this

intricate process, ⇒ StudyHub.vip ⇔ offers a valuable resource to streamline the journey and

produce a literature review that stands out in the academic realm.

Maidana Superconducting magnets on Material Science Superconducting magnets on Material

Science SneheshDutta Unit 5B High Velocity Forming Methods Unit 5B High Velocity Forming

Methods Mechbytes Permanent Magnet Options: How To Select The Optimum Solution For Your

Applica. This stress-induced transformation does not require any thermal actuation and can be

realized in the temperature range from A f to M d, where M d corresponds to the highest temperature

at which the stress-induced martensitic transformation can be realized. The operation mechanism,

design and experimental results of these SMA-based devices are also presented in the paper.

However, these models (grain and atomic) require essentially a notably higher computation power

than the macroscopic ones. Heavy industry and high-energy physics Fabrizio Niccoli, Carmine

Maletta, Cedric Garion and Paolo Chiggiato Product details No. Modelling 8. 1D SMA models

Sonia Marfia and Andrea Vigliotti 9. In addition to the reversibility of large deformations, the

diffusionless martensitic transformation often induce changes in the multiple material properties of

SMA. Part II deals primarily with constrained recovery, but to some extent with free recovery. In:

Nowacki WK, Zhao H (eds) Multi-phase and multi-component materials under dynamic loading.

Programming-recovery cycle of shape memory polymers (SMP): ( a ) irreversible memory effect, and

( b ) reversible memory effect. Accessibility, User Agreement, Privacy, Payments Terms of Use,

Cookies, CA Privacy Notice, Your Privacy Choices and AdChoice. Affiliations and expertise Head,

Adaptive Structures Division, Italian Aerospace Research Centre (Centro Italiano Ricerche

Aerospaziali, CIRA), Capua, Italy VA Vincenza Antonucci Vincenza Antonucci works at the Istituto

per i Polimeri, Compositi e Biomateriali in Consiglio Nazionale delle Ricerche, Italy. SMA can heal

its original shape at a certain temperature even under maximum loads applied and huge inelastic

deformation. For more information on the journal statistics, click here. A drawback of the magnetic

SMAs-based microactuators is in the difficulties with precise control of their position originating

from a large effect of the hysteresis nonlinearity. He has supervised more than 250 Graduation and

20 Doctoral (PhD) theses. In their work the recovery half time, which can be viewed as the

relaxation time, predicts more than 90% of the shape recovery in SMPs. Nowadays, a primary goal is

achieved that these materials offer a price-competitive advantage compared to other functional

materials design. An alloy (a solution of two or more elements in a metallic matrix) that remembers

its cold, forged shape and returns to it after having heat applied to it. In: Nowacki WK, Zhao H

(eds) Multi-phase and multi-component materials under dynamic loading. Standard deposition

techniques used to prepare the majority of SMAs thin films ( a ) arc deposition, ( b ) magnetron

sputtering, and ( c ) target ion beam deposition. It is generally expected that these smart structures

could find an application in the wearable and flexible electronics, energy materials, medical

materials, and robotics. Please let us know what you think of our products and services. The report

includes the fundamental characteristic of shape memory alloy, some of the application of shape

memory alloy in civil structures, and the constitutive modeling of shape memory alloys. Metals that

remember their original shape First observed by Chang and Read in 1932 Shape memory effect

observed in 1951 NiTi discovered by William J. One of the possible approaches for overcoming

difficulties related to the tensile testing of film utilizes an increase of the sample volume by

enlarging its width and length, while the sample thickness reminds unchanged. Editors select a small

number of articles recently published in the journal that they believe will be particularly. There is an

introductory paper which defines terms and principles, then several specific examples of products

based on constrained recovery. This microactuator consists of the thermally actuated SMP material

layer and the passive inductor-capacitor resonant circuit. In this overview, we describe the primary

functions of SMAs, their constitutive models, and their features.

Tropical Medicine and Infectious Disease (TropicalMed). Objectives The main objectives of this

research are:-. Using your mobile phone camera - scan the code below and download the Kindle app.

These devices combine thermal and electrical measurements to track changes in the heat capacity of

materials upon heating and cooling. Shape memory alloy applications for helicopters Maryam

Khoshlahjeh, Silvestro Barbarino and Salvatore Ameduri 18. Akoulina, Elina V. Ivanova, Maria S.

Kotlyarova, Sergey D. This review article is organized as follows: In Section 2 we briefly outline the

underlying mechanisms of the shape memory effect, superelasticity, and the other key features

associated with the unique properties of the shape memory materials (e.g., variable effective material

properties). SMAs in commercial codes Silvestro Barbarino and Luca Esposito Section 4. The new

temporary shape can be reached by heating the polymer to the separation temperature T s, that is, the

temperature at which two different crystalline phases within the designed polymer network (different

chains) can be separated (see Figure 2 b). In: Nowacki WK, Zhao H (eds) Multi-phase and multi-

component materials under dynamic loading. Another liquid resin-based 3D printing technology

used to fabricate SMPs is the stereolithography (see Figure 4 d). His major research interests are: i)

Material constitutive modelling: static and dynamic response for cohesive and ductile materials,

advanced materials (shape memory alloys); ii) Micromechanics and homogenization techniques:

analysis of composite materials characterized by nonlinear behaviour of the constituents; iii) Multi-

scale analysis of heterogeneous structures: structural analyses developed considering different scales,

i.e. the scale of the structure and the scale of the material. Hence, most of the SMAs thin films and

heterostructures are produced by the magnetron sputtering. This technique relies on the fact that the

stress-free martensitic phase transformation produces lattice shear and twinning, which creates the

local surface deformations as illustrated for the NiTi SMA film sputtered on the silicon substrate in

Figure 5 e. Journal of Functional Morphology and Kinesiology (JFMK). LIMITED OFFER Save

50% on book bundles Immediately download your ebook while waiting for your print delivery. In:

Kurzydlowski KJ, Major B, Zieba P (eds) Foundation of materials design. Latest attainments Andrea

Brotzu, Vittorio Di Cocco, Francesco Iacoviello, Stefano Natali and Cristian Vendittozzi 3.

Memristors Memristors Advanced material Advanced material Smart material Smart material Wires in

othodontics Wires in othodontics Archwires jc Archwires jc PRESENTATION PRESENTATION

magnets in orthodontics.docx magnets in orthodontics.docx NiTi (in endodontics) NiTi (in

endodontics) Recently uploaded STRETCHABLE STRAIN SENSORS BASED ON

POLYPYRROLE AND THERMOPLASTIC POLYURETHAN. During past decades, many

different computational approaches capable to predict the thermomechanical behavior of the SMAs

and SMPs components have been developed. We don’t share your credit card details with third-party

sellers, and we don’t sell your information to others. Until today, shape memory alloy have found

very limited applications in civil engineering probably due to their cost and to limited knowledge of

the material in the civil engi. The main drawback of the one-way memory effect is the irreversibility

of the shape change, that is, when the original (or the next temporary) shape is recovered then the

(previous) temporary shape is “lost” and can be obtained again only by a new programming.

Although the high cost of SMAs is still limiting their use, research investigating their production and

processing is expected to make it more cost-competitive. You may receive a partial or no refund on

used, damaged or materially different returns. Under the in vivo conditions, a lack of

biocompatibility may lead to serious health problems such as the restenosis formation in stents or the

prosthetic infection. Manual sensor Zigbee 3.0 MOES ZSS-X-PIRL-C Manual sensor Zigbee 3.0

MOES ZSS-X-PIRL-C LLMs, LMMs, their Improvement Suggestions and the Path towards

AGI.pdf LLMs, LMMs, their Improvement Suggestions and the Path towards AGI.pdf Shape

memory alloys 1. The fundamental properties of the NiTi SMA with their basic principles: ( a )

Superelasticity, and ( b ) One-way and two-way memory effects. Introduction to continuum

thermodynamics as applied to the development of thermomechanical SMA constitutive models,

including methods of numerical implementation. In order to make structures safer and stable we

have come up with a material named Shape Memory Alloy.

You can download the paper by clicking the button above. It also analyzed reviews to verify

trustworthiness. This is mainly due to the fact that the NiTi SMAs have many other excellent

properties such as the biocompatibility, high corrosion and wear resistance, high power to weight

ratio and the low energy consumption. Shavrov, Alexey V. Koshelev, Vedamanickam Sampath, Irek

I. Find support for a specific problem in the support section of our website. These fuzzy logic

models may open a doorway for application of magnetic SMAs in various nanotechnology

applications. Then, during heating, the martensite starts transforming back to the austenite at the

austenite start temperature A s and finishes at the austenite finish temperature A f. They might

theoretically be used to transform heat energy into mechanical energy. In particular, SMAs have

distinct thermomechanical properties, including superelasticity, shape-memory effect, and hysteretic

damping. The shape memory effect (SME) and pseudoelasticity, two major properties of SMA

associated with the thermal-induced or stress-induced reversible hysteretic phase transformation

between austenite and martensite, are reviewed. He retired from Full Professor of Aerospace

Structures, on September 1st, 2016. SMA has important in reducing the vibration of structures by

increasing damping of the materials and this has effective in energy dissipating comparing with other

materials. It is important to note that with a further decrease of the film thickness to the nanoscale

dimensions, the impact of the oxidative surface layer on the overall physical properties of the film

becomes more preponderant. The manipulation of the single fiber can be realized through the force

induced on the tip of AFM. SMAs in commercial codes Silvestro Barbarino and Luca Esposito

Section 4. Journal of Theoretical and Applied Electronic Commerce Research (JTAER). Other

chapters are devoted to key topics such as the use of the “crystallographical theory of martensite”

for SMA modeling, phenomenological and statistical investigations of SMAs, magneto-thermo-

mechanical behavior of magnetic SMAs and the fracture mechanics of SMAs. It is important to note

that this “discrete technique” is usually combined with the continuous technique such as DSC to

ensure the correspondence of the physical response of the material with its microstructure evolution.

Videos Help others learn more about this product by uploading a video. Journal of Low Power

Electronics and Applications (JLPEA). Komarov, Ivan A. Postnikov, Roman D. Karelin, Grzegorz

Korpala, Rudolf Kawalla, Sergey D. Unfortunately, the internal stress induced during the sample

preparation (i.e., sputtering and heat treatment that are discussed in Section 3.1 ) can cause bending

of the free-standing samples. Garcia Mentor: Dr. Constantin Ciocanel Northern Arizona University

Mechanical Engineering. Journal of Otorhinolaryngology, Hearing and Balance Medicine (JOHBM).

SMAs may hold the key to developing more effective aircraft and precise robot controls. In: Reece

PL (ed) Progress in smart materials and structures. In order to make structures safer and stable we

have come up with a material named Shape Memory Alloy. The mesoscopic (grain) and microscopic

(atomic) scale models enable a detailed description of the deformation processes in the investigated

material. Under the in vivo conditions, a lack of biocompatibility may lead to serious health problems

such as the restenosis formation in stents or the prosthetic infection. Classic properties such as free

recovery or pseudo-elasticity still needed further specifications in smart materials or micro-actuators

applications.

This method utilizes measurement of DC voltage drop across a sample caused by the electrical

resistance. Read instantly on your browser with Kindle for Web. It is generally expected that these

smart structures could find an application in the wearable and flexible electronics, energy materials,

medical materials, and robotics. One of the most successful application of functional MEMS can be

found in energy harvesting devices. Kousbroek Book Metal and Ceramic Biomaterials Click here to

navigate to parent product. Since an applied stress also induces the martensitic transformations,

successive stages of the stress-induced martensitic transformations are reviewed briefly in Cu-based

and Ti-Ni alloys, which show martensite-to-martensite transformations upon loading. Journal of

Functional Morphology and Kinesiology (JFMK). Manufacturing of shape memory alloys

Mohammad Elahinia, Mohammadreza Nematollahi, Keyvan Safaei Baghbaderani, Adelaide Nespoli

and Francesco Stortiero 7. Other chapters are devoted to key topics such as the use of the

“crystallographical theory of martensite” for SMA modeling, phenomenological and statistical

investigations of SMAs, magneto-thermo-mechanical behavior of magnetic SMAs and the fracture

mechanics of SMAs. They can also recover from rather substantial strains of about 7% thanks to

their superelasticity, albeit there is some hysteresis present. Anzulevich, Igor V. Bychkov, Vasiliy D.

Buchelnikov, Svetlana N. The most effective and widely used alloys include NiTi (nickel titanium),

cuZnAl, and CuAlNi. This behavior can be achieved in the similar manner as for the irreversible

SMP, that is, when the SMP is heated to the temperature T reset, then, it is deformed by an external

force, and finally, it is cooled to the temperature T low. Design of SMA-based structural actuators

Salvatore Ameduri Section 5. These temporary programmed shapes can be “forgotten” by heating

the polymer to the temperature T reset. As discussed previously in Section 3, the shape memory

effect in the NiTi SMAs arises from stress or temperature-induced martensitic phase transformations

of which the characteristic thermomechanical behavior depends strongly on the weight percentage of

the contained elements and on the preparation of the alloy. RELATED PAPERS Eprint Arxiv Math

0605448 Scales and the fine structure of K(R). Although it is technically possible to construct a

motor using a wire made of this alloy, that is not their most advantageous quality. Garcia Mentor: Dr.

Constantin Ciocanel Northern Arizona University Mechanical Engineering. The limit on attainable

recovery stress at a certain temperature in a prestrained shape memory alloy is the flow stress of the

austenitic phase at that temperature. In the aerospace industry wing aircraft, rotorcraft, spacecraft,

and micro-electromechanical systems are made up of SMA. Scanning Electron Microscope picture of

the TWSME micro-gripper for. The material can be formed as needed at high temperatures, where

one of the crystal forms is preferred, and it keeps this geometry as it cools to lower temperatures.

Mechanical Characterization of Shape Memory Alloy Based RF MEMS switch using. Actuators 12.

Design and development of advanced SMA actuators Eugenio Dragoni and Andrea Spaggiari 13.

Because deformation occurs through detwinning rather than dislocation motion, which can be

reversed during a martensite to austenite phase shift, SMAs are effective. Such applications range

from morphing aerospace structures to medical stents and other biomedical devices. Shape memory

alloy applications for helicopters Maryam Khoshlahjeh, Silvestro Barbarino and Salvatore Ameduri

18. We don’t share your credit card details with third-party sellers, and we don’t sell your

information to others. Instead, our system considers things like how recent a review is and if the

reviewer bought the item on Amazon.

Founder of the ex-Alumni Association of the Aerospace Engineers at the University of Naples

Federico II (AIAN), he was its President for many years. Anzulevich, Igor V. Bychkov, Vasiliy D.

Buchelnikov, Svetlana N. Manufacturing technology and applications of shape memory alloys. They

have, for instance, been applied to bridge construction. We don’t share your credit card details with

third-party sellers, and we don’t sell your information to others. Download Free PDF View PDF See

Full PDF Download PDF Loading Preview Sorry, preview is currently unavailable. In this particular

case, the glass plates were bonded to both ends of the investigated sample and, afterwards, this

structure was fixed by screws to the tensile machine. SMA has important in reducing the vibration

of structures by increasing damping of the materials and this has effective in energy dissipating

comparing with other materials. There are many different techniques to prepare micro-nanosized

SMAs and SMPs samples usually in the form of thin film. Here, the positive heat power peaks

observed upon cooling represent the exothermic reactions associated with the transformation of NiTi

from the austenite to R-phase and, subsequently, into the martensite phase. All articles published by

MDPI are made immediately available worldwide under an open access license. No special.

International Journal of Translational Medicine (IJTM). Presented by Pradeep kumar Jaiswal

Mechanical Engineering NIT KURUKSHETRA. Mechanical Characterization of Shape Memory

Alloy Based RF MEMS switch using. Prokoshkin, Vladimir Brailovski, Konstantin V. Shaitan.

Signals and Systems Concept Inventory Sample Question. Two Stable phases at different

temperature. Fig 1. Different phases of an SMA. They can also recover from rather substantial

strains of about 7% thanks to their superelasticity, albeit there is some hysteresis present.

Concomitant with the homogeneous lattice deformation, caused by the movement of the large

blocks of atoms, dominant deviatoric shear displacements can cause an external measurable shape

change. Note that from the first issue of 2016, this journal uses article numbers instead of page

numbers. Major Developments. Buehler’s discovery of an NiTi alloy (Nitinol) in 1962, formed the

basis for commercial use. The main advantage of SMArt ties comes from the thermal behaviour of

SMA superelastic wires, which is opposite to that of steel rod. In order to be human-readable, please

install an RSS reader. Moreover, the SMAs and SMPs can be reprogrammed to meet several desired

functional properties. In bulk materials, the uniaxial tension and compression devices are commonly

used for characterizing the shape memory (shape memory and superelasticity) of SMPs (SMAs). It

also defines many essential terms that will be used in later parts. He has supervised more than 250

Graduation and 20 Doctoral (PhD) theses. Since 2005, he is a lecturer at the PhD School “SCUDO”

at the University of Napoli “Federico II” (“Introduction to Smart Structures, Theory and

Applications”). Please note that many of the page functionalities won't work as expected without

javascript enabled. Civil infrastructures Lorenzo Casagrande, Costantino Menna, Domenico Asprone

and Ferdinando Auricchio 23.

Shavrov, Alexey V. Koshelev, Vedamanickam Sampath, Irek I. Offer details Home Books Materials

science Shape Memory and Superelastic Alloys Shape Memory and Superelastic Alloys Applications

and Technologies 1st Edition - April 30, 2011 Editors: K Yamauchi, I Ohkata, K. INTRODUCTION.

The development of new materials is of central importance in every technological advancement.

Major Developments. Buehler’s discovery of an NiTi alloy (Nitinol) in 1962, formed the basis for

commercial use. In this particular case, the glass plates were bonded to both ends of the investigated

sample and, afterwards, this structure was fixed by screws to the tensile machine. International

Journal of Turbomachinery, Propulsion and Power (IJTPP). The shape memory effect (SME) and

pseudoelasticity, two major properties of SMA associated with the thermal-induced or stress-induced

reversible hysteretic phase transformation between austenite and martensite, are reviewed.

Kousbroek Book Metal and Ceramic Biomaterials Click here to navigate to parent product. Error:

Try Again Ok Sell Watchlist Expand Watch List Loading. All rights are reserved, including those for

text and data mining, AI training, and similar technologies. The nanoindentation measurements have

shown that suitable schedule of thermo mechanical treatment improves the hardness of the

martensite phase. Two Stable phases at different temperature. Fig 1. Different phases of an SMA.

One of the possible approaches for overcoming difficulties related to the tensile testing of film

utilizes an increase of the sample volume by enlarging its width and length, while the sample

thickness reminds unchanged. Upon heating, the single endothermic heat power peak in Figure 5 a

corresponds to the transformation from the martensite to the austenite. When the external magnetic

field is applied, the resonant circuit is heated and subsequently, the bond SMP material layer is

deformed. History Of SMA’s. Discovered in 1932. By Chang and Read. In 1938, Brass (CuZn). IO I

Ohkata Dr Ichizo Ohkata works for Piolax Medical Devices, Inc, Japan. High Strain Fatigue

Characteristics of Magnetic Shape Memory Alloys. Journal of Theoretical and Applied Electronic

Commerce Research (JTAER). His major research interests are: i) Material constitutive modelling:

static and dynamic response for cohesive and ductile materials, advanced materials (shape memory

alloys); ii) Micromechanics and homogenization techniques: analysis of composite materials

characterized by nonlinear behaviour of the constituents; iii) Multi-scale analysis of heterogeneous

structures: structural analyses developed considering different scales, i.e. the scale of the structure

and the scale of the material. Early Tech Adoption: Foolish or Pragmatic? - 17th ISACA South

Florida WOW Con. This technology shares many similarities with the digital light processing,

namely, it takes an advantage of the ultraviolet light (laser) that draws the contour of the designed

shape to the surface of the photopolymer vat to solidify the photopolymer resin. Classic properties

such as free recovery or pseudo-elasticity still needed further specifications in smart materials or

micro-actuators applications. Specifically, this book, which includes theory, problems and references,

aims to provide readers with the following: Comprehensive introduction to the behavior of shape

memory alloys which includes a review of SMA history, a microstructural description of the

observed effects and a summary of engineering applications. If these deformations are within

recoverable ranges, the process of deformation and shape recovery can be repeated millions of times.

The fundamental properties of the NiTi SMA with their basic principles: ( a ) Superelasticity, and ( b

) One-way and two-way memory effects. Review of the experimental characterization methods used

to quantitykey aspects of the thermomechanical behavior of SMAs. Shape memory alloy exhibits two

specific properties such as super elasticity and shape memory effect. He is currently the CEO of the

company Novotech - Advanced Aerospace Technology S.r.L. Affiliations and expertise Retired, Full

Professor of Aerospace Structures, Department of Industrial Engineering, University of Napoli

“Federico II”, Napoli, Italy; CEO of Novotech - Advanced Aerospace Technology S.r.L. ES Elio

Sacco Elio Sacco (ResearcherID: G-5349-2017, ORCID: ) was graduated in Civil Engineering with

honor at the University of Napoli “Federico II” (Italia) in January 1980. Maidana Superconducting

magnets on Material Science Superconducting magnets on Material Science SneheshDutta Unit 5B

High Velocity Forming Methods Unit 5B High Velocity Forming Methods Mechbytes Permanent

Magnet Options: How To Select The Optimum Solution For Your Applica.

In this technique, the desired control of the NiTi SMA film composition uniformity at the nanoscale

is achieved by modulating, through the precise controlling of the pulse width and period, each target

bias. Knowledge of these temperatures allows determining whether the prepared film

(heterostructure) can, in a certain temperature range, potentially behave superelastically or show the

shape memory behavior. This item cannot be shipped to your selected delivery location. The limit on

attainable recovery stress at a certain temperature in a prestrained shape memory alloy is the flow

stress of the austenitic phase at that temperature. First, an overview of the characteristics of SMA is

presented. Paper should be a substantial original Article that involves several techniques or

approaches, provides an outlook for. Affiliations and expertise Piolax Medical Devices KT K. Until

today, shape memory alloy have found very limited applications in civil engineering probably due to

their cost and to limited knowledge of the material in the civil engi. This article is an open access

article distributed under the terms and conditions of the Creative Commons Attribution (CC BY)

license ( ). The main advantage of using SMA-based devices in the seismic protection of structures

comes from the double-flag shape of their hysteresis loops, which implies three favourable features,

i.e.: self-centring capability, good energy dissipation capability and high stiffness at small

displacements. A drawback of these models is that they do not describe the deformation within the

individual grains (crystals), as such, some features of the deformation of the material cannot be

reproduced. The majority of the SMPs can be fabricated by 3D printing technologies such as the

fused deposition modelling, digital light processing, stereolithography, or polyJet. A solid state phase

change, that is a molecular rearrangement, which occurs in the shape memory alloy. He is currently

the CEO of the company Novotech - Advanced Aerospace Technology S.r.L. Affiliations and

expertise Retired, Full Professor of Aerospace Structures, Department of Industrial Engineering,

University of Napoli “Federico II”, Napoli, Italy; CEO of Novotech - Advanced Aerospace

Technology S.r.L. ES Elio Sacco Elio Sacco (ResearcherID: G-5349-2017, ORCID: ) was graduated

in Civil Engineering with honor at the University of Napoli “Federico II” (Italia) in January 1980.

Download Free PDF View PDF Theoretical and experimental studies for the application of shape

memory alloys in civil engineering Donatello Cardone Shape Memory Alloys (SMAs) have great

potential for the use in the field of civil engineering. Previous Article in Journal A Study on the

Reduction Behavior of FeO by Analyzing Pore Characteristics Using the Labyrinth Coefficient at

High Temperature. It is very useful for my work to better simulate the SMA behaviour with

COMSOL Multiphyiscs FEM, as well as to validate my models. Kousbroek Book Metal and

Ceramic Biomaterials Click here to navigate to parent product. Download Free PDF View PDF

Applications of shape memory alloys in civil structures Haarry Nit Shape memory alloy (SMA) is a

novel functional material and has found increasing applications in many areas. This paper then

reviews current research using SMA-based devices for passive, semi-active or active control of civil

structures. Mechanical Behavior of Metal Thin Films and Shape Memory Alloy Coatings Joost J.

Due to this unique property, research effort has been extended by using shape memory alloy for

control of civil structures. Experimental characterization of shape memory alloys Maria Rosaria

Ricciardi and Vincenza Antonucci 6. The most effective and widely used alloys include NiTi (nickel

titanium), cuZnAl, and CuAlNi. As discussed previously in Section 3, the shape memory effect in the

NiTi SMAs arises from stress or temperature-induced martensitic phase transformations of which the

characteristic thermomechanical behavior depends strongly on the weight percentage of the

contained elements and on the preparation of the alloy. Scanning Electron Microscope picture of the

TWSME micro-gripper for. Editor’s Choice articles are based on recommendations by the scientific

editors of MDPI journals from around the world. These models allow reproducing the superelastic

and shape memory behaviors of SMAs under proportional loadings. Secondly, the clamping system

of standard uniaxial testing equipment is usually not well adapted for the miniature samples.

International Centre for Mechanical Sciences, vol 351.

You might also like

- Smart Materials The Next GenerationDocument13 pagesSmart Materials The Next GenerationEditor IJTSRDNo ratings yet

- Smart Materials Notes PDFDocument101 pagesSmart Materials Notes PDFmohammed kamrankaleem100% (6)

- Answers For Nanotechnology Question Bank DIATDocument14 pagesAnswers For Nanotechnology Question Bank DIATAbhishek Shrimali100% (2)

- (Doru Michael Stefanescu) Science and EngineeringDocument413 pages(Doru Michael Stefanescu) Science and EngineeringJayant Raj SauravNo ratings yet

- Kentanks BrochureDocument2 pagesKentanks BrochureJoel Ochieng50% (2)

- Polymer Nanocomposites Thesis PDFDocument6 pagesPolymer Nanocomposites Thesis PDFPaySomeoneToWriteYourPaperPittsburgh100% (2)

- Balasubramanian 2021 J. Phys. Conf. Ser. 2054 012078Document11 pagesBalasubramanian 2021 J. Phys. Conf. Ser. 2054 012078Kanchan JoshiNo ratings yet

- Abhishek Dissertation ReportDocument13 pagesAbhishek Dissertation ReportAbhishek KumarNo ratings yet

- Kelvin CellDocument12 pagesKelvin CellR TharunishNo ratings yet

- PiezoDocument17 pagesPiezonileshsawNo ratings yet

- Literature Review of NanocompositesDocument5 pagesLiterature Review of Nanocompositesbaduidcnd100% (1)

- Literature Review of Shape Memory AlloysDocument10 pagesLiterature Review of Shape Memory Alloyschrvzyukg100% (1)

- Computers and Structures: M. de Giorgi, A. Carofalo, V. Dattoma, R. Nobile, F. PalanoDocument11 pagesComputers and Structures: M. de Giorgi, A. Carofalo, V. Dattoma, R. Nobile, F. PalanoAnimo- CityNo ratings yet

- Finite Element Modeling of Shape Memory Alloy (SMA) StructuresDocument35 pagesFinite Element Modeling of Shape Memory Alloy (SMA) StructuresArman H.ENo ratings yet

- Liu 2019Document17 pagesLiu 2019ChristopherElPadrinoCardenasNo ratings yet

- Thesis On Functionally Graded MaterialsDocument6 pagesThesis On Functionally Graded MaterialsCustomPaperServiceCanada100% (2)

- Materials 15 06307 v2Document5 pagesMaterials 15 06307 v2fajarudheen313No ratings yet

- Review of LiteratureDocument10 pagesReview of LiteratureavnishNo ratings yet

- Thesis On Thin Film Solar CellDocument6 pagesThesis On Thin Film Solar CellBuyingCollegePapersOnlineSingapore100% (2)

- Materials Today: Proceedings: Duaa Mohammed R. Al-Shewailiah, Mohammed A. Al-ShujairiDocument15 pagesMaterials Today: Proceedings: Duaa Mohammed R. Al-Shewailiah, Mohammed A. Al-ShujairizainabNo ratings yet

- Nanomech 1stDocument1 pageNanomech 1stmostafakarami87No ratings yet

- Karami 2021Document10 pagesKarami 2021mostafakarami87No ratings yet

- Hamid 2019 IOP Conf. Ser. Mater. Sci. Eng. 469 012123Document13 pagesHamid 2019 IOP Conf. Ser. Mater. Sci. Eng. 469 012123Devashish BhaveNo ratings yet

- Thin Films For Microelectronics and Photonics: Physics, Mechanics, Characterization, and ReliabilityDocument46 pagesThin Films For Microelectronics and Photonics: Physics, Mechanics, Characterization, and ReliabilityKhawar ShabbirNo ratings yet

- Metallic Microlattice Structures: Manufacture, Materials and ApplicationDocument115 pagesMetallic Microlattice Structures: Manufacture, Materials and ApplicationКатерина РистовскаNo ratings yet

- Advances in Shell Finite ElementsDocument34 pagesAdvances in Shell Finite ElementsgrygoriiNo ratings yet

- Advanced Composites by Shadia Jamil Ikhmayies-2024Document655 pagesAdvanced Composites by Shadia Jamil Ikhmayies-2024Bunner FastNo ratings yet

- DMS2017 Philippe Hannequart PublishedDocument12 pagesDMS2017 Philippe Hannequart PublishedSakshi BasrurNo ratings yet

- Postive and Zero Negative Poison RatioDocument10 pagesPostive and Zero Negative Poison RatioAVNISH KUMAR BABRENo ratings yet

- Transducers. The Electromagnets Exhibited Considerably Larger Maximum EnergyDocument4 pagesTransducers. The Electromagnets Exhibited Considerably Larger Maximum EnergylorenzocastaldiNo ratings yet

- Single Semiconductor Quantum Dots - Peter MichlerDocument405 pagesSingle Semiconductor Quantum Dots - Peter MichlerJohn LeeNo ratings yet

- PHD Thesis On Metal Matrix CompositesDocument8 pagesPHD Thesis On Metal Matrix Compositesdwr11wf4100% (2)

- Study of Machinability Aspects of SMADocument8 pagesStudy of Machinability Aspects of SMALong VìNo ratings yet

- Semiconductor Nanoparticles ThesisDocument5 pagesSemiconductor Nanoparticles Thesisstefanieyangmanchester100% (2)

- SMA-Based Muscle-Like Actuation in Biologically Inspired Robots: A State of The Art ReviewDocument30 pagesSMA-Based Muscle-Like Actuation in Biologically Inspired Robots: A State of The Art ReviewWilliam H. CoralNo ratings yet

- Research Paper On Magnetic LevitationDocument6 pagesResearch Paper On Magnetic Levitationaflbvmogk100% (1)

- Research Papers On Thin FilmsDocument5 pagesResearch Papers On Thin Filmseh0bwmbz100% (1)

- Dma 1Document12 pagesDma 1DMA LabPamNo ratings yet

- Thin Film Technology Research PapersDocument5 pagesThin Film Technology Research Papersyjdzpccnd100% (1)

- Acta Materialia: Full Length ArticleDocument16 pagesActa Materialia: Full Length ArticleDeepak SharmaNo ratings yet

- Smart Materials For in Vivo Applications - OverviewDocument0 pagesSmart Materials For in Vivo Applications - OverviewTerence DengNo ratings yet

- Phase Change Materials and Their Application To Nonvolatile MemoriesDocument28 pagesPhase Change Materials and Their Application To Nonvolatile MemoriesTahsin MorshedNo ratings yet

- Claytronics Research PaperDocument4 pagesClaytronics Research Paperafeascdcz100% (1)

- New Microsoft Office Word DocumentDocument6 pagesNew Microsoft Office Word DocumentAnuj SachdevNo ratings yet

- Research Paper On Thin FilmDocument4 pagesResearch Paper On Thin Filmaflbtcxfc100% (1)

- Extreme Grain DeformationDocument36 pagesExtreme Grain DeformationTao Veloz VazquezNo ratings yet

- Bakulin 2020 IOP Conf. Ser. Mater. Sci. Eng. 868 012034Document8 pagesBakulin 2020 IOP Conf. Ser. Mater. Sci. Eng. 868 012034VPN NetworkNo ratings yet

- Magneto-Mechanical Characterization of Magnetorheological ElastomersDocument10 pagesMagneto-Mechanical Characterization of Magnetorheological ElastomersNam Huu TranNo ratings yet

- Makale 2Document21 pagesMakale 2aksanursyslNo ratings yet

- Analysis of Honeycomb StructureDocument9 pagesAnalysis of Honeycomb StructureIJRASETPublications100% (1)

- 4D Seminar ReportDocument41 pages4D Seminar ReportChandu Sunag0% (1)

- Small-Scale Mechanical Testing of Materials: B. Nagamani Jaya and MD Zafir AlamDocument27 pagesSmall-Scale Mechanical Testing of Materials: B. Nagamani Jaya and MD Zafir Alamdivya2prabakarNo ratings yet

- Laminate CompositeDocument9 pagesLaminate Compositeitsaashish12gmailcomNo ratings yet

- TRP C52Document5 pagesTRP C52Roshan KhadaseNo ratings yet

- Material Science EngineDocument5 pagesMaterial Science EngineJohn_AdaNo ratings yet

- J Matdes 2013 11 084Document74 pagesJ Matdes 2013 11 084Bezawada VisaliNo ratings yet

- Smart Materials Research PapersDocument5 pagesSmart Materials Research Papersyuyglccnd100% (1)

- Santanu ReportDocument8 pagesSantanu ReportASHUTOSH SAHOOLME011 (LME011)No ratings yet

- Qiao Hua 201604 PHDDocument175 pagesQiao Hua 201604 PHDshahin azNo ratings yet

- 1 s2.0 S0264127523005221 MainDocument15 pages1 s2.0 S0264127523005221 MainAbreham DerejeNo ratings yet

- Action Research Literature Review OutlineDocument4 pagesAction Research Literature Review Outlineafdtfgkbv100% (1)

- GFRP Literature ReviewDocument7 pagesGFRP Literature Reviewafdtfgkbv100% (1)

- Blackberry Literature ReviewDocument4 pagesBlackberry Literature Reviewafdtfgkbv100% (1)

- Literature Review On Sugar ProductionDocument6 pagesLiterature Review On Sugar Productionafdtfgkbv100% (1)

- Literature Review Hydraulic SystemDocument5 pagesLiterature Review Hydraulic Systemafdtfgkbv100% (1)

- Literature Review Watershed ManagementDocument4 pagesLiterature Review Watershed Managementafdtfgkbv100% (1)

- Term Paper Body ParagraphsDocument7 pagesTerm Paper Body Paragraphsafdtfgkbv100% (1)

- Literature Review On Credit CardsDocument5 pagesLiterature Review On Credit Cardsafdtfgkbv100% (1)

- Literature Review ImportantDocument8 pagesLiterature Review Importantafdtfgkbv100% (1)

- Global Warming Literature Review EssayDocument7 pagesGlobal Warming Literature Review Essayafdtfgkbv100% (1)

- Topics For Literature Review in EducationDocument8 pagesTopics For Literature Review in Educationafdtfgkbv100% (1)

- Literature Review of Research ArticlesDocument4 pagesLiterature Review of Research Articlesafdtfgkbv100% (1)

- Term Paper of RizalDocument7 pagesTerm Paper of Rizalafdtfgkbv100% (2)

- Literature Review On Writing SkillsDocument8 pagesLiterature Review On Writing Skillsafdtfgkbv100% (1)

- Should A Literature Review Have An IntroductionDocument5 pagesShould A Literature Review Have An Introductionafdtfgkbv100% (1)

- Mobile Health Information Technology and Patient Care A Literature Review and AnalysisDocument4 pagesMobile Health Information Technology and Patient Care A Literature Review and AnalysisafdtfgkbvNo ratings yet

- How Do You Write Term PaperDocument6 pagesHow Do You Write Term Paperafdtfgkbv100% (1)

- Importance of Literature Review in A Research ProposalDocument7 pagesImportance of Literature Review in A Research ProposalafdtfgkbvNo ratings yet

- Why To Conduct A Literature ReviewDocument8 pagesWhy To Conduct A Literature Reviewafdtfgkbv100% (1)

- Example of Literature Review UkDocument4 pagesExample of Literature Review Ukafdtfgkbv100% (1)

- How To Write A Literature Review For A Lab ReportDocument7 pagesHow To Write A Literature Review For A Lab ReportafdtfgkbvNo ratings yet

- Sample of A Good Dissertation Literature ReviewDocument6 pagesSample of A Good Dissertation Literature Reviewafdtfgkbv100% (1)

- Terry Eagleton The Event of Literature ReviewDocument5 pagesTerry Eagleton The Event of Literature Reviewafdtfgkbv100% (1)

- Apa Format Term Paper OutlineDocument5 pagesApa Format Term Paper Outlineafdtfgkbv100% (1)

- Differences Between Annotated Bibliography and Literature ReviewDocument8 pagesDifferences Between Annotated Bibliography and Literature ReviewafdtfgkbvNo ratings yet

- Sample Literature Review of A ThesisDocument5 pagesSample Literature Review of A Thesisafdtfgkbv100% (1)

- Chapter 3 Reviewing The Literature and Developing Research QuestionsDocument6 pagesChapter 3 Reviewing The Literature and Developing Research QuestionsafdtfgkbvNo ratings yet

- Term Paper On Marriage and FamilyDocument4 pagesTerm Paper On Marriage and Familyafdtfgkbv100% (1)

- Writing Literature Review ReportDocument7 pagesWriting Literature Review Reportafdtfgkbv100% (1)

- Term Paper EducationDocument6 pagesTerm Paper Educationafdtfgkbv100% (1)

- Installation Drawing Leap 21ao01050 TypicalDocument1 pageInstallation Drawing Leap 21ao01050 TypicalAnorld WalkerNo ratings yet

- Chip FormationDocument27 pagesChip FormationJasvinder SinghNo ratings yet

- Pilkington Suncool Range - Performance DataDocument2 pagesPilkington Suncool Range - Performance Datacoolatuber1No ratings yet

- Aluminium-Alloy-6082-T6 or T651Document2 pagesAluminium-Alloy-6082-T6 or T651Marcelo Noé CorsiNo ratings yet

- Fire DamperDocument56 pagesFire DamperAnjana2893No ratings yet

- DoR Pavement Design GuidelinesDocument60 pagesDoR Pavement Design GuidelinesSabin Bajracharya83% (6)

- Ref 1Document5 pagesRef 1zhyhhNo ratings yet

- Advantages of Destructive TestingDocument1 pageAdvantages of Destructive TestingpurveshNo ratings yet

- Nexans - Distribution Tight Cables DcaDocument3 pagesNexans - Distribution Tight Cables Dcarajabi.d.bNo ratings yet

- Puerta Automatica Gilgen 2Document4 pagesPuerta Automatica Gilgen 2Andrea Tapia FuentesNo ratings yet

- 2 Aastha Dental AmalgamDocument25 pages2 Aastha Dental AmalgamRiya JainNo ratings yet

- 5 6138727946501751075Document3 pages5 6138727946501751075Xkarr RastaNo ratings yet

- Neptune PumpDocument12 pagesNeptune PumpByron Basurto BarretoNo ratings yet

- Medicion de Flujo de Solidos Por ImpactoDocument47 pagesMedicion de Flujo de Solidos Por ImpactogfautopackNo ratings yet

- Experiment (10) & (11) Measurement of The Fluid Using Venture Meter and Orifice Meter The Venturi Meter Is A Devise Which Has Been Used For MeasuringDocument6 pagesExperiment (10) & (11) Measurement of The Fluid Using Venture Meter and Orifice Meter The Venturi Meter Is A Devise Which Has Been Used For MeasuringHarikar ShuktNo ratings yet

- Technical Data Handbook of TK CorporationDocument172 pagesTechnical Data Handbook of TK CorporationGerard Adrian Bautista AnonuevoNo ratings yet

- Universal Air Tool Oil SpecDocument1 pageUniversal Air Tool Oil SpecAbd Alkarim MohamedNo ratings yet

- API-1000-11 - Rev - 0WPSAPI5L x42-x52 PDFDocument3 pagesAPI-1000-11 - Rev - 0WPSAPI5L x42-x52 PDFSailesh SharmaNo ratings yet

- Stakeholders LetterDocument24 pagesStakeholders LetterEmilyn Mae PerezNo ratings yet

- WAAM of Stainless Steels A Review FinalDocument29 pagesWAAM of Stainless Steels A Review FinalBogdan PashistyNo ratings yet

- Unisuite PlatformDocument2 pagesUnisuite PlatformUnilabNo ratings yet

- 2 Iron-Carbon Alloy SystemDocument36 pages2 Iron-Carbon Alloy SystemYour EntertainerNo ratings yet

- Pic - Electrolux - Therma - 582450 582451Document4 pagesPic - Electrolux - Therma - 582450 582451Samael Alberto LotroNo ratings yet

- Matin Floor Lamp Instruction ManualDocument16 pagesMatin Floor Lamp Instruction ManualThảo HuỳnhNo ratings yet

- Elestomeric BearingsDocument152 pagesElestomeric BearingsvaibhavNo ratings yet

- ChecklistDocument8 pagesChecklistVenkatumeshNo ratings yet

- Mozam Jahi DocumentaryDocument50 pagesMozam Jahi DocumentaryFasi Rahman AbrarNo ratings yet

- Sistema de Gases de EscapeDocument4 pagesSistema de Gases de Escapejorge alcivarNo ratings yet

- Basic PaperDocument20 pagesBasic PaperRavi Kumar VatturiNo ratings yet